In Vitro Study of Ration Containing Corncobs Soaked by Rice Hull Ash Filtrate

Research Article

In Vitro Study of Ration Containing Corncobs Soaked by Rice Hull Ash Filtrate

Iman Hernaman1*, Budi Ayuningsih1, Diky Ramdani2, Romy Zamhir Islami1, Shelvia Octaviana1, Ina Aviana1, Galuh Rahayu1, Aldena Bina Salimah1, Urip Rosani1, Atun Budiman1, Muhammad Rifqi Ismiraj3

1Department of Animal Nutrition and Feed Technology, Faculty of Animal Husbandry, Universitas Padjadjaran Jl. Raya Bandung-Sumedang KM 21 Jatinangor Sumedang 45363, Indonesia; 2Department of Animal Production, Faculty of Animal Husbandry, Universitas Padjadjaran Jl. Raya Bandung-Sumedang KM 21 Jatinangor Sumedang 45363, Indonesia; 3Animal Husbandry PSDKU Pangandaran, Faculty of Animal Husbandry, Universitas Padjadjaran, Pangandaran, West Java, Indonesia.

Abstract | The study aimed to evaluate the digestibility of ration-containing corncobs soaked in rice hull ash filtrate. The research was conducted experimentally using a descriptive method and complete randomized design (RAL) followed by the Duncan test. Analysis of mineral rice hull comes from three locations in three different regencies in West Java. Corncobs were soaked with rice hull ash filtrate with a ratio of 1: 1 for three hours with four different concentrations, ie RHAF 1 = 0.05 w/v, RHAF 2 = 0.1 w/v, RHAF 3 = 0.15 w/v, and RHAF 4 = 0.2 w/v. In vitro, evaluation was used to measure the fermentability and digestibility of ration-containing corncobs soaked by ash hull ash filtrate (0.2 w/v) at CSRHAC 1 = 10%, CSRHAC 2 = 20%, CSRHAC 3 = 30%, and CSRHAC 4 = 40%. The results show that rice hull ash contains alkaline minerals of calcium (Ca), potassium (K), magnesium (Mg), and sodium (Na) with potassium having the highest value with an average of 0.522%. Dissolving rice husk ash with distilled water produces an alkaline filtrate and forms a linear regression equation, namely Y = 3.3X + 8.45, R2 = 0.7806. The highest pH value achieved in RHAF 4 of 9.15±0.13. The levels of NDF, ADF, cellulose, hemicellulose, and crude fiber decreased significantly (P <0.05) while rice hull ash filtrate concentrations increased. The highest decrease in ADF and NDF was achieved at concentrations of 0.2 w/v. The use of corncobs with rice hull ash filtrate soaked by 0.2 w/v (RHAF 4) in rations resulted in differences between treatments (P <0.05). CSRHAC 2 gave the highest (P <0.05) of DMD, OMD, N-NH3, and VFA among the treatments, namely 52.65±0.73%, 44.76±1.38 %, 2.68±0.10 mM, and 115.80 mM. Thus, it concluded that processing of corncobs with rice hull ash filtrate at concentrations of 0.20 w/v resulted in maximum decreased ADF and NDF and its use of 20% in rations yielded the best in vitro digestibility and fermentability.

Keywords | Ash, Corncob, Digestibility, Fermentability, In vitro, Rice hull

Received | April 15, 2024; Accepted | May 09, 2024; Published | June 25, 2024

*Correspondence | Iman Hernaman, Department of Animal Nutrition and Feed Technology, Faculty of Animal Husbandry, Universitas Padjadjaran Jl. Raya Bandung-Sumedang KM 21 Jatinangor Sumedang 45363, Indonesia; Email: iman.hernaman@unpad.ac.id

Citation | Hernaman I, Ayuningsih B, Ramdani D, Islami RZ, Octaviana S, Aviana I, Rahayu G, Salimah AB, Rosani U, Budiman A, Ismiraj MR (2024). In vitro study of ration containing corncobs soaked by rice hull ash filtrate. Adv. Anim. Vet. Sci., 12(8):1525-1531.

DOI | https://dx.doi.org/10.17582/journal.aavs/2024/12.8.1525.1531

ISSN (Online) | 2307-8316

Copyright: 2024 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

INTRODUCTION

Corn is recognized as a strategic food crop within the national agricultural landscape of Indonesia. To bolster corn production, the Indonesian government has been actively expanding corn plantation acreage annually. An inevitable by-product of this increased corn production is corncobs, which hold significant potential as fibrous feed material for ruminants due to their higher hemicellulose content compared to other plant materials (Liu et al., 2011). However, the utilization of corncobs as feed has been suboptimal, primarily due to their high fiber content with neutral detergent fiber (NDF) exceeding 80% (Eniolorunda et al., 2015), and a low in vitro digestibility (Yulistiani et al., 2012). As such, exploring technologies to enhance corncobs’ nutritional value and digestibility is warranted.

One promising approach to enhance the nutritional value of corncobs is through alkaline pretreatment. Alkaline pretreatment is among the most established techniques for removing or redistributing lignin and mercerizing biomass (Grimaldi et al., 2015). Alkaline pretreatments are relatively affordable compared to other methods because they generally use mild reaction conditions, alkaline chemicals can be recovered, reused and have a high selectivity for lignin separation (Kim et al., 2016). These technologies can be divided into (1) sodium hydroxide pretreatment, (2) ammonia pretreatment, (3) aqueous ammonia pretreatment, (4) anhydrous ammonia pretreatment, and (5) lime (Ca (OH)2) pretreatment (Kim et al., 2016).

Alkaline pretreatments can also be conducted using organic ash filtrate (Eniolorunda et al., 2015). Organic ash, a residue from the combustion of organic compounds commonly found in rural areas or around corn plantations such as rice hull ash, is rich in alkaline minerals. According to Kumar et al. (2013), rice hull ash contains alkaline oxides including potassium oxide (K2O), sodium oxide (Na2O), calcium oxide (CaO), magnesium oxide (MgO), alumunium oxide (Al2O3), iron (III) oxide (Fe2O3) are available in less than 1 % on a dry matter basis. These minerals position rice hull ash as a potential local alkaline source for processing corncobs. Utilizing local alkaline sources like rice hull ash reduces costs and hazards associated with chemical treatments (Eniolorunda et al., 2015) and promotes environmental sustainability (Hernaman et al., 2022).

This research evaluates the fermentability and digestibility of rations containing corncobs treated with rice hull ash filtrate.

MATERIALS AND METHODS

Preparation of rice hull ash filtrate

The rice hull was obtained from the rice dehulling process from three different regencies in West Java Provinces, Indonesia (Sumedang, Indramayu, and Bogor regency). Then the rice hulls are burned until they become ashes by using a heating stove, as in ash burning carried out by farmers. Rice hull ash was measured for its mineral content. The minerals - Potassium (K), Sodium (Na), Calcium (Ca), and Magnesium (Mg) were quantified using the wet ash method (Reitz et al., 1960) and the atomic absorption spectroscopy (AAS) utilizing Shimadzu AA-7000 instrument.

The rice hull ash from the three regencies in the same proportions was mixed with distilled water (aqua dest) at varying ratios of 0.05, 0.10, 0.15, and 0.20 w/v. The mixture was stirred until homogeneous, allowed to precipitate for 24 hours, and subsequently filtered through a calico cloth to obtain rice hull ash filtrate (RHAF). The pH of the filtrate was measured using a digital pH meter (Hanna-instrument, Romania) conducted in four replications for each treatment ratio. The pH meter was pre-calibrated using the standard solution at pH 4 and 7.

Preparation of corncob substrate

Dry corncobs were milled with a screen size diameter of 8-10 mm. The milled corncobs were soaked in the prepared RHAF at a 1: 1 (w/v) ratio, placed in airtight plastic containers, and allowed to cure for three hours. The treated substrate was then dried using sunlight and an oven, before being analyzed for crude fiber and fiber fractions following the AOAC (2002) guidelines.

In vitro digestibility assessment

The research was conducted at the Laboratory of Ruminant Animal Nutrition and Animal Food Chemistry, Faculty of Animal Husbandry, Padjadjaran University. The in vitro digestibility of the treatment rations was assessed following the method of Tilley and Terry (1963). The optimal corncob substrate treated with RHAF, designated as CSRHAC, replaced field grass in sheep rations at proportions of 10%, 20%, 30%, and 40% as a fiber source. All raw materials for treatment rations were ground and screened using a 1 mm Shiever. The sample was weighed at ± 0.5 g, then fed into a fermenter tube, mixed with McDougall’s solution (McDaugall’s, 1948) as an artificial saliva and rumen fluid of sheep at a ratio of 40 mL:10 mL and flowed with CO2 for 30 seconds (Tilley and Terry 1963), and incubated in a water bath at a maintained temperature of ± 39oC.

The sample was divided into 2 parts. The first sample was used to measure fermentability. Three hours post-incubation, rumen fluid samples were analyzed for ammonia (N-NH3) content using the micro-diffusion Conway method (Conway and O’Malley, 1942), total volatile fatty acid (VFA) content by the steam distillation method (AOAC, 2002), and the pH was measured using the same procedure as measuring the pH of the rice hull ash filtrate.

A Conway plate and its cap were given by vaseline on the edges of the cups, and then about 1 mL of the supernatant was put on one side of the bulkhead plate, and on the other position was put 1 mL. solution of saturated Na2CO3. The plates were placed at an angle towards the bulkhead so that they were not mixed before the plate was sealed. At the center of the plate was put 1 ml of boric acid indicator solution, and then the plate was sealed. The plates were shaken until Na2CO3 and supernatant were mixed. After 24 hours, boric acid was titrated by 0.0059 N H2SO4 solution until the color changes returned to the original color. The concentration of N-NH3 is measured by following this formula:

N-NH3 mM = mM H2SO4 × N H2SO4 × 1000 mL

A supernatant of as much as 5 mL was put into a steam distillation tube and then heated with water vapor. The tube is filled with 1 mL of 15% H2SO4 and closed tightly. Volatile fatty acids carried by water vapor will pass through the cooling tube and experience a condensation process, then be collected in a tube Erlenmeyer containing 5 mL NaOH solution 0.5 N. Then leave it until it reaches the tube Erlenmeyer volume is ± 300 mL. Into the tube, Erlenmeyer added 2 drops of phenolphthalein solution, and then titration was carried out with 0.5 N HCl solution until the color changed from red to clear. For blanks, titration is carried out on 5 mL NaOH 0.5 N solution. Total calculation of volatile fatty acids using the formula.

Total volatile fatty acid (mM)= (b−s) × NHCl × 1000/5 mM

Where; b= vol. blank titrant; N= normality of HCl solution; s= vol. the sample titrant.

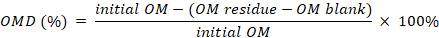

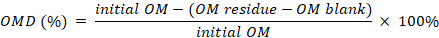

The second sample was subjected to digestibility analysis. The method for measuring the dry and organic matter digestibility used were Tilley and Terry (1963). After 48 hours, HgCl2 solution was added as much as 0.2 mL which functions to kill microbes. The tube is centrifuged at a speed of 10,000 rpm for 10 minutes. The supernatant liquid was discarded and the sediment was removed add 50 mL of 0.2% pepsin solution acidic atmosphere which was then incubated again in an aerobic atmosphere for 48 hours. The precipitate was filtered out of Whatman paper 41 and analyzed dry matter digestibility (DMD) and organic matter digestibility (OMD). Fluid untreated rumen is used as blank.

Statistical analysis

The data collected were subjected to analysis using the Duncan test to identify significant differences between treatments. Descriptive analysis was employed to elucidate the mineral content of rice hull ash. All statistical analyses are processed using the SPSS 21 software and Excell.

RESULTS AND DISCUSSION

Mineral composition of rice hull ash

The mineral composition of rice hull ash from various regencies in West Java is presented in Table 1. It was found to contain significant amounts of Calcium (Ca), Magnesium (Mg), Sodium (Na), and Potassium (K), underscoring its potential as a local alkaline source for processing fibrous feed. Among the regencies, Bogor exhibited a higher content of alkaline minerals, except for Potassium, which was higher in Indramayu. Variations in mineral composition can be attributed to factors such as plant species, age, soil type, local agronomic practices, climatic conditions, and other environmental factors (Olafisoye et al., 2016; Gebremariam and Belay, 2021).

When rice hull ash is dissolved in distilled water to become rice hull ash filtrate, it produces a condition where the greater the rice hull ash dissolved, the higher the pH value in rice hull ash filtrate and forms a linear regression equation (Figure 1). The highest value is RHAF 4 (9.15±0.13) and the lowest value is RHAF 1 (8.65±0.06), meanwhile, the RHAF 2 and RHAF 3 values are 8.75±0.13 and 8.9±0.08, respectively. In essence, organic ash is alkaline (Naumoska et al., 2023). There is providing the temperature is high enough on rice hull, and the calcined ash contains oxides of calcium and carbonates of alkaline metals. As such, contact with water will give an alkaline reaction (Naumoska et al., 2023).

Impact of rice hull ash filtrate on fiber composition

As depicted in Table 2, treatment with rice hull ash filtrate significantly reduced the neutral detergent fiber (NDF) and acid detergent fiber (ADF) content of corncobs, in

Table 1: Mineral in rice hull ash (%) of three regencies in West Java.

|

Regency |

Ca |

Mg |

Na |

K |

|

Sumedang |

0.059±0.002 |

0.069±0.001 |

0.048±0.0003 |

0.503±0.001 |

|

Indramayu |

0.254±0.001 |

0.156±0.0004 |

0.080±0.0003 |

0.621±0.004 |

|

Bogor |

0.281±0.001 |

0.156±0.002 |

0.109±0.0002 |

0.442±0.017 |

|

Means |

0.198±0.105 |

0.127±0.044 |

0.079±0.026 |

0.522±0.079 |

Table 2: Crude fiber fraction and crude fiber of corncob which has been soaked with a rice hull ash filtrate.

|

Treatments |

Crude fiber (%) |

NDF % |

ADF % |

Cellulose |

Hemicellulose |

|

RHAF 1 |

38.29±0.30d |

77.85±0.36d |

53.19±0.66d |

43.57±0.44d |

24.66±0.93c |

|

RHAF 2 |

37.07±0.12c |

72.62±0.43c |

49.94±0.55c |

41.57±0.65c |

22.68±0.86b |

|

RHAF 3 |

35.24±0.25b |

69.96±0.96b |

48.09±0.74b |

40.30±0.68b |

21.87±1.58b |

|

RHAF 4 |

34.63±0.35a |

66.25±0.71a |

46.22±0.16a |

39.10±0.24a |

20.02±0.62a |

|

Significant |

** |

** |

** |

** |

** |

a,b,c,d different superscripts in the same columns showed significant differences (P<0.01).

Table 3: Ingredients and nutrient composition of complete ration.

|

Feed ingredients |

Treatments |

|||

|

CSRHAC 1 |

CSRHAC 2 |

CSRHAC 3 |

CSRHAC 4 |

|

|

Native grass |

50 |

40 |

30 |

20 |

|

Corncob Soaked by RHAF (0.20 w/v) |

10 |

20 |

30 |

40 |

|

Concentrate |

40 |

40 |

40 |

40 |

|

Nutrients |

||||

|

Ash (%) |

9.63 |

8.83 |

8.04 |

7.24 |

|

Crude protein/CP (%) |

11.43 |

10.76 |

10.08 |

9.40 |

|

Extract ether/EE (%) |

4.65 |

4.57 |

4.50 |

4.42 |

|

Crude fiber/CF (%) |

23.60 |

24.33 |

25.05 |

25.78 |

|

Nitrogen-free extract/ NFE (%) |

50.69 |

51.51 |

52.33 |

53.16 |

|

Total digestible nutrient/TDN (%)1 |

63.50 |

62.78 |

62.05 |

61.33 |

1TDN was calculated using the Sutardi equation as described in Hernaman et al. (2022): (70.6+ 0.259% CP + 1.01% EE-0.76%CF + 0.0991 % NFE).

comparison to the values found for untreated corncobs (87.7% and 47.7%, respectively; Wachirapakorn et al., 2016). The reduction in crude fiber and fiber fractions (ADF, NDF, cellulose, and hemicellulose) was observed to be more pronounced at a concentration of 0.20 w/v of the filtrate. This is congruent with the findings of Vadivel et al. (2017), who noted enhanced solubility of phenolic compounds and other cell wall components upon alkaline pretreatment. Furthermore, this reduction aligns with the findings of Martelli-Tosi et al. (2017) who reported similar decreases in fiber content with alkaline pretreatments. The technical significance of this concentration of rice hull ash filtrate, compared to other alkali treatment concentrations reported in the literature, suggests a potential optimum concentration for achieving desirable fiber reduction in corncobs.

High NDF and ADF reduction at 0.20 w/v treatment became the basis for using the ration. ADF and NDF caused low digestibility because this part is difficult to digest in the rumen (Stergiadis et al., 2015). NDF and ADF analyses are required for the evaluation of fiber quality for ruminant feed (Nurdianti et al., 2023). The implications of these findings are multifold. The 20% inclusion rate of treated corncobs could significantly impact animal nutrition by improving digestibility, potentially leading to better animal growth performance and health. Moreover, the utilization of rice hull ash filtrate as a local alkaline source could present a cost-effective and environmentally sustainable solution to enhancing the nutritional value of corncob-based sheep rations, addressing some of the current challenges in feed technology. The statistical analysis further revealed a significant difference (P<0.01) in fiber content across different treatments, consistent with the statistical methods and results reported in similar studies (Sahare et al., 2012). Table 2 represents the changes in fiber composition and digestibility across different treatments, providing a clearer understanding of the data.

Table 4: In vitro digestibility and fermentability of complete rations.

|

Treatments |

DMD (%) |

OMD (%) |

N-NH3 (mM) |

VFA (mM) |

pH |

|

CSRHAC 1 |

50.15±0.29c |

42.22±0.54b |

1.77±0.08b |

78.30±5.26a |

7.04±0.05a |

|

CSRHAC 2 |

52.65±0.73d |

44.76±1.38c |

2.68±0.10c |

115.80±5.03c |

7.14±0.05b |

|

CSRHAC 3 |

49.18±0.61b |

41.26±0.88b |

1.34±0.10a |

111.10±4.71c |

7.10±0.00ab |

|

CSRHAC 4 |

43.59±0.90a |

36.48±1.73a |

1.20±0.19a |

101.30±1.68b |

7.16±0.05b |

|

Significant |

** |

** |

** |

** |

** |

a,b,c,d different superscripts in the same columns showed significant differences (P<0.01).

Furthermore, corncobs became part of the ration to replace the native grass as a source of fiber (Table 3). Table 3 shows that the higher the use of corncobs followed the lower the percentage of crude protein and ash, but the more crude fiber and nitrogen-free extract, while the same crude fat.

In vitro digestibility and fermentability assessment

Table 4 presents the in vitro digestibility and fermentability data of the treatment rations. A notable effect on rumen fluid pH was observed within the corncob treatment (P <0.05), but the difference is very slight and albeit within the normal physiological range of 6-7 (Grünberg and Constable, 2009). McDougall’s solution added to the rumen fluid in this experiment which functions as a buffer solution will maintain the pH value within the normal range (Camacho et al., 2019). The highest fermentability and digestibility (P <0.05) were achieved with a 20% inclusion rate of treated corncobs.

The use of processed corncobs can improve digestibility and fermentability to replace grass fields. The mechanistic insights underlying the observed improvements in digestibility and fermentability involve the breakdown or stretching of cell wall structures, facilitating easier access for rumen microbes to ferment and digest corncobs. These mechanisms align with the proposed microbial and biochemical processes reported in the literature. Feeding values of low-quality forages can be improved via alkaline treatment by increasing the rate and extent of cellulose and hemicellulose digestion (Canale et al., 1990). Improved feeding value may be attributed to swelling of the forage, thereby allowing microbial attachment, which results in increased digestibility compared with untreated residues (Shreck, 2011; Shreck et al., 2015). However, the use of processed corncobs should not be more than 20%. High use of corncobs decreases the protein content in the ration (Table 3). This limitation is crucial for balancing the nutritional composition of the sheep ration, ensuring adequate protein intake while benefiting from improved fiber digestibility. As a result, N-NH3 content decreased on the treatment of 30% (CSRHAC 3) and 40% (CSRHAC 4) corncobs. Ammonia is used as the N source for optimal microbial growth (Shen et al., 2023). Therefore, the growth of rumen microbial is suspected to be inhibited due to lower N supply. Rumen microbes have a role in degrading feed fibers, so the inhibition of rumen microbial growth results in reduced degradation of dietary fiber seen with lower VFA content in CSRHAC 3 and CSRHAC 4 treatments. Further impact is decreased DMD and OMD. Future research should explore other locally sourced alkali treatments, investigate long-term effects on animal health, and assess the scalability of this treatment process for commercial applications

The present study has demonstrated the potential of using rice hull ash filtrate as an effective alkaline pretreatment to enhance the digestibility and fermentability of corncob-based sheep rations. The findings hold promising implications for improving animal nutrition and advancing sustainable feed technology, warranting further exploration and validation in broader contexts.

CONCLUSIONS and Recommendations

The study demonstrated that the treatment of corncobs with rice hull ash filtrate significantly enhances their nutritional quality, thereby offering a viable strategy to utilize corncobs, an agricultural by-product, more effectively in sheep rations. The optimal concentration of rice hull ash filtrate was identified as 0.20 w/v, which achieved a maximum reduction in Acid Detergent Fiber (ADF) and Neutral Detergent Fiber (NDF), key indicators of digestibility. The incorporation of these treated corncobs at a level of 20% in the rations yielded the highest digestibility, showcasing the potential to improve the nutritional value of sheep rations substantially.

This finding not only advances the understanding in the realm of animal nutrition and feed technology but also presents a sustainable, cost-effective, and locally sourced solution to enhancing feed digestibility. The use of rice hull ash filtrate as an alkaline pretreatment further aligns with the broader goals of environmental sustainability by promoting the recycling of agricultural by-products and reducing the dependency on chemical treatments.

Future research is encouraged to explore the scalability of this treatment method, its long-term effects on animal health and performance, and the potential applicability to other types of livestock rations or other agricultural by-products. Additionally, investigating the economic and environmental implications of this treatment method on a larger scale could provide valuable insights for stakeholders in the agricultural and animal feed industries.

ACKNOWLEDGMENT

This research is supported by the PUPT research fund from the Ministry of Research of Technology and Higher Education with No.718/UN6.3.1/PL/2017.

Novelty Statement

This study offers a novel viable strategy to utilize corncobs, an agricultural by-product, more effectively in sheep rations.

Author’s Contribution

Iman Hernaman is a leader in research who prepares research, conducts research, collects data, interprets data, and writes manuscripts. Budi Ayuningsih is the co-author who assisted in conducting research and financial administration. Diky Ramdani and Romy Zamhir Islami are the co-authors who assisted in conducting research, collecting data, interpreting data, and writing manuscripts. Urip Rosani, Atun Budiman, and Muhammad Rifqi are the co-authors who assisted in interpreting data, and writing manuscripts. Shelvia Octaviana, Ina Aviana, Galuh Rahayu, Aldena Bina Salimah, are the co-authors who assisted in conducting research

Conflict of interest

The authors have declared no conflict of interest

REFERENCES

AOAC (2002). Official methods of analysis. 18th Ed. Association of official analytical chemistry, Washington DC Washington.

Camacho LF, Silva TE, Palma MNN, Assunção AS, Rodrigues JP, Silva LFC, Detmann E (2019). Evaluation of buffer solutions and urea addition for estimating the in vitro digestibility of feeds. J. Anim. Sci., 97: 922–931. https://doi.org/10.1093/jas/sky464

Canale CJ, Abrams SM, Varga GA, Muller LD (1990). Alkali-treated orchardgrass and alfalfa: Composition and in situ digestion of dry maner and cell wall components. J. Dairy Sci., 73: 2404-2412. https://www.journalofdairyscience.org/article/S0022-0302(90)78924-2/pdf, https://doi.org/10.3168/jds.S0022-0302(90)78924-2

Conway EJ, O’Malley E (1942). Microdiffusion methods. Ammonia and urea using buffered absorbents. (Revised methods for ranges greater than 10 p.g N). Biochem. J., 36: 655-661. https://doi.org/10.1042/bj0360655

Eniolorunda OO, Ogunlusi OO, Fasina OE (2015). Chemical composition and variation in mean values of selected crop residues fermented with local alkali sources and rumen filtrate. Assiut J. Agric. Sci., 46: 35-44. http://www.aun.edu.eg/faculty_agriculture/arabic. https://doi.org/10.21608/ajas.2016.518

Gebremariam T, Belay S (2016). Chemical composition and digestibility of major feed resources in Tanqua-abergelle district of Central Tigray, Northern Ethiopia. Sci. World J., 2021: 1-8. https://doi.org/10.1155/2021/5234831

Gramkow JL, Bittner CJ, Jolly ML, Burken DB, Erickson GE, MacDonald JC (2016). Effects of processing treated corn stover and distillers grains on total-tract digestion and performance of growing cattle. Prof. Anim. Sci., 32: 183–191. https://doi.org/10.15232/pas.2015-01429

Grimaldi MP, Marques MP, Laluce C, Cilli EM, Pombeiro Sponchiado SRP (2015). Evaluation of lime and hydrothermal pretreatments for efficient enzymatic hydrolysis of raw sugarcane bagasse. Biotechnol. Biofuels, 8: 1–14. https://biotechnologyforbiofuels.biomedcentral.com/articles/10.1186/s13068-015-0384-y, https://doi.org/10.1186/s13068-015-0384-y

Grünberg W, Constable PD (2009). In food animal practice (Fifth Edition), Chapter 6 - Function and Dysfunction of the Ruminant Forestomach pp. 12-19. https://doi.org/10.1016/B978-1-4160-3591-6.10006-5

Hernaman I, Ayuningsih, B, Ramdani D, Islami RZ (2022). The improvement of maize cobs quality through soaking in firewood ash filtrate and its impact on in vitro rumen fermentability and digestibility. Int. J. Adv. Sci. Eng. Inf. Technol., 12: 372-378. https://doi.org/10.18517/ijaseit.12.1.10690

Kim JS, Lee YY, Kim TH (2016). A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol., 199: 42–48. https://doi.org/10.1016/j.biortech.2015.08.085

Kumar S, Sangwan P, Dhankhar R, Mor V, Bidra S (2013). Utilization of rice husk and their ash: A review. Res. J. Chem. Environ. Sci., 1: 126-129. http://www.aelsindia.com

Liu H, Liu K, Liu K, Yan M, Xu L, Ouyang P (2011). gTME for improved adaptation of Saccharomyces cerevisiae to corncob acid hydrolysate. Biotechnol Appl. Biochem., 164: 1150-1159. https://doi.org/10.1007/s12010-011-9201-7

Martelli-Tosi M, Assis OBG, Silva NC, Esposto BS, Martins MA, Tapia-Blácido DR (2017). Chemical treatment and characterization of soybean hull and soybean protein isolate/straw composite films, Carbohydrate Polymers, pp. 157. https://doi.org/10.1016/j.carbpol.2016.10.013

McDougall EI (1948). Studies on ruminant saliva. 1. The composition and output of sheep’s saliva. Biochem. J., 43: 99–109. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1274641/, https://doi.org/10.1042/bj0430099

Naumoska A, Stojanovska M, Petruševski VM (2023). The wood ash is alkaline. Educación Química, pp. 34. https://doi.org/10.22201/fq.18708404e.2023.1.81816

Nurdianti RR, Nuryana RS, Handoko A, Hernaman I, Ramdani D, Jayanegara A, Dickhoefer U, Böttger C, Südekum KH (2023). Nutritional compositions of Katuk leaves and their supplementation to hays of different quality: An in vitro study. J. Agric. Sci., pp. 1–10. https://doi.org/10.1017/S002185962300031X

Olafisoye BO, Oguntibeju OO, Osibote OA (2016). An assessment of the bioavailability of metals in soils on oil palm plantations in Nigeria. Pol. J. Environ. Stud., 25: 11251140. https://doi.org/10.15244/pjoes/60858

Reitz LL, Smith WH, Plumlee MP (1960). A simple wet oxidation procedure for biological material. Animal Science Department, Purdue University, West La Fayeetee. Anim. Chem., 32: 1728. https://doi.org/10.1021/ac60168a065

Sahare P, Singh R, Laxman RS, Rao M (2012). Effect of alkali pretreatment on the structural properties and enzymatic hydrolysis of corn cob. Appl. Biochem. Biotechnol., 168: 1806–1819. https://doi.org/10.1007/s12010-012-9898-y

Shen J, Zheng W, Xu Y, Yu Z (2023). The inhibition of high ammonia to in vitro rumen fermentation is pH dependent. Front. Vet. Sci., 10: 1163021. https://doi.org/10.3389/fvets.2023.1163021

Shreck AL (2011). Digestibility of crop residues after chemical treatment and anaerobic 48 storage. Nebraska Beef Cattle Rep., pp. 35-36. https://digitalcommons.unl.edu/animalscinbcr/633/

Shreck AL, Nuttelman BL, Harding JL, Griffin WA, Erickson GE, Klopfenstein TJ, Cecava MJ (2015). Digestibility and performance of steers fed low-quality crop residues treated with calcium oxide to partially replace corn in distillers grains finishing diets. J. Anim. Sci., 93: 661–671. https://doi.org/10.2527/jas.2013-7194

Stergiadis S, Allen M, Chen XJ, Wills D, Yan T (2015). Prediction of nutrient digestibility and energy concentrations in fresh grass using nutrient composition. J. Dairy Sci., 98: 3257–3273. https://doi.org/10.3168/jds.2014-8587

Tilley JMA, Terry RA (1963). A two-stage technique for the in vitro digestion of forage crops. J. Br. Grassl. Soc. 18: 104-111. https://doi.org/10.1111/j.1365-2494.1963.tb00335.x

Vadivel V, Moncalvo A, Dordoni R, Spigno G (2017). Effects of an acid/alkaline treatment on the release of antioxidants and cellulose from different agro-food wastes. Waste Manage., pp. 1-10.

Van Soest PJ (1994). Nutritional ecology of the ruminant, 2nd ed. Cornel/ University Press. Ithaca, YP, pp. 45-62. https://doi.org/10.7591/9781501732355

Wachirapakorn C, Pilachai K, Wanapat M, Pakdee P, Cherdthong A (2016). Effect of ground corncobs as a fiber source in total mixed ration on feed intake, milk yield and milk composition in tropical lactating crossbred Holstein cows. Anim. Nutr., 2: 334-338. https://doi.org/10.1016/j.aninu.2016.08.007

Yulistiani D, Puastuti W, Wina E, Supriati (2012). Effect of processing on nutritive value of corn cobs: Chemical composition and in vitro digestibility. J. Ilmu Ternak Vet., 17: 59-66.

To share on other social networks, click on any share button. What are these?