Application of Saccharomyces cerevisiae in Egg Yolk to The Functional and Physicochemical Characteristics of Fermented Eggs

Research Article

Application of Saccharomyces cerevisiae in Egg Yolk to The Functional and Physicochemical Characteristics of Fermented Eggs

Nahariah Nahariah1*, Hikmah Hikmah1, Faridah N. Yuliati1, Endah Murpiningrum1, Abdul W. Jamaluddin2, Titis S. Kusuma3, Andi Febyana4, Kartina Kartina1

1Animal Science Faculty, Hasanuddin University, Jln Perintis Kemerdekaan Km 10, Tamalarea, Makassar 90245 South Sulawesi; 2Study Program of Veterinary Medicine, Faculty of Medicine Jln Perintis Kemerdekaan 8 Makassar South Sulawesi; 3Nutrition Departement, Medicine Faculty, Brawijaya University; 4Research and Development Staff, Planning Agency The Development of Parepare City, South Sulawesi.

Abstract | The production of egg yolk flour is influenced by the fermentation process. We aimed to identify the application of yeast Saccharomyces cerevisiae levels with different fermentation times in egg yolks to the functional and physicochemical characteristics of egg yolks. This research was conducted using a 3 x 3 factorial Completely Randomized Design with 5 replications. Factor A was the fermentation times (hours) 1, 2, and 3, respectively. Factor B was the fermentation level (%) of yeast was 10, 20, and 30, respectively. Parameters measured were swelling ability, emulsion stability, pH value, and water content and color profile of fermented egg yolk. The results showed that the level of yeast Saccharomyces cerevisiae in egg yolk fermentation had a significant effect (P<0.05) on the swelling ability and stability of the egg yolk emulsion. There was no effect of fermentation time and the interaction between the two on the swelling ability and stability of the egg yolk emulsion. However, the treatment showed a significant effect on the pH value of fermented egg yolks. Fermentation time and level had no significant effect on L* value and b* values. However, the fermentation time has a significant effect (P<0.05) on the value of a*. Application of fermentation time and yeast level to fermented egg yolks did not show changes in water content, L* value (lightness), and b* value (yellowness) of egg yolks. The use of 30% yeast for 3 hours can optimize the functional and physical characteristics of fermented egg yolks.

Keywords | Fermentation, Functional characteristic, Physical characteristic, Egg yolk

Received | June 22, 2023; Accepted | November 19, 2023; Published | January 08, 2024

*Correspondence | Nahariah Nahariah, Animal Science Faculty, Hasanuddin University, Jln Perintis kemerdekaan Km 10, Tamalarea, Makassar, Soth Sulawesi; Email: nahariah11@gmail.com

Citation | Nahariah N, Hikmah H, Yuliati FN, Murpiningrum E, Jamaluddin AW, Kusuma TS, Febyana A, Kartina K (2024). Application of Saccharomyces cerevisiae in egg yolk to the functional and physicochemical characteristics of fermented eggs. Adv. Anim. Vet. Sci., 12(1):125-131.

DOI | https://dx.doi.org/10.17582/journal.aavs/2024/12.1.125.131

ISSN (Online) | 2307-8316

Copyright: 2024 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

INTRODUCTION

Egg yolk is a raw material in large quantities in the process of making cakes. Several types of cakes use egg yolks as their main raw material, including types of pastries and biscuits. The availability of fresh egg yolks is greatly influenced by the price of eggs due to over-production, rising feed prices, religious holidays, and other commemorations of holidays. Likewise, the limited shelf life of eggs requires efforts to process eggs as raw material for further processing. Egg yolk powder is the result of drying fresh egg yolks. Egg yolk powder as an effort to extend shelf life. In addition, egg yolk powder can maintain the availability of egg yolks throughout the year at an affordable price. However, drying egg yolks can have an impact on changes in the color and properties of egg yolks, so efforts are needed to minimize these changes. One way is to carry out the fermentation process on egg yolks. The application of the yeast S. cerevisiae to the fermentation of egg whites and whole eggs has been studied previously.

Some research results have been conducted previously, namely research by Tian et al. (2021) reported that yolk fermentation using lactic acid bacteria can modify physicochemical properties and increase yolk emulsifying activity. Similarly, research by Jiang et al. (2020) reported that the application of short-term fermentation using lactic acid bacteria on egg whites also showed changes in characteristics, rheology, and foaming activity. Fermentation using S. cerevisiae has also been applied to egg whites and has an impact on the functional properties of egg whites (Kartina et al., 2023). Nahariah and Hikmah (2023) reported that the application of different types of yeast in fermentation also had an impact on the functional characteristics of chicken eggs. However, fermentation using yeast in the production of egg yolk powder is still limited.

Fermentation is influenced by several factors, including microbial levels and fermentation time. The application of yeast levels of S. cerevisiae with different fermentation times on egg yolks is thought to have an impact on the functional and physicochemical characteristics of the resulting egg yolk flour. This study aims to identify the application of yeast levels with different fermentation times in egg yolks to the functional and physicochemical characteristics of egg yolks.

MATERIALS AND METHODS

Research material

The materials used in this study consisted of egg yolks of 225 infertile eggs from partner farms and commercial yeast starters of the S. cerevisiae type. The equipment used included spoons type SM0503 Merk Golden Flying fish brand produced by Golden Dragon Houseware. Mixer type CM-1579 Merk Cosmos brand produced by PT. Star Cosmos Indonesia. Containers/basin Type Stainless Steel Merk Komodo brand, produced by PT. Naga Komodo. Spatula Type J-050002 (d=2 mm, and P= 20 cm) Merk Shanghai Hegi, The brand produced by Shanghai Hegi Glassware Co., Ltd (Shanghai, Cina). Blender Type BL-152 GF Merk Miyako brand, produced by PT. Kencana Gemilang Indonesia. Sample bottles Type 1101-04 Merk Nikko brand, produced by Nikko Co., Ltd. Measuring cups Type IWAKI Beaker Glass 500 mL Merk AGC IWAKI brand produced by AGC Techno Glass Thailand (ATGT). Test tubes Type IWAKI Pyrex Volume 10 mL Merk AGC IWAKI brand produced by AGC Techno Glass Thailand (ATGT). Stopwatch Type 055.01.001 Merk ISOLAB brand produced by CV. Wahana Hilab Indonesia. Ovens Type Food Dehydrator Merk Getra brand, produced by PT. Royal Sultan Agung. pH meter Hand-type pH meter; PHS-25 Merk TBTSCIETECH brand, produced by Nanjing T-Bota Scietech Instruments and Equipment Co.Ltd Cina. Digital scales Type HP-1/2000(500g/0.001g) Merk SOJIKYO brand produced by PT. Huinindo Multi Niagatama. Centrifuges type 80-2 Merk CORONA brand, and color meters type TES-135A Merk NJouka brand, produced by Shenzhen Graigar Technology Co., Ltd.

Research methods

This research was conducted using a 3x3 factorial completely randomized design with 5 replications. Factor A was the fermentation times (hours) 1, 2, and 3, respectively. Factor B was the fermentation level (%) of yeast was 10, 20, and 30, respectively. The total treatment units were 45 units. Each treatment unit used 5 eggs. The total number of egg yolks used was 225 eggs.

Measured parameter

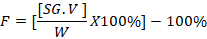

The swelling ability of yolk egg fermentation

The swelling ability of the egg yolk fermentation is calculated as follows: Egg yolks are put into a measuring cup of 50 mL. Calculation of the swelling ability of egg yolk fermentation begins by calculating the specific gravity of the egg yolk with the formula:

g = W/V

g= Yolk specific gravity; W= The weight of the yolk swelling; V= The swelling volume of the yolk egg.

The calculation of the swelling power (F) was 50 mL of egg yolk shaken at full power until fluffy for 3 minutes. Furthermore, the measurement of the swelling weight (W) of the yolk and the swelling volume (V) of the yolk. The swelling ability of the yolk (F) was calculated by the formula (Awuchi et al., 2019).

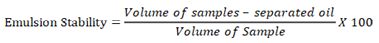

Emulsion stability

The emulsion stability test was measured by placing the sample in a centrifuge tube and rotating it for 15 minutes at 3000 rpm. The separated oil is then taken with a dropper pipette and the volume of the oil is measured (modified Taylor and Bigbee, 1973). The emulsion stability testing formula is as follows.

The pH value

The pH value was measured by turning on the pH meter and calibrating it with a pH 4 and pH 7 buffer solution. The pH meter electrode was then rinsed with distilled water and then dried with tissue paper. The electrode was immersed in the sample and let stand until the number on the pH meter showed a stable number. The pH value of the sample was displayed on the monitor screen (Nahariah et al., 2019).

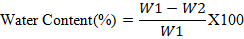

Water content

Samples were weighed as much as 2 g (W1). Then put it in the oven at 105oC for 24 hours. The sample was removed from the oven, allowed to stand, and cooled before being weighed. Weigh the final weight to a constant weight (W2) (Nahariah et al., 2010). The water content of the sample can be calculated by the following formula:

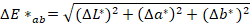

Color profile

Color measurement using a Colorimeter tester. These tools refer to the Hunter color system (L*, a*, b*). The scoring system consists of L*= brightness level, a*= redness level, and b*= yellowness level, notation L*= 0 (black), 100 (white). The a* notation with the value +a* (positive) from 0 to +60 was for red color while the value –a*(negative) was 0 to -60 for green color. The b* notation was with values +b*(positive) and 0 to +60 for yellow colors and -b*(negative) values from 0 to -60 for blue colors. Color measurements were carried out using a portable colorimeter TES-135 Digital color. Then the value of E* (total color difference) was calculated using the formula (Sharma and Garuva, 2003):

RESULT AND DISCUSSION

Swelling ability characteristics of fermented egg yolks at different levels of the yeast S. cerevisiae and different fermentation times

Analysis of variance in Table 1 shows that the level of yeast Saccharomyces cerevisiae in egg yolk fermentation had a significant (P<0.05) effect on the swelling ability of egg yolks. There is no effect of fermentation time and the interaction between the two on the swelling ability of egg yolks.

Duncan’s test showed that there was no difference between the addition of 10 and 20% yeast S. cerevisiae on the swelling ability of egg yolks. However, the level of both shows a significantly lower difference compared to the addition of the 30% level. This indicates that the addition of yeast with a greater amount will have an impact on increasing the ability to swell the egg yolks.

Table 1: The swelling ability of fermented yolks with different fermentation times and yeast level (%).

|

Fermentation times (Hours) |

Yeast levels (%) |

Total |

||

|

10 |

20 |

30 |

||

|

1 |

167±18.29 |

173±9.00 |

181±24.52 |

174±17.11 |

|

2 |

173±8.53 |

189±17.07 |

202±2.99 |

188±16.07 |

|

3 |

178±11.08 |

170±31.87 |

206±12.17 |

185±24.42 |

|

Total |

172±12.45x |

177±20.64x |

197±17.98y |

182±19.77 |

Notes: x,y Superscripts on the same line indicate significant differences (P<0.05).

The swelling ability of the egg yolk is lower than the swelling or foaming power of the egg white. This is related to the protein content that contributes to the ability to form foam in egg whites. The type of protein that dominates egg white and is thought to contribute to the swelling or foaming power is ovomucin (Stadelman and Cotterill, 1986). The swelling ability of both is determined by the type of protein. The ability to swell is not determined by the amount of protein content. This considers the protein content in egg whites to be 9.7%-10.6%, lower than egg yolks with a protein content of 15.7-16.6%. However, the swelling ability of the egg white is higher than the yolk. The high protein content of egg yolk is bound to the phospholipid component so it does not contribute to swelling ability.

The swelling ability of the egg yolk is probably influenced by the fermentation process. The addition of more yeast levels can increase the blooming power of the egg yolks. This is possible, because of the ability of the yeast S. cerevisiae to produce enzymes that break down carbohydrates contained in egg yolks. Egg yolks contain carbohydrates of 0.2-1% (Stadelman and Cotterill, 1986). The result of decomposition is carbon dioxide. The carbon dioxide that is formed can cause the egg yolks to expand when beaten.

The application of different fermentation times did not show a change in the swelling ability of the egg yolks. This indicates that fermentation of egg yolks for 1, 2 or 3 hours does not contribute to the swelling ability of the yolks. But for effectiveness, it can be done for 1 hour of fermentation.

Characteristics of emulsion stability in fermented egg yolk at different levels of the yeast S. cerevisiae and different fermentation times

Table 2, analysis of variance shows that the level of yeast S. cerevisiae in egg yolk fermentation had a significant effect (P<0.05) on the stability of the egg yolk emulsion. There was no effect of fermentation time and the interaction between the two on the stability of the egg yolk emulsion.

Table 2: Emulsion stability of fermented egg yolk at different fermentation times and yeast levels (%).

|

Fermentation times (Hours) |

Yeast levels (%) |

Total |

||

|

10 |

20 |

30 |

||

|

1 |

94.84±3.03 |

96.74±1.78 |

95.71±3.55 |

95.76±2.63 |

|

2 |

97.30±1.09 |

96.34±1.75 |

93.17±1.68 |

95.60±2.29 |

|

3 |

95.87±2.15 |

95.71±2.07 |

91.82±4.14 |

94.47±3.23 |

|

Total |

96.00±2.21xy |

96.26±1.68y |

93.57±3.32x |

95.28±2.70 |

Note: : x,y Superscripts on the same line indicate significant differences (P<0.05).

Duncan’s test showed that there was no difference between the addition of 10 and 20% yeast S. cerevisiae on the stable emulsion of the egg yolk. However, the 20% level showed a significant difference (P<0.05) in higher emulsion stability compared to the addition of the 30% level. This indicates that the addition of yeast with a greater amount will have an impact on decreasing the stability of the egg yolk emulsion.

Emulsion stability is related to the lecithin content in the egg yolk. Lecithin is a compound component composed of minerals bound to fat, namely phospholipids. The lecithin constituent structure can change due to processing, temperature, and shaking. The low emulsion stability in the addition of 30% yeast S. cerevisiae is possibly due to structural changes due to fermentation so that the water content in carbohydrates will be released. The emulsion is a dispersion of oil or fat particles in water or water in oil. Egg yolk is an example of an oil/fat in water emulsion. However, water can be strongly bound to proteins and carbohydrates. The addition of S. cerevisiae yeast with a high level may result in changes to the components of the ingredients, especially those containing carbohydrates. Carbohydrates can help in the process of developing egg yolks but result in decreased emulsion stability due to unbound water. Protein can function as an emulsifier because it has an active surface that contains a mixture of amino acids. Amino acids are hydrophilic and hydrophobic along the polypeptide chain and form a layer at the oil-water interface resulting in a stable bond. However, changes in protein structure can also occur due to fermentation activity so that the bonds become unstable and reduce the surface tension ability of the material.

Physicochemical characteristics

The pH value of fermented egg yolk

Analysis of variance in Table 4 shows that differences in fermentation time and the level of the yeast S. cerevisiae had a significant effect (P<0.05) on the pH value of fermented egg yolks. However, there is no interaction between the two on the pH value.

Table 3: The pH value of fermented eggs yolk with different fermentation times and yeast levels.

|

Fermentation times (Hours) |

Yeast levels (%) |

Total |

||

|

10 |

20 |

30 |

||

|

1 |

6.36±0.15 |

6.20±0.26 |

6.16±0.35 |

6.24±0.25a |

|

2 |

6.33±0.41 |

5.97±0.05 |

5.91±0.30 |

6.07±0.28ab |

|

3 |

6.02±0.05 |

5.95±0.03 |

5.88±0.60 |

5.95±0.07b |

|

Total |

6.24±0.27x |

6.04±0.18xy |

5.98±0.22y |

6.08±0.24 |

Note: a,b,x,y Different superscripts in the same column and row show a significant difference (P<0.05).

Table 4: Water content of fermented eggs with different fermentation times and levels of yeast.

|

Fermentation times (Hours) |

Yeast levels (%) |

Total |

||

|

10 |

20 |

30 |

||

|

1 |

50.39±0.51 |

55.32±0.52 |

56.23±5.75 |

53.98±3.97 |

|

2 |

51.46±4.67 |

49.73±5.12 |

56.98±8.74 |

52.72±6.47 |

|

3 |

54.89±1.69 |

52.38±5.65 |

54.41±4.60 |

53.89±3.91 |

|

Total |

52.25±3.22 |

52.47±4.52 |

55.87±5.82 |

53.53±4.77 |

Duncan’s test showed that the pH value was significantly (P<0.05) higher at 1 hour of fermentation compared to 3 hours of fermentation. However, the 2 hours of fermentation did not show a significant difference with the 1 and 3 hours of fermentation on the pH value. The pH value of egg yolk decreased with increasing fermentation time. The pH value of egg yolk decreased due to the fermentation of S. cereviseae yeast which can break down reducing sugars into gluconic acid. D’Souza and Godbole (1989) said that this is due to the activity of fermentation, the carbohydrates in the eggs are converted to acids, water, and other end products. Kartina et al. (2023) reported that the application of S. cerevisiae fermentation to chicken eggs showed a significant change in pH value which decreased as the fermentation time increased. Egg flour that has been previously fermented for 3 hours shows a lower change in pH value (Kartina et al., 2023).

The pH value of fermented egg yolk was significantly different (P<0.05) and decreased between 10 and 30% addition of S. cerevisiae yeast. However, the pH value did not show a difference at 2% with all levels of yeast added. This indicates that the addition of yeast with a greater amount will have an impact on decreasing the pH value of the egg yolk. Fermentation using S. cerevisiae can break down carbohydrates or sugar into carbon dioxide and water. Meyer and Hood (1973) revealed that the loss of carbon dioxide (CO2) in eggs will cause an increase in the pH value.

Water content of fermented egg yolks

Table 3 showed that the fermentation time with different levels of S. cerevisiae did not significantly affect the value of the moisture content of the egg yolk. This shows that the fermentation time with different levels of S. cerevisiae in egg yolks does not result in changes in the resulting water content.

The water content value of the fermented egg yolk is higher than the water content of the unfermented egg yolk. Zhang et al. (2023) reported that the water content in fresh egg yolk is 47-50% while according to Lai et al. (2010), the water content of fresh egg yolk is 44.53%. In addition, Wulandari’s and Arief (2022) says that the water content of purebred chicken egg yolk per 100 grams is around 50.33. This is due to the fermentation activity that can loosen water bonds with carbohydrates or proteins so that a lot of free water. However, the amount of free water is still limited. This limitation is probably caused by the level and time of fermentation that has not fully broken down the bound water present in the egg yolks. Egg yolk has a high water content but the condition of the water in the yolk is bound to water.

Lightness value color ( L*) in fermented egg yolk

Table 5 showed that fermentation time with different yeast levels of S. cerevisiae did not significantly affect the brightness color (L*) of fermented egg yolks. Likewise, there is no interaction between the two. This shows that the duration of fermentation with differences in the levels of the yeast S. cerevisiae in egg yolks does not result in changes in the resulting lightness color (L*).

Table 5: Lightness value color (L*) in fermented eggs with different fermentation times and yeast levels.

|

Fermentation times (Hours) |

Yeast level (%) |

Total |

||

|

10 |

20 |

30 |

||

|

1 |

68.31±6.62 |

66.57±2.46 |

66.42±4.31 |

67.10±4.24 |

|

2 |

66.25±11.37 |

65.31±6.17 |

65.34±5.82 |

65.64±7.11 |

|

3 |

63.62±0.61 |

63.85±8.94 |

61.44±4.50 |

62.97±5.14 |

|

Total |

66.06±6.89 |

65.24±5.69 |

64.40±4.83 |

65.23±5.68 |

Note: Lightness value (0 (black) -100 (white).

The lightness value color (L*) of fermented egg yolk at the time of fermentation and the level of the yeast S. cerevisiae showed an average value of 65.23 with the color criteria tending to be bright. These results illustrate that the higher the level of yeast S.cerevisiae, the brighter the appearance of the observed egg yolk color. Prakusya (2021), found that this is thought to have occurred because the higher the level of baker’s yeast, the more sugar will be reduced. Dieudonne et al. (2023) stated that the color in egg yolks is formed due to the presence of xanthophyll pigments, lutein, and zeaxanthin in large quantities as well as beta carotene in eggs. Danajaya et al. (2018) that the increase in egg yolk color occurred due to the presence of β-carotene in the treatment ratio which functions as an enhancer of egg yolk color. This β-carotene has a role as a precursor of vitamin A which can be used as a pigment in egg yolks. Things are different in the research by Wicaksono et al. (2021), that in food products of meat origin, changes in the lightness value (L*) are determined by changes in myoglobin in the tissues.

Redness Value Color (a*) in fermented egg yolk

Table 6 showed that egg yolk fermentation time had a significant (P<0.05) effect on the value of the redness color (a*) in fermented egg yolks. However, there was no effect on the levels of the yeast S. cerevisiae and their interaction on the redness color value (a*) in fermented egg yolks.

Table 6: Redness color value (a*) of fermented eggs with different fermentation times and yeast levels.

|

Fermentation times (Hours) |

Yeast level (%) |

Total |

||

|

10 |

20 |

30 |

||

|

1 |

15.23±1.51 |

13.36±0.55 |

11.83±1.30 |

13.47±1.80a |

|

2 |

14.46±1.95 |

14.40±1.90 |

15.43±2.53 |

14.76±1.92a |

|

3 |

16.40±0.98 |

16.86±1.45 |

19.76±0.81 |

17.67±1.85b |

|

Total |

15.36±1.57 |

14.87±1.98 |

15.67±3.74 |

15.30±2.53 |

Note:: a,b Superscripts in the same column show significant differences (P<0.05). Reddish Value (-60 (green)-+60 (red).

The value of redness color (a*) was significantly (P<0.05) different with increasing fermentation time. There is no difference in fermentation time between 1 and 2 hours. However, both were significantly (P<0.05) lower than 3 hours of fermentation. This shows that increasing the fermentation time will increase the redness value of fermented egg yolks. Kartina et al. (2022) reported that egg yolk contains carotenoids which can provide yellow, orange to red pigments. Yunitasari et al. (2023) stated that the yellow color of egg yolks is influenced by feed containing carotenoid pigments, especially beta-carotene, and xanthophyll.

Yellowness value color (b*) in fermented egg yolk

The fermentation time and the yeast level of S. cerevisiae in Table 7 had no significant effect on the value of the yellowness color (b*) of fermented egg yolks. Likewise, there is no interaction between the two on the yellowness values (b*) in fermented egg yolks.

Color profile differences (L*, a*, b*)

Differences in color profiles between L*= lightness, a*= redness, and b*= yellowness for fermented egg yolks. Fermentation time and the addition of the yeast S. cerevisiae was 3.50 (Large) which means the difference is big. The difference between the large L, a, and b values in fermented egg yolks has L* (lightness) values that tend to be bright. The a* (reddish/greenish) values are slightly red, and the b* (bluish/yellowness) values are yellow. This is influenced by the content of carotenoids in fermented egg yolks. In the opinion of Sujana et al. (2006) stated that the yellow color of egg yolks is influenced by feed containing carotenoid pigments, especially beta-carotene, and xanthophyll. Aziz et al. (2023) revealed that the value of the color difference in mayonnaise is 4.1 (normal/moderate).

Table 7: Yellowness color (b*) fermented eggs with different fermentation times and yeast levels.

|

Fermentation times (Hours) |

Yeast level (%) |

Total |

||

|

10 |

20 |

30 |

||

|

1 |

55.51±3.51 |

52.91±0.94 |

52.00±9.27 |

53.47±5.22 |

|

2 |

55.71±1.33 |

57.34±4.85 |

57.23±2.85 |

56.76±3.00 |

|

3 |

58.03±4.67 |

56.78±4.60 |

53.48±1.14 |

56.10±3.90 |

|

Total |

56.41±3.23 |

55.68±3.97 |

54.24±5.41 |

55.44±4.23 |

Note: Yellowness value (-60 (blue)-+60 (yellow)).

CONCLUSIONS and Recommendations

The application of S. cerevisiae fermentation to the characterization of functional and physicochemical properties of egg yolk has been investigated. The results showed that the treatment of different fermentation levels and times can improve functional characteristics including expandability and emulsion stability. Similarly, fermentation level and time also improved the physicomic characteristics including pH value, moisture content and color profile (L, a and b). The use of 30% yeast for 3 hours can optimize the functional and physical characteristics of fermented egg yolks.

Acknowledgements

Thanks to the Hasanuddin University Research and Community Service Institute for the funding provided so that this research can be carried out.

Novelty Statement

The specific purpose and novelty of this work is to explore the use of consumer egg yolk as a food ingredient. The fermented egg yolk is expected to be further developed for other processed food products made from egg yolk.

AUTHORS’S CONTRIBUTION

All authors contributed equally. NN and HH conducting research, and drafted the initial manuscript. FNY EM, and AWJ contributed to the implementation of the research and assisted in data collection. AF and KK assist in preparing research materials and TSK help interpret the data. All author partipated in the manuscript draft and review of manuscript.

Conflict of interest

The authors have declared no conflict of interest.

REFERENCES

Aziz, SF, Nahariah N, Faridah NY, Hikmah H (2023). The effect of different types and levels of oils on the color profile and fondness of mayonnaise made from chicken egg yolk. AIP Con. Proc. AIP Publishing. 2628. https://doi.org/10.1063/5.0144040

Awuchi, Godswill C, Igwe, Somtochukwu V, Echeta and Kate C (2019). The functional properties of food and flours. Int. J. Adv. Acad. Res., 5(11): 139-160.

Dananjaya, IBPO, Bidura IGNG, Candrawati DPMA (2018). Pengaruh pemberian probiotik bakteri selulolitik B-6 melalui air minum terhadap kadar protein, lemak, kolesterol dan warna kuning telur ayam lohmann brown umur 40-48 minggu. J. Trop. Anim. Sci., 6(2): 489-500.

Dieudonne D, Zhang H, Yu Y, Hao W (2023). Carotenoid enrichment in egg: From biochemistry perspective. Anim. Nutr., 14(10): 315-333. https://doi.org/10.1016/j.aninu.2023.05.012

D’Souza SF, Godbole (1989). Removal of glucose from egg prior to spray drying by fermentation with immobilized yeast cells. Biotechnol. Lett., 11(3): 210-212. https://doi.org/10.1007/BF01026061

Jiang Y, Jia J, Xiong D, Xu X, Yang Y, Liu X, Duan X (2020). Effects of short-term fermentation with lactic acid bacteria on egg white: Characteristic, rheological and foaming activities. Food Hydrocolloids, 101: 105507. https://doi.org/10.1016/j.foodhyd.2019.105507

Kartina K, Nahariah N, Hikmah H (2023). Functional characteristic of egg powder the addition of Saccharomyces cerevisiae with different fermentation times. AIP Conf. Proc. AIP Publishing. 2628: 060002. https://doi.org/10.1063/5.0144173

Kartina K, Nahariah N, Hikmah H (2022). Penambahan jenis dan level bahan pengisi yang berbeda terhadap nilai profil warna L*, a*, b* produk chip telur. Jurnal Ilmu dan Teknologi Peternakan. 10(1): 6-10.

Lai KM, Chuang YS, Chou YC, Hsu YC, Cheng YC, Shi CY, Chi HY, Hsu KC (2010). Changes in physicochemical properties of egg white and yolk proteins from duck shell eggs due to hydrostatic pressure treatment. Poult. Sci., 89: 729-737. https://doi.org/10.3382/ps.2009-00244

Meyer R, Hoo LF (1973). The effect of pH heat on the ultrastructure of chick and thin hen`s egg albumen. J. Poult. Sci., 52: 1814-1817. https://doi.org/10.3382/ps.0521814

Nahariah N, Hikmah H (2023). Application of types of yeast with different fermentation times on the functional properties of chicken egg. AIP Conf. Proc. AIP Publ., 2628: 050017. https://doi.org/10.1063/5.0144172

Nahariah, HN.Hikmah and F.N Farida (2019). Microbiological activities in fermented egg whites with different levels of milk and fermentation times. IOP Conf. Series: Earth and Environmental Science. IOP Publishing . 247 012028. doi:10.1088/1755-1315/247/1/012028

Nahariah, Effendi A, Ratmawati M (2010). Karakteristik fisikokimia tepung putih telur hasil fermentasi Saccharomyces cereviceae dan penambahan sukrosa pada putih telur segar. 1(1): 37-38.

Prakusya TN (2021). Sifat fisikokimia dan fungsional tepung telur utuh dengan penambahan berbagai konsentrasi ragi roti (saccharomyces cerevicieae). Skripsi. Fakultas Teknologi Pertanian. Universitas Semarang. Semarang.

Sharma, Gaurav (2003). Digital color imaging handbook. Voluume X: CRC Press: 1.7.2 ed. ISBN 0-8493-0900-X.

Stadelman WJ, Cotterill OJ (1986). Egg science and technology. Food Product Press an Imprint of The Haworth Press, Inc., New York, London. https://doi.org/10.1007/978-1-349-09142-3

Sujana, SE. Wahyuni, H. Burhanuddin (2006). Efek pemberian ransum yang mengandung tepung daun singkong, daun ubi jalar, dan eceng gondok sebagai sumber pigmen karotenoid terhadap kualitas kuning telur itik tegal. J. Anim. Sci.Padjadjaran Univ., 6(1): 53-56.

Taylor MH, Bigbee DE (1973). Poultry and egg products. In: A. Kramer and B.A. Twigg (Eds.), Quality control for the Food Industry, 2rd ed. The Avi Publishing Co. Inc., Westport Connecticut.

Tian L, Hu S, Jia J, Tan W, Yang L, Zhang Q, Liu X, Duan X (2021). Effects of short-term fermentation with lactic acid bacteria on the characterization, rheological, and emulsifying properties of egg yolk. Food Chem., 341(1): 128163. https://doi.org/10.1016/j.foodchem.2020.128163

Wicaksono AD, Hikmah MA, Nahariah N (2021). Color’s profile of duck meat marinated with different levels of liquid smoke and papain enzyme. Hasanuddin J. Anim. Sci., 3(1): 35-41. https://doi.org/10.20956/hajas.v3i1.13837

Wulandari Z, Arief II (2022). Review: Tepung Telur Ayam: Nilai Gizi, sifat fungsional dan manfaat. J. Ilmu Prod. Teknol. Hasil Petern., 10(2): 62-68. https://doi.org/10.29244/jipthp.10.2.62-68

Yunitasari F, Jayanegara A, Ulupi N (2023). Performance egg quality and ummunity of laying hens due to natural carotenoid supplementation: A meta-analysis. Food Sci. Anim. Resour., 43(2): 282-304. https://doi.org/10.5851/kosfa.2022.e76

Zhang R, Yao F, Ning Z (2023). Characterization of flour thermogelled egg yolk varieties based on moisture and protein content. Poult. Sci., 102(4): 102499. https://doi.org/10.1016/j.psj.2023.102499

To share on other social networks, click on any share button. What are these?