Effect of Drying Temperature on Bioactive Compound Content of Red Onion Using Photovoltaic Ventilation Solar Dryers

Research Article

Effect of Drying Temperature on Bioactive Compound Content of Red Onion Using Photovoltaic Ventilation Solar Dryers

Suherman Suherman1*, Muhammad Fahri Rizky1, Zaki Bahrul Fikri1, Hadiyanto Hadiyanto1,

Zane Vincevica-Gaile2, Anwar Saeed Khan3, Erkata Yandri4,5 and Iswahyudi Iswahyudi6

1Diponegoro University, Semarang 50275, Central Java, Indonesia; 2University of Latvia, Riga LV-1004, Latvia; 3Department of Geography and Geomatics, University of Peshawar (KP), Pakistan; 4Graduate School of Renewable Energy, Darma Persada University, Special Region of Jakarta 13450, Indonesia; 5Center of Renewable Energy Studies, Darma Persada University, Jakarta 13450, Indonesia; 6Universitas Islam Madura, Pamekasan 69317, Madura, East Java, Indonesia.

Abstract | Onions (Allium ascalonicum L.) are one spiced vegetable that serves as a culinary spice, food flavoring, and traditional medicine. Onions have relatively high minerals, flavonoids, tannins, saponins, and essential oils. Agricultural products are still dried using conventional methods. Although, traditional drying is relatively simple, it has disadvantages such as relatively long drying time, relatively low drying quality, significant damage, and the sun’s ultraviolet rays can also damage the chemical components of dried materials. Therefore, a new drying process technology, Photovoltaic Ventilation (Solar Dryer) was developed to overcome the above problems. In this research, onions were dried using a photovoltaic ventilated solar dryer, and temperature analysis and bioactive compounds were performed to evaluate the performance of the system in terms of energy efficiency compared to drying in the sun in 8 h. Onions were scattered on trays in the drying room during the experiment. Temperature, relative humidity, sun intensity, and shallot mass were measured every 15 min. The results obtained showing that the fastest drying rate occurs in photovoltaic ventilation solar drying at a temperature variable of 50 °C, which is 6 gh–1. The average efficiency of drying onions traditionally for 8 h is 4.54 %. It has the highest R2 value of 0.982 2, and the lowest RMSE and x2 values are 0.008 31 and 0.000 69. In addition, the decrease in bioactive compounds due to high-temperature drying was attributed to the deterioration of bioactive components such as polyphenol compounds due to excessive heat.

Received | July 06, 2023; Accepted | May 24, 2024; Published | June 13, 2024

*Correspondence | Suherman Suherman, Department of Chemical Engineering, Faculty of Engineering, Diponegoro University, Jl. Prof. Soedarto, Tembalang, Semarang 50275, Central Java, Indonesia; Email: suherman.mz@che.undip.ac.id

Citation | Suherman, S., M.F. Rizky, Z.B. Fikri, H. Hadiyanto, Z. Vincevica-Gaile, A.S. Khan, E. Yandri and I. Iswahyudi. 2023. Effect of drying temperature on bioactive compound content of red onion using photovoltaic ventilation solar dryers. Sarhad Journal of Agriculture, 39(Special issue 1): 23-35.

DOI | https://dx.doi.org/10.17582/journal.sja/2023/39/s1.23.35

Keywords | Allium ascalonicum L., Drying process technology, Environmentally friendly, Economically sustainable, Renewable energy, Secondary metabolites

Copyright: 2023 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Onions (Allium ascalonicum L.) are a type of plant that includes root crops with fibrous roots at the base of the tubers. This type of shallot plant is native to Southeast Asia and is commonly used as a seasoning in every food dish because it gives a unique taste (Irawan and Rozalia, 2022). In addition to its delicious taste, onions have a reasonably high mineral content of potassium. Potassium plays a vital role in metabolic processes. This mineral is also essential in maintaining blood pressure balance, preventing hardening of the arteries, and cleaning blood vessels from harmful cholesterol deposits; it helps regulate the contractions of skeletal and smooth muscles and plays a vital role in the functioning of the nerves and brain. The minerals, calcium, and phosphorus in onions are essential for maintaining healthy bones and teeth (Aryanta, 2019). Besides mineral content, onions contain secondary metabolites such as flavonoids, tannins, saponins, essential oils, kaempferol, flavon glycosides, fluroglucin, dihydroaliin, cycloalkane, methicillin, quercetin, polyphenols, sulfur in shallot bulbs (Hasibuan et al., 2020).

Phenolic compounds (PCs), also known as polyphenols, are present in substantial amounts in plant foods such as cereal grains, vegetables, legumes, fruits, nuts, pulp, husk, and berries and their related processed foods (berry juices, teas, coffees, and wines). Their consumption has been linked with reduced risk of multiple non-communicable chronic diseases (NCCD), e.g., cardiovascular (CVD) and neurodegenerative diseases, certain cancers, type II diabetes and osteoporosis, putatively attributed to their multifaceted bioactions, e.g., antioxidation, anti-inflammation, modulation of signal transduction, anti-microbial activity, and anti-proliferation (Asmawati et al., 2021, 2022; Setyobudi et al. 2023; Velderrain-Rodríguez et al., 2014).

Flavonoids include natural phenolic compounds that have the potential as antioxidants and have bioactivity as drugs. In the human body, flavonoids function as antioxidants, perfect for cancer prevention (Kasmui, 2016; Setyobudi et al., 2019, 2022). Flavonoids can also be inhibitors that can kill tumor cells in the human body (Damat et al., 2019, 2020; Xiao et al., 2016). Because of the benefits of onions, the demand for onions will increase over time. That causes onions to have a high selling value in the market. High demand and high selling value encourage farmers to produce more.

The storage of shallots has an important role, both in the reserve of shallot seeds and in saving crop yields. Post-harvest disease is one of the main factors suspected of causing a decrease in the quality and quantity of production (Rahman and Umami, 2019). Water content has a vital role in the storage of shallots. Water content that is too high at the start of storage can cause rot and damage, such as the appearance of roots. However, if the water content is too low, it can cause weight loss in the shallots. Thus, knowing the appropriate water content for storing shallots for a long time is necessary, but the quality is maintained (Mutia et al., 2014).

Drying agricultural products is still done traditionally, namely drying directly under the sun. Although traditional drying is relatively easy, some weaknesses make traditional drying less desirable, such as relatively long drying time, relatively poor drying quality, significant damage, and ultraviolet rays from the sun also cause damage to the chemical content of the dried material (Pochont et al., 2020). because it uses sunlight, the drying results from traditional drying are very dependent on the weather conditions at the time of drying (Setyobudi et al., 2018, 2021a).

Apart from using the drying method directly under the sun, drying can be done using a dryer that uses external fuel such as firewood, fossil fuels, biogas, or electricity; this dryer could be more practical and economical for small and medium businesses. This is because, generally, the dryers on the market have a relatively large capacity and are relatively complex for novice operators to operate (Argo et al., 2018; Susanto et al., 2020a, b). Of course, using fossil fuels for dryers will exacerbate the current environmental conditions (Abdullah et al., 2020; Setyobudi et al., 2021b). Therefore, a new drying process technology, the Photovoltaic Ventilation Solar Dryer, was developed to overcome the above problems. This new technology uses photovoltaic ventilation, which converts sunlight directly into electricity. The result is faster drying of onions, lower operating costs, and avoiding unwanted contamination.

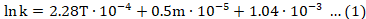

Ummah et al. (2016) demonstrated the drying of shallot slices using a tunnel dehydrator dryer at various operating temperatures (40 oC, 50 oC, and 60 oC) and various sample weights (300 g, 400 g, and 500 g) with airflow rate udara 0.093 3. From the results of the study, the value of the drying rate (k) was obtained in the range 0.01 min–1 to 0.019 min–1, and the predicted drying rate value, which is a function of sample mass (m) and temperature (T) as follows (Equation 1).

In research that has been conducted by Manfaati et al. (2019), sliced shallots are dried using a tray drier at various temperatures (50 oC, 55 oC, 60 oC, 65 oC, and 70 oC) with drying time varying between 4 h to 8 h and drying air rate of it is obtained that the optimum temperature for drying shallots on a tray dryer is 70 oC

and the drying rate varies by 0.672 5 min–1 to 1.296 9 min–1.

Zamharir et al. (2016) researched drying whole shallots in a greenhouse-effect dryer. The research results found that the temperature of the drying chamber was around with an ambient temperature ranging from an RH profile in the drying chamber. In addition, it is also obtained that the efficiency ranges from. Islami et al. (2017) also researched drying whole shallots using the same tool. The study’s results obtained the temperature profile and relative humidity (RH) in the drying chamber. Drying rate and predicted moisture ratio value.

From the literature review above, three types of dryers are often used: tunnel dehydrators, tray dryers, and greenhouse dryers. Tunnel dehydrators and tray dryers require external fuel, while greenhouse effect dryers do not. Islami et al. (2017) and Zamharir et al. (2016) do not use a temperature control device to prevent excessive temperature or analyze the effective diffusivity and activation energy during drying.

In this study, the photovoltaic ventilation solar dryer has five main components. These include solar panels to capture solar energy, batteries to store energy generated by solar panels and power other components, temperature controllers to regulate the temperature during drying, ventilation fans, and drying chambers. This technology is renewable, environmentally friendly, and economically sustainable for most developing countries. Therefore, this study aims to investigate the effect of temperature on shallot drying temperature profiles, drying curves and drying rates, energy analysis, mathematical modeling of thin layer drying, and bioactive compounds.

Materials and Methods

The experiments were conducted in the laboratory of the Department of Chemical Engineering, Diponegoro University, Semarang, Indonesia, from 08.00 to 16.00 (West Indonesia Time) in 4 d. There are two types of drying carried out in this experiment, namely drying using a photovoltaic ventilation solar dryer with operating temperature variables of 40 °C, 45 °C, and 50 °C, and drying by natural convection using sunlight. The raw material used in this study is onions. The onions used are from Demak Regency, Central Java Province, Indonesia. The initial moisture content of onions is 87.92 %.

Onions were scattered on trays in the drying room during the experiment. Temperature, relative humidity, sun intensity, and shallot mass were measured every 15 min using Solar Power Meter SM206, Thermometer, Digital Scales, and Temperature Humidity Meter. Solar Power Meter SM206 and Temperature Humidity Meter are installed outside the dryer to measure the ambient temperature. At the same time, the thermometer is placed in the drying chamber to measure the temperature in the drying chamber. In photovoltaic ventilation solar dryers, the collector (glass film) acts as a solar heat absorber and distributes the heat throughout the room (Figure 1). A collector can block some of the UV light so that the dried material is not damaged. Exhaust fans, on the other hand, draw in room air along with water vapor.

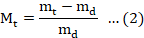

The temperature measurement is calculated by measuring the temperature every 15 min and then concluding with the operation time. This will give a graph of temperature versus time. On the other hand, Moisture content calculations are performed over time using dry and wet weight data of onions (Hadibi et al., 2022) on Equation 2.

Where is the moisture content at any given time on a dry basis, is onions mass at any given time, and is dried onions mass? The moisture ratio was calculated using data from Equation 2 as follows in Equation 3 (Rousan et al., 2022):

Since the value is minimal compared to and, the value of (moisture content equilibrium) is neglected. So, Equation 3 become Equation 4:

Where is the moisture ratio at any given time, is moisture content at any given time on a dry basis, and is initial moisture content on a dry basis. The drying rate (g water x g solid x min–1) was calculated from Equation 4 as follows in Equation 5 (Hadibi et al., 2022).

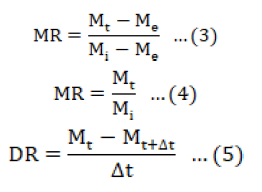

DR is drying rate, Mt is moisture content at any given time, Mt+△t is moisture content at t+△t, △t is drying time. Efficiency from the solar dryer was measured by Equation 6 (Hadibi et al., 2022).

m0 is initial shallot’s mass, m1 is shallot’s mass after drying, λ, is latent heat of water (2.26 X 103 Kj kg-1) I is Solar radiation (Wm-2) A is the surface area of dryer (m2), it is drying time.

Effective diffusivity was calculated by plotting the value from the following Equation 7 (Syah et al., 2020).

The authors have the gradient value from the plot after plotting. So, there is effective diffusivity in Equation 8.

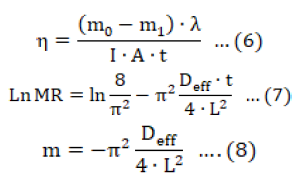

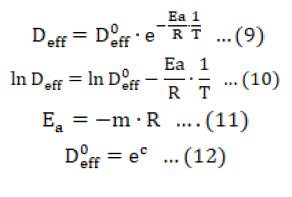

Where; m is gradien, Deff is eeffective diffusivity (m2s-1), and L is the thickness of onions (m). The relationship between effective diffusivity and temperature is stated on Equation 9 (Asiah et al., 2017).

Linearization Equation 9, the authors got the Equation 10.

Activation energy and pre-exponential factor was determined by plotting the value of ln Deff vs (1/T) so the authors got the value of gradient and intercept from that plot (Equations 11 and 12).

Where Ea is activation energy (J mol-1), Deff0 is pre-exponential factor (m2 s-1), R is gas constant (8.314 Jmol-1 K-1) and T is temperature (K), m is gradient and c is intercept from the plot. The Newton and Henderson and Pabis drying models (Table 1) are suitable for drying agricultural products (Haryani et al., 2015). The thin layer drying model can be determined by finding unknown constants such as a, and k from each equation.

Table 1: Exponential and linear form of drying models.

|

Dying models |

Exponential |

Linear form |

|

form |

||

|

Newton |

MR=e-kt |

ln MR= -kt |

|

Henderson and Pabis |

MR= a e-kt |

ln MR= -kt +In a |

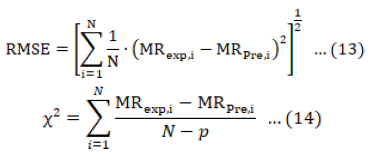

The coefficient of determination R2 obtained using the help of Microsoft Excel, root mean square error (RMSE), and chi squared χ2 is used in determining the right model (Inyang et al., 2018) by Equations 13 and 14.

Where MRexp,i is moisture ratio experimental at any given time; MRPre,i is predicted moisture ratio at any given time; N is total observation were made; P is total constant.

Results and Discussion

Profile of inlet, outlet temperature, and intensity of solar radiation

Based on the experiments results, data on the temperature of the inlet and outlet and the intensity of sunlight are obtained. The test results are displayed in a graph showing the relationship between the temperature of the inlet and outlet and the intensity of the drying time on various variables (Figure 2a, b, c, d).

In variable I, the inlet temperature of the dryer ranges from 27.9 oC to 32 oC. After drying, the air temperature soared from 28.9 °C to 50.1 °C at the outlet with varying light intensity between

790.6 Wm-2 to 1 283.5 Wm-2. The inlet temperature in variable II is also not much different from variable I, where the inlet temperature ranges from 27.5 °C to 31.6 oC with an outlet temperature of 28.6 °C to 45.3 °C, and the intensity of sunlight is 756.1 Wm-2 to 1 187.9 Wm-2. In variable III, the inlet temperature interval is 27.4 °C to 31.0 °C with an outlet temperature of 28.2 °C to 40.2 °C, and the intensity of sunlight ranges from 692.9 Wm-2 to 81.9 Wm-2.

Based on Figure 2, it can be seen that the intensity of sunlight received by the dryer fluctuates. According to Wijayanto and Nurunnajah (2012), the reception of solar radiation on the Earth’s surface is strongly influenced by the place and time of measurement. According to the place, such as differences in latitude and atmospheric conditions, such as the presence of clouds. Meanwhile, according to the time, it is both day (morning to evening) and seasonal (from day to day). Fluctuations in the intensity of sunlight also impact the inlet and outlet temperatures of the dryer on various variables where the sun’s intensity is directly proportional to the air temperature. The higher the intensity of sunlight, the greater the thermal energy converted to raise the air temperature in the dryer (Dina et al., 2018).

Profile of relative humidity over time on various variables

Figure 3 shows the relative humidity of whole onions using a photovoltaic vented solar dryer at various variables.

Based on Figure 3, it can be seen that the average value of rh at temperature 40 °C is higher than RH at temperature variables 45 °C and 50 °C. An increase in air relative humidity can be a significant factor that might slow the drying speed but protect the surface’s quality or the product’s inside. During drying, convection air is a carrier for volatile compounds continuously emitted from the material being dried. The diffusion model for volatile compounds is similar to the Equation for the displacement of water vapor, in which the driving force depends on the difference in concentration. Full or semi-saturated humidity from the convection air around the sample can prevent the product’s rapid depletion of beneficial volatile compounds and reduce the drying energy to avoid product damage (Pu et al., 2016).

This phenomenon is also because higher RH causes a rapid increase in sample temperature. After that, a higher sample temperature may provide an additional driving force for water diffusion, thereby increasing the drying rate (Ju et al., 2016). Relative humidity will affect the equilibrium moisture content. Equilibrium moisture content is the water in a material at a specific temperature and relative humidity. By lowering the relative humidity, the equilibrium moisture content in onions decreases, thereby increasing the reduction in water content (Sasongko et al., 2020).

Effect of temperature on moisture content

Figure 4 shows the moisture content of onions dried using a solar dryer and traditional drying. The moisture content during drying is calculated every

15 min for 8 h.

Based on Figure 4, it can be seen that drying begins when onions have a moisture content of 87.92 %; this is to the statement put forward by (Islami et al., 2017) that freshly harvested onions have a moisture content ranging from 87 % to 90 %. At the end of drying variable I, a moisture content of 84.92 % was obtained; in variable II, 85.26 % was obtained, while for variable III and variable IV, 85.44 % and 85.67 % were obtained. Drying was stopped when the water content of onions reached 85 %, according to Wazri (2019).

From Figure 4, it can be seen that the higher the drying temperature, the faster the decrease in water content in onions. This is because the higher the drying temperature, the greater the heat energy carried by air, so the amount of liquid mass evaporated from the sample’s surface will also increase (Fitriani, 2008). In addition, the longer the drying time, the lower the water content. This phenomenon occurs for all temperature variables. This is because the longer the drying process, the lower the water content in the onions. Drying will make the water content in the onions move from the onions to the surrounding environment. This causes a decrease in the water content of onions, which gets smaller and finally becomes constant (Lewicki et al., 1998).

In addition, Figure 4 shows that drying using a dryer has a higher rate of decrease in water content when compared to variables that do not use a dryer. This is because the dryer has a transparent cover. This transparent cover allows sunlight in the form of shortwave radiation to enter and heat the drying chamber, and the sample is dried. During this process, the shortwave radiation coming from the sun decreases in energy. The decrease in energy affects the wavelength, which is where the wavelength becomes longer. Some of this solar radiation will reflect off the dryer; however, solar radiation cannot penetrate the transparent cover layer, so all the energy carried by sunlight is trapped inside the drying chamber, causing higher temperatures (Djamalu et al., 2008).

Effect of temperature on moisture ratio

The drying rate of whole onions using a photovoltaic vented solar dryer at various variables is shown in Figure 5.

Based on Figure 5, the average value of the drying rate for variable I is 0.104 g min–1 for variable II it is 0.094 min–1, followed by variable III. The lowest drying rate was found in variable IV, namely

0.008 2 g min–1. Based on the figure above, the drying rate fluctuates. These fluctuations are caused by external factors such as temperature, humidity, and airflow. The existence of this variation is also influenced by the opening of the drying rack during the weighing of the sample (Rozana et al., 2016).

Stage events during the drying process include several stages such as a warming-up period, a constant-rate period, and a falling-rate period (Green and Southard, 2019). During the warming-up period, solar energy will be transferred to the material to be dried so that the temperature increases from the initial temperature to the wet-bulb temperature. The drying rate in this period is relatively small compared to other periods. The constant-rate period occurs when the free water on the material’s surface evaporates. During this period, there is no free water on the surface, so the drying rate is affected by diffusion (Neikov, 2019).

Figure 5 shows that the drying rate obtained is by the opinion (Green and Southard, 2019; Prakash and Kuma, 2012). In addition, the figure above also shows that the higher the drying temperature, the higher the drying rate. According Ummah et al. (2016), the higher the air temperature in the dryer, the higher the heat energy carried by the air so that the mass of water material being evaporated will be more incredible so that the drying rate will increase. At the beginning of drying, there is an increase in temperature inside the dryer due to the rise in the intensity of sunlight, so an increase in the drying rate is obtained at the beginning.

Drying efficiency

The research results for drying time on drying efficiency of onions for various variables are shown in Figure 6. Drying efficiency using photovoltaic ventilation solar dryers at temperatures of 50 °C, 45 °C, and 40 °C is in the range of 0.231 % to 5.672 %; 0.229 % to 5.004 %; and 0.259 % to 4.632 %. Meanwhile, the efficiency of traditional drying methods is in the range of 0.234 % to 3.673 %. The highest efficiency was achieved at 60 min at a temperature variable of 50 °C, while at 40 °C, 45 °C, and traditional, it was completed at 105 min.

Drying efficiency is strongly influenced by the intensity of sunlight, the speed of the inlet air, the inlet air temperature, the area of the drying area, and the glass material used in solar collectors (Jangde et al., 2022). The results showed an increase in drying efficiency as the drying temperature increased. This was due to the hot air in the drying chamber. This large heat affects the drying efficiency because, with sufficient hot air, the process of evaporating water on the material’s surface can run faster (Yuliasdini et al., 2020), so efficiency increases as the drying temperature increases.

In addition, there is a phenomenon of increasing efficiency at the beginning of drying, followed by a decrease in efficiency at the end. The increase in efficiency at the beginning of drying occurs because the drying process is still in the warming-up phase. In this phase, there is an increase in temperature in the drying chamber (Green and Southard, 2019). This increase in temperature has an impact on increasing drying efficiency. Meanwhile, the decrease in efficiency at the end of drying occurs because the free water on the surface has almost completely evaporated, so the evaporation process is slow (Neikov, 2019). So that the efficiency decreases at the end of drying. The total efficiency obtained in this study is shown in Table 2.

Table 2: Total drying efficiency of onions on various variables.

|

Variabel |

Total |

|

Overall efficiency (%) |

|

|

I (50 oC) |

3.138618 |

|

II (45 oC) |

2.965251 |

|

III (40 oC) |

2.901682 |

|

IV (Traditional) |

2.481845 |

These results show that the drying temperature greatly influences the drying efficiency. The data show that the drying efficiency in this test is low. Things that can be done to increase drying efficiency are maximizing the drying space and adding the number of shallot slices. This is still possible, considering the temperature/hot air for drying is also large, so it is still possible to increase drying capacity (Lestari et al., 2020).

Model of effective diffusivity and activation energy

The results of the study for determining the diffusivity value of drying onions using photovoltaic ventilation solar dryers with various variables are presented in Table 3.

Drying is a complex phenomenon involving simultaneous heat and mass transfer, which may change the physical structure/appearance and chemical or biological reactions. The determination of the diffusion value of the unsteady state in one direction is carried out by assuming that the onion bulbs can be approximated to a spherical shape (Asiah et al., 2017). Based on Table 3, it can be seen that the practical diffusivity values for temperature variables 50 oC, 45 oC, 40 oC, and traditional variables are, respectively, 2.156 41 x 10-8 m2s-1, 1.948 52 x 10-8 m2s-1, 1.827 42 x 10-8 m2s-1 and 1.716 77 x 10-8 m2s-1. The values above are still acceptable for most agricultural products. According to Zogzas and Maroulis (1996), the effective diffusivity values for food range from 10-12 m2s-1 to 10-8 m2s-1.

Table 3: Total drying efficiency of onions on various variables.

|

Variabel |

Deff (m2s-1) |

R2 |

|

I (50 oC) |

2.15641 x 10-8 |

0.9642 |

|

II (45 oC) |

1.94852 x 10-8 |

0.9707 |

|

III (40 oC) |

1.82742 x 10-8 |

0.9709 |

|

IV (Tradisional) |

1.71677 x 10-8 |

0.9798 |

In addition, the diffusion value is affected by temperature. It can be seen that the higher the temperature, the higher the practical diffusivity value; this is due to an increase in temperature inside the water molecule causing the water vapor pressure inside the molecule to increase so that the air inside the material more easily escapes from the material molecule (Dobry et al., 2009). In addition, the diffusivity value is influenced by several other factors, such as the thickness of the material being dried and the structure of the material itself (Afifah et al., 2017).

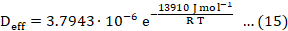

Data from Table 3 can be plotted to determine the drying activation energy value and the predicted effective diffusivity value at various temperatures. The plotting results are shown in Figure 7.

From the above plotting results, the gradient value is -1673.1. Using Equation 11, the drying activation energy obtained from this experiment is 13.910 KJmol-1. The Doeff constant can be determined using Equation 12, where the intercept value obtained from Figure 5 is -12.482 so the value is 3.7043 x 10-6 m2 s-1. The calculation above shows the practical diffusivity value at various temperatures, according to Equation 15.

Activation energy is the minimum energy required to initiate the diffusion of water from a material (Syah, 2020). The value of the activation energy obtained from this research is 19.192 KJ mol-1. This number is relatively small; however, according to Aghbashlo et al. (2008), the value of activation energy for foodstuffs ranges from (12.7 to 110) KJ mol-1 so the value obtained in this study is based on the results of previous studies.

Drying model

From the results of observational calculations, three models are by the MR reduction behavior found in the water content of onions. The three models are the Lewis model and the Henderson and Pabis model. The results of this test are the constant values and correspondence values for each model tested.

Table 4: Total drying efficiency of onions on various variables.

|

Model |

Variabel |

Konstanta |

R2 |

RMSE |

X2 |

|

|

k |

a |

|||||

|

Lewis Model |

I (50 oC) |

0.00065 |

- |

0.9617 |

0.01373 |

1.9440 x 10-4 |

|

II (45 oC) |

0.00057 |

- |

0.9697 |

0.01118 |

1.2890 x 10-4 |

|

|

III (40 oC) |

0.00053 |

- |

0.9699 |

0.01058 |

1.1542 x 10-4 |

|

|

IV (Tradisional) |

0.00047 |

- |

0.9696 |

0.00839 |

7.2639 x 10-5 |

|

|

Henderson & pabis model |

I (50 oC) |

0.00061 |

0.99147 |

0.9742 |

0.01358 |

1.9634 x 10-4 |

|

II (45 oC) |

0.00055 |

0.99491 |

0.9707 |

0.01115 |

1. 3234 x 10-4 |

|

|

III (40 oC) |

0.00051 |

0.99529 |

0.9709 |

0.01054 |

1.1820 x 10-4 |

|

|

IV (Tradisional) |

0.00047 |

1.00203 |

0.9798 |

0.00824 |

7.2231 x 10-5 |

|

From Table 4, it can be concluded that the model with the highest value and the smallest RMSE best matches the experimental data obtained. The Henderson and Pabis model was then chosen to predict the drying characteristics.

Analysis of phenolic and flavonoid levels

Based on tests conducted at the Integrated Research and Testing Laboratory (LPPT) Gadjah Mada University, it was found that the content of onions at variable 50°C had total phenolic content and flavonoid levels, as shown in Table 5.

Table 5: Levels of total phenolic and flavonoids in onions.

|

No |

Parameter |

Result |

|

1 |

Total phenolic |

|

|

2 |

Total flavonoid |

GAE, Gallic acid equivalent; QE, Quercetin equivalent.

Table 5 shows that the shallot sample has a total phenolic content of 3.2 % w w–1 or (3 200±28) mg EAG 100 g–1 sample. The flavonoids contained in the product amounted to 0.21 % w w–1 or (210±17) mg QE 100 g–1 sample.

In previous research, Yang et al. (2004) stated that onions contained a total phenolic content of 114.7 mg 100 g–1 sample. In addition, Tangkanakul et al. (2009) also reported that the total phenolic content contained in shallots was 88.90 mg g–1. Based on the two sources above, it can be concluded that the total phenolic levels obtained in this study were very excellent. Yang et al. (2004) declared that flavonoid levels were at 69.2 mg g–1. Meanwhile, Nurcahyo et al. (2020) stated that the phenolic content of shallots ranges from 181.5 mg g–1 to 271.5 mg g–1.

This study’s phenolic and flavonoid content is excellent based on previous research. This finding proves that the photovoltaic ventilation drying method can maintain the quality of shallots, especially in the scope of bioactive compounds. Determining temperature data of 50 °C is the breakdown threshold for bioactive compounds. It also supports the predictions described by Setyobudi et al. (2022).

Conclusions and Recommendations

The fastest drying rate for solar drying with photovoltaic ventilation occurs at a temperature variable of 50 °C, which is 0.104 g min–1. Total phenolic and flavonoid levels found in the best variable of dried sliced onions were (3 200±28) mg EAG 100 g–1 and (210±17) mg QE 100 g–1. This finding proves that the photovoltaic ventilation drying method can maintain the quality of shallots, especially in the scope of bioactive compounds. Determining temperature data of 50 °C is the breakdown threshold for bioactive compounds.

Acknowledgements

The authors would like to express their appreciation and gratitude to the “RP Editage” for assisting with editing and formatting during submission, up to the revision stage in manuscript modification, and up to the check galley proof stage of this manuscript.

Novelty Statement

Red onion (Allium ascalonicum L.) drying is a post-harvest problem for Indonesian farmers. Drying with the traditional system in direct sunlight takes a long time and is dependent on climate, with a detrimental impact on the quality of the red onion. This research shows that photovoltaic ventilation solar dryers at 50 °C can produce the best quality, especially when it comes to the damage of bioactive compounds. Photovoltaic ventilation solar dryers are also environmentally friendly because they are renewable energy and economically sustainable.

Author’s Contribution

Suherman Suherman: Conceptualized and designed the study, elaborated the intellectual content, manuscript review, and supervision.

Muhammad Fahri Rizky: Conceptualized and designed the study, carried out literature search, experimental studies, data acquisition, data analysis, manuscript preparation, and manuscript revision.

Zaki Bahrul Fikri: Conceptualized and designed the study, carried out literature search, experimental studies, manuscript review, the figure, and administration.

Hadiyanto Hadiyanto, Zane Vincevica-Gaile, Anwar Saeed Khan, and Iswahyudi Iswahyudi: Carried out the literature search and manuscript review.

Erkata Yandri: Carried out the literature search, manuscript review, Turnitin, and Grammarly checks

All authors have read and approved the final manuscript.

Conflict of interest

The authors have declared no conflict of interest.

References

Abdullah, K., A.S. Uyun, R. Soegeng, E. Suherman, H. Susanto, R.H. Setyobudi, J. Burlakovs and Z. Vincevica-Gaile. 2020. Renewable energy technologies for economic development. E3S Web Conf., 188(00016): 1–8. https://doi.org/10.1051/e3sconf/202018800016

Afifah, N., A. Rahayuningtyas and S.I. Kuala. 2017. Modeling of drying kinetics of several agricultural commodities using infrared dryer. Agritech, 37(2): 220–228. https://doi.org/10.22146/agritech.10394

Aghbashlo, M., M.H. Kianmehr and H. Samimi-Akhijahani. 2008. Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energy Convers. Manage., 49(10): 2865–2871. https://doi.org/10.1016/j.enconman.2008.03.009

Argo, B.D., S. Sandra and U. Ubaidillah. 2018. Mathematical modeling on the thin layer drying kinetics of cassava chips in a multipurpose convective-type tray dryer heated by a gas burner. J. Mech. Sci. Technol., 32(7): 3427–3435. https://doi.org/10.1007/s12206-018-0646-2

Aryanta, I.W.R., 2019. Red onion and its benefits for health. Widya Kesehatan, 1(1): 29–35. https://doi.org/10.32795/widyakesehatan.v1i1.280

Asiah, N., M. Djaeni and C.L. Hii. 2017. Moisture transport mechanism and drying kinetic of fresh harvested red onion bulbs under dehumidified air. Int. J. Food Eng., 13(9): 1–8. https://doi.org/10.1515/ijfe-2016-0401

Asmawati, A., M. Marianah, M.F.M. Atoum, D.A. Sari, I. Iqrar, Z. Hussain, R H. Setyobudi and N. Nurhayati. 2022. The potential of cashew apple waste as a slimming agent. Jordan J. Biol. Sci., 15(5): 887–892. https://doi.org/10.54319/jjbs/150518

Asmawati, A., M. Marianah, A. Yaro and R.H. Setyobudi. 2021. The potential of cashew apple juice as anti hypercholesterol agent on whistar rats (Rattus norvegicus Berkenhout, 1769). E3S Web of Conf. 226(00009): 1–8. https://doi.org/10.1051/e3sconf/202122600009

Cheng, A., X. Chen, Q. Jin, W. Wang, J. Shi and Y. Liu. 2013. Comparison of phenolic content and antioxidant capacity of red and yellow onions. Czech J. Food Sci., 31(5): 501–508. https://doi.org/10.17221/566/2012-CJFS

Damat, D., R. Anggriani, R.H. Setyobudi and P. Soni. 2019. Dietary fiber and antioxidant activity of gluten-free cookies with coffee cherry flour addition. Coffee Sci., 14(4): 493–500. https://doi.org/10.25186/cs.v14i4.1625

Damat, D., R.H. Setyobudi, P. Soni, A. Tain, H. Handjani and U. Chasanah. 2020. Modified arrowroot starch and glucomannan for preserving physicochemical properties of sweet bread. Ciência e Agrotecnologia, 44(014820): 1–9. https://doi.org/10.1590/1413-7054202044014820

Dina, S.F., S.M. Rambe, A. Azwardi and E.H. Sipahutar. 2018. Design and testing of evacuated tube collector. J. Dinamika Penelitian Industri, 29(1): 74–83. https://doi.org/10.28959/jdpi.v29i1.3919

Djamalu, Y., E.S. Antu, R. Djafar, B. Liputo and S. Botutihe. 2008. Utilization of greenhouse effect dryer as an alternative to fish processed dryer. J. AbdiMas Terapan, 1(1): 5–9. https://ejurnal.ung.ac.id/index.php/jat/article/download/12035/3525, https://doi.org/10.56190/jat.v1i1.2

Dobry, D.E., D.M. Settell, J.M. Baumann, R.J. Ray, L.J. Graham and R.A. Beyerinck. 2009. A model-based methodology for spray-drying process development. J. Pharm. Innov., 4(3): 133–142. https://doi.org/10.1007/s12247-009-9064-4

Fitriani, S., 2008. Effect of temperature and drying time on some quality of dried candied belimbing wuluh (Averrhoa bilimbi L.). Sagu Agric. Sci. Technol. J., 7(1): 32–37. https://sagu.ejournal.unri.ac.id/index.php/JSG/article/view/1100/1092

Green, D. and M.Z. Southard. 2019. Perry’s chemical engineers handbook (9th editions). McGraw-Hill Companies, Inc. McGraw-Hill, New York, USA.

Hadibi, T., A. Boubekri and D. Mennouche. 2022. Effect of ventilated solar-geothermal drying on 3E (exergy, energy, and economic analysis), and quality attributes of tomato paste. Energy, 243: 122764. https://doi.org/10.1016/j.energy.2021.122764

Haryani, K., Suherman and Suryanto. 2015. Thin layer drying model using the rack dryer method. J. Teknis, 10(1): 11–16. https://jurnal.polines.ac.id/index.php/teknis/article/view/671/588

Hasibuan, A. S., V. Edrianto and N. Purba. 2020. Phytochemical screening of red onion ethanol extract (Allium cepa L.). J. Farmasimed., 2(2): 45–49. https://doi.org/10.35451/jfm.v2i2.357

Hikmah, S.I. and M.A. Anggarani. 2021. Content of bioactive compounds and antioxidant activity of red onion (Allium cepa L.) from Nganjuk. Unesa J. Chem., 10(3): 220–230. https://doi.org/10.26740/ujc.v10n3.p220-230

Inyang, U.E., I.O. Oboh and B.R. Etuk. 2018. Kinetic models for drying techniques food materials. Adv. Chem. Eng. Sci., 8(2): 27–48. https://doi.org/10.4236/aces.2018.82003

Irawan, S. and Rozalia. 2022. The use of shallots and soaked coconut water for deli honey water guava cuttings in the village Amplas Medan. J. Liaison Acad. Soc., 2(2): 123–137. https://www.j-las.lemkomindo.org/index.php/J-LAS/article/view/346/506

Islami, A., Murad and A. Priyati. 2017. Characteristics of drying red onions (Alium ascalonicum L) using a dryer ERK (Greenhouse). J. Ilmiah Rekayasa Pertanian dan Biosistem, 5(1): 330–338. https://doi.org/10.29303/jrpb.v5i1.42

Jangde, P.K., A. Singh and T.V. Arjunan. 2022. Efficient solar drying techniques: A review. Environ. Sci. Pollut. Res., 29(34): 50970–50983. https://doi.org/10.1007/s11356-021-15792-4

Ju, H.Y., H.M. El-Mashad, X.M. Fang, Z. Pan, H.W. Xiao, Y.H. Liu and Z.J. Gao. 2016. Drying characteristics and modeling of yam slices under different relative humidity conditions. Drying Technol., 34(3): 296–306. https://doi.org/10.1080/07373937.2015.1052082

Kasmui, F.K.N., 2016. Antioxidant activity test on modification of chrysin compounds with alkoxy groups using the recife model 1 (Rm1). J. MIPA, 38(2): 160–168.

Lestari, N., S. Samsuar, E. Novitasari and K. Rahman. 2020. Performance of cabinet dryer on drying red ginger by utilizing waste heat of air conditioning. J. Agritech., 13(1): 57–70. https://doi.org/10.20956/at.v13i1.250

Lewicki, P.P., D. Witrowa-Rajchert and D. Nowak. 1998. Effect of drying mode on drying kinetics of onion. Dry Technol., 16(1–2): 59–81. https://doi.org/10.1080/07373939808917392

Manfaati, R., H. Baskoro and M.M. Rifai. 2019. The effect of time and temperature on the drying process of shallots using a tray dryer. Fluida, 12(2): 43–49. https://doi.org/10.35313/fluida.v12i2.1596

Mutia, A.K., Y.A. Purwanto and L. Pujantoro. 2014. Changes in quality of red onion (Allium ascalonicum L.) during storage at different water content and temperature. J. Pascapanen, 11(2): 108–115. https://doi.org/10.21082/jpasca.v11n2.2014.108-115

Neikov, O.D., 2019. Processing of powders and processing equipment. In: (eds. O. Neikov, D. Stanislav, N. Naboychenko). Handbook of non-ferrous metal powders: Technologies and applications (2nd ed.). Elsevier Ltd. pp. 403–455. https://doi.org/10.1016/B978-0-08-100543-9.00014-2

Nurcahyo, H., S.A. Sumiwi, E. Halimah and G. Wilar. 2020. Total flavonoid levels of ethanol extract and ethyl acetate fraction dry shallots (Allium cepa L. var. garden onion of Brebes) with maceration methods using UV-Vis spectrophotometry. Syst. Rev. Pharm., 11(10): 286–289.

Pochont, N.R., M.N. Mohammad, B.T. Pradeep and P.V. Kumar. 2020. A comparative study of drying kinetics and quality of Indian red chilli in solar hybrid greenhouse drying and open sun drying. Mater. Today Proc., 21: 286–290. https://doi.org/10.1016/j.matpr.2019.05.433

Prakash, O. and A. Kumar. 2012. Solar drying technology: Concept, design, testing, modeling, economics and environment, 1st edition. Springer Singapore.

Pu, H., Z. Li, J. Hui and G.S.V. Raghavan. 2016. Effect of relative humidity on microwave drying of carrot. J. Food Eng., 190: 167–175. https://doi.org/10.1016/j.jfoodeng.2016.06.027

Rahman, R.S. and S.S. Umami. 2019. Isolation and identification of fungi in post harvesting of red onions Allium ascalonicum L. var. Super Philip. Biodikdaktika, 14(1): 1–6. https://doi.org/10.30870/biodidaktika.v14i1.4837

Rousan, P., N. Asiah, S. Budi and R. Ratnawati. 2022. Evaluation of drying temperature on water removal and physicochemical quality of onion slice. Chem. Eng. Trans., 92: 721–726.

Rozana, R. R. Hasbullah and T. Muhandri. 2016. Temperature response on drying rate and quality of candied dried mango (Mangifera indica L.). J. Keteknikan Pertan., 4(1): 59–66. https://doi.org/10.19028/jtep.04.1.59-66

Sasongko, S.B., H. Hadiyanto, M. Djaeni, A.M. Perdanianti and F.D. Utari. 2020. Effects of drying temperature and relative humidity on the quality of dried onion slice. Heliyon, 6(7). https://doi.org/10.1016/j.heliyon.2020.e04338

Setyobudi, R.H., E. Yandri, Y.A. Nugroho, M.S. Susanti, S.K. Wahono, W. Widodo, L. Zalizar, E.A. Saati, M. Maftuchah, M.F.M. Atoum, M.I. Massadeh, D. Yono, R.K. Mahaswa, H. Susanto, D. Damat, D. Roeswitawati, P.G. Adinurani and S. Mindarti. 2021a. Assessment on coffee cherry flour of mengani Arabica coffee, Bali, Indonesia as iron non-heme source. Sarhad J. Agric., 37(Special Issue 1): 171–183. https://doi.org/10.17582/journal.sja/2022.37.s1.171.183

Setyobudi, R.H., L. Zalizar, S.K. Wahono, W. Widodo, A. Wahyudi, M. Mel, B. Prabowo, Y. Jani, Y.A. Nugroho, T. Liwang and A. Zaebudin. 2019. Prospect of Fe non-heme on coffee flour made from solid coffee waste: Mini review. IOP Conf. Ser.: Earth Environ. Sci., 293(1): 1–25. https://doi.org/10.1088/1755-1315/293/1/012035

Setyobudi, R.H., D. Damat, S. Anwar, A. Fauzi, T. Liwang, L. Zalizar, Y.A. Nugroho, M. Wedyan, M. Setiawan, S. Husen, D. Hermayanti, T.D.N. Subchi, P.G. Adinurani, E. D. Septia, D. Mariyam, I.R. Utarid, I. Ekawati, R. Tonda, E.D. Purbajanti, S. Suherman, M.S. Susanti, T.A. Pakarti, I. Iswahyudi, B.A. Prahardika and A.R. Farzana. 2023. Amino acid profiles of coffee cherry flour from different origins: A comparative approach. E3S Web Conf., 432(00032): 1–13. https://doi.org/10.1051/e3sconf/202343200032

Setyobudi, R.H., E. Yandri, M.F.M. Atoum, S.M. Nur, I. Zekker, R. Idroes, T.E. Tallei, P.G. Adinurani, Z. Vincēviča-Gaile, W. Widodo, L. Zalizar, N.V. Minh, H. Susanto, R.K. Mahaswa, Y.A. Nugroho, S.K. Wahono and Z. Zahriah. 2021b. Healthy-smart concept as standard design of kitchen waste biogas digester for urban households, Jordan J. Biol. Sci., 14(3): 613–620. https://doi.org/10.54319/jjbs/140331

Setyobudi, R.H., M.F.M. Atoum, D. Damat, E. Yandri, Y.A. Nugroho, M.S. Susanti, S.K. Wahono, W. Widodo, L. Zalizar, A. Wahyudi, E.A. Saati, M. Maftuchah, Z. Hussain, D. Yono, S.S. Harsono, R.K. Mahaswa, H. Susanto, P.G. Adinurani, I. Ekawati, A. Fauzi and S. Mindarti. 2022. Evaluation of coffee pulp waste from some coffee cultivation areas in Indonesia as iron booster. Jordan J. Biol. Sci., 15(3): 475–488.

Setyobudi, R.H., S.K. Wahono, P.G. Adinurani, A. Wahyudi, W. Widodo, M. Mel, Y.A. Nugroho, B. Prabowo and T. Liwang. 2018. Characterisation of arabica coffee pulp- hay from Kintamani- Bali as prospective biogas feedstocks, Matec Web. Conf., 164(01039): 1–13. https://doi.org/10.1051/matecconf/201816401039

Susanto, H., A.S. Uyun, R.H. Setyobudi, S.M. Nur, E. Yandri, J. Burlakovs, A. Yaro, K. Abdullah, S.K. Wahono and Y.A. Nugroho. 2020b. Development of moving equipment for fishermen’s catches using the portable conveyor system. E3S Web Conf., 190(00014): 1–10. https://doi.org/10.1051/e3sconf/202019000014

Susanto, H., R.H. Setyobudi, D. Sugiyanto, M.S. Nur, E. Yandri, H. Herianto, Y. Jani, S.K. Wahono, P.G. Adinurani, Y. Nurdiansyah and A. Yaro. 2020a. Development of the biogas-energized livestock feed making machine for breeders. E3S Web Conf., 188(00010): 1–13. https://doi.org/10.1051/e3sconf/202018800010

Syah, H., 2020. Drying kinetics of Dutch teak leaves. J. Keteknikan Pertan., 8(2): 53–62. https://doi.org/10.19028/jtep.08.2.53-62

Syah, H., A.H. Tambunan, E. Hartulistiyoso and L.P. Manalu. 2020. Thin layer drying kinetics of Guazuma ulmifolia leaves. Keteknikan Pertanian, 8(2): 53–62. https://journal.ipb.ac.id/index.php/jtep/article/view/28558

Tangkanakul, P., P. Auttaviboonkul, B. Niyomwit, N. Lowvitoon, P. Charoenthamawa and G. Trakoontivakorn. 2009. Antioxidant capacity, total phenolic content and nutritional composition of Asian foods after thermal processing. Int. Food Res. J., 16(4): 571–580.

Ummah, N., Y.A. Purwanto and A. Suryani. 2016. Determination of the red onion (Allium ascalonicum L.) using tunnel dehydrator. Warta Industri Hasil Pertanian, 33(2): 49–56.

Velderrain-Rodríguez, G.R., H. Palafox-Carlos, A. Wall-Medrano, J.F. Ayala-Zavala, C.Y.O. Chen, M. Robles-Sánchez, H. Astiazaran-García, E. Alvarez-Parrilla and G.A. González-Aguilar. 2014. Phenolic compounds: Their journey after intake. Food Funct., 5(2): 189–197. https://doi.org/10.1039/C3FO60361J

Wahono and Y.A. Nugroho. 2020b. Development of moving equipment for fishermen’s catches using the portable conveyor system. E3S Web Conf., 190(00014): 1–10. https://doi.org/10.1051/e3sconf/202019000014

Wazri, H., 2019. Shallot cultivation guide. https://distan.lomboktimurkab.go.id/baca-berita-162-panduan-budidaya-bawang-merah.html

Wijayanto, N. and Nurunnajah. 2012. Light intensity, temperature, humidity and lateral rooting of mahogany (Swietenia macrophylla King.) on RPH Babakan Madang, BKPH Bogor, KPH Bogor. J. Silvikultur Tropika, 3(1): 8–13.

Xiao, J., E. Capanoglu, A.R. Jassbi and A. Miron. 2016. Advance on the flavonoid C-glycosides and health benefits. Crit. Rev. Food Sci. Nutr., 56: S29–S45. https://doi.org/10.1080/10408398.2015.1067595

Yang, J., K.J. Meyers, J. Van der Heide and H.L. Rui. 2004. Varietal differences in phenolic content and antioxidant and antiproliferative activities of onions. J. Agric. Food Chem., 52(22): 6787–6793. https://doi.org/10.1021/jf0307144

Yuliasdini, N.A., S.U. Putri, T.A. Makaminan and S. Yuliati. 2020. Thermal efficiency tray dryer type dryer for drying sugarcane bagasse based silica gel. Prosiding Seminar Mahasiswa Teknik Kimia, 1(1): 29–33. Politeknik Negeri Sriwijaya, Palembang, Indonesia.

Zamharir, Sukmawaty and A. Priyati. 2016. Analysis of the utilization of heat energy in drying red onions (Allium ascalonicum L.) using the greenhouse effect dryer. J. Ilmiah Rekayasa Pertanian Dan Biosistem, 4(2): 264–274.

Zogzas, N.P, Z.B. Maroulis and D. Marinos-Kouris. 1996. Moisture diffusivity data compilation in foodstuffs. Dry. Technol., 14(10): 2225–2253. https://doi.org/10.1080/07373939608917205

To share on other social networks, click on any share button. What are these?