Impact of Maggot Black Soldier Fly (Hermetia illucens) Flour Supplementation in Broiler Chickens

Research Article

Impact of Maggot Black Soldier Fly (Hermetia illucens) Flour Supplementation in Broiler Chickens

Riko Noviadi, Dwi Desmiyeni Putri, Gusma Gama Maradon*, Agung Adi Candra, Nani Irwani, Gadis Apriani, Made Guntur Candra Adinata, I Made Krisnanda

Animal Husbandry Production of Technology, Politeknik Negeri Lampung, Bandar Lampung, Lampung Province, Indonesia.

Abstract | Protein is the most expensive component of feed, resulting in economically burdensome production costs. The Maggot Black Soldier Fly (Hermetia illucens) can be utilized as protein source feed ingredients. We aimed to analyze the implications of maggot black soldier fly (Hermetia illucens) flour with various processing techniques in broiler rations. This study used a completely randomized design (CRD) with 4 treatments and 5 replications, each replication consisting of 5 broilers. We designed four treatments, P1 = Sundried for 2 days + grinding, P2 = Oven dried at 50°C for 7 h + grinding, P3 = Roasting at 100 °C for 15 min + grinding, and P4 = Water scalding at 96 °C for 1 min + grinding. The processing techniques can provide a comparison of price differences in each treatment and can reduce production costs with the application of as much as 11.25% in broiler rations. The oven-drying (P2) can improve the water quality, roasting (P3) can increase metabolic energy, and hot water scalding (P4) can reduce production costs and has economic value by analysis results price BEP of Rp. 25,645.35, Product BEP of 21.38 kg, IOFC of Rp. 734,032.90, R/C value of 1.44, and B/C value of 0.44.

Keywords | Economic, Maggot, Metabolic, Processing, Productivity

Received | December 30, 2022; Accepted | March 07, 2023; Published | March 21, 2023

*Correspondence | Gusma Gama Maradon, Animal Husbandry Production of Technology, Politeknik Negeri Lampung, Bandar Lampung, Lampung Province, Indonesia; Email: gusma@polinela.ac.id

Citation | Noviadi R, Putri DD, Maradon GG, Chandra AA, Irwani N, Apriani G, Adinata MGC, Krisnanda IM (2023). Impact of maggot black soldier fly (Hermetia illucens) flour supplementation in broiler chickens. Adv. Anim. Vet. Sci. 11(4):606-613.

DOI | https://dx.doi.org/10.17582/journal.aavs/2023/11.4.606.613

ISSN (Online) | 2307-8316

Copyright: 2023 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

INTRODUCTION

The main obstacle that faces the feeding regimens of broilers in Indonesia as a developed country is the high prices of the ingredient. The rations ingredient that has the highest price in broiler rations is fish meal because of the importing issues. So we have to find out another protein resource that can still induce broiler performance.

One of the feed materials that has potential is maggot from flies Black Soldier Fly (Hermetia illucens). The BSF (Black Soldier Fly) maggot is the larva of a large black fly that looks like a wasp. Maggot of Hermetia illucens contains 36.5% crude protein, 28.12% crude fat, 8.36% crude fiber, 9.34% ash, 1.52% calcium, 0.83% phosphorus, and 4720.59 Kcal/kg (Fauzi and Sari, 2018). In the process of feed, fresh BSF maggot will be processed into flour to make it easier for the ingredients to be mixed in processed as feed.

Processing into flour can reduce the water and fat content which will increase the storage time. The high water contents will contribute to mould growth which can damage the nutritional contents, while high fat will contribute to quicker rancidity due to the oxidation of fat. Processing BSF maggot into flour can reduce the antitoxin in the form of chitin found in insects. Most of the chitin cannot be digested because chitin can bonds with other nutrients. Metabolic energy is used by livestock in various activities such as physical activity, maintaining body temperature, metabolism, tissue formation, production, and reproduction (Portocarero and Braun, 2021). If the metabolic energy needs of the broiler are met, the remaining energy (net energy) will be used for productivity. Productivity can increase because the inhibiting factor for nutrient absorption in chitin is denatured. BSF flour has the potential as a substitute for a fish meal up to 25% for mixed feed without any negative effect on digestibility (Rambet et al., 2015). BSF amino acid profile is similar to fish meal amino acid profile. We aimed to add BSF maggot flour with various processing techniques in the broiler’s ration to study crumble physical characteristics, metabolic energy, productivity, and economic analysis.

MATERIALS AND METHODS

Production of maggot black soldier fly (Hermetia illucens) flour

The production was carried out using sun drying (Aini et al., 2018); oven drying (Natsir et al., 2020); roasting (Lestariningsih, 2021), and hot water scalding (Nyangena et al., 2020).

Preparation of crumbles

The ingredients are weighed according to their formulation and then mashed. Then, the refined ingredients are mixed according to the formulation. Furthermore, the homogeneous feed is shaped into pellets with a diameter of 3 mm. After cooling, the pellets were crushed using a blender for 10 sec and became crumbly.

Nutritional content

The nutritional content of rations that have been used during maintenance in the study has been adjusted to the standard nutritional requirements of feed in starter (1-15 days) and finisher (16-32 days). The nutritional can be seen in Tables 4 and 5 in tables and figures.

Maintenance of broilers

Broilers were kept in open system cages measuring 1.5 x 1.5 m containing 5 broiler chickens. The average temperature during the study was 25oC with an Rh 84.63%. Lighting uses a 30 W capsule led lamp with a 850 lm led flux. The feed container uses a yellow tube hanging feeder with a capacity of 5 kg and the drinking water container uses a gallon model with a capacity of 5 L. To prevent rats, birds and insects from disturbing all the walls of the cage, ¼ in ram wire is used. The disinfection procedure carried out during the study was spraying all parts of the cage starting from the ceiling, walls, poles and floor of the cage, as well as the cage environment. The one-day-old chicks (DOC) were weighed to determine the initial weight and placed into the cage. DOC has been vaccinated in the hatchery. Supplementation with sugar water was carried out to the newly arrived DOC so that his energy recovers quickly after the trip. Feeding was carried out in the morning, afternoon, and evening. Feed supplied to the broiler aged 1-3 days are commercial, and the treatment rations were supplied in the starter and finisher period. Drinking water is given ad libitum.

Data collection

Water content

Measurement of water content can be done using an infrared moisture meter. 5 grams of sample is placed on the sample plate and then irradiated by an infrared lamp, the irradiation distance can be adjusted by rotating the support leg. Exposure can be done for 15 minutes, by pressing the button until the light is on. After 15 min the light is turned off, and the scale needle is shifted, so the balance needle shows zero. These measurements were repeated until the sample reached a constant weight and the sample weight was calculated as the final weight.

Specific gravity

Specific gravity can be obtained by adding 100 ml of water to a measuring cup. Then 50g of sample was added and the volume change was observed.

Specific gravity (gr/cm3) = (mass of the object (gr))/ change in water volume (cm3))

Crumble size

Crumble size can be measured using a screw micrometer to see the diameter and length

Crumble durability index (CDI)

Crumble durability index can be obtained by adding 500 g of sample to the crumble durability tester in 10 min. Sample sifted by sieve number 8 and calculate the mass of the remaining sample.

Crumble Durability Index (CDI) = (number of whole crumbles (gr))/(total crumble dropped (gr)) x 100%

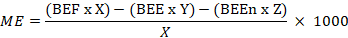

Metabolic energy (ME)

After the feeding trial was completed, 25 roosters (1.5 to 1.7 kg in weight) were selected and separated. Each chick was housed in an individual metabolic cage with a tray at the bottom to collect excreta. Chickens fasted for 24 h to empty the contents of the digestive tract. Drinking water is still provided ad libitum. A total of 20 chickens (4 treatments and 5 replications) were each given 100 g of the test ration with a time limit of 2 h to eat. The remaining rations were weighed to determine the consumption of rations. The other 5 chickens were kept fasted to measure endogenous excreta. Excreta were collected after 24 h and then weighed fresh and frozen for 24 h. The excreta is then thawed, dried, and ground to a size of 20 mesh. Excreta samples and test rations were analyzed for gross energy content. Formula model for calculating Metabolic Energy according to a modification of the method of Sibbald and Morse (1983).

BEF= Brutto Energy Feed (kcal/kg); BEE = Brutto Energy Excrete (kcal/kg); BEEn= Brutto Energy Endogenus (kcal/kg); X = Ration Consumption (g); Y = Excrete weight (g); Z = Endogenus excrete weight (g).

Broiler performance

Broiler performance is obtained by calculating the amount of feed given, body weight gain, feed conversion, and the number of chickens that die during the feeding trial.

Ration Consumption (gr/bird) = Number of gifts - The remaining amount

Body Weight Gain (gr/bird) = Final maintenance weight/Initial weight

Feed Conversions Ratio = (Total of fed (gr))/(Total of weight gain (gr))

Mortality (%) = (Number of deaths recorded)/(Number of population) x 100%

Economic analysis

Economic analysis is obtained by calculating the costs incurred during the broiler feeding trial and the costs obtained from broiler sales.

Break Event Points (BEP) = Total Cost/ Selling price

IOFC (Income over feed cost) = Income – Feed cost

R/C (Return Cost Ratio)= Revenue/Cost

B/C (Benefit Cost Ratio) = Benefit/Cost

Observed variables

The observed variables regarding the physical characteristics of crumble and metabolic energy in broiler rations containing BSF maggot flour with various processing techniques i.e., water content, specific gravity, crumble size, crumble durability index, and metabolic Energy (ME). The observed variables regarding the effect of black soldier fly (Hermetia illucens) maggot flour resulting from various physical processing on broiler performance i.e: ration consumption, body weight gain, feed conversions ratio, and mortality. The observed variables regarding the economic analysis of black soldier fly (Hermetia illucens) maggot flour with various processing techniques in broiler rations i.e.: Break Event Points (BEP), IOFC (Income over feed cost), R/C (Return Cost Ratio), and B/C (Benefit Cost Ratio).

Statistical analysis

The study used a completely randomized design (CRD) with 4 treatments and 5 replications (each replication consisting of 5 broilers). The data obtained were analyzed by Analysis of variance (ANOVA) using Microsoft Excel 2010. The research was carried out by mixing maggot flour into broiler rations of 11.25% which were reared for 35 days, then made observations on the physical characteristics of the crumble and energy metabolism, productivity, and economy. The study was conducted using 100 broilers.

RESULTS and Discussion

The results of giving maggot BSF flour as much as 11.25% in the rations produced by various processing techniques in broiler rations based on the observed variables, namely water content results of the analysis of the variety of crumble form rations there were significant differences in the effect (P < 0.05) on water content and Duncan’s test results showed significant differences between P2 and P1, P3, and P4. Specific gravity results of the analysis showed that there was no significant difference in specific gravity. Processing techniques P1, P2, P3, and P4 have the same feed composition so that the volume and mass are relatively the same. Crumble size results of the analysis of variance had a significant (P < 0.05) effect on size crumbles and results of Duncan’s test showed a significant difference between P1 and P2, P3 and P4. Crumble durability index results of the analysis of variance gave a significant difference (P < 0.05) to the impact resistance. The Duncan test results showed significant differences between P1 and P2, P3 and P4. Metabolic energy results of the analysis of variance gave significant differences (P < 0.05) in energy metabolism. The Duncan test results showed significant differences between P3 with P1, P2, P3, and P4. The results of ration consumption, weight gain body, ration conversion (FCR), mortality the effect of giving maggot black soldier fly (Hermetia illucens) flour as a result of various physical processing on broiler performance as much as 11.25% in broiler rations has no significant effect on broiler performance. Black soldier fly (Hermetia illucens) maggot flour processing techniques P4 can reduce production costs and has economic value by analysis results BEP Price of Rp. 25,645.35, Product BEP of 21.38 kg, IOFC of Rp. 734,032.90, R/C value of 1.44 and B/C value of 0.44. The results can be seen in Tables 1, 2, and 3 in tables and figures.

Physical characteristics of crumble and energy metabolism in broiler rations containing flour BSF maggot with various processing techniques

Table 1: Nutritional content of the initial maintenance phase ration (Starter).

|

Nutrition composition |

Amount |

|||

|

P1 |

P2 |

P3 |

P4 |

|

|

Proteins (%) |

22.10 |

22.09 |

22.08 |

22.10 |

|

Fat (%) |

7.62 |

7.86 |

7.56 |

7.66 |

|

Crude fiber (%) |

5.99 |

5.95 |

5.72 |

5.72 |

|

Ca (%) |

0.94 |

0.94 |

0.95 |

0.95 |

|

P (%) |

0.71 |

0.70 |

0.70 |

0.70 |

|

ME (Kcal/kg) |

3,194.85 |

3195.25 |

3,194.70 |

3195.24 |

*The calculation results of the ration formulation using the Microsoft Excel 2010 application.

Description: P1 = Sundried for 2 days + grinding; P2 =Baking at 50 oC for 7 hours + grinding; P3 = Roasting at 100 oC for 15 minutes + grinding; P4 = Scalding with hot water at 96 oC for 1 minute + grinding.

Table 2: Nutritional content of final maintenance phase rations (Finisher).

|

Nutrition composition |

Amount |

|||

|

P1 |

P2 |

P3 |

P4 |

|

|

Proteins (%) |

21.49 |

21.59 |

21.91 |

21.60 |

|

Fat (%) |

7.60 |

6.80 |

8.00 |

7.44 |

|

Crude fiber (%) |

5.99 |

5.90 |

5.63 |

5.96 |

|

Ca (%) |

0.86 |

0.87 |

0.87 |

0.87 |

|

P (%) |

0.70 |

0.70 |

0.68 |

0.69 |

|

ME (Kcal/kg) |

2999.31 |

2,968.40 |

3019.40 |

3,205.92 |

*The calculation results of the ration formulation using the Microsoft Excel 2010 application.

Description: P1 = Sundried for 2 days + grinding; P2 =Baking at 50 oC for 7 hours + grinding; P3 = Roasting at 100 oC for 15 minutes + grinding; P4 = Scalding with hot water at 96 oC for 1 minute + grinding.

Water content

Baking treatment at 50 °C for 7 hours resulted in the lowest water content among all treatments. This is due to the constant temperature of 7 hours causing a decrease in the effective water content in maggot. The duration of time affects the effectiveness of evaporation of moisture content. Temperature can decrease water content when drying BSF maggot flour. The higher the temperature generated during the heating process the more water was lost. Daud (2019) stated that the decrease in water content was caused by the temperature and humidity of the surrounding environment during the ration measurement process. Purnamasari et al. (2020) stated that BSF larvae can be dried with a temperature range of 55-75°C with a duration of 18-24 hours.

Specific gravity

Akbar et al. (2017) stated the same feed composition produces the same specific gravity. Compact feed texture will withstand the influence of the pressing so that the bond between the constituent particles is not filled with air cavities (Nurhayatin and Maya, 2017).

Crumble size

This is due to size crumbles influenced by the ration preparation, adhesives, and processing (Idan et al., 2023). The process during the BSF P1 maggot flour processing technique produced less refined maggot flour because it was suspected that it was sundried for 2 days after testing the proximate analysis of BSF maggot flour which had the highest water contents of 10.45%. Drying magot in the sun produces a higher water content when compared to other treatments. This causes when it is mixed into the ration then it is printed to produce pellets which are then broken down into crumbs to produce crumbles with a larger size.

The process of processing crumble through a pellet processing process so that the characteristics of the crumble depend on the quality of the pellets. Several factors influence pellet quality, such as nutritional composition, feed ingredient particle size, time and conditioning temperature, material humidity and die hole size (pellet sieve) (Colovic et al., 2010).

Crumble durability index

The crumble durability index is affected by crumble size (Idan et al., 2023). Treatment P1 had the highest. This is in line with Akbar et al. (2017) who stated that the resistance of the crumble is determined by the size of the particles of

Table 3: Physical characteristics of crumble and energy metabolism in broiler rations containing flour BSF maggot with various processing techniques.

|

Variable |

P1 |

P2 |

P3 |

P4 |

|

Water content (%) |

11.90b |

10.17a |

11.37b |

11.71b |

|

Specific gravity (gr/cm³) |

1.02a |

1.10a |

1.00a |

1.02a |

|

Crumble Size(mm) |

8.00b |

6.00a |

5.20a |

6.0a |

|

Crumble durability index (%) |

80.00a |

90.20b |

92.00b |

90.00b |

|

Metabolic energy (Kcal/gr) |

2,999.31a |

2,968.40a |

3,205.92b |

3004.32a |

Description: P1 = Sundried for 2 days + grinding; P2 =Baking at 50 oC for 7 hours + grinding; P3 = Roasting at 100 oC for 15 minutes + grinding; P4 = Scalding with hot water at 96 oC for 1 minute + grinding

Table 4: Effect of maggot black soldier fly (Hermetia illucens) flourvarious physical processing on broiler performance.

|

Variable |

P1 |

P2 |

P3 |

P4 |

|

Ration consumption |

1,854.87±145.6ª |

1,765.24±145.53ª |

1,784.64±176.12ª |

1,734.44±14.12ª |

|

Body weight gain |

1,164.70±88.86ª |

1,139.87±85.49ª |

1,138.33 ±68,10ª |

1,187.83±65.15ª |

|

ration conversion |

1.60±0.10ª |

1.57±0.25ª |

1.57±0.11ª |

1.46±0.08ª |

|

Mortality |

0 |

0 |

0 |

0 |

Description: P1 = Sundried for 2 days + grinding; P2 =Baking at 50 oC for 7 hours + grinding; P3 = Roasting at 100 oC for 15 minutes + grinding; P4 = Scalding with hot water at 96 oC for 1 minute + grinding

Table 5: Economic analysis of maggot black soldier fly (Hermetia illucens) flour with various processing techniques in broiler rations.

|

Variable |

P1 |

P2 |

P3 |

P4 |

|

BEP price (Rp) |

29,427.85 |

26,362.17 |

28,543.94 |

25,645.35 |

|

Product BEP (Kg) |

21.94 |

20,39 |

21.86 |

21.38 |

|

IOFC (Rp) |

592,860.41 |

686,291.82 |

623,844.37 |

734,032.90 |

|

R/C |

1.26 |

1.40 |

1.30 |

1.44 |

|

B/C |

0.26 |

0.40 |

0.30 |

0.44 |

*Results of analysis calculations using the Microsoft Excel 2010 application. Description: P1 = Sundried for 2 days + grinding; P2 =Baking at 50 oC for 7 hours + grinding; P3 = Roasting at 100 oC for 15 minutes + grinding; P4 = Scalding with hot water at 96 oC for 1 minute + grinding.

the raw material. Rosmiati (2019) states that the factors that affect pellet quality include Coarse fiber ration which serves as a pellet frame and raw material moisture content. Table 4 shows that the ration that uses maggot with the sun drying treatment for 2 days has a higher crude fiber content than the other treatments so that the cohesiveness of the crumble decreases. When testing durability it will produce a lower value (80%) where the standard value of crumble durability index 85-90%.

Another explanation is the rations that used the magot treatment by drying for 2 days under the sun significantly had different PDI values lower than the other treatments. This is due to heating through drying in the sun is less effective in reducing the water content resulting in higher humidity of the material. High humidity of the feed ingredients will affect the final appearance of the resulting pellets, namely the resistance of the pellets to impact (decreasing Pellet Durability Index) becomes low so that the pellets are easily crushed (brittle). Brittle pellets will also produce brittle crumble so that it will reduce the value of the crumble durability index.

Metabolizable energy

The ration using maggot with a roasting treatment of 100 °C for 15 minutes produces the highest metabolic energy, this is due to this is because this treatment contains a crude fiber value of 16.3% lower than other treatments. Low crude fiber can increase metabolic energy because the crude fiber content will affect digestibility. It is supported by Udayana et al. (2020) who stated that feed ingredients are relatively easier to digest when heated (roasted) due to digestion-inhibiting factors that can be destroyed. However, heating at high temperatures (not more than 100 °C) needs to be avoided to avoid damage to the nutrient contents.

Effect of maggot black soldier fly (Hermetia illucens) flour resulting from various physical processing on broiler performance

Ration consumption

Ration consumption is affected by nutritional content, the lower provided energy and protein the lower the ration consumption (Liu et al., 2020). The research was carried out using the same raw materials and particle sizes. According to Sundari et al. (2015), the use of temperatures of 180 ºC-300 ºC can damage the nutritional contents. The treatment of each study uses a temperature that does not exceed the temperature that has been mentioned so that the energy content of metabolism is neither too high nor too low. According to Maharjan et al. (2021), dietary energy levels affect energy retention efficiency. The metabolic energy requirement of the finisher ration is 2800-3200 kcal/kg. The metabolic energy of each treatment was 2968-3200 kcal/kg.

Body weight gain

Qurniawan et al. (2016) argue that some factors that influence body weight gain are sex, feed consumption, environment, seed, and feed quality. Consumption of rations in research has shown no significant differences in each treatment. There is no difference in maintenance procedures for each treatment or repetition so you get the same maintenance management treatment. There was no significant difference in the nutritional content of each treatment or it was still within nutritional standards, resulting in no significant differences in body weight gain. Protein is the main element used in the organs and soft tissue of the broiler body. Uzer et al. (2013) reported that the weight gain body is closely related to feeding concerning the quantity involved, if feed consumption is disturbed it will interfere with growth.

Feed conversion ratio

Ration conversion is the ratio of feed consumed to body weight gain. According to Irwani and Noviadi (2017), ration conversion can also be referred to as the feed coefficient during the maintenance of broiler chickens which are converted into heaps of tendons. The smaller the ration conversion value, the better. If the ration conversion value is 1.6, broilers need 1.6 kg to get 1 kg of meat. The results of ration conversion were not significantly different. The ration conversion index will increase if the relationship between the amount of internal energy formula and protein content is adjusted technically (Mookiah et al., 2014).

Mortality

Susanti et al. (2016) reported that mortality in one maintenance period of broiler chickens for 5 weeks in closed houses by 4% and opened houses by 5%. Marom et al. (2017) stated that high mortality shows the appearance of low production. If the mortality rate was found too high, then it must be looked at the cause (de Gussem et al., 2017), so the problem was quickly resolved. Mortality in the current study was 0% in each treatment. This shows that the ration using maggot with various drying treatments does not have an impact on health which can cause death in broilers

Economic analysis of maggot black soldier fly (Hermetia illucens) flour using various techniques processing in broiler rations

Break event points (BEP)

BEP provides information on various levels of sales and illustrates the relationship between sales volume, costs, selling prices, and sales mix to the profits of a business (cost-volume-profit analysis) (Retnaningsih, 2013). There were differences in each treatment caused by different production costs and total production and specifically between treatments to produce different BEP prices. BEP the lowest price is the best result because it has a price that is smaller than the selling price and can generate greater profits so that it meets the feasibility of economic analysis. There were differences in each treatment due to different production costs so the amount of production varies between treatments causing different product BEP results, but BEP products that have a value smaller than the number of products are in a profitable position and fulfill the feasibility of economic analysis.

Income over feed cost (IOFC)

The higher the Income Over Feed Cost (IOFC) value, the better because the revenue obtained from the sale of chickens is also high (Riyanti et al., 2015). The average weight of the ration treatment using the H. illucens flour processing technique Scalding with hot water at 96 °C for 1 minute + grinding a higher weight so that you get higher income and become IOFC highest.

Revenue cost ratio (R/C)

Different R/C of each treatment produced was influenced by the production costs, the cost of producing rations using H. illucens maggot flour was different because the processing techniques were different. The highest production costs were found in treatment with sundried for 2 days + grinding. The income received by a business is determined by the size of the costs used in the production process, so it is necessary to analyze the effect of the magnitude of production costs on income in a farming business (Penggu et al., 2014). This is supported by Altahat et al. (2012), the greater the costs incurred in the production of a business, the higher the selling price and the profit earned. One of the production factors that have a significant effect on the broiler business is feed (Wuryanto et al., 2015).

Benefit cost ratio (B/C)

The difference in B/C is due to differences in profits and total production costs for each treatment. The highest profit was found in rations with scalding with hot water at 96 °C for 1 minute + grinding so it has the highest B/C value, while the lowest profit and the highest total production costs are contained in ration with magot by bundried for 2 days + grinding so it has the lowest B/C value. Rana et al. (2012) stated that profit is the biggest goal for every livestock business that is run along with various challenges according to the scale of the business being run.

CONCLUSIONS and Recommendations

Oven drying can improve the water quality and roasting can increase metabolic energy. The effect of giving maggot black soldier fly (H. illucens) flour as a result of various physical processing on broiler performance as much as 11.25% in broiler rations has no significant effect on broiler performance. Hot water scalding of black soldier fly (H. illucens) maggot flour can reduce production costs and has economic value by analysis results BEP Price of Rp. 25,645.35, Product BEP of 21.38 kg, IOFC of Rp. 734,032.90, R/C value of 1.44, and B/C value of 0.44.

ACKNOWLEDGEMENT

The study was supported by Politeknik Negeri Lampung through It’s contribution to all the facilities during the research.

NOVELTY STATEMENT

This research resulted in the best technique for producing BSF flour for use as broiler feed.

AUTHOR’S CONTRIBUTION

RN, GGM, and DDP design the research. GGM, AAC, and NI supervised the field experiment. RN and DDP supervised the laboratory experiment. GA, MGCA, and IMK experimented and drafted the manuscript. RN, DDP, GGM, AAC, and NI revised the manuscript.

Conflict of interest

The authors have declared no conflict of interest.

REFERENCES

Aini LN, Ahmad F, Saratunsara H (2018). Cultivation of black soldier fly (BSF) larvae as an ingredient for making maggot flour on bran media. J. Res. Innov., 1(3): 1–4.

Akbar MR, Suci DM, Wijayanti I (2017). Quality evaluation of duct feed pellet supplemented with morinda (Morinda citrifolia) leave powder after 6 weeks storage. Bull. Ilmu Makanan Ternak, 104(2): 31-48.

Altahat E, Al-Sharafat A, Alatarawneh M (2012). Factors Affecting Profitability of Layer Hens Enterprises Related papers. Am. J. Agric. Biol. Sci., 7(1): 106-113. https://doi.org/10.3844/ajabssp.2012.106.113

Colovic R, Vukmirovic D, Matulaitis R, Bliznikas S, Uchockis V, Juskiene V, Levic J (2010). Effect of die channel press way length on physical quality of pelleted cattle feed. Food Feed Res., 31(1): 1–6.

Daud A (2019). Suriati Nuzulyanti. Study of the application of factors that affect the accuracy of determining the moisture content of the thermogravimetric method. J. Lutjanus., 24(2): 11-16. https://doi.org/10.51978/jlpp.v24i2.79

de Gussem M, Mailyan E, van Middelkoop K, van Mullem K, van‘t Veer E (2017). Broiler signal: A practical guide to broiler focused management. Roodbont Publisher BV, Netherlands.

Fauzi R, Sari E (2018). Business analysis of maggot cultivation as a catfish feed alternative. Industria: J. Agro-ind. Technol. Manag., 7(1): 39–46. https://doi.org/10.21776/ub.industria.2018.007.01.5

Idan F, Paulk C, Beyer S, Stark C (2023). Effects of pellet diameter and crumble size on the growth performance and relative gizzard weight of broilers. J. Appl. Poult. Res., 32(2). https://doi.org/10.1016/j.japr.2023.100331

Irwani N, Noviadi R (2017). Productivity and broiler carcass fed with ratio based on cassava leaf flour with the addition of black cumin (Nigella sativa). Dev. Innov. Res. J., 5(01): 1-7.

Lestariningsih (2021). The chemical quality of maggot flour uses roasted processing method. J. Dev. Res., 5(1): 28–33. https://doi.org/10.28926/jdr.v5i1.140

Liu SY, Chrystal PV, Selle PH (2020). Pre-determined starch and protein digestion rates attain optimal feed conversion ratios in broiler chickens. Proc. Aust. Poult. Sci. Symp., 31: 90.

Maharjan, P., Hilton, K.M., Mullenix, G., Weil, J., Beitia, A., Suesuttajit, N., Umberson, C., Martinez, D.A., Caldas, J.V., Kalinowski, A. and Yacoubi, N., 2021. Effects of dietary energy levels on performance and carcass yield of 2 meat-type broiler lines housed in hot and cool ambient temperatures. Poultry science, 100(3), p.100885.

Marom AT, Kalsum U, Ali U (2017). Evaluation of broiler performance in close house and open house systems with different altitudes. Welfare Dyn., 2(2): 21.

Mookiah S, Sieo CC, Ramasamy K, Abdullah N, Ho YW (2014). Effect of dietary prebiotics, probiotics and synbiotics on performance, caecal bacterial populations and caecal fermentation concentrations of broiler chickens. J. Sci. Food Agri., 94(2): 341-348. https://doi.org/10.1002/jsfa.6365

Natsir WNI, Rahayu RS, Daruslam MA, Azhar M (2020). Palatibility of maggot as a feed source of protein for poultry. J. Agrisyst., 16(1): 27–32.

Nurhayatin T, Maya P (2017). The effect of processing method of arrow root tuber (Maranta arundinacea) as binder and length of storage time on physical quality pellet feed for chicken broiler. J. Anim. Husb. 2(1): 32-40. https://doi.org/10.52434/janhus.v2i1.260

Nyangena DN, Mutungi C, Imathiu S, Kinyuru J, Hippolyte A, Ekesi M, Nakimbugwe D, Fiaboe KM (2020). The effect of traditional processing techniques on the nutritional and microbiological quality of four Edible insect species used for food and feed in East Africa. Foods, 9(5): 1–16. https://doi.org/10.3390/foods9050574

Penggu P, Santa NM, Anie M, Waleleng POV (2014). The relationship between production costs and income from native chicken farming (a case study in Pungkol Village, Tatapaan District, South Minahasa Regency). J. Zoot., 34 (Special Edition): 67-75. https://doi.org/10.35792/zot.34.0.2014.4794

Portocarero N, Braun U (2021). The physiological role of guanidinoacetic acid and its relationship with arginine in broiler chickens. Poult. Sci., 100(7): 101203. https://doi.org/10.1016/j.psj.2021.101203

Purnamasari L, Sucipto I, Muhlison W, Pratiwi N (2020). Nutrient composition of black soldier fly (Hermetia illucent) larvae using different growth media, temperature and drying time. Prosiding Seminar Nasional Teknologi Peternakan dan Veteriner, pp. 687-692.

Qurniawan A, Arief II, Afnan R (2016). Broiler productions performance on the different breeding altitude in South Sulawesi. J. Vet., 17(4): 622-633. https://doi.org/10.19087/jveteriner.2016.17.4.622

Rambet V, Umboh JF, Tulung YL, Kowel YH (2015). Kecernaan protein dan energi ransum broiler yang menggunakan tepung maggot (Hermetia illucens) sebagai pengganti tepung ikan. Zootec, 36(1): 13-22. https://doi.org/10.35792/zot.36.1.2016.9314

Rana KMAA, Rahman MS. dan Sattar MN. 2012. Profitability of small scale broiler production in some selected areas of Mymensingh. Progress. Agric. 23(1 dan 2): 101 – 109.

Retnaningsih N (2013). Break even point analysis (BEP) and bread business profitability at Ganep Bakery in Surakarta. J. Widyatama., 1(22): 55–63.

Riyanti E, Gustira D, Kurtini T (2015). The effect of cage density on the performance of laying hens in the early phase of the grower. Integ. Anim. Husb. Sci. J., 3(1): 87-92.

Rosmiati (2019). Determination of pellet durabilty index in broiler chicken pellet feed. Ready Star., 2(1): 212-216.

Sibbald IR, Morse PM (1983). Effect of the nitrogen correction and feed intake on true metabolizable value. Poult. Sci., 62(1): 138-142. https://doi.org/10.3382/ps.0620138

Sundari D, Almasyhuri A, Lamid A (2015). The effect of the cooking process on the nutritional composition of food sources of protein. Media R & D., 25(4): 235-242. https://doi.org/10.22435/mpk.v25i4.4590.235-242

Susanti ED, Dahlan M, Wahyuning D (2016). Perbandingan produktivitas ayam broiler terhadap sistem kandang terbuka (open house) dan kandang tertutup (closed house) di UD Sumber Makmur Kecamatan Sumberrejo Kabupaten Bojonegoro. J. Ternak, 7(1): 25-32. https://doi.org/10.30736/jy.v7i1.5

Udayana IDGA, Mahardika IG, Sumadi IK, Budaarsa K, Biduram IGNG (2020). Effect of energy-protein ratio in diets on Balinese duck (Anas sp) performance and feed digestibility. Int. J. Fauna Biol. Stud., 7(1): 41–46.

Uzer F, Iriyanti N, Roesdiyanto (2013). Use of functional feed in rations on feed consumption and body weight gain of broiler chickens. J. Anim. Husb. Sci., 1(1): 282-288.

Wuryanto D., Ichwani dan Kadarso. 2015. Analisis produksi usaha peternakan ayam pedaging di Kabupaten Sleman. Journal Argros Vol. 17(1): 71–80.

To share on other social networks, click on any share button. What are these?