The Relationship of Lignin and Crude Fiber in Rice Bran with Ultrasonic Wave Parameters

Research Article

The Relationship of Lignin and Crude Fiber in Rice Bran with Ultrasonic Wave Parameters

Urip Rosani1*, Iman Hernaman1, Rahmat Hidayat1, Darmawan Hidayat2

1Department of Animal Nutrition and Feed Technology, Faculty of Animal Husbandry, Universitas Padjadjaran Sumedang 45363, West Java, Indonesia; 2Department of Electrical Engineering, Faculty of Mathematics and Natural Sciences, Universitas Padjadjaran, Sumedang 45363, West Java, Indonesia.

Abstract | This study was designed to determine the ability of ultrasonic waves to detect rice husks added to rice bran based on physical properties associated with nutrient content. This research utilizes low-intensity ultrasonic waves of 50 kHz transmitted on rice bran mixed with rice husks with particle sizes passing 30 mesh (<0.595 mm). The purpose of this study was to determine the correlation between ultrasonic parameters (attenuation and velocity) and the nutrient content (crude fiber and lignin) of rice bran containing different rice husks. Based on the results of research, there is a strong relationship between ultrasonic parameters and the nutrient content of rice bran containing various rice husks. The positive correlation between attenuation with crude fibre is 0.975, and attenuation with lignin is 0.965. The attenuation coefficient can be used as a parameter for estimating the content of lignin and crude fibre in rice bran. This research proves the high nutritional value of rice bran can be detected with ultrasonic waves. These results still need further research to measure the factors that affect ultrasonic wave transmission (amplitude) when measuring samples, as well as the manufacture of a series of compact ultrasonic test systems so that they can be applied in industry or practically in the field.

Keywords | Ultrasonic Wave, Attenuation, Velocity, Rice Bran, Rice Husk

Received | January 09, 2024; Accepted | Febraury 05, 2024; Published | February 26, 2024

*Correspondence | Urip Rosani, Department of Animal Nutrition and Feed Technology, Faculty of Animal Husbandry, Universitas Padjadjaran Sumedang 45363, West Java, Indonesia; Email: [email protected]

Citation | Rosani U, Hernaman I, Hidayat R, Hidayat D (2024). The Relationship of Lignin and Crude Fiber in Rice Bran with Ultrasonic Wave Parameters. Adv. Anim. Vet. Sci. 12(4): 791-801.

DOI | https://dx.doi.org/10.17582/journal.aavs/2024/12.4.791.801

ISSN (Online) | 2307-8316

Copyright: 2024 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

INTRODUCTION

The nutrient content of ingredients can be estimated using their physical properties. Physical parameters that are often used are density and phloroglucinol tests. In addition to these two methods, estimation is also carried out using ultrasonic waves. This method was developed to speed up the testing of adulteration of rice bran with rice husks quickly and accurately, and it can also estimate nutrient content based on lignin content. In detecting contamination in materials, the advantage of ultrasonic waves is that they are nondestructive to the material (nondestructive test).

Rice bran is a feed ingredient that has been generally used as a constituent of livestock rations in Indonesia for a long time. Rice bran is obtained from the by-products of milling rice grains. Rice grains consist of endosperm, husks, bran, and contaminants, of which endosperm accounts for 70%, rice husks 20–21% each, rice bran 6–8%, and rice contamination 1% of the total weight of the seed. During the production of milled rice, a large amount of rice husks is produced as a by-product (Zou & Yang, 2019). Rice bran is rich in vitamins, minerals, essential fatty acids, dietary fiber, and other sterols (Gul et al., 2015). Rice bran is not only a widely produced resource but also has high nutritional value. The nutrient content of rice bran is 12–16% protein, 12–23% fat, and 23–30% dietary fiber. In addition, it is rich in vitamins, minerals, and other nutritional factors such as phenantren, inositol, phytic acid, and glutamate (Sohail et al., 2017), crude protein 12.57%, crude fat 16.58%, crude fiber 7.57%, Ca 0.07% and 1.43% (Zhang et al., 2021), crude protein 13.52% (Najamuddin et al., 2021), oil 12–22%, protein 11–17%, fiber 6–14%, moisture 10–15%, and ash 8–17% as well as substantial amount of minerals like K, Ca, Mg and Fe (Sharif et al., 2014).

Rice husks are an important byproduct of the rice milling process, with very large quantities produced worldwide each year. During the production of milled rice, a large amount of 20–21% rice husks is produced as a by-product (Zou & Yang, 2019). Rice husks contain 24% cellulose, 12% hemicellulose, and 4.5% lignin components, so they can be recommended to be given to ruminants who are more able to utilize insoluble carbohydrate components. In addition, rice husks contain 14.4–23.4% glucose and 12-28.6% silos, which are the largest components in rice husks. Rice husks are agricultural by-products that can still be used as feed and are even categorized as an alternative energy source for livestock (Piliang, 1997). Although it has compounds that can be used as nutrients for ruminants, rice husks, in addition to containing lignin, also contain silica (Zou & Yang, 2019).

Rice husks are lignocellulose biomass waste rice milling products. The use of rice husks in rations is very limited due to the presence of lignin compounds. The molecular structure of lignin complexes in lignocellulose material will prevent degradation by rumen microbial enzymes (Khatoon et al., 2022). These compounds are difficult to degrade by rumen microbes, so rice husks are difficult to digest by the digestive tract. When the lignin content is low, the rate of degradation increases, but when the lignin content increases, the rate of degradation decreases. This suggests that lignin content is the limiting factor in determining the degree of degradation of the lignin-hemicellulose complex (Brice & Morrison, 1982).

Several works reported the method for the detection of rice husk-adulterated rice bran, and the quality of rice bran. They include the applications of image processing method based on convolutional neural network (CNN) (Albarki et al., 2023), liquid chromatography (Sabir et al., 2017), and image processing techniques (Uyeh et al., 2021). However, these methods have limitation in their applications, such as: time consuming, costly, and non-portable, and hence it is impractical for the usage in the field.

Because the need for rice bran as a feed ingredient is very high, it is often mixed with milled rice husks. This process will affect the quality of rice bran because there is a decrease in its nutrient content. Ultrasonic clusters are known to detect rice bran mix with rice husks because they have advantages. Ultrasonic waves are longitudinal mechanical waves whose frequency exceeds the hearing limit of the human ear (above 20 kHz). Ultrasonic waves are included in the category of sound waves, which means that they have the same properties as the sound waves themselves. This wave is a mechanical wave that requires a medium for its propagation (Dharmendra & Pandey, 2010). The intermediate medium of ultrasonic waves can be solid, liquid, gas, or liquid semi-solid. Ultrasonic wave propagation is easier to occur in a solid medium. While the gas or air medium is a bad medium for ultrasonic wave propagation (Gooberman & Mayer, 1970).

The working principle of ultrasonic waves from the transducer is passed to the material under test. Ultrasonic waves penetrate the material while the receiver records the reflected waves (pulse-echo mode) or the transmitted (through-transmission mode) sound waves. The screen on the diagnostic machine will show these results in the form of amplitude and pulse readings (Kaufmann, 2009). The speed of propagation of these ultrasonic waves is influenced by the physical properties of an object being passed through, including distance, porosity, cracks, and others (Suwandi et al., 2015). Materials with high porosity produce ultrasonic waves that will be passed on more than those absorbed. The smaller the particle density, the less energy is absorbed and dissipated. Therefore, it can also be concluded that the increase in rice husk content in rice bran makes the media density smaller, so that the value of the ultrasonic wave attenuation coefficient is also smaller (Bhagaspati et al., 2021).

In general, the acoustic properties of ultrasonic waves are transmission, attenuation, and speed. Acoustic properties that can determine the physico-chemical properties of a material are speed and attenuation, because these two parameters depend on the nature or state of the medium through which it passes. The ultrasonic waves used should be ultrasonic waves with low intensity so as not to damage the material or medium through which they pass (Rejo, 2002).

Ultrasonic waves propagate at different velocities in different materials. This is because the mass of the atomic particles and the spring constants are different for different materials. The mass of the particles is related to the density of the material, and the spring constant is related to the elastic constants of the material. The longitudinal ultrasonic wave speed in a solid material can be found in Equation 1.

(1)

(1)

Where, VL is the sound velocity (m/s), E medium Young’s Modulus (N/m2), υ is Poisson’s ratio, and ρ is medium density (kg/m3).

When an ultrasonic wave propagates through a medium, its intensity diminishes with distance. The sound pressure (signal amplitude) is reduced due to wave scattering. The ultrasonic wave amplitude is further weakened due to scattering and absorption. Scattering is the reflection of the ultrasonic wave in directions other than its original propagation direction. Absorption is the conversion of the wave energy to other forms of energy. The combined effect of scattering and absorption is called attenuation (symbol a).

Hence, when an ultrasonic wave propagates through the husk-adulterated rice bran powder, its attenuation differs as the husk concentration varies. This became the basic principle of this method to evaluate the husk concentration in the adulterated rice bran.

Ultrasonic waves can be used to detect parts of objects in detail because they have short wavelengths and great penetrating power (Omar, 2012; Whangchai et al., 2015). In addition, ultrasonic waves travel quite slowly, which is about 100,000 times slower than electromagnetic waves, allowing timely information, creating variable delays, and so on (Omar, 2012). The ultrasonic wave transmission technique is also commonly referred to as the Non-Destructive Testing (NDT) technique (Alonso et al., 2017; Pierre et al., 2013). In this technique, the parameters of velocity (velocity propagation) and attenuation form the basis of measurements to investigate information such as physical and chemical properties (Hidayat et al., 2010), structural changes, phase changes, charge transfers, and microstructural changes (Fakhlaei et al., 2020).

The applications of ultrasonic waves in the evaluation of testing various mediums and objects have not been reported, nor in solid, liquid, gas, or powder mediums. It has been reported that the acoustic attenuation of propagated ultrasonic waves in the husk-adulterated rice bran is strongly correlated with husk concentration (Bhagaspati et al., 2021). The propagating ability of ultrasonic waves in powder medium constitutes a special feature compared to other methods (Al-Lashi et al., 2018).

Distance, porosity, fractures, and other physical characteristics of the item being passed are all correlated with the propagation velocity of ultrasonic waves (Suwandi et al., 2015). The user’s wording is insufficient and does not give enough details to be rewritten clearly and concisely. However, the use of velocity propagation may include an unclear association, which calls for the inclusion of the concept of the attenuation coefficient. The energy loss that happens during the propagation of ultrasonic waves through a particular medium is measured by the attenuation coefficient. The particular properties of a media determine how energy is transferred through it (Alawsi, 2015; Pandin, 2021).

Previous research has shown that ultrasonic wave parameters (attenuation) can accurately be used to detect the physical properties of materials. Measuring turbine steam exhaust wetness (Zhu et al., 2023), particle size distribution of carbonyl iron powder (Wei et al., 2023), determine the material level, thickness, and temperature of carbon steel materials (Tai et al., 2023), measuring the surface roughness of materials (H. Liu et al., 2023), material measurement aluminum alloy 2219-O (S. Li et al., 2023), cavity content and density of polyester filaments (K. Liu et al., 2017), testing the porosity of composite laminates (Z. Li et al., 2014), detect Escherichia coli bacteria (Ravinder Reddy et al., 2001), metal-polymer composites (Hidayat et al., 2020) and detect contamination in the material (Bhagaspati et al., 2021; Khairurrahman et al., 2021; Salsabila et al., 2021).

Previous research measured the content of rice husks in rice bran according to the results of the rice milling mill. The result of the study is that rice husks can be detected by ultrasonic waves based on their acoustic properties, namely attenuation. However, previous studies have not provided information on the relationship between acoustic parameters and the chemical content of materials, especially crude fibers and lignin, only linking the physical properties of materials based on density.

This study was designed to determine the ability of ultrasonic waves to detect rice husks added to rice bran based on physical properties associated with nutrient content. This research utilizes low-intensity ultrasonic waves of 50 kHz transmitted on rice bran mixed with rice husks with particle sizes passing 30 mesh (<0.595 mm). The purpose of this study was to determine the correlation between ultrasonic parameters (attenuation and velocity) and the nutrient content (crude fiber and lignin) of rice bran containing different rice husks. We believe that ultrasonic waves can be used to determine the quality of rice bran without chemical analysis.

MATERIAL AND METHODS

Material Characterization

The rice bran used is Banowati’s superior local strain of rice from the Sindanglaya regional rice factory, Sindangsari Village, Sukasari District, Sumedang Regency. The grain milling process goes through two stages: the first is breaking rice husks using Yanmar ECH60AN machines, and the second is sowing using Ichi N70 750 machines. Characterization of rice bran using the sieve shaker filtering method with meshes 10, 20, 30, 40, and 50. On the mesh 40 and 50, it looks not like rice husks and groats but flour-like. This mesh is thought to consist of pericarp, tegmen, and aeluron layers, as well as fine fragments of endosperm (rice seeds) and as much as 48.1% of rice bran (Figure 1). The mesh of 10, 20, and 30 consists of husks and groats, as well as 51.9% of rice bran.

Treatment

This study detected the content of rice husks in rice bran. The sample is carefully designed with the proportions of rice husk and rice bran as follows:

R1 = rice bran 0% + rice husks 100%

R2 = rice bran 25% + rice husks 75%

R3 = rice bran 50% + rice husks 50%

R4 = rice bran 75% + rice husks 25%

R5 = rice bran 100% + rice husks 0%

In cases found in the field with dairy cows in the working area of the Bayongbong KUD, the use of rice bran mixed with high-milled rice husks (above 50%) in dairy cows causes milk production, health, and reproductive systems to be disrupted. 100% rice bran is a positive control, and 100% rice husk is a negative control.

Rice bran and rice husks are milled using a disk mill until they all pass through a 30 mesh (0.58 mm). The sample is then filtered using a sieve shaker for 10 minutes, then filtered using a 30 mesh. Rice bran and rice husks are put in the oven for 24 hours at 60°C. Then it is weighed based on the proportion of treatment.

The treatment sample is made of 50 grams of rice bran and rice husk, which are weighed according to the treatment. Homogenization using the stirring technique (Lacorte et al., 2012). The sample is placed into a clean glass or stainless steel bowl, and the homogenization process is stirred using a stainless steel spatula or spoon until homogeneity of texture and color is achieved. All impurities in non-representative materials (stones, wood chips, plant material) must be removed. After homogenization, the sample is stored in an airtight jar.

Nutrient Quality Measurement

The nutrient content of the sample is analyzed using proximate analysis and lignin content using van soest analysis in the laboratory of ruminant animal nutrition and animal feed chemistry, Faculty of Animal Husbandry, Padjadjaran University.

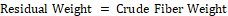

Crude Fiber Content Analysis (Sudarmadji et al., 1997). The sample is mashed so that it can go through a sieve with a diameter of 1 mm and mix thoroughly. Next, extract 2 grams of fat using Soxhlet. The sample is transferred into an Erlenmeyer of 600 ml. added 200 ml of boiling H2SO4 solution. closed with reverse cooling. Simmer for 30 minutes with an occasional wiggle. Filtered suspension through filter paper. The residue left in the Erlenmeyer is washed with boiling water. Wash the residue in filter paper until the washing water is no longer acidic. Quantitatively transferred residue from filter paper into an Erlenmeyer back with a spatula. The rest is washed again with 200 ml of boiling NaOH solution until all residues get into the Erlenmeyer. Bring to a boil with a reverse cooler while sometimes shaking for 30 minutes. It is filtered again through filter paper of known weight while being washed with a 10% solution of K₂SO4. Wash off the residue again with boiling water. Then, with 95% alcohol, about 15 ml. Dried filter paper with contents at 110°C to a constant weight (1-2 hours), cool in a desiccator, and weigh. The crude fiber can be calculated as follows Equation 2:

(2)

(2)

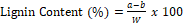

Lignin Content Analysis (Sudarmadji et al., 1997). Weigh 0.5 grams of sample and put it into an Erlenmeyer. Added 100 ml of ADF solution. Simmer on an upright cooler for 60 minutes. Filtered the mixture with filter paper and washed the precipitate with hot water. Take the precipitate and transfer it to another Erlenmeyer. Added 2.5 ml of 72% H2SO4. Shake the mixture for 2 to 3 hours at 20°C. Diluted concentration with aqueous to a mixture concentration of 3%. Heated the mixture in a water bath at 100°C for 2–4 hours. Filtered the mixture with a glass filter (2-G-4) and washed the precipitate with hot aquadest several times. Rinse the precipitate with acetone several times. Drain, filter, and precipitate in a 100°C oven until a fixed weight is obtained. Spray filters and deposits in furnaces at 400°–450°C until a fixed weight is obtained. The lignin percent can be calculated as follows Equation 3:

(3)

(3)

a = Filter weight and precipitate after drying (grams)

b = Filter weight and precipitate after grinding (grams)

W = Initial weight of the sample (grams).

Ultrasonic Measurement

Ultrasonic parameter measurement using a self-assembled device by the Laboratory of Electrical Engineering, Department of Electrical Engineering, Faculty of Mathematics and Natural Sciences, Padjadjaran University. The devices used consist of a power supply, an ultrasonic pulse generator, a signal amplifier connected to an ultrasonic receiver, a 50 kHz ultrasonic transducer (Table 1), an oscilloscope, and a sample holder. The ultrasonic wave signal is set using waveform pulser ultrasound software. The distance between the transmitter transducer and the receiver transducer is 1 cm (Figure 1).

Table 1: Transducer specifications used

|

Transducer Model |

Diameter |

Frequency |

|

50K-P28F SDE323 |

3.5 (cm) |

50 kHz |

The wave is sent to the test material by the transmitter and received by the receiver. The power amplifier then first amplifies the signal before sending it to the oscilloscope. Ultrasonic waves experience a decrease in power as they pass through the sample. Signal amplification is carried out when a power drop occurs. The oscilloscope then displays the information provided by the transducer and analyzes the data obtained. Readings were taken on each mixture five times. The block diagram of the system is presented in Figure 2. The parameters measured are attenuation and velocity.

Referring to Figure 2, the transmitter transducer generates the ultrasonic wave by stimulating the transmitter with an electrical pulse. The generated ultrasonic wave propagated through the husk-adulterated sample and was received by the receiver transducer. The received signal was amplified, displayed, and recorded by a digital storage oscillator. The wave velocity was calculated by measuring the distance (L) and the time of flight (ToF) of the propagating signal. The ToF was determined by measuring the initial time (the excitation pulse) and the received time. In addition, the attenuation was calculated by measuring the initial signal amplitude generated by the transmitter transducer (Ai) and the signal amplitude received by the receiver transducer (Ax).

The amplitude and travel time values are recorded as control or calibration. The values of amplitude and travel time can be observed through an oscilloscope. The amplitude value measures the distance between the upper peak of the wave and the lower peak of the wave during the transmission process to the sample object. The initial value of amplitude (Ai), amplitude of each sample (Ax), and travel time are recorded. Samples with different concentrations will produce different Ax values. This difference in Ax values will also result in different attenuation coefficient values in each sample.

The way ultrasonic parameter measurement works is that ultrasonic waves are passed on the sample, and the initial amplitude before passing through the sample and after passing through the sample is measured. The amplitude will experience a reduction in energy as it passes through the sample (Figure 3).

The stages of ultrasonic parameter measurement are as follows: First, the wave standard is set in amplitude, as seen from the waveform. To get the wave, the position of the two transducers is set so that the distance and position are completely parallel and produce the desired wave. Then the position of the transducer is locked and set as the amplitude and start of calibration. The second stage is sample measurement; the sample is inserted in a container between two transducers, and then the amplitude value and travel time are recorded. After sample measurement, the sample is removed from the container and then viewed for amplitude and travel time. The amplitude and unsampled velocity after measurement should be the same if unsampled. If there is a difference in amplitude and travel time, calibration is carried out to match the initial amplitude.

Testing rice bran using ultrasonic waves is currently a high investment due to the high price of equipment and limited availability. It is a challenge to innovate in the manufacture of spare parts to make portable rice bran testing equipment. In addition, the measurement of rice bran using ultrasonic waves is influenced by the environment, especially temperature and the structure that supports and connects the two transducers. Previous research reported that testing using ultrasonic waves is strongly influenced by ambient temperature. Signal response amplitude increases at 20–90 °C but decreases at 90–150 °C. (Raghavan & Cesnik, 2007). The structure of the tool should be made of a material that does not conduct ultrasonic waves to reduce the propagation of waves that would otherwise pass through the material (Gooberman & Mayer, 1970). The measurement obstacle is to ensure the voltage that enters the power supply, because there are often changes that will cause the circuit to burn. Next, make sure the sample site is made of material that does not conduct waves. This will affect the reading because the waves are supposed to propagate through the material instead of through the sample container.

Velocity

The ultrasonic velocity calculation is obtained from the distance traveled by the wave or the thickness of the medium (L) divided by the time traveled by the wave during transmission (t). The propagation speed is the distance that the wave travels from the transmitter to the receiver Equation 4.

(4)

(4)

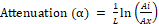

Attenuation

The calculation of the attenuation coefficient (α) is obtained from one divided by the distance traveled (L) of the wave during transmission, then multiplied by the natural logarithm (ln), the ratio of the amplitude of the wave before transmission (Ai) versus the amplitude of the wave after transmission (Ax) Equation 5.

(5)

(5)

Analysis Statistics

The data were analyzed using a one-way ANOVA if there was a noticeable difference, followed by the Duncan test. Pearson correlation analysis was performed to determine the effect of husks on attenuation and velocity, the effect of husks on crude fiber and lignin content, and the relationship between ultrasonic parameters and nutrient content.

RESULTS AND DISCUSSION

The effect of rice husks on attenuation and velocity

The physical properties of materials affect the parameter values of ultrasonic waves. The effect of rice husks on velocity and attenuation is presented in Table 2.

Table 2: The effect of rice husks in rice bran on attenuation and velocity

|

Parameters |

Treatment |

||||

|

R1 |

R2 |

R3 |

R4 |

R5 |

|

|

Attenuation, α (dB) |

0.275d |

0.247c |

0.230b |

0.200a |

0.195a |

|

Velocity (m/s) |

0.138a |

0.156b |

0.158b |

0.164c |

0.167d |

Description: R1 = 0% rice bran + 100% rice husk, R2 = 25% rice bran + 75% rice husk, R3 = 50% rice bran + 50% rice husk, R4 = 75% rice bran + 25% rice husk, R5 = 100% rice bran + 0% rice husk. Different superscripts show noticeable differences (0.05).

Based on the statistical analysis of attenuation content and velocity of experimental rations in Table 2, the addition of rice husks to rice bran significantly reduces attenuation and increases velocity. Attenuation is highest at R1 0.275 and lowest at R5 0.195; velocity is highest at R5 0.167 and lowest at R1 0.138. The magnitude of ultrasonic velocity at the microscopic level is regulated by the molecular mass and local stiffness, which in turn depend on the strength of the interaction between molecules and their separation (Guillermic et al., 2023). Therefore, velocity depends on the density and elasticity of the material, which is a good check of the material properties.

The attenuation value in this study was lower than the previous study. In testing rice bran samples mixed with rice husks using a transducer for liquids with a frequency of 185 kHz, attenuation values range from 1.15 to 1.35 dB (Bhagaspati et al., 2021). Ethanol mixed with water using a transducer for liquids with a frequency of 15 MHz has an attenuation value ranging from 0.9 to 1.4 dB (Figueiredo et al., 2011, 2012). This is due to the difference in the transducer used as well as the sample used.

The speed of propagation of these ultrasonic waves is influenced by the physical amount of an object being passed through, including distance, porosity, cracks, and others (Suwandi et al., 2015). Materials with high porosity produce ultrasonic waves that will be passed on more than those absorbed. The smaller the particle density, the less energy is absorbed and dissipated. Rice husks have a high density because they contain semicrystalline silica and cellulose nanofiber structures, and silica nanoparticles are amorphous and have a larger specific surface area of 37.5 m (Shahi et al., 2021).

Among the components of lignocellulose, cellulose is an important part of plant biomass, and homogeneous polymers consist of glucose monomers. Cellulose can be converted into cellulose nanofibers and cellulose nanocrystals. In general, these two forms are demanding on nanocellulose due to their unique properties such as nanodimensional size, large surface area, low density, high strength, high temperature resistance, and biocompatibility (Salas et al., 2014).

Individual lignocellulose and silica components from plant biomass can be assembled into functional composite membranes for the filtration of solute and gaseous particles. For example, Kauldhar et al. developed flexible composite membranes from cellulose, nano-sized silica, and lignin nanofibers isolated from bagasse for water purification (Kauldhar et al., 2021).

In Figure 4, this ultrasonic wave measurement shows that the velocity increases along with the decrease in the rice husk content in rice bran. In other words, the increase in rice bran content is equal to the decrease in rice husk concentration or more rice bran in the sample. The ultrasonic speeds of pure rice husk (at rice bran content of 0%) and pure rice bran (at rice bran content of 100%) are 0.137 and 0.167 m/s, respectively. The ultrasonic wave propagates faster at higher rice bran concentrations.

Attenuation decreased along with the decrease in rice husk content in rice bran. This can be understood because the increase in rice bran contains more rice bran in the sample. This results in more interfacial contacts between rice bran grains and, hence, more wave absorption in the sample, which in turn increases the attenuation value. The response trend of crude fiber and lignin content in rations containing rice husks is very markedly linear, with a coefficient of determination of 94.87% for attenuation and 82.55% for velocity. This shows that the addition of rice husks to rice bran has a very real effect on attenuation and velocity. The linear regression equation model of increasing the addition of rice husk (x) in rice bran to attenuation (y) is -0.0008x + 0.2704, and velocity (y) is 0.0003x + 0.1437.

Influence of rice husk on Crude Fiber Content and Lignin

In the preparation of rations, it is important to ensure that the nutrients in the ration can be digested by livestock. This digestibility is greatly influenced by the content of crude fiber and lignin in the ration. The effect of rice husks on crude fiber and lignin content is presented in Table 3 and Figure 5.

Table 3: The Effect of the Percentage of Rice Husks in Rice Bran on the Content of Crude Fiber and Lignin

|

Parameters |

Treatment |

||||

|

R1 |

R2 |

R3 |

R4 |

R5 |

|

|

Crude Fiber (%) |

41.82e |

34.75d |

28.74c |

21.61b |

14.25a |

|

Lignin (%) |

19,60e |

15.33d |

11.44c |

7.83b |

3.85a |

Description: R1 = 0% rice bran + 100% rice husk, R2 = 25% rice bran + 75% rice husk, R3 = 50% rice bran + 50% rice husk, R4 = 75% rice bran + 25% rice husk, R5 = 100% rice bran + 0% rice husk. Different superscripts show noticeable differences (0.05).

Based on statistical analysis of crude fiber content and lignin in experimental rations In Table 3, the addition of rice husks to rice bran significantly reduces the content of crude fiber and lignin. Crude fiber was highest at R1 41.82% and lowest at R5 14.25%; lignin was highest at R1 19.60% and lowest at R5 3.85%. With the decrease in rice husk content in rice bran, it is very noticeable to decrease also crude fiber and lignin. This is because rice husks are lignocellulose biomass composed of 15−28% silica (Chiew & Cheong, 2011; Ma et al., 2011), 72−85% lignocellulose (Kumar et al., 2009; Lim et al., 2012), 35−40% cellulose, 15−20% hemicellulose, and 20−25% lignin (Kumar et al., 2009; Yu et al., 2009). The results of crude fiber and lignin analysis may differ due to variety, age, and analysis method. So to get consistent results, you must know the variety and age of rice and use standard analytical methods.

Efforts to utilize rice husks are limited due to their hard, woody, and abrasive nature; have low nutrients; resistance to degradation; in large quantities; and high ash content (Sun & Gong, 2001). Despite being high in lignocellulose, rice husks have a complete nutrient content, such as small amounts of other substances such as metal ions, chlorides, phosphates, etc. (Chen et al., 2013;), glucose 35.1%, xylan 9.2%, galactan 3.3%, arabinan 2.3%, manan 3.1%, ().

Other researchers report that, in particular, rice husks contain lignin, carbohydrates, nitrogenous substances, vitamins, organic acids, and mineral components, the content of which depends on the rice variety and is influenced by the geographical location and agronomic way of rice cultivation. The carbohydrate components of rice husks include cellulose (the main component) and hemicellulose (contained in slightly smaller amounts), which are dominated by pentosan. Depending on the technique applied, raw or pure lignin can be recovered from rice husks. Raw lignin contains cellulose and ash. Nitrogenous substances are mainly represented by proteins, and a small amount of nitrogen consists of vitamins contained in rice husks. Organic acids contained in rice husks include acetic, citric, fumaric, oxalic, and succinic acids, as well as some aromatic acids. The main mineral component of rice husks that causes the high ash content is silica. Ash also contains potassium, sodium, magnesium, calcium, iron, and phosphorus, as well as small amounts of copper, iron, manganese, and others (Efremova, 2012).

Proximate analysis showed the presence of carbohydrates (37.04%), crude protein (1.85%), water content (7.93%), crude fat (3.76%), fiber (25.74%), and ash content (23.39%). Phytochemical screening of high amounts of flavonoids, carotenoids, and glycosides in RH samples. Vitamins such as A, C, D, E, K, and B complex (B1, B2, B3, B5, B6, B7, B9, and B12) as well as minerals (calcium, magnesium, potassium, sodium, zinc, iron, selenium, cobalt, manganese, copper, and phosphorus) were also identified in the samples. The GC-MS test on the samples found cynarin, demecolcine, penta-triacontene, hyoscyamine, kheltin, acetyldigoxin, quinoline-3-methyl, coumaric acid, copaene, benzyl benzoate, caryophyllene, danthron, lupenon, beta-amyrin, ephedrine, alpha-ergosterol, galanthamine, kawain, eugenol, anabasine, benzylisoquinoline, carpaine, phytol, phytic acid, myrcene, lobeline, beta-caryophyllene, sparteine, and emetine (Nnadiukwu et al., 2023).

The results of this study prove that the high nutritional value and bioactive composition of rice husks indicate that rice milling by-products have enormous potential to be developed into feed ingredients with many benefits for livestock. So that future research examines methods of optimizing the use of rice husks that have complete nutrient content to improve livestock health and productivity.

In Figure 4, the response trend of crude fiber and lignin content in rations containing rice husks is very linear, with a coefficient of determination of 99.74% for crude fiber and 99.81% for lignin. This shows that the addition of rice husks to rice bran significantly reduces the content of crude fiber and lignin. The linear regression equation model increases the addition of rice husks (x) in rice bran to the crude fiber content (y), which is -0.2732x + 41.891, and the lignin content (y), which is -0.156x + 19.405.

Decrease in crude fiber and lignin content with reduced rice husk content because rice husk is a material rich in crude fiber. Crude fibers consist of cellulose, hemicellulose and lignin (Zou & Yang, 2019). rice husk with lignin and crude fiber, 25.74% (Nnadiukwu et al., 2023), Based on the results of the analysis (Table 2), crude fiber was 41.82% and lignin was 19.60%. Until then, the addition of rice husk will increase crude fiber and lignin.

Lignin is a component of plant cell walls that cannot be digested by livestock. Lignin in plants always binds to cellulose and hemicellulose. The higher the lignin content in the ration, the lower the digestibility of the ration, because lignin is a compound that is resistant to chemical and enzymatic degradation (Lestari & Nuswantara, 2012). The total lignin content (Klason lignin plus acid-soluble lignin) increased during growth (from 16% in the 1-month-old sample to 25% in the 9-year-old wood), whereas the content of other constituents (namely acetone extractives, water-soluble material, and ash) decreased with maturity (Rencoret et al., 2011).

Although there is a linear relationship between the addition of rice husks and the content of crude fiber and lignin, there may be other factors that influence nonlinear results. The presence of contaminants will affect the measurement results. So it must be ensured that there are no other ingredients that are sources of contaminants in rice bran and husks. Contaminants are usually dust, sand, rice parts, and grain jams (leaves and stems) (Lacorte et al., 2012).

The Relationship Between Ultrasonic Parameters and Nutrient Content

After describing the effect of treatment on ultrasonic parameters and nutrient content, then we will discuss the pattern of relationship between ultrasonic parameters and nutrient content. The results of the correlation test of the relationship between ultrasonic parameters and nutrient content are presented in Table 4.

Table 4: Correlation of the Effect of the Percentage of Rice Husks in Rice Bran on the Content of Crude Fiber and Lignin

|

Parameters |

Rice Bran |

Attenuation |

Velocity |

Crude Fiber |

Lignin |

|

Rice Bran |

1 |

-.974** |

.909** |

-.999** |

-.999** |

|

Attenuation |

-.974** |

1 |

-.919** |

.975** |

.965** |

|

Velocity |

.909** |

-.919** |

1 |

-.896** |

-.912** |

|

Crude Fiber |

-.999** |

.975** |

-.896** |

1 |

.997** |

|

Lignin |

-.999** |

.965** |

-.912** |

.997** |

1 |

**. Correlation is significant at the 0.01 level.

There was a strong link (P<0.01) between the acoustic properties of attenuation and velocity and the nutritional content of crude fiber and Lignin rice bran, as shown by the correlation test. The positive correlation between attenuation with crude fiber is 0.975, and attenuation with lignin is 0.965. This means that the higher the attenuation, the higher the crude fiber and lignin. The negative correlation between velocity with crude fiber (-0.896) and velocity with lignin (-0.912) This means that the higher the velocity, the lower the coarse fiber and lignin.

In Figure 6, based on regression analysis between attenuation with crude husky content and lignin, it was found that in the experimental ration measurement of the effect of adding rice husks in rice bran, there was a very real relationship: the higher the attenuation of food, the higher the content of crude fiber and lignin. The regression equation of the attenuation relationship pattern (y) and crude fiber (x) is linear: y = 310.17x - 43.305, with a coefficient of determination of 95%, which means the relationship is very strong. The regression equation of the attenuation (y) and lignin (x) relationship pattern is linear: y = 175.36x - 28.84, with a coefficient of determination of 93.17%, which means the relationship is very strong.

These results show that the quality of rice bran based on the crude fiber and lignin content can be estimated using ultrasonic parameters, i.e., attenuation. Future research will focus on the use of low-frequency ultrasonic waves and accommodate factors that affect measurements so that accurate results are obtained.

CONCLUSION

Based on the results of research, there is a strong relationship between ultrasonic parameters and the nutrient content of rice bran containing various rice husks. The positive correlation between attenuation with crude fibre is 0.975, and attenuation with lignin is 0.965. The attenuation coefficient can be used as a parameter for estimating the content of lignin and crude fibre in rice bran. This research proves the high nutritional value of rice bran can be detected with ultrasonic waves. These results still need further research to measure the factors that affect ultrasonic wave transmission (amplitude) when measuring samples , as well as the manufacture of a series of compact ultrasonic test systems so that they can be applied in industry or practically in the field.

ACKNOWLEDGEMENTS

Acknowledgment to the Rector of Universitas Padjadjaran who has allowed the author to attend school in the animal science doctoral study program through the Universitas Padjadjaran Lecturer Dissertation Research, scheme award number 1549/UN6.3.1/PT.00/2023.

novelty statement

The study found that ultrasonic waves can detect rice bran containing rice husks and infer the crude fiber and lignin content of the material based on attenuation. Ultrasonic waves can be used to determine the quality of rice bran without chemical analysis.

CONFLICT OF INTEREST

The authors state that they have no competing financial interests or personal relationships that could affect the work reported in this paper.

AUTHOR’S CONTRIBUTION

These authors each contributed equally.

REFERENCES

Alawsi T (2015). Oscilloscope and its applications. https://doi.org/10.13140/RG.2.2.34436.12166

Albarki HR, Agustin AF, Permana AT, Jayanegara A (2023). Identification of adulterated rice bran with rice husks by using the image analytics. IOP Conference Series: Earth Environ. Sci., 1241(1): 12130.

Al-Lashi RS, Povey MJW, Watson NJ (2018). Ultrasonic wave propagation in powders. J. Phys. Conference Series, 1017(1): 12001.

Alonso E, Solis-Najera S, Vazquez F, Medina L (2017). Design and Construction of an ultrasound transmit pulser system for non-destructive testing. J. Phys. Conference Series., 792(1): 12055.

Bhagaspati DD, Syafei NS, Hidayat D (2021). Investigation of Husk-Adulterated Rice Bran Using Ultrasonic Wave. AIMS 2021 – Int. Conference Artificial Intelligence Mechatron. Syst., 1–5. https://doi.org/10.1109/AIMS52415.2021.9466011

Brice RE, Morrison IM (1982). The degradation of isolated hemicelluloses and lignin-hemicellulose complexes by cell-free, rumen hemicellulases. Carbohydr. Res., 101(1): 93–100. https://doi.org/10.1016/S0008-6215(00)80797-1

Chen H, Wang W, Martin JC, Oliphant AJ, Doerr PA, Xu JF, DeBorn KM, Chen C, Sun L (2013). Extraction of lignocellulose and synthesis of porous silica nanoparticles from rice husks: A comprehensive utilization of rice husk biomass. ACS Sustain. Chem. Engineer., 1(2): 254–259. https://doi.org/10.1021/sc300115r

Chiew YL, Cheong KY (2011). A review on the synthesis of SiC from plant-based biomasses. Mater. Sci. Engineer. B., 176(13): 951–964. https://doi.org/10.1016/j.mseb.2011.05.037

Dharmendra, PS (2010). Ultrasonics: A Technique of Material Characterization. Acoustic Waves. https://doi.org/10.5772/10153

Efremova SV (2012). Rice hull as a renewable raw material and its processing routes. Russian J. Gen. Chem., 82(5): 999–1005. https://doi.org/10.1134/S1070363212050349

Fakhlaei R, Selamat J, Khatib A, Razis AFA, Sukor R, Ahmad S, Babadi AA (2020). The toxic impact of honey adulteration: A review. Foods., 9(11): 1538.

Figueiredo MKK, Costa-Felix RPB, Maggi LE, Alvarenga AV, Romeiro GA (2011). Sensibility of hydrous ethanol adulteration detection using ultrasonic parameters validated in a metrological base. J. Phys.: Confer. Series., 279(1): 012028. https://doi.org/10.1088/1742-6596/279/1/012028

Figueiredo MKK, Costa-Felix RPB, Maggi LE, Alvarenga AV, Romeiro GA (2012). Biofuel ethanol adulteration detection using an ultrasonic measurement method. Fuel., 91(1): 209–212. https://doi.org/10.1016/j.fuel.2011.08.003

George WH (1956). A textbook of sound. In Nature (Vol. 177, Issue 4514, p. 814). American Institute of Physics. https://doi.org/10.1038/177814c0

Gooberman GL, Mayer WG (1970). Ultrasonics: Theory And Application. Phys. Today., 23(11): 50.

Guillermic RM, Franczyk AJ, Kerhervé SO, House JD, Page JH, Koksel F (2023). Characterization of the mechanical properties of high-moisture meat analogues using low-intensity ultrasound: Linking mechanical properties to textural and nutritional quality attributes. Food Res. Int., 173: 113193. https://doi.org/10.1016/j.foodres.2023.113193

Gul K, Yousuf B, Singh AK, Singh P, Wani AA (2015). Rice bran: Nutritional values and its emerging potential for development of functional food - A review. In Bioact. Carbohydrat. Diet. Fibre. 6(1): 24–30. https://doi.org/10.1016/j.bcdf.2015.06.002

Hidayat D, Syafei NS, Wibawa BM, Taufik M, Bahtiar A, Risdiana (2020). Metal-polymer composite as an acoustic attenuating material for ultrasonic transducers. Key Engineer. Mater., 860 KEM, 303–309. https://doi.org/10.4028/www.scientific.net/KEM.860.303

Hidayat D, Widiyastuti W, Ogi T, Okuyama K (2010). Droplet generation and nanoparticle formation in low-pressure spray pyrolysis. Aerosol Sci. Technol., 44(8): 692–705.

Kaufmann M (2009). Cost Optimization of Aircraft Structures [Doctoral Thesis, Kungliga Tekniska H¨ogskolan (KTH), Stockholm, Sweden]. In Technology. https://www.researchgate.net/publication/256547725_Cost_Optimization_of_Aircraft_Structures

Kauldhar BS, Sooch BS, Rai SK, Kumar V, Yadav SK (2021). Recovery of nanosized silica and lignin from sugarcane bagasse waste and their engineering in fabrication of composite membrane for water purification. Environ. Sci. Pollut. Res., 28(6): 7491–7502. https://doi.org/10.1007/s11356-020-11105-3

Khairurrahman AA, Wibawa BM, Hidayat D (2021). The Evaluation of Adulteration in Milk Using the Propagation of Ultrasonic Waves. AIMS 2021 – Int. Confer. Artificial Intelligence Mechat. Syst., 1–4. https://doi.org/10.1109/AIMS52415.2021.9466070

Khatoon M, Jakhesara SJ, Rank DN, Joshi CG, Kunjadiya AP (2022). Exploration of rumen microbial and carbohydrate-active enzyme profiles in cattle fed coir a lignin-rich diet using a metagenomic approach. Gene., 846: 146868. https://doi.org/10.1016/j.gene.2022.146868

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009). Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Indust. Engineer. Chem. Res., 48(8): 3713–3729. https://doi.org/10.1021/ie801542g

Lacorte S, Bono-Blay F, Cortina M (2012). Sample Homogenization. Comprehens. Sampling Sample Preparat., 1: 65–84. https://doi.org/10.1016/B978-0-12-381373-2.00006-5

Lestari T, Nuswantara LK (2012). Degradasi Bahan Kering dan Bahan Organik dengan Berbagai Level Jerami Padi secara In Sacco pada Kambing Jawarandu. Anim. Agricult. J., 1(1): 875–888.

Li S, Zhao Y, Cui J, Yu Z, Kou L (2023). Ultrasonic energy attenuation characteristics in plastic deformation of 2219-O aluminum alloy. Int. J. Adv. Manufactur. Technol., 125(1–2): 267–278. https://doi.org/10.1007/s00170-022-10715-0

Li Z, Zhou X, Yang C, Wang J, Xu J, Zheng H (2014). Ultrasonic attenuation model for porosity test of CFRP with variable thickness. Nongye Jixie Xuebao/Transact. Chinese Societ. Agricult. Machin., 45(7): 325–332. https://doi.org/10.6041/j.issn.1000-1298.2014.07.050

Lim JS, Abdul Manan Z, Wan Alwi SR, Hashim H (2012). A review on utilisation of biomass from rice industry as a source of renewable energy. Renew. Sustain. Energy Rev., 16(5): 3084–3094. https://doi.org/10.1016/j.rser.2012.02.051

Liu H, Peng X, Zhang G, Fu T, Yin A (2023). Method of contact ultrasonic-attenuation coefficient correction considering surface roughness. Chongqing Daxue Xuebao/J. Chongqing Uni., 46(5): 21–30. https://doi.org/10.11835/j.issn.1000-582X.2022.104

Liu K, Zhou H, Pan L, Sun B (2017). Ultrasonic attenuation characteristics of composites void contents standard test block with embedded hollow fiber. Fuhe Cailiao Xuebao/Acta Materiae Compositae Sinica, 34(1): 91–95. https://doi.org/10.13801/j.cnki.fhclxb.20160330.001

Ma Y, Zhao X, Zhang H, Wang Z (2011). Comprehensive utilization of the hydrolyzed productions from rice hull. Indust. Crops Prod., 33(2), 403–408. https://doi.org/10.1016/j.indcrop.2010.11.001

Najamuddin U, Gorji SG, Fitzgerald M (2021). Genotypic variability in the composition of soluble protein from rice bran – Opportunities for nutrition. J. Food Composit. Analys., 103: 104077. https://doi.org/https://doi.org/10.1016/j.jfca.2021.104077

Nnadiukwu UC, Onyeike EN, Ikewuchi CC, Patrick-Iwuanyanwu KC (2023). Phytochemical and Nutrient Composition of Rice Husks. Trop. J. Nat. Prod. Res., 7(2): 2457–2463. https://doi.org/10.26538/tjnpr/v7i2.24

Olisa SC, Khan MA, Starr A (2021). Review of Current Guided Wave Ultrasonic Testing (GWUT) Limitations and Future Directions. In Sensors (Vol. 21, Issue 3). https://doi.org/10.3390/s21030811

Omar M (2012). Nondestructive Testing Methods and New Applications. BoD–Books on Demand.

Pandin T (2021). Application of Oscilloscope Technology in the Early 21st Century: A Systematic Literature Review. https://doi.org/10.20944/PREPRINTS202106.0090.V1

Pierre J, Elias F, Leroy V (2013). A technique for measuring velocity and attenuation of ultrasound in liquid foams. Ultrasonics, 53(2): 622–629. https://doi.org/10.1016/j.ultras.2012.10.011

Piliang WG (1997). Strategi Penyediaan Pakan Ternak Berkelanjutan Melalui Pemanfaatan Energi Alternatif. Orasi Ilmiah Guru Besar Tetap Ilmu Nutrisi, Fapet IPB, Bogor.

Raghavan A, Cesnik CES (2007). Studies on effects of elevated temperature for guided-wave structural health monitoring. Proc.SPIE, 6529, 65290A. https://doi.org/10.1117/12.715016

Ravinder RB, Hari Babu Y, Linga Reddy D (2001). Ultrasonic measurements in Escherichia coli at various growth stages. Mater. Lett., 49(1): 47–50. https://doi.org/10.1016/S0167-577X(00)00340-2

Rejo A (2002). Aplikasi jaringan saraf tiruan untuk menentukan tingkat ketuaan dan kematangan buah durian dengan metode destruktif dan non-destruktif.

Rencoret J, Gutiérrez A, Nieto L, Jiménez-Barbero J, Faulds CB, Kim H, Ralph J, Martínez ÁT, del Río JC (2011). Lignin Composition and Structure in Young versus Adult Eucalyptus globulus Plants. Plant Physiol., 155(2): 667–682. https://doi.org/10.1104/pp.110.167254

Sabir A, Rafi M, Darusman LK (2017). Discrimination of red and white rice bran from Indonesia using HPLC fingerprint analysis combined with chemometrics. Food Chem., 221: 1717–1722.

Salas C, Nypelö T, Rodriguez-Abreu C, Carrillo C, Rojas OJ (2014). Nanocellulose properties and applications in colloids and interfaces. Curr. Opin. Colloid Interf. Sci., 19(5): 383–396. https://doi.org/10.1016/j.cocis.2014.10.003

Salsabila I, Hidayat D, Taufik M (2021). Measurement of Attenuation and Velocity on Ultrasonic Waves in Adulteration of Honey to Find Their Correlation. AIMS 2021 – Int. Conference Artificial Intellig. Mechatron. Syst., 1–4. https://doi.org/10.1109/AIMS52415.2021.9466024

Shahi N, Wang P, Adhikari S, Min B, Rangari VK (2021). Biopolymers fractionation and synthesis of nanocellulose/silica nanoparticles from agricultural byproducts. ACS Sustain. Chem. Engineer., 9(18): 6284–6295. https://doi.org/10.1021/acssuschemeng.0c09342

Sharif MK, Butt MS, Anjum FM, Khan SH (2014). Rice bran: A novel functional ingredient. Crit. Rev. Food Sci. Nutr., 54(6): 807–816. https://doi.org/10.1080/10408398.2011.608586

Sohail M, Rakha A, Butt MS, Iqbal MJ, Rashid S (2017). Rice bran nutraceutics: A comprehensive review. Crit. Rev. Food Sci. Nutr., 57(17): 3771–3780. https://doi.org/10.1080/10408398.2016.1164120

Sudarmadji S, Haryono B, Suhardi (1997). Prosedur analisa untuk bahan makanan dan pertanian. In Liberty, Yogyakarta.

Sun L, Gong K (2001). Silicon-based materials from rice husks and their applications. Indust. Engineer. Chem. Res., 40(25): 5861–5877. https://doi.org/10.1021/ie010284b

Suwandi R, Jacoeb AM, Sofia M (2015). Application of ultrasonic waves on maintaining freshness of tilapia fillet. J. Pengolahan Hasil Perikanan Indonesia, 18(1).

Tai JL, Sultan MTH, Łukaszewicz A, Shahar FS, Tarasiuk W, Napiórkowski J (2023). Ultrasonic Velocity and Attenuation of Low-Carbon Steel at High Temperatures. Materials., 16(14). https://doi.org/10.3390/ma16145123

Uyeh DD, Ha Y, Park T (2021). Animal feed formulation: Rapid and non-destructive measurement of components from waste by-products. Anim. Feed Sci. Technol., 274: 114848.

Wei Q, Yang Q, Gao W (2023). Particle size distribution measurements of widely distributed carbonyl iron powder particles in concentrated suspensions using ultrasonic attenuation. Measur. Sci. Technol., 34(7). https://doi.org/10.1088/1361-6501/acc8f0

Whangchai N, Pimolrat P, Suwanpakdee S, Gutierrez R, Nomura N, Ramaraj R, Itayama T (2015). Using Ultrasonic Irradiation for Harvesting of Phytoplankton Biomass in Fish Ponds and Eutrophication Water. SICLSBE-48.

Wood, AB (1955). A Textbook of Sound Ed. 3rd. London: G. Bell & Sons.

Yu J, Zhang J, He J, Liu Z, Yu Z (2009). Combinations of mild physical or chemical pretreatment with biological pretreatment for enzymatic hydrolysis of rice hull. Biores. Technol., 100(2): 903–908. https://doi.org/10.1016/j.biortech.2008.07.025

Zhang YC, Luo M, Fang XY, Zhang FQ, Cao MH (2021). Energy value of rice, broken rice, and rice bran for broiler chickens by the regression method. Poult. Sci, 100(4): 100972. https://doi.org/10.1016/j.psj.2020.12.069

Zhu J, Lin Y, Wang B, Wen J, Tian R (2023). Study on ultrasonic attenuation characteristics in air-droplet two-phase flow. Ann. Nucl. Energ, 185. https://doi.org/10.1016/j.anucene.2023.109742

Zou Y, Yang T (2019). Chapter 9 - Rice Husk, Rice Husk Ash and Their Applications (L.-Z. Cheong & X. B. T.-R. B. and R. B. O. Xu, Eds.; pp. 207–246). AOCS Press. https://doi.org/10.1016/B978-0-12-812828-2.00009-3

To share on other social networks, click on any share button. What are these?