Enhancing Milk Yield and Quality of Holstein Friesian through Special Formulation Urea Molasses Multinutrient Block

Research Article

Enhancing Milk Yield and Quality of Holstein Friesian through Special Formulation Urea Molasses Multinutrient Block

A. Arif Rahman1, Renny Fatmyah Utamy2*, Ambo Ako2, Mohammad Mijanur Rahman3, Siti Annisa Sukri1

1Graduate Student of Science and Technology, Faculty of Animal Science, Hasanuddin University, Makassar, South Sulawesi, Indonesia; 2Department of Animal Production, Faculty of Animal Science, Hasanuddin University, Makassar, South Sulawesi, Indonesia; 3Faculty of Sustainable Agriculture, University Malaysia Sabah, Sandakan, Sabah, Malaysia.

Abstract | The production of urea molasses multinutrient block (UMMB) typically involves cement and molasses. However, prolonged use of cement can lead to health issues in livestock, while molasses is often in short supply due to its extensive use as a raw material in various industries. Thus, alternative materials are highly needed as substitutes for both cement and molasses. This study assesses the effects of using cocoa pulp as filler and tapioca meal as an adhesive in UMMB production on Holstein Friesian dairy cows’ performance, milk yield, and milk quality. The experiment applied a complete randomized design (CRD) with three treatments, namely without UMMB supplementation (T0 as control), supplementation with 500g of regular UMMB (T1), and supplementation with 500g of UMMB made with cocoa pulp and tapioca meal (T2). Each treatment had five replications. The results indicated that UMMB supplementation significantly affected (p < 0.05) forage dry matter intake (DMI), total DMI, milk fat, and milk viscosity. Up to 50% of the molasses and cement used in UMMB production can be replaced with cocoa pulp and tapioca meal without reducing the final product’s physical quality. Substitution of molasses filler and cement adhesive with cocoa pulp and tapioca meal enhances forage DMI and total DMI while maintaining the yield and physical quality of milk in Holstein Friesian cows.

Keywords | UMMB, Cocoa pulp, Tapioca meal, Milk yield, Milk quality, Dairy cows

Received | September 15, 2024; Accepted | November 05, 2024; Published | December 30, 2024

*Correspondence | Renny Fatmyah Utamy, Department of Animal Production, Faculty of Animal Science, Hasanuddin University, Makassar, South Sulawesi, Indonesia; Email: [email protected]

Citation | Rahman AA, Utamy RF, Ako A, Rahman MM, Sukri SA (2025). Enhancing milk yield and quality of Holstein Friesian through special formulation urea molasses multinutrient block. Adv. Anim. Vet. Sci. 13(1): 139-145.

DOI | https://dx.doi.org/10.17582/journal.aavs/2025/13.1.139.145

ISSN (Online) | 2307-8316; ISSN (Print) | 2309-3331

Copyright: 2025 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

INTRODUCTION

Urea Molasses Multinutrient Block (UMMB), a solid feed supplement consumed by dairy cows through licking, is typically made of urea, molasses, rice bran, and cement. UMMB contains high levels of non-protein nitrogen and simple carbohydrates efficiently utilized by rumen bacteria. This leads to increased digestibility of crude fiber from forage feed and enhanced livestock productivity (Sansoucy and Hassoun, 2007). However, excessive urea consumption can cause numerous issues, such as bloating and acidosis due to imbalanced rumen bacterial growth conditions (Millen et al., 2016).

Molasses is a readily digestible energy source for rumen bacteria. Along with cement, it acts as an adhesive to form a sturdy structure, preventing easy destruction when consumed by dairy cows (Omoniyi et al., 2013). Nonetheless, molasses is often in short supply due to its extensive use in various industries, such as food preservation, bakery product manufacturing, alcohol manufacturing, and the production of lactic acid, fertilizer, culture media, ethanol, and biohydrogen, causing its use in feedstuff to compete with human needs (Jamir et al., 2021; Kassa et al., 2024). Furthermore, Broderick and Radloff (2004) found that the addition of >6% liquid molasses to dairy cattle feed can reduce milk yield, lactose yield, and FCM/DMI. This is in line with the finding of another study by Torres et al. (2021) that adding molasses to animal feed of more than 60g/kg DMI negatively impacts milk yield, lactose yield, and milk protein.

The long-term use of cement as a raw material for animal feeds, particularly UMMB, has also become a serious cause for concern as it contains heavy metals (Cd, Co, Cr, Ni, Pb, Hg, and Cu) which can pose various health risks to animals. The limit of heavy metals that enter the body of livestock such as Cd is 5µg/day, Cr is 250µg/day, Ni is 250µg/day, Pb is 10µg/day, Hg is 15µg/day, Cu is 2500µg/day. Excessive accumulation of heavy metals in the body of livestock can cause poisoning and even death (Omoniyi et al., 2013; Akpambang et al., 2022; Govind and Madhuri, 2014). According to Raikwar et al. (2008), heavy metals can enter and accumulate in the animal body through animal feeds, causing toxicity in livestock. Monteverde et al. (2022) added that heavy metals in the livestock’s body will accumulate in the blood circulation and ultimately cause the presence of heavy metals in the generated milk products. For these reasons, finding healthier alternatives to molasses and cement is crucial for producing UMMB.

This study aims to examine the impacts of using cocoa pulp and tapioca meal as fillers and adhesives in UMMB production on the performance, milk production, and milk quality of Holstein Friesian cows. Cocoa pulp, the membrane that encases the cocoa bean, is rich in carbohydrates (mainly sugars such as sucrose, glucose, and fructose) and also contains protein, vitamins, and minerals (Afokawa et al., 2013; Guehi et al., 2010; Lefeber et al., 2011). Despite its uncommon use as an ingredient of animal feed, prior studies have shown that cocoa pulp has the potential to be a substitute for molasses in UMMB production. Utamy et al. (2021) found that using cocoa pulp as an energy source in feed can enhance the performance of Bali cattle. Meanwhile, Ako et al. (2019) demonstrated that incorporating cocoa pulp into complete feed formulations can improve the performance of goats. Furthermore, the high starch content of tapioca meal makes it a natural and safe adhesive in the production of UMMB. When heated, the starch undergoes gelatinization, giving tapioca meal adhesive properties (Nas et al., 2014). Both cocoa pulp and tapioca meal contain nonstructural carbohydrates which can be a source of energy for dairy cattle. In the rumen, nonstructural carbohydrates are broken down and fermented by microbes, producing volatile fatty acids (VFA) which are subsequently absorbed from the rumen and other digestive organs to be used as energy sources and precursors for the formation of milk and lactose for dairy cattle (Navikov and Beitz, 2007). Nonstructural carbohydrates that can stimulate microbial activity are also contained in molasses (Broderick and Radloff, 2004).

MATERIALS AND METHODS

Research Site

This study was conducted at a dairy farm in Talaga Hamlet, Juppandang Village, Enrekang, South Sulawesi, Indonesia. The daily mean temperature and humidity ranged from 26.45°C ± 6.01°C and 74.33% ± 6.01% (in the morning) to 29.53°C ± 8.92°C and 58.08% ± 8.92% (in the afternoon). Milk samples were analyzed at the Public Health Laboratory of Makassar, South Sulawesi, Indonesia.

Dairy Cows and Feeding

This study has received approval from the Hasanuddin University Research Ethics Committee under approval number 470/UN4.6.4.5.3L/PP36/2023. Experiments were conducted on 15 Holstein Friesian dairy cows in their early–middle lactation stages, weighing approximately 500 kg, and aged 4–5 years. The dairy cows were housed in a group-tied stall and fed three times a day at 06:30, 12:30, and 15:30 with a diet consisting of 30 kg/head/day of elephant grass (Pennisetum purpureum) and 12 kg/head/day of concentrate made from a mixture of rice bran and tofu dregs. Both types of animal feed are generally given to livestock in the research location. Water was provided ad libitum.

Experimental Design and Treatments

This experiment employed a complete randomized design (CRD) with three treatments and five replications. Fifteen early-middle lactation dairy cows were grouped into 3 treatment groups, each consisting of 5 cows, i.e., 1 cow in the early lactation stage and 4 cows in the middle lactation stage. The three treatments are: 1) without supplementation of UMMB (T0 as a Control), supplementation with 500g of regular UMMB (T1), and supplementation with 500g of UMMB made of cocoa pulp and tapioca meal (T2).

T1 and T2 UMMBs were made by combining feedstuffs with a hand mixer (Krisbow KW0901595, Indonesia) until evenly mixed, molding them into a cylinder shape with a diameter of 15 cm and a thickness of 5.5 cm using a UMMB molding tool, and drying them using a dehydrator (Getra ST-02, Indonesia) for 15 hours at 70°C. All treatments, except for T2 molasses and tapioca meal, were heated to 70°C before being mixed with other feedstuffs.

Feedstuff composition and UMMB chemical composition are presented in Tables 1 and 2.

Table 1: Composition of the UMMB.

|

No. |

Feed Stuff |

Amount (%DM) |

|

|

T1 |

T2 |

||

|

Adhesive |

|||

|

1. |

Cement |

10 |

5 |

|

2 |

Tapioca meal |

- |

5 |

|

Filler |

|||

|

1. |

Urea |

5 |

5 |

|

2. |

Molasses/cocoa pulp |

30 |

15 |

|

3 |

Cocoa pulp |

- |

15 |

|

4. |

Coconut cake meal |

15 |

15 |

|

5. |

Rice bran |

35.5 |

35.5 |

|

6. |

Commercial mineral |

1 |

1 |

|

7. |

Salt |

2 |

2 |

|

8. |

Limestone |

1 |

1 |

|

9. |

Commercial vitamin |

0.5 |

0.5 |

|

Total |

100 |

100 |

|

Table 2: Chemical composition of the UMMB.

|

UMMB |

Chemical Composition |

||||||

|

Dry Matter (%)* |

Ash (%)* |

Crude Protein (%)* |

Crude Fat (%)* |

Crude Fiber (%)* |

Ca (%)* |

Gross Energy (kcal/kg )** |

|

|

T1 |

95.51 |

22.29 |

28.19 |

1.21 |

17.61 |

3.57 |

3302.46 |

|

T2 |

93.86 |

21.93 |

32.39 |

0.67 |

19.82 |

3.50 |

3261.85 |

Source: *Livestock product quality testing laboratory, Department of Animal Husbandry and Animal Health of South Sulawesi; **Cikole Lembang feed/feed ingredients quality and safety testing laboratory.

Sampling and Parameter Measurements

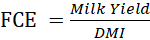

The amount of feed given and the remaining feed were recorded daily and converted into dry matter (DM). Dairy cows were milked daily, and the yield was recorded at each milking time (06:00 and 15:00). Feed conversion efficiency (FCE) is the amount of milk yield when dairy cows consume the same quantity of feed, measured using the following formula (Arndt et al., 2015):

Milk samples were collected at the end of the experiment. The Kjeldahl method modified by Barbano et al. (1991) and the gravimetric method according to AOAC (1990) were employed to analyze milk protein and milk fat, respectively. Meanwhile, total solids (TS) and solids-not-fat (SNF) were determined using measurements adopted by Draaiyer et al. (2009). TS can be estimated from the corrected lactometer reading (CLR) and the fat content of the milk using the following formula:

TS = (0.25×LR) + (1.22×fat %) + 0.72

Once the TS data is obtained, SNF can be estimated using the formula below:

SNF=TS-fat %

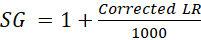

A pH meter (Hanna, Indonesia) was used to measure the pH value of the milk immediately after milking, while the specific gravity (SG) of the milk was determined using the method described by Davide (1977). Milk samples within the temperature range of 50°F–70°F were mixed and poured into a high glass cylinder. Subsequently, the lactometer was slowly lowered into milk, and the scale reading (LR) was observed when it became stationary. Milk temperature was recorded using a thermometer. The LR was corrected (CLR) accordingly by any deviations from the standard temperature of 60°F: 0.1 was added for each degree above 60°F or subtracted for each degree below 60°F. The following formula was used to determine the SG:

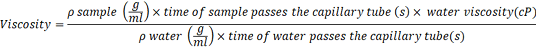

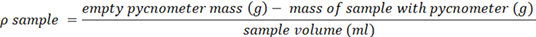

Viscosity was measured utilizing an Ostwald viscometer with the formula used by Rizqiati et al. (2021) as follows:

Statistical Analysis

The ANOVA test was performed in SPSS version 16.0 (IBM, USA) to statistically analyze the obtained data. Further analysis was made using the Duncan test at p < 0.05 if there were any differences between the treatments.

RESULTS AND DISCUSSION

Feed Intake and Milk Yield

The parameters used in this study are feed intake and milk yield, which show the production performance of dairy cows as feed consumption can affect milk production, and FCE, which indicates the efficiency of feeding (Arndt et al., 2015). Data on feed intake, milk yield, and FCE of Holstein Friesian dairy cows fed with UMMB supplementation can be seen in Table 3.

The results of this study found that both treatments with UMMB supplementation significantly affected (p < 0.05) forage DMI and total DMI. The highest values of forage DMI and total DMI were recorded in T1, at 5.82 ± 0.47 and 10.74 ± 0.45 kg/day, respectively. Conversely, the effect of the treatments on concentrate DMI, milk yield, and FCE was not significant (p>0.05). Nevertheless, the values of concentrate DMI in T1 and T2 were higher (4.92 ± 0.83 and 4.92 ± 0.84, respectively) than that in T0 (4.09 ± 1.72). The highest milk yield values were achieved in T2 and T1 (6.37 ± 2.02 and 6.32 ± 2.14 kg/day, respectively), whereas that in T0 was comparatively lower (5.46 ± 1.37 kg/day). The highest feed conversion efficiency (FCE) value was observed in T2, at 0.70 ± 0.25 kg of milk per kg of DMI.

While the total DMI value in T2 was lower than that in T1, the milk yield was higher, as presented in Table 3. According to previous studies by Figueroa et al. (2020) and Oyiyenka et al. (2019), this is likely attributed to the energy contribution of cocoa pulp and tapioca meal, both notably rich in carbohydrates (68.3%–67.9% and 83%–85%, respectively), compared to molasses which only contains 48-53% carbohydrate (Mordenti et al., 2021). Allen (2014) also suggested that the energy dairy cows require to produce milk influences their feed consumption. Similarly, Leduc et al. (2021) underscored the importance of adequate energy intake for dairy cows to achieve high milk yields. Therefore, incorporating 50% cocoa pulp instead of molasses in the production of UMMB can elevate the energy content that dairy cows consume, leading to an increase in DMI and milk yield without compromising the milk quality.

The rumen carbohydrate digestion pattern greatly influences dairy cows’ ability to produce more milk. When ingested, complex carbohydrates such as cellulose and hemicellulose are broken down in the rumen to produce acetic acid which is then absorbed into the rumen wall and used for fat synthesis in the mammary gland, resulting in increased milk production. Similiarly, when dairy cows consume simple carbohydrates such as sugars and starches (in this case, from cocoa pulp and tapioca meal), degradation in the rumen causes the production of propionic acid. This acid is absorbed from the rumen wall to the liver, forming glucose used for lactose synthesis in the mammary gland (Linn, 1988; Weimer, 2022; Sun et al., 2022). Lactose is a precursor for milk production, and increased glucose in the mammary gland also improves amino acid maintenance, potentially resulting in higher milk production and protein content (Sammad, 2020).

According to Duressa and Bersissa (2016), UMMB supplementations (T1 and T2) can result in a higher total DMI value compared to T0 (without UMMB supplementation). UMMB is ingested through licking and can enhance feed digestibility in the rumen. When cows lick UMMB, the produced saliva acts as a buffer to stabilize the rumen pH, thus optimizing the feed degradation process. This aligns with the statement of Mordenti et al. (2021) that the primary role of UMMB is to buffer and stimulate rumen bacteria, thereby aiding in stabilizing rumen pH and improving feed digestibility in the rumen.

Table 3: Dry matter intake and performance of dairy cows supplemented with UMMB.

|

Parameters |

Treatments |

p |

||

|

T0 |

T1 |

T2 |

||

|

DMI (kg/day) |

||||

|

Forage |

4.54 ± 0.22a |

5.82 ± 0.47b |

5.66 ± 0.95b |

0.01 |

|

Concentrate |

4.09 ± 1.72 |

4.92 ± 0.83 |

4.92 ± 0.84 |

0.48 |

|

Total |

8.63 ± 1.58a |

10.74 ± 0.45b |

10.58 ± 0.83b |

0.01 |

|

Milk Yield (kg/day) |

5.46 ± 1.37 |

6.32 ± 2.14 |

6.37 ± 2.02 |

0.54 |

|

FCE (kg milk/kg DMI) |

0.69 ± 0.21 |

0.66 ± 0.26 |

0.70 ± 0.25 |

0.96 |

Description: abDifferent superscripts on same rows indicate significant difference between group (p< 0.05); T0: without UMMB (control); T1: Supplementation 500gr of UMMB; T2: Supplementation 500gr of UMMB with cocoa pulp and tapioca meal.

The results of another study by Jayawickrama et al. (2013) showed that UMMB supplementation using 40% molasses acted as an energy source for lactating dairy cows fed with good quality feed, while the additional provision of rice straw feed at night had no effect (p>0.05) on their production performance. However, milk production and milk fat content increased by 0.32 liters/head/day and by 0.21%, respectively, compared to dairy cows not treated with UMMB.

Suharyono et al (2014) investigated the uses of UMMB with the addition of anthelmintic in the form of albendazole (UMMB-MB-A) at a dose of 5g/80kg and UMMB with the addition of herbal agent in the form of Curcuma aeruginosa (UMMB-MB-C) at a dose of 21g/500gr, with the amount of UMMB given being 500 gr/head/day. UMMB-MB-A supplementation showed an average increase in milk production of 1.3 l/head compared to the control (0.70 l/head), while UMMB-MB-C supplementation showed an average increase in milk production of 14.20 l/head compared to the control (13.60 l/head).

Although UMMB supplementation did not have a significant effect (p > 0.05) on FCE, the FCE value in T2 was notably higher, as indicated in Table 3. FCE denotes the milk produced from each DM intake, and a higher FCE value signifies greater milk yield when dairy cows consume the same amount of feed (Arndt et al., 2015). Consequently, replacing 50% of molasses and cement with cocoa pulp and tapioca meal as filler and adhesive materials in UMMB production can enhance feed digestibility in dairy cows, ultimately resulting in increased DMI and milk yield.

Milk Quality

The findings indicated that T2 had the highest milk protein content at 2.71 ± 0.15 %, while T0 had the lowest at 2.63 ± 0.10 %. Additionally, T1 and T2 had significantly different (p<0.05) milk fat contents, measuring 2.90 ± 0.09 % and 2.94 ± 0.07 % respectively, compared to that of T0 (2.61 ± 0.19 %). The total solids (TS) values for T0, T1, and T2 showed no significant differences, at 11.11 ± 0.15 %, 11.13 ± 0.35%, and 11.14 11.14 ± 0.18 %, respectively. Similarly, the solids-not-fat (SNF) values for T0, T1, and T2 also demonstrated no significant differences, at 8.49 ± 0.08 %, 8.46 ± 0.37 %, and 8.46 ± 0.14 %, respectively.

All treatments appeared to have comparable pH values, with the highest to lowest pH values recorded in T2, T1, and T0, namely 6.78 ± 0.07, 6.74 ± 0.24, and 6.41 ± 0.51, respectively. There were no differences in milk SG value between the treatments, measuring 1.029 ± 0.001 g/cm3. The milk viscosity values in T1 and T2 were 1.16 ± 0.08 cP and 1.11 ± 0.11 cP, respectively, and these values were significantly different (P < 0.05) from that in T0, which was 1.00 ± 0.11 cP.

Table 4: Milk quality of dairy cows supplemented with UMMB.

|

Parameters |

Treatments |

p |

||

|

T0 |

T1 |

T2 |

||

|

Protein (%) |

2.63 ± 0.10 |

2.66 ± 0.15 |

2.71 ± 0.15 |

0.71 |

|

Fat (%) |

2.61 ± 0.19a |

2.90 ± 0.09b |

2.94 ± 0.07b |

0.003 |

|

Total Solid (%) |

11.11 ± 0.15 |

11.13 ± 0.35 |

11.14 ± 0.18 |

0.16 |

|

Solid non Fat (%) |

8.49 ± 0.08 |

8.46 ± 0.37 |

8.46 ± 0.14 |

0.96 |

|

pH |

6.41 ± 0.51 |

6.74 ± 0.24 |

6.78 ± 0.07 |

0.19 |

|

Specific Gravity (g/cm3) |

1.029 ± 0.001 |

1.029 ± 0.001 |

1.029 ± 0.001 |

0.83 |

|

Viscosity (cP) |

1.00 ± 0.11 |

1.16 ± 0.08 |

1.11 ± 0.11 |

0.07 |

Description: abDifferent superscripts on same rows indicate significant difference between group (p< 0.05); T0: without UMMB (control); T1: Supplementation 500gr of UMMB; T2: Supplementation 500gr of UMMB with cocoa pulp and tapioca meal.

The milk protein and fat content were higher in T2 than in T1 and T0. This is attributed to the presence of cocoa pulp and tapioca meal in the UMMB used in T2, which contain high levels of sugars and carbohydrates. These sugars and carbohydrates act as precursors for lactose formation during milk synthesis. This finding supports the statement of Nichols et al. (2019) that carbohydrates and proteins are necessary for lactose synthesis, ultimately leading to an increase in fat and protein synthesis in the udder gland.

Data from Table 4 indicates a difference in milk viscosity between T0 and T1, which can be linked to the high energy content of UMMB derived from molasses, cocoa pulp, and tapioca meal, all of which serve as precursors for fat formation in milk. Furthermore, UMMB contains urea which can enhance the activity of rumen bacteria and also serves as a source of microbial protein for dairy cows. This finding is consistent with the study by Genzebu and Tesfay (2015) which suggested that urea is utilized by rumen bacteria for growth and eventually absorbed into the small intestine, where the bacteria cell walls are used in the process of synthesizing milk in the udder glands. The viscosity value of milk becomes an indicator of the amount of friction between protein and fat particles in milk. Accordingly, higher amounts of protein and fat result in higher viscosity (Khalifa and Ghanimah, 2013).

This study discovers that the average pH value of Holstein Friesian dairy cow milk falls within the normal range of 6.3–6.8. This aligns with the findings of a study by Rahmadiati et al. (2023) which reported an average pH value of 6.4. This is within the normal threshold for fresh cow milk according to the National Standardization Agency of Indonesia (BSN, 2011). Notably, UMMB supplementation does not impact the pH value of the produced milk. A pH value above 6.8 may indicate mastitis in Holstein Friesian dairy cows, while a pH value below 6.2 suggests acidic milk conditions due to bacterial growth (Gemechu et al., 2015; Pramesthi et al., 2015).

Furthermore, the SG value in the study is also within the normal threshold for fresh cow milk, specifically 1.027, according to BSN (2011). SG value reflects the ratio between solids and liquids in milk, with higher solids resulting in a higher SG value (Gemechu et al., 2015).

CONCLUSIONS AND RECOMMENDATIONS

While having no effect on milk yield, supplementation using UMMB made by substituting 50% of the molasses filler and cement adhesive with cocoa pulp and tapioca meal may increase milk fat content. The utilization of cocoa pulp as an additional animal feed ingredient is expected to reduce the environmental impact of cocoa processing industry waste. However, further studies on the use of UMMB with the substitution of molasses filler and cement adhesive with cocoa pulp and tapioca meal over a longer period and on a larger scale are highly recommended to determine the effects of UMMB feeding on the long-term health of dairy cows.

ACKNOWLEDGMENTS

The authors would like to express their gratitude to the Directorate of Research, Technology and Community Service, Directorate General of Higher Education, Research, and Technology of the Ministry of Education, Culture, Research, and Technology of the Republic of Indonesia for funding this study through the Master Thesis Research scheme for fiscal year 2024 with contract number 02035/UN4.22.2/PT.01.03/2024.

NOVELTY STATEMENT

We would like to add the following novelty statement: “Cocoa pulp and tapioca meal can be used as substitutes for molasses fillers and cement adhesives up to 50% in the UMMB manufacturing process.

AUTHOR’S CONTRIBUTIONS

Renny Fatmyah Utamy: Conception and design of the study, critical review of the manuscript; Ambo Ako: Conception and design of the study, critical review of the manuscript; Mohammad Mijanur Rahman: Critical review of the manuscript; A Arif Rahman: Field experiments, data acquisition, data tabulation, data analysis and interpretation, and manuscript preparation and revision; Siti Annisa Sukri: Field experiments, data acquisition, data tabulation, and data analysis and interpretation.

Conflict of Interest

The authors would like to state that there are no conflicts of interest regarding the material discussed in this manuscript.

REFERENCES

Akpambang VOE. Ebuzeme GC Akinola JO (2022). Heavy metal contamination of topsoil around a cement factory – a case study of Obajana Cement Plc. Environ. Pollut. Bioavailability, 34(1): 12-20. https://doi.org/10.1080/26395940.2021.2024090

Afokawa EO, Kongor JE, Takrama JF, Budu AS (2013). Changes in acidification, sugars and mineral composition of cocoa pulp during fermentation of pulp pre-conditioned cocoa (Theobroma cacao) beans. Int. Food Res. J., 20(3): 1215-1222.

Ako A, Mujnisa A, Natsir A (2019). Performance of local goat fed on complete feed containing cocoa pulp with different fiber sources. IOP Conference Series: Earth Environ. Sci., 247(012004): 1-7. https://doi.org/10.1088/1755-1315/247/1/012004

Allen MS (2014). Drives and limits to feed intake in ruminants. Anim. Prod. Sci., 54(1): 1513-1524. https://doi.org/10.1071/AN14478

AOAC (1990). Official Methods of Analysis, 15th edition. AOAC Inc. Arlington, Virginia, USA.

Arndt C, Powell JM, Aguerre MJ, Crump PM, Wattiaux MA (2015). Feed conversion efficiency in 17 dairy cows: repeatability, variation in digestion and metabolism of energy and nitrogen, and ruminal methanogens. J. Dairy Sci., 98(6): 3938-3950. https://doi.org/10.3168/jds.2014-8449

Badan Standardisasi Nasional (BSN).(2011). Susu Segar-Bagian 1:Sapi. SNI-3141.1-2011. Badan Standardisasi Nasional. Jakarta. Indonesia.

Barbano DM, Lynch JM, Fleming JR (1991). Direct and indirect determination of true protein content of milk by Kjeldahl analysis: collaborative study. J. AOAC Int.rnational, 74(2): 281-288. https://doi.org/10.1093/jaoac/74.2.281

Broderick GA, Radloff WJ (2004). Effect of molasses supplementation on the production of lactating dairy cows fed diets based on alfalfa and corn silage. J. Dairy Sci., 87(9):2997-3009. https://doi.org/10.3168/jds.S0022-0302(04)73431-1

Davide CL (1977). Laboratory Guide in Dairy Chemistry Practical. Dairy Training and Research Institute, Univ. Philippines, Los Bamos College, Langnene, Philippines.

Draaiyer J, Dugdill B, Bennett A, Mounsey J (2009). Milk Testing and Payment System Resource Book a Practical Guide to Assist Milk Producer Groups. FAO, Rome, Italy

Duressa D, Bersissa T (2016). Effects of urea-molasses multi-nutrient blocks (UMMB) supplementation on some production parameters of lactating Horro Cows at Horro Guduru Animal Production and Research Center, Western Ethiopia. Sci. Technol. Arts Res. J., 5(1): 35-38. https://doi.org/10.4314/star.v5i1.5

Figueroa KHN, Garcia NVM, Vega RC (2020). Cocoa By-Products in Food Waste and By-products, 1st Edition. pp. 373-411. John Wiley and Sons, New Jersey, USA. https://doi.org/10.1002/9781119534167.ch13

Gemechu T, Beyene F, Eshetu M (2015). Physical and chemical quality of raw cow’s milk produced and marketed in Shashemene Town, Southern Ethiopia. J. Food Agric. Sci., 5(2): 7-13.

Genzebu D, Tesfay G (2015). The role of bacteria in nitrogen metabolism in the rumen with emphasis of cattle. Res. J. Agric. Environ. Manage., 4(7): 282-290.

Govind P, Madhuri S (2014). Heavy Metals Causing Toxicity in Animal and Fishes. Res. J. Anim. Vet. Fish. Sci., 2(2): 17-23.

Guehi TS, Dadie AT, Koffi KPB, Dabonne S, Ban-Koffi L, Kedjebo KD, Nemlin GJ (2010). Performance of different fermentation methods and the effect of their duration on the quality of raw cocoa beans. Int. J. Food Sci. Technol., 45(12): 2508–2514. https://doi.org/10.1111/j.1365-2621.2010.02424.x

Jamir L, Kumar V, Kaur J, Kumar S, Singh H (2021). Composition, valorization and therapeutical potential of molasses: a critical review. Environ. Technol. Rev., 10(1): 131-142. https://doi.org/10.1080/21622515.2021.1892203

Jayawickrama DR, Weerasinghe PB, Jayasena DD, Mudannayake DC (2013). Effect of supplementation of urea-molasses multinutrient block (UMMB) on the performance of dairy cows feed goog quality forage based diets with rice straw as a night feeding, 40(2): 123-129. https://doi.org/10.7744/cnujas.2013.40.2.123

Kassa MG, Asemu AM, Belachew MT, Satheesh N Abera BD, Teferi DA (2024). Review on the aplicatiton, health usage, and negative effect of molasses. CyTA-J. Food, 22(1): 2321984. https://doi.org/10.1080/19476337.2024.2321984

Khalifa MY, Ghanimah MA (2013). Studies on fluid milk viscosity as affected by some factors. J. Biol. Chem. Environ. Sci., 8(2): 57-66.

Leduc A, Souche S, Gelé M, Provost FL, Boutinaud M (2021). Effect of feed restriction on dairy cow milk production: a review. J. Anim. Sci., 99(7): 1-12. https://doi.org/10.1093/jas/skab130

Lefeber T, Janssens M, Moens F, Gobert W, De Vuyst L (2011). Interesting starter culture strains for controlled cocoa bean fermentation revealed by simulated cocoa pulp fermentations of cocoa-specific lactic acid bacteria. Appl. Environ. Microbiol., 77(18): 6694-6698. https://doi.org/10.1128/AEM.00594-11

Linn JG (1988). Factors affecting the composition of milk from dairy cows, in Designing Foods: Animal Product Options in the Marketplace. pp. 224-241.National Academy Press, Washington DC, USA.

Millen DD, Pacheco RDL, Cabral LS, Cursino LL, Watanabe DHM Riguero ALN (2016). Chapter 5: Ruminal Acidosis, in Rumenology. Springer, Cham, Switzerland. 127-156. https://doi.org/10.1007/978-3-319-30533-2_5

Monteverde V, Camilleri G, Arfuso F, Pennisi M, Perillo L, Patito G, Gioia G, Castronovo C, Piccione G (2022). Heavy metal level ini milk and serum of dairy cows from different farms located near an industrial area. Animals, 12(9):2547. https://doi.org/10.3390/ani12192574

Mordenti AL, Giaretta E, Campidonico L, Parazza P, Formigoni A (2021). A review regarding the use of molasses in animal nutrition. Animal, 11(1): 1-17. https://doi.org/10.3390/ani11010115

Nas MY, Sulaiman SA, Ariwahjoedi B, Shaari KZK (2014). Characterization of modified tapioca starch solutions and their sprays for high temperature coating applications. The Sci. World J., 1-10. https://doi.org/10.1155/2014/375206

Navikov RA, Beitz DC (2007). Carbohydrate and lipid metabolism in farm animals. The J. Nutr., 137(1): 702-705. https://doi.org/10.1093/jn/137.3.702

Nichols K, Van Laar H, Bannik A, Dijkstra J (2019). Mammary gland utilization of amino acids and energy metabolites differs when dairy cow rations are isoenergetically supplemented with protein and fat. J. Dairy Sci., 102(2): 1160-1175. https://doi.org/10.3168/jds.2018-15125

Omoniyi LA, Isah OA, Adewumi OOO, Arigbede OM, Onwuka, CFI (2013). Physico-chemical properties and storability of urea molasses multi-nutrient feed-block (UMMB) as dry season supplement for ruminants. J. Appl. Agric. Res., 5(1): 113-121.

Oyiyenka SA, Adeloye AA, Smith SA, Adesina BO, Akinwande FF (2019). Physicochemical properties of meal and starch from two cassava varieties. Agrosearch, 19(1): 28-45. https://doi.org/10.4314/agrosh.v19i1.3

Pramesthi R, Teguh HS, Sudjatmogo (2015). Total bakteri dan ph susu segar sapi perah Friesian Holstein di unit pelaksana teknis daerah dan pembibitan ternak unggul Mulyorejo Tengaran-Semarang. Anim. Agric. J., 4(2): 69-74.

Rahmadiati OC, Rochmi SE, Yuliani MGA, Ma’aruf A, Sofyan MS, Achmad AB Chrismanto D (2023). Quality and quantity of dairy cow milk production in view of differences in concentrate use at KUD Kertajaya Kandangan, Kediri Regency, East Java. J. Appl. Vet. Sci. Technol., 4(1): 11-14. https://doi.org/10.20473/javest.V4.I1.2023.11-14

Raikwar MK, Kumaar P, Singh M, Singh A (2008). Toxic effect of heavy metals in livestock. Vet. World, 1(1): 28-30. https://doi.org/10.5455/vetworld.2008.28-30

Rizqiati H, Nurwantoro S, Susanti A, Febrisiantosa T, Setyawardani CA, Shauma (2021). Physical and chemical characteristics of goat milk powder with different drying methods after storage. Jurnal Ilmu Teknologi Hasil Ternak, 16(1): 65-74. https://doi.org/10.21776/ub.jitek.2021.016.01.7

Sammad A, Wang YJ, Umer S, Lirong H, Khan I, Khan A, Ahmad B, Wang Y (2020). Nutritional physiology and biochemistry of dairy cattle under the influence of heat stress: consequences and opportunities. Animal, 10(5): 1-20 https://doi.org/10.3390/ani10050793

Sansoucy R, Hassoun P (2007). The block Story, FAO Animal Production and Health, Food and Agriculture Organization of the United Nations working paper No. 164. Rome, Italy ISSN 0254-6019

Sun X, Cheng L, Jonker A, Munidasa S, Pacheco D (2022). A review: plant carbohydrate types—the potential impact on ruminant methane emissions. Frontline Vet. Sci., 9(880115): 1-15. https://doi.org/10.1103/PhysRevA.105.062458

Suharyono, Susanto H, Purwanti Y, Martanti, Agus A, Utomo R (2014). The effect of urea molasses multinutrient and medicated block for beef cattle, beef and dairy cow. Atom Indones., 4(2): 77-87. https://doi.org/10.17146/aij.2014.274

Torres RDNS, Bertoco JPA, de Arruda MCG, de Melo Coelho L, Paschoaloto JR, de Almeida Júnior GA, Ezequiel JMB, Almeida MTC (2021). Meta-analysis to evaluate the effect of including molasses in the diet for dairy cows on performance, milk fat synthesis and milk fatty acid. Livestock Sci., 250(104551): 1-13. https://doi.org/10.1016/j.livsci.2021.104551

Utamy RF, Asbar F, Sonjaya H, Ako A, Dagong MIA, Bandong A, Ardianto (2021). Evaluation of the utilization of cocoa pulp in feed concentrate on the hematological parameter of Bali Cattle. Int. J. Sci. Basic Appl. Res., 59(2): 85-90.

Weimer PJ (2022). Degradation of cellulose and Hemicellulose by ruminal microorganism. Microorganism, 10(12): 1-30. https://doi.org/10.3390/microorganisms10122345

To share on other social networks, click on any share button. What are these?