Postharvest Life of Guava (PsidiumguajavaL.) Varieties as Affected by Storage Intervals at Room Temperature

Research Article

Postharvest Life of Guava (PsidiumguajavaL.) Varieties as Affected by Storage Intervals at Room Temperature

Said Rawan1, Farzana Bibi1, Nadeem Khan1*, Abdul Mateen Khattak1, Zahir Shah3, Asif Iqbal2, Madeeha Alamzeb2, Saeed Ul Haq1, Abid Kamal3, Fawad Ali Shah2, Ahmad Naeem1 and Wajid Ali3

1Horticulture Department, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan; 2Agronomy Department, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan; 3SES Department, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan.

Abstract | The research study entitled“Postharvest life of guava (PsidiumguajavaL.) varieties as affected by storage intervals at room temperature” was conducted at post harvest laboratory, Department of Horticulture, The University of Agriculture Peshawar, during the year 2015. The research work was conducted in Complete Randomized Design (CRD) with three replications and two factors i.e. guava varieties (Safeda and Karela) and storage intervals (0, 3, 6, and 9 days). The data was recorded onfirmness (kg/cm2), weight loss (%), moisture contents (%), taste, decay fruits (%) and total soluble solids (TSS). The experimental result showed that both the varieties were significantly influenced the fruit decay (%), TSS (%), taste and moisture content (%), while firmness (kg/cm2) and weight loss (%) was found non-significant. Also storage interval significantly affected all the parameters. Interactive affect of varieties and storage intervals significantly affected all the parameters except firmness (kg/cm2), taste and weight loss (%). The fruits of safeda variety lowest fruit decay (5.82%), more TSS (11.530Brix), taste (5.17) and moisture content (42.68%), while fruit store for zero days no fruit decay (%), weight loss (%), less firmness(1.43 kg/cm2) and more moisture content (44.24%), however on 9 days storage more TSS (15.130Brix) and taste (6) was observed. The fruit store for 9 days and safeda variety perform better on all the parameter, so recommended for postharvest life extension of guava fruits under uniform room temperature 210C.

Received | 02 November, 2016; Accepted | 11 April, 2017; Published | June 20, 2017

*Correspondence | Nadeem Khan, Horticulture Department, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan; Email: nadeemaup@yahoo.com

Citation | Rawan, S., F. bibi, N.Khan, A.M. Khattak, Z. Shah, A. Iqbal, M. Alamzeb, S. Haq, A. Kamal, F.A. Shah, A. Naeem and W. Ali. 2017. Postharvest life of guava (PsidiumguajavaL.) varieties as affected by storage intervals at room temperature. Pakistan Journal of Agricultural Research, 30(2): 155-161.

DOI | http://dx.doi.org/10.17582/journal.pjar/2017/30.2.155.161

Keywords | Guava, Varieties, Postharvest, Storage, Temperature

Introduction

Guava (Psidiumguajava L.) is an important subtropical fruit grown widely in tropical and subtropical regions of the world. Major guava producing countries are Pakistan,South Africa, India, Brazil, Egypt, Mexico, Venezuela and Columbia. In Pakistan, it is grown on an area of 62.3 thousand hectares and getting yield of 512.3 thousand tons of fruits (Hassan et al., 2012). On the basis of area under cultivation, it ranks fifth after citrus, mango, banana and apple in Pakistan. It is a highly valuable fruit with a rich source of vitamin C (Pal et al., 2004). It contains the group of major antioxidants like polyphenols and carotenoids, which are responsible for its high nutritional value (Hassimottoet al., 2005). Guava fruit has high demand but severe fruit fly infestation during summer by AnastrephastriataSchiner and Bactrocerazonata Saunders badly reduces the marketable yield, and leads to economic losses to the growers.Larvae of the fruit fly causes the main damage by feeding inside the fruits during their growth and development, and reduce the quality, yield and postharvest life of the fruits (Stonehouse et al., 2005).

At harvesting stage there are high respiration rate and ripening of the varieties of the guava fruits that leads to perishable during storage interval. However, it is important to reduce the postharvest losses of guava fruits after harvesting. Fresh and quality fruits availability to the consumer during the whole year, and increase their market value, development of postharvest technologies related to quality maintenance and life extension of guava varieties (Zhong et al., 2006; Chien et al., 2007). Guava fruit is highly susceptible to chilling injury and mechanical damage.During storage and transportation soft rot of guava fruits caused by Rhizopusstolonifer (Adisa, 1985). Removing of field heat and store at room temperature reduce the decay of fruits. Proper covering, postharvest treatment with chemical and hot water, long term refrigeration for improving fruits resistance to chilling injury and diseases (Rodov et al., 1995). Postharvest applications with calcium chloride during ripening stage have been used to delay aging or ripening, efficiently reducing postharvest decay and controlling many diseases in fruits and vegetables (El-Gamal et al., 2007). Essential oil extracted from lemon grass (CymbopogoncitreatusDC.) and olive oil has antifungal activity against several plant pathogens (Raweewon, 2008). In Pakistan 20-40% of fruits losses of fruits occurs are due to improper management of postharvest operation and lack of advance techniques. For this reason the present study was designed to find out the best storage time and variety for prolonging the postharvest life of guava fruits.

Materials and Methods

Guava varieties (safeda and karela) were obtained from Harichand guava orchid. After harvesting in the morning, the fruits were immediately brought to laboratory, Department of Horticulture, The University of Agriculture Peshawar, and store post harvest under 21oCover night. Guava fruits of the uniform color, shape, size disease and defect free were selected from both varieties for the experiment.

Experimental design

The experiment was laid in completely randomize Design (CRD) with two factors i.e. varieties (safeda and karela) and days to interval (0, 3, 6 and 9 days), and repeated three time. Total number of experimental units was 24 and each experimental unit having 50 fruits. Data recorded on 5 fruits randomly selected from experimental unit for comparison after 3nd day of testing both the varieties. It was tested four times in the experiment. Data were recorded on taste, firmness (kg/cm2), weight loss percent, moisture contents percent, decay fruits percent and total soluble solids (TSS). not clear revise it.

The following parameters were studied in this experiment.

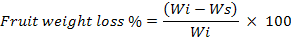

Fruit decay (%)

The number of decayed fruits due to fungus or any micro-organisms infection was recorded at days 0, 3, 6 sand 9, which were compared with a day 0, and calculated as a percentage of the total number of fruits using the following equation:

Total Soluble Solids (0Brix)

Total soluble solids (TSS0Brix) were determined at a room temperature of 21°C, with a hand refractometer using 2 to 3 drops of juice obtained by squeezing the fruits (AOAC, 1994).

Fruit firmness (Kg cm-2)

Firmness was determined using Penetrometer (Effigies, FT-011). Fruit surface was peeled with the help of blade, set the Penetrometer on zero error, then pushing the Penetrometer hanger on the peeled surface, and note the reading in unit kg cm-2. After each three days interval, five fruits were randomly selected from each lot and their firmness was determined by pressing the knob of the Penetrometer into the fruit. The average of these five was the firmness of the whole lot.

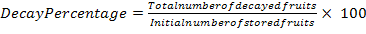

Weight loss determination (%)

The weight loss during storage was determinedby the weight differences at days 0, 3, 6 and 9, which were then compared with day 0, and expressed in percentage (fresh weight basis). Fruit was weighted using a weighing scale. Fruits weight was recorded, then the percentage of weight loss were calculated according to the following equation:

Wi: Fruit weight at initial period; Ws: Fruit weight at sampling period

Taste

Organolaptic test of the fruit was done to identify their taste on five fruits, so the three judges give the marks from (1-10) and it was on this manner that poor taste having marks from 1-2, fair have 3-4, good have 4-6, very good have 6-8 and excellent have 8-10 marks.

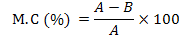

Moisture content (%)

moist sample was weighed immediately and record as “wet weight of sample” Dry the weight sample again to a constant weight, at a temperature not exceeding 90°C using the suitable drying equipment. Allow the sample to cool. And weight to know again, and recorded as the “dry weight of sample”. The moisture content of the five randomly selected samples was calculated using the following equation:

M.C (%): Percentage of moisture in the sample; A: Weight of wet sample (gram); B: weight of dry sample (gram).

Statistical analysis

The data recorded on different parameter were analyzed by using the statistical computer software, MSTATC (Michigan state university, USA). Analysis of variance (ANOVA) and LSD test were performed to find out the difference between treatments and interaction. The mean values for difference were compared by using least Significant Difference Test (Steel et al., 1997).

Results and Discussion

Fruits decay (%)

Data regarding fruit decay (%) were significantly affected by varieties and storage intervals (Table 1), and also interaction was found significant.In variety Karela highest fruits decay (7.92 %) was found as compare to fruits decay (5.82%) in safedavariety.Maximum decay of fruits (12.03 %) were noted a t 9 days storage duration, while lowest fruits decay (6.67 %) were obtained on 3 days of storage interval. Karela variety and storage duration on 9 days had maximum fruits decay as compare to remaining storage condition and safeda variety (Figure 1). During the storage duration fruits decay reduces in initial days of fresh commodities and having all the physiological attributes are more in the fruits.Antifungal appearance (Hernandez et al., 2007) and antimicrobial activities higher when the respiration is higher and loss of sugar (Gil et al., 2004). Disruption and death of the microbial cells decay of fruits faster (Helanderet al., 2001). Abbasiet al. (2009) found that, chinitin contents of cell wall reduce loss of fruits from fungal infection.Similar studied were observed by Wang et al. (2007) and Zhu et al. (2008) that pathogenic microorganisms were restricted when mango fruits were coated with Chitosan.The storage life of guava fruits might be increased if the fruits are higher in calcium concentration in the plants storage life increase after removing from plants and store for later use.

TSS (0Brix)

Varieties of guava fruit significantly affected total soluble solid (0Brix) at different storage intervals (Table 1), interaction (Varieties x Storage interval) was also found significant (Figure 2). Total soluble solid (11.540Brix) in highest concentration were calculated in safeda variety and lowest concentration (10.50Brix) in Karela variety, while storage duration maximum amount of TSS (15.140Brix) was found that store for 9 days and lesser amount (8.500Brix) observed which stored first days. Interaction of varieties and storage duration showed that variety safeda had maximum fruit TSS (0Brix) when stored for 9 days. Nature of TSS during the ripening of climacteric fruits increase significantly, mainly from the conversion of starch into

Table 1: Storage condition and guava varieties affected fruits decay (%), TSS (0Brix), weight loss (%), taste (%) and moisture content (%).

| Parameters | ||||||

| Varieties | Fruits decay (%) |

TSS (0Brix) |

Firmness (Kg cm-2) |

Weight loss (%) | Taste | Moisture content (%) |

| Safeda | 5.82 b | 11.53 a | 3.58 a | 16.44 a | 5.17 a | 42.68 a |

| Karela | 7.92 a | 10.49 b | 3.36 a | 16.54 a | 4.08 b | 28.52 b |

| LSD | 0.44 | 0.44 | ns | ns | 0.62 | 0.69 |

| Storage interval (Days) | ||||||

| 0 | 0 d | 8.49 c | 1.43 d | 0 d | 3.50 c | 44.24 a |

| 3 | 6.67 c | 9.00 c | 2.72 c | 14.07 c | 3.93 c | 37.50 b |

| 6 | 8.78 b | 11.44 b | 4.33 b | 21.30 b | 5.08 b | 31.11 c |

| 9 | 12.03 a | 15.13 a | 5.40 a | 30.60 a | 6.00 a | 29.56 d |

| LSD | 0.62 | 0.87 | 0.5 | 1.65 | 0.88 | 0.98 |

| Interaction | ||||||

| LSD | 0.88 | 0.88 | ns | ns | ns |

1.39 |

Means followed by similar letters are statistically non-significant / similar at 5% level of significance. ANOVA tables are given on page 161.

simple sugars such as glucose, fructose and sucrose that causing in the flavor (Chitarra, 2005). It might be in later stages of storage increase in ethylene synthesis due to respiration total soluble solid increased. Cultivar of guava Pedro Sato no variation in the levels of TSS during the ripening, but the ethylene level increased starting from 6 days of ripening and leads to increase in TSS because guava is not a climacteric fruit.

Firmness (Kg/cm2)

Data pertaining firmness significantly affected by storage intervals, while varieties and interaction was found non-significant (Table 1). Safedavariety contains highest firmness (3.58kg/cm2) as the firmness (3.36kg/cm2) in variety karela. Maximum fruit firmness were calculated when the fruits are harvested time (5.40kg/cm2),while the lesser fruits firmness (1.43kg/cm2) were obtained when the fruits are store for 9 days. Softening of the fruits, loss of color, physiological changes, ethylene production and ripening process the fruits cause firmness (Oliveiraet al., 2006). Degree of methylation varied firmness from green and rife fruits mainly due to protein polymers (Fertonani, 2006), calcium which maintain adjacent chains bonded among themselves, alsoglycoside chains interconnected among themselves by phenolic compounds (Taiz, 2004). Hydrolytic enzyme activation due to ripening increase firmness that promote intense solubilization of pectin present in the cell wall, mainly pectin methyl esterase (PME) and polygalacuronases (PG). High esterase activities in the cell wall of guava kernel suggest that rapid decrease in firmness (Jain et al., 2001). It might be due to in the initial stages firmness more and ripening increase with decrease the firmness of guava fruit if storage time increased.

Weight Loss (%)

Guava fruits store for different days were significantly affected weight loss (%), while varieties and interaction has non-significant affect on weight loss percentage of guava fruits at room temperature (Table 1). There were no difference among variety safeda weight loss (16.54%) and karela variety (16.44%) weight loss. Weight loss (30.60%) rapidly if the fruit of guava store for 9 days while at first day of storage the no weight loss were obtained.Loss of water from the surface of fruits, cell wall degradation, rapid respiration and ethylene concentration results to weight loss of fruits (Zhu et al., 2008). Storage of guava fruits period increase with increased in Cumulative Physiological Loss in Weight (CPLW).It might be due to increase in ethylene, respiration and loss of moisture from the surface of fruits cause significant loss in fruit weight of guava.

Taste

Data recorded on taste were significantly affected by both varieties and storage of fruits time, and interaction among these found non-significant (Table 1). Taste of variety safeda (5.17%) was found more than variety karela (4.08%). The fruits are stored for 9 days result more taster (6%) as compare to fruits store harvesting stage (3.50%). Maturity cause increase in sugar and decrease in acidity the taste of fruits better as compare to time of harvesting (Bhattacharya, 2004).Taste retain higher with acid concentration (Ulrich, 1970). Malic acid, citric and quinic acid have a significant effect on taste and flavor of the fruits.Ripening consumed these organic acid and sugars efficiently enhance the taste and flavor. Ramana et al. (1979) reported that, during the storage change in acidity is due to increase in metabolic activities of living tissues. Organolaptic characteristics maintaining by the physiochemical properties of the treatments retained.

Moisture content (%)

Data on moisture content were significantly affected by varieties of guava and storage intervals, also interaction among these treatments were found significant (Table 1). Moisture content was found higher in variety safeda (42.68%) while variety karela contain less amount of moisture (28.52%), and fruits store for 9 days moisture concentration were decreased (44.24%) while increased moisture in the initial stage of storage (29.52%). Variety safeda and their interaction with fruits store in zero days less moisture were calculated (Figuer 3). Weight loss decrease regularly having direct affect on moisture content. Increase in weight loss, reduced metabolic activity and moisture loss from skin of the fruits (Alves et al., 2004). Moisture levels totally depend on storage temperature and water pressure gradient between the fruit tissue and the surrounding atmosphere (Munoz et al., 2008).

The experimental result showed that both the varieties were significantly influenced the fruit decay (%), TSS (%), taste and moisture content (%), while firmness (kg/cm2) and weight loss (%) was found non-significant. Also storage interval significantly affected all the parameters. Interactive affect of varieties and storage intervals significantly affected all the parameters except firmness (kg/cm2), taste and weight loss (%). Recommendation of safeda variety and fruits store for 9 days for postharvest life extension.

Authors Contribution

SR and FB conceived the study and designed the experiments; SR, AK and AN performed the experiments; AI, MA and WA analyzed the data. FAS, AMK and ZS contributed with reagents/ materials/ analysis tools and NK and SUH wrote the manuscript.

References

Abbasi, N.K., Z. Iqbal, M. Maqbool and I.A. Hafiz. 2009. Postharvest quality of mango (MangiferaindicaL.) fruit as affected by Chitosan coating. Pak. J. Bot. 41(1): 343 357.

Adisa, V.A. 1985. Fruit rot disease guava (Psidiumguajava) in Nigeria. J. Indian Phytopath. 38(3): 427-430.

Alves, R.E., H.A.C. Filgueiras, A.S. Almeida, M.E.C. Pereira, F.M. Cocozza and J.T. Jorge. 2004. Postharvest ripening of ‘Tommy Atkins’ mangoes on two maturation stages treated with 1-MCP. Acta. Hort. 645: 627- 632. https://doi.org/10.17660/ActaHortic.2004.645.82

Bhattacharya, G. 2004. Served fresh spot light times. Food Process. J. http://www.timesb2b.com/foodprocessing/dec03_jan04/spotlig ht.html.

Chien, P.J., F. Sheu and F.H. Yang. 2007. Effects of edible Chitosan coating on quality and shelf life of sliced mango fruit. J. Food Eng. 78(1): 225-229. https://doi.org/10.1016/j.jfoodeng.2005.09.022

El-Gamal, Nadia, G.F. Abd, El-Kareem, Y.O. Fotouh and S. El-Mougy-Nehal. 2007. Induction of systemic resistance in potato plants against late and early blight diseases using chemical inducers under greenhouse and field conditions. Research conditions. Res. J. of Agri. Biol. Sci. 3(2): 73-81.

Fertonani, H.C.R. Estabelecimento de um modelo de extracaoacida de pectina de bagaco de maca. 2006. Dissertacao (MestradoemCiencia e Technology de Alimentos)-Universidade Federal de Ponta Grossa, Ponta Grossa. pp. 82

Gil, G., D.S. Monaco, P. Cerruti and M. Galvagano. 2004. Selective antimicrobial activity of Chitosan on beer spoilage bacteria and brewing yeast. Biotechnol. Lett. 26(7): 569-574. https://doi.org/10.1023/B:BILE.0000021957.37426.9b

Hassimotto, N.M.A., I.S. Genovese and F.M. Lajolo. 2005. Antioxidant activity of dietary fruits, vegetables, and commercial frozen fruit pulps. J. Agric. Food Chem. 53: 2928- 2935. https://doi.org/10.1021/jf047894h

Helander, I.M., E.L.N. Lassila, R.N. Ahvenainen, J. Rhoades and S. Roller. 2001. Chitosan disrupts the barrier properties of the outer membrane of Gram-negative bacteria. Int. J. Food Microbial. 71(2-3): 235-244. https://doi.org/10.1016/S0168-1605(01)00609-2

Jain, N. 2001. Compositional and enzymatic changes in guava (Psidiumguajava L.) fruits during ripening. Acta Physiological Planetarium. 23: 357-362. https://doi.org/10.1007/s11738-001-0044-7

Munoz, P.H., E. Almenar, V.D. Valle, D. Velez and R. Gavara. 2008. Effect of Chitosan coating combined with postharvest calcium treatment on strawberry (Fragarananassa) quality during refrigerated storage. FoodChem. 110(2): 428-435. https://doi.org/10.1016/j.foodchem.2008.02.020

Pal, P.K., M.S. Ahmad, S.K. Roy and M. Singh. 2004. Influence of storage environment, surface coating, and individual shrink wrapping on quality assurance of guava (Psidiumguajava) fruits. Plant Foods Hum. Nut. 59: 67-72. https://doi.org/10.1007/s11130-004-0022-5

Raweewon, D. 2008. Natural essential oils from lemon grass (Cymbopogon citrates) to control postharvest anthracnose of mango fruit. Int. J. Biotechnol. 10: 104-108. https://doi.org/10.1504/IJBT.2008.017971

Rodov, V., S. Ben-Yehoshua, R. Albagli and D.Q. Fang. 1995. Reducing chilling injury and decay of stored citrus fruit by hot water dips. Postharvest Biol. Technol. 5: 119-127. https://doi.org/10.1016/0925-5214(94)00011-G

Stonehouse, J.M., A. Verghese, J.D. Mumford, J. Thomas, T. Jiji, R. Faleiro, Z.P. Patel, R.C. Jhala, R.K. Patel, R.P. Shukla, S. Satpathy, H.S. Singh, A. Singh and H.R. Sardana. 2005. Research conclusions and recommendations for the on-farm IPM of Tephritid fruit flies in India. Pest Manage. Horti. Ecosys. 11: 172-180.

Taiz, L., Zeiger and E. Fisiologia. 2004. Vegetal. 3. ed. Porto Alegre: Artmed. pp.719.

Ulrich, R. 1970. Organic acidsinthe biochemistry of fruit and their products.Academic Press, New York, USA. 1: 89-115.

Wang, J., B. Wang, W. Jiang and Y. Zhao. 2007. Quality and shelf life of mango (MangiferaindicaL. cv. Tainong) coated by using Chitosan and polyphenols. Food Sci. Technol. Int. 13(4): 317-322. https://doi.org/10.1177/1082013207082503

Zhu, X., Q. Wang, J. Cao and W. Jiang. 2008. Effects of Chitosan coating on postharvest quality of mango (MangiferaindicaL. cv. Tainong) fruits. J. Food Process. Pres. 32(5): 770- 784. https://doi.org/10.1111/j.1745-4549.2008.00213.x

Table 1a: ANOVA for decay fruits (%) as affected by different storage intervals and varieties of guava fruit.

| SOV | DF | SS | MS | F-cal | Prob. |

| Rep | 2 | 1.44 | 0.72 | ||

| SI | 3 | 465.537 | 155.179 | 603.30 | 0.001 |

| Varieties | 1 | 26.586 | 26.586 | 103.36 | 0.002 |

| SI x V | 3 | 78.414 | 26.138 | 101.62 | 0.001 |

| Error | 14 | 3.601 | 0.257 | ||

| Total | 23 | 575.578 |

|

C.V 7.38

Table 1b: ANOVA for TSS (0Brix) as affected by different storage intervals and varieties of guava fruit.

| SOV | DF | SS | MS | F-cal | Prob. |

| Rep | 2 | 1.015 | 0.507 | ||

| SI | 3 | 165.424 | 551.141 | 111 | 0.020 |

| Varieties | 1 | 6.5 | 6.5 | 13.08 | 0.002 |

| SI x V | 3 | 7.841 | 2.6136 | 5.26 | 0.012 |

| Error | 14 | 6.955 | 0.4968 | ||

| Total | 23 | 187.734 |

|

CV 6.40

Table 1c: ANOVA for firmness as affected by different storage intervals and varieties of guava fruit.

| SOV | DF | SS | MS | F-cal | Prob. |

| Rep | 2 | 0.336 | 0.1682 | ||

| SI | 3 | 55.0876 | 18.3625 | 116.62 | 0.001 |

| Varieties | 1 | 0.2774 | 0.2774 | 1.76 | 0.205 |

| SI x V | 3 | 0.2583 | 0.0861 | 0.55 | 0.658 |

|

Error |

14 | 2.2045 | 0.1575 | ||

| Total | 23 | 58.1641 |

|

CV 11.42

Table 1d: ANOVA for weight loss as affected by different storage intervals and varieties of guava fruit.

| SOV | DF | SS | MS | F-cal | Prob. |

|

Rep |

2 | 0.43 | 0.21 | ||

| SI | 3 | 3000.41 | 1000.14 | 559.35 | 0.022 |

| Varieties | 1 | 0.06 | 0.06 | 0.03 | 0.855 |

|

SI x V |

3 | 8.92 | 2.97 | 1.66 | 0.220 |

| Error | 14 | 25.03 | 1.79 | ||

| Total | 23 | 3034.85 |

|

CV 8.11

Table 1e: ANOVA for Taste as affected by different storage intervals and varieties of guava fruit.

| SOV | DF | SS | MS | F-cal | Prob. |

| Rep | 2 | 0.600 | 0.300 | ||

| SI | 3 | 23.067 | 7.689 | 15.22 | 0.000 |

|

Varieties |

1 | 7.150 | 7.150 | 14.15 | 0.002 |

| SI x V | 3 | 2.217 | 0.739 | 1.46 | 0.267 |

| Error | 14 | 7.072 | 0.505 | ||

| Total | 23 | 40.109 |

|

CV 15.35

Table 1f: ANOVA for as affected by different storage intervals and varieties of guava fruit.

| SOV | DF | SS | MS | F-cal | Prob. |

| Rep | 2 | 7.93 | 3.96 | ||

| SI | 3 | 1203.37 | 1203.37 | 1907.92 | 0.010 |

| Varieties | 1 | 809.14 | 269.71 | 427.63 | 0.003 |

| SI x V | 3 | 355.32 | 118.44 | 187.78 | 0.030 |

| Error | 14 | 8.83 | 0.63 | ||

| Total | 23 | 2384.59 | |||

| CV 2.23 |

To share on other social networks, click on any share button. What are these?