Thermal Degradation Kinetics of Immature Melon Manis Terengganu (MMT) Heated by a Convective Hot Air Dryer

Thermal Degradation Kinetics of Immature Melon Manis Terengganu (MMT) Heated by a Convective Hot Air Dryer

Che Ku Nur Ain Mardhiah Che Ku Azman and Norlia Muhamad*

Faculty of Bioresources and Food Industry, Universiti Sultan Zainal Abidin, Besut Campus, 22200 Besut, Terengganu.

Abstract | Immature Melon Manis Terengganu (MMT) contains high moisture content, making the fruit highly perishable and rapidly deteriorating. Drying is the most common method used in food processing to extend its shelf life. The main objective of this project was to investigate the thermal degradation kinetics of the dried immature Melon Manis Terengganu (MMT) using a hot air dryer at four different temperatures (40, 50, 60, and 70 °C). Drying kinetics is very helpful as it can design and optimize thermal processes to maximize the quality of dried products. The immature MMT was immersed in 0.2% sodium metabisulfite before drying. The sample was weighed in 60 min intervals until it reached the equilibrium conditions. The experimental data were fitted to five drying models; the Newton model, Page model, Henderson and Pabis model, Midili et al. model, and Two-Term Exponential model. The drying time at 70 °C showed a shorter time, which is 4 hours, as compared to 40, 50, and 60 °C, which are 9, 6, and 5 hours, respectively. The drying rate for 40 °C showed the lowest value (0.4405 g water g-1 dry matter/ min) for the first hour, while the drying rate for 50, 60, and 70 °C were 0.6358, 0.7087 and 1.0429 g water g-1 dry matter/ min, respectively. The Page model was selected as the most fitted drying model for 40, 50, and 60 °C, while the Newton model was selected for 70 °C based on the values of chi-square and root means square error. Drying could cause some colour and nutrients effects on the products, thus modeling is essential to predict the drying process of the sample.

Received | February 22, 2024; Accepted | August 06, 2024; Published | October 07, 2024

*Correspondence | Norlia Muhamad, Faculty of Bioresources and Food Industry, Universiti Sultan Zainal Abidin, Besut Campus, 22200 Besut, Terengganu; Emai: [email protected]

Citation | Azman, C.K.N.A.M.C.K. and N. Muhamad. 2024. Thermal degradation kinetics of immature Melon Manis Terengganu (MMT) heated by a convective hot air dryer. Sarhad Journal of Agriculture, 40(Special issue 1): 61-68.

DOI | https://dx.doi.org/10.17582/journal.sja/2024/40/s1.61.68

Keywords | Degradation kinetics, Drying, Effective moisture diffusivity, Modeling, Melon Manis Terengganu

Copyright: 2024 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Melon Manis Terengganu (MMT) is a very popular fruit in Terengganu as the taste is sweet, crunchy, juicy, pleasant flavour, and contains many nutrients. MMT (Cucumis melo var. Inodorus cv.) is one of the fruits whose consumption has increased over the past years as it contains high vitamins and minerals with some benefits including lessening the chances of cancer, improved the strength of the immune system and healthful skin and eyes (Muhamad et al., 2019). MMT is a species from the Cucurbitaceae family, including watermelon, cucumber, pumpkin, and squash. Compared to others, MMT has smooth yellow-golden skin, flawless and unnetted skin, and orange-coloured flesh (Fauzie-Jusoh et al., 2022; Muhamad et al., 2018). There are three major parts of this melon which are pulp, peel, and seeds. In addition, this MMT took around 60 days to produce a very good and nutritious melon. During the cultivation, there is a stage called pruning process where around three or four immature MMT on the same tendrils will be removed. The purpose of this stage is to make sure only one melon on that tendrils will get full nutrients. The pruning process is a process of removing unwanted tendrils or branches to encourage their growth and make sure there is no competition between the melons. Thus, it could provide a high-quality MMT. The removal of unwanted items could increase the total waste of the agricultural sector.

To reduce the amount of waste, the preservations are applied in order to transform that item into something beneficial. The drying process is the favored preservation methods that was used to preserve and extend life span of the fruits. The drying process could increase the life span of the products and decrease the growth and reproduction of the microorganisms as the amount of moisture in that product is low. The drying process would vary the uses, making it possible to be in flour forms and utilize it in baked products (Leite et al., 2023). However, using high temperatures able to remove or decrease the nutritional values inside the fruits, which leads to thermal degradation. The traditional method of drying that has been used by people is sun drying, which is not very practical due to the long time it takes, hygiene issues, poor quality of product with microbial growth, and low capability of the process (Naderinezhad et al., 2016). However, sun drying is advantageous to cost, as no energy is required except sunlight. Nowadays, new technologies have been developed to make our life easier. Examples of the methods of drying are hot air drying (Abraham-Juárez et al., 2019), freeze drying (Morais et al., 2017; Ong et al., 2021; Sroy et al., 2022), foam mat drying (Sanwiriya and Suleiman, 2019) and vacuum drying (Sramek et al., 2015).

Hot air drying is very convenient for small and medium enterprises as it will invest low cost in equipment, resulting in high efficiency in the process (Yang et al., 2018). It also can generate passive income for the farmer as most factories in Malaysia use oven dryers to dry their product. However, the quality and nutritional properties of the dried products could be degraded if inappropriate processes or temperatures are used. Thus, the selection of a suitable temperature is needed in order to produce a very good end product. According to Parikh (2015), vacuum drying is a favor to dry faster than other drying methods. It also results in less damage to the end product because vacuum drying functions to keep the actual product without damaging it with heat. Foam mat drying is a simple process that can dry a sample in the form of liquid, semi-solid, or solid. According to Sanwiriya and Suleiman (2019), this drying method works by converting the liquid inside the sample into a stable foam with additional gas and foaming agents. After that, the sample will be dried using hot air to form a powder state. This foam mat drying method is cheaper than freeze drying and spray drying and also able to create a higher quality product with a low browning effect, and nutrient content could be preserved. Freeze drying, also known as lyophilisation process, has an advantage in terms of transportation. It is more convenient for workers to transport it as the weight of the product is reduced. This method reduces around 98% of the water content in the sample. Parikh (2015) demonstrated that freeze-drying works by freezing the sample while reducing the surrounding pressure, and then it will sublimate directly the frozen water into the gas form. Different methods of drying have their own specialty based on the efficiency of the equipment’s performance.

However, Inyang et al. (2018) stated that understanding the fundamental transport mechanism and successfully simulating or scaling up the entire process for optimization or control of the operational conditions requires mathematical modeling. Mathematical modeling is very crucial in drying activities as it can predict the movement of the moisture inside the sample at different temperatures. Kinetics modeling is a useful approach to design and optimize thermal processes to maximise the quality of the final products (Adetoro et al., 2020). Chang et al. (2022) stated that drying kinetics is very practical for the optimization of process parameters, product quality improvement, and heat and mass transfer in the drying process. According to Siqueira et al. (2020), the information from mathematical models is possible to estimate the drying time and the expenditure of energy, which could lead to control the process costing. Table 1 depicts some of the list of mathematical models that were used for the drying process.

Table 1: The list of mathematical models for drying process.

|

Model |

Model designation |

References |

|

Lewis model |

MR= exp(-kt) |

Adetoro et al. (2020) |

|

Henderson and Pabis model |

MR= a. exp(-kt) |

Adetoro et al. (2020) |

|

Logarithmic model |

MR= a. exp(-kt)+c |

Adetoro et al. (2020) |

|

Page model |

MR= exp(-ktn) |

Adetoro et al. (2020) |

|

Wang and Singh model |

MR= 1+at+bt2 |

Adetoro et al. (2020) |

|

Modified page model |

MR= exp(-kt)n |

Adetoro et al. (2020) |

|

Midilli et al. model |

MR= a. exp(-ktn)+bt |

Adetoro et al. (2020) |

|

Approximation of diffusion model |

MR= a. exp(-kt)+(1-a).exp (-kbt) |

De Farias Leite et al. (2023) |

|

Two-terms model |

MR= a. exp(-k0t)+ b.exp (-k1t) |

De Farias Leite et al. (2023) |

|

Thompsom model |

MR= exp -a-(a2+4bt)0.5/2b |

Siqueira et al. (2020) |

|

Valcam model |

MR= a+bt+ct1.5+dt2 |

Siqueira et al. (2020) |

Where MR is moisture ratio, t is time, and k, a, c, n, b and d are parameters.

Thus, this study aimed to determine the drying kinetics of dried MMT at different temperatures (40, 50, 60, and 70 °C). Other than that, to calculate the effective moisture diffusivity of dried MMT and to find out the most fitted models that describe the drying curve of the dried MMT.

Materials and Methods

Sample preparation

The immature MMT was collected from Ladang Tanaman Melon, Universiti Sultan Zainal Abidin (UniSZA) in Besut, Terengganu. The samples were selected based on similar °Brix or total soluble solids, which were 4-6 °Brix. The samples were kept at room temperature until further use.

Drying procedure

The drying process followed the methodology by Kamaruzaman et al. (2022) with some modifications. Firstly, the 100 g of samples were washed and sliced into 0.2 cm of thickness using the food slicer. The sliced samples were dipped into 0.2% sodium metabisulphite for 15 minutes. After that, the samples were drained for another 15 minutes before drying. The samples were dried using a convective hot air dryer (Memmert) at four different temperatures; 40, 50, 60, and 70 °C. The samples were weighed every one hour until they reached constant weight or equilibrium conditions. All the drying temperatures were done in triplicates.

Calculation for the drying process of immature MMT

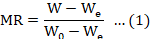

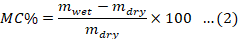

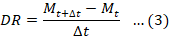

The moisture ratio (MR), moisture content (MC) and drying rate (DR) of this analysis were calculated according to the following equations:

Where; W is the moisture content at a time, t, We is equilibrium moisture content and W0 is the initial moisture content.

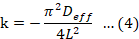

While, the effective moisture diffusivity (Deff) was calculated based on this equation:

Where k is the value of slope taken from the drying curve graph and L is the half thickness of the sample (in m).

Mathematical modelling of drying curves

The experimental data were fitted to five drying models stated by Adetoro et al. (2020) as following:

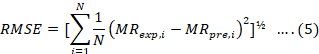

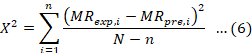

MR is moisture ratio, t is time, and k, n, a, b, k1 and k2 are parameters. All the parameters were calculated using ‘Solver’ in Microsoft Office Excel. However, Root Means Square Error (RSME) and chi-square (X²) were also calculated to choose the most fitted mathematical model to report the drying curve of the dried MMT. The formula for RMSE and X² are as follows:

Where MRexp is the moisture ratio of experimental data, MRpre is the moisture ratio of predicted data (mathematical models).

Results and Discussion

Effects of different temperatures on drying process of immature MMT

The relationship between drying rate versus time at different temperatures of 40, 50, 60, and 70 °C has been plotted in Figure 1. From the graph, the drying rate for 40 °C showed the lowest value (0.4405 g water g-¹ dry matter/ min) for the first hour, while the drying rates for 50, 60, and 70 °C were 0.6358, 0.7087, and 1.0429 g water g-¹ dry matter/ min, respectively. The drying rate for four experimental temperatures decreases as time increased. A similar experimental finding was found by da Silva et al. (2020) where the drying period of their sample decreases as the temperature increased. They claimed that was due to the increasing in pressure gradient between the interior of the sample (leaf) and the surrounding air. The finding was studied about the bitter melon (Momordica charantia) leaves that were subjected to dry in an oven at 20, 30, 40, and 50°C. From the graph, there are no constant drying rate periods that occur during the drying process of immature MMT. All of the temperatures started to dry at the falling rate periods. However, the removal of moisture in other samples probably occurred during constant and falling rate periods or falling rate periods only. Adetoro et al. (2020) and Yang et al. (2018) stated that their samples (pomegranate arils and bitter melon slices) also started at falling rate periods. Based on a previous study by Muhamad et al. (2019), as the drying time increases, the drying rates will decrease due to the diffusion-controlled process by moisture movement during drying times. The graph in Figure 1 confirms the previous statement that at any temperature, the drying rates increased as time increased. During the drying process, the case hardening of the surface of samples could occur when the free movement of the moisture resists (Zhao et al., 2014).

The drying time for 40, 50, 60, and 70 °C were 9, 6, 5, and 4 hours, respectively. The data from the last 1 hour in the graph was collected to ensure the final weight of the sample was consistent. The drying time for the drying process was affected by temperatures. From the graph, the drying times increase as temperature decreases. da Silva et al. (2020) explained that the changes in the pressure gradient between the core of the samples and the drying air suggest a faster drop in water content. Thus, a shorter time is adequate to dry samples during high temperatures. The moisture content in the food is an indicator of its water activity and a measurement of its stability and susceptibility to microbial infection (Mamman et al., 2022). Therefore, a low amount of moisture content in the food shows decreased and longer time in the microbial infection process.

Table 2: Mathematical models and equations.

|

Model |

Formula |

|

Newton model |

MR= exp(-kt) |

|

Page model |

MR=exp(-kt^n) |

|

Henderson and Pabis model |

MR=a exp (-kt) |

|

Midilli et al. model |

MR=a exp (-kt^n) + bt |

|

Two-term exponential model |

MR= a exp (-k1t)+ b exp (-k2t) |

Effective moisture diffusivity (Deff) of different temperatures

The calculated values of effective moisture diffusivity Deff and slope (k) for each temperature are shown in Table 2. The values of Deff were influenced by the value of slope that was obtained from the graph of drying rate versus time. The values of slope decreased and Deff increased as the temperature increase. At 70 °C, the value of Deff was higher (1.1141 x10-7 m²/s) than temperatures of 40, 50 and 60 °C, which are 2.2129 x10-⁶, 4.8148 x10-⁶ and 6.6264 x10-⁶ m²/s, respectively. The high temperature would lead to greater Deff. Chang et al. (2022) reported that the increase of Deff was definitely due to the transferred moisture molecules inside the cantaloupe slices to the surface of the materials for the evaporation process at higher temperatures.

Chang et al. (2022) have calculated the values of Deff for that cantaloupe slices at 55, 60 and 65 °C were 1.10x10-⁹, 1.64 x 10-⁹, 2.09x10-⁹ m²/s, respectively. This showed that the trend of their result is similar to this present work as the values of Deff are increased as the temperature increases. Another research by Macedo et al. (2020) showed the same trend as the values of Deff for 80 °C is 3.538 x 10-⁹, higher than 60 and 40 °C, which are 1.727 x 10-⁹ and 0.584 x 10-⁹, respectively.

Mathematical modeling of dried immature MMT

The drying data were subjected to five mathematical modelings: Newton, Page, Henderson, and Pabis, Midilli and two- term exponential model. Tables 4 and 5 shows the result of RMSE and X². Page model was chosen as the most fitted drying model for temperatures of 40, 50, and 60 °C. However, Newton model was chosen as the most fitted at 70 °C. The chosen models were selected according to the smallest values of root means square error (RMSE) and chi-square (X²) and nearer to zero. This can be seen on the Tables 4 and 5. Table 6 shows the values of parameters for Newton, Page, Henderson, and Pabis, Midilli, and Two- Term exponential model.

Table 3: The values of k and Deff for each temperature.

|

Temperature (°C) |

Slope (k) |

Deff (m²/s) |

|

40 |

-0.0546 |

2.2129 x10-⁶ |

|

50 |

-0.1188 |

4.8148 x10-⁶ |

|

60 |

-0.1635 |

6.6264 x10-⁶ |

|

70 |

-0.2749 |

1.1141 x10-7 |

Table 4: The values of root means square error for each model.

|

Model |

40 °C |

50 °C |

60 °C |

70 °C |

|

Newton model |

0.0546 |

0.0517 |

0.0593 |

0.0000 |

|

Page model |

0.0192 |

0.0117 |

0.0069 |

0.0473 |

|

Henderson and Pabis model |

0.0356 |

0.0228 |

0.0162 |

0.0043 |

|

Midilli et al. model |

0.0387 |

0.0203 |

0.0100 |

0.0025 |

|

Two-term exponential |

0.0356 |

0.0228 |

0.0162 |

0.0043 |

|

model |

Table 5: The values of the chi-square for each model.

|

Model |

40 °C |

50 °C |

60 °C |

70 °C |

|

Newton model |

0.0030 |

0.0027 |

0.0035 |

0.0000 |

|

Page model |

0.0004 |

0.0001 |

0.0000 |

0.0022 |

|

Henderson and Pabis model |

0.0013 |

0.0005 |

0.0003 |

0.0000 |

|

Midilli et. al model |

0.0015 |

0.0004 |

0.0001 |

0.0000 |

|

Two-term exponential model |

0.0013 |

0.0005 |

0.0003 |

0.0000 |

Table 6: The values of parameters for each model.

|

Model/ Parameter |

40 °C |

50 °C |

60 °C |

70 °C |

|

Newton model |

||||

|

k Page model |

0.3750 |

0.5941 |

0.7281 |

1.0000 |

|

k |

0.2304 |

0.4257 |

0.5233 |

1.0061 |

|

n Henderson and Pabis model |

1.4044 |

1.4424 |

1.6049 |

1.0061 |

|

a |

1.2564 |

1.4539 |

1.8448 |

2.8254 |

|

k midilli et al model |

0.4566 |

0.8001 |

1.1355 |

1.8779 |

|

a |

1.3686 |

1.3237 |

1.0694 |

1.2693 |

|

k |

0.5244 |

0.6980 |

0.6079 |

1.0778 |

|

n |

0.9428 |

1.1024 |

1.4435 |

1.4449 |

|

b |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

|

Two-term model |

||||

|

a |

0.6282 |

0.7269 |

0.9224 |

1.4127 |

|

k1 |

0.4566 |

0.8001 |

1.1355 |

1.8779 |

|

b |

0.6282 |

0.7269 |

0.9224 |

1.4127 |

|

k2 |

0.4566 |

0.8001 |

1.1355 |

1.8779 |

From the data above, the value of RMSE and X² for the page model at 40, 50, and 60 °C were nearer to zero than other drying models. For immature MMT, the lowest values of RMSE for the Page model at 40, 50, and 60 °C were 0.0192, 0.0117, and 0.0069, while at 70 °C was 0.0000 by the Newton model. The X² values observed in the Page model for temperatures 40, 50, and 60 °C were 0.0004, 0.0001, and 0.0000, which is the lowest compared to the Newton model, Henderson and Pabis model, Midilli model, and two-term exponential model. Similar results was reported by Adetoro et al. (2020) and Yang et al. (2018), where the page model is also suitable for predicting their samples, which are pomegranate and. However, different sample used by Adetoro et al. (2020) also reported the same result as above, where the page model is suitable for predicting their pomegranate samples. Besides, a study by Macedo et al. (2020) found that the Midilli model was suitable to describe their banana samples. The fitted model was selected differently for each sample and drying method according to the values of RMSE and X². The mathematical modeling was conducted to investigate the appropriate drying model that is suitable and as a prediction of the drying process (Adetoro et al., 2020). Figures 2, 3, 4, and 5 show the experimental and predicted data (model) for 40, 50, 60 and 70 °C.

Figures 2 to 4 show the relationship of moisture ratio between experimental data and the Page model, while Figure 5 shows the relationship between experimental data and the Newton model. The graphs displayed that the experimental data was not significantly different from the model. Thus, the Page model and Newton model were chosen as they fitted to the drying data at 40, 50, 60, and 70 °C.

A comparison of mathematical models by da Silva et al. (2020) was conducted for drying kinetics of bitter melon. It was found that the Midilli et al model and Page model were the most fitted models that describe the drying kinetics at four different temperatures (20, 30, 40, and 50 °C) of dried bitter melon. Another research by Stephenie et al. (2021) studied the drying kinetics of melon seeds and fluted pumpkin seeds. From this research, the Logarithmic model was selected as the most suitable mathematical model compared to Newton model and Henderson and Pabis model, which describes better the thin layer slices of seeds based on the highest values of R². Leite et al. (2023) conducted a study on the mathematical modeling of citron watermelon seeds. The watermelon was harvested in a ripe state, washed, and then the seeds were separated with the flesh before starting the drying process. The seeds were dried at four different temperatures of 50, 60, 70, and 80℃ in a convective dryer. From the results, the two-terms model and approximation of diffusion model showed excellent descriptions of the drying kinetics of citron watermelon seeds, followed by the Midilli model and Page model. The two-terms model has the highest coefficients of determination (R2 > 0.9991), sharing with the approximation of the diffusion model the lowest mean squared deviations (MSD) and chi-square (X²), resulting in almost equivalent fitting parameters.

Conclusions and Recommendations

In conclusion, the thermal degradation of immature MMT has been investigated. High temperature would lead to high moisture loss during the first hour and shorter drying time. Deff values were also affected by the temperature. The high temperature would increase the values of the Deff. However, the drying process could cause some effects on the products, thus modeling is essential to predict the drying process of the sample. Page model was chosen as the most fitted to describe the drying characteristics at 40, 50, and 60 °C, while the Newton model was chosen for 70 °C.

Acknowledgments

This research was supported by the Ministry of Higher Education (MOHE) through the Fundamental Research Grant Scheme (FRGS/1/2021/TK0/UNISZA/02/1).

Novelty Statement

The current research work investigates the thermal degradation kinetics of the dried immature Melon Manis Terengganu which will pave the way towards developing a processing method for immature Melon Manis Terengganu that can preserve its nutritional properties from thermal degradation to produce a high-quality product.

Author’s Contribution

Che Ku Nur Ain Mardhiah Che Ku Azman and Norlia Muhamad: Designed the study.

Che Ku Nur Ain Mardhiah Che Ku Azman: Performed the experiments and collected the data. All the authors read and approved the final manuscript.

Conflict of interest

The authors have declared no conflict of interest.

References

Abraham-Juárez, M.D.R., V. Olalde-Portugal, A. Cerón-García and M.E. Sosa-morales. 2019. Hot air drying kinetics of thin layers of prickly pear fruit paste. Sains Malaysiana, 48(2): 361–367. https://doi.org/10.17576/jsm-2019-4802-13

Adetoro, A.O., A.A. Tsige and U.L. Opara. 2020. Mathematical modelling of blanch-assisted drying. Processes, 8(5): 611-629. https://doi.org/10.3390/pr8050611

Chang, A., X. Zheng, H. Xiao, X. Yao, D. Liu, X. Li and Y. Li. 2022. Short-and medium-wave infrared drying of cantaloupe (Cucumis melon L.) slices: Drying kinetics and process parameter optimization. Processes, 10(1): 114-132. https://doi.org/10.3390/pr10010114

da Silva, D.P., S.G.F. Dos Santos, I.L. Silva, H.W. da Silva and R.S. Rodovalho. 2020. Drying kinetics and thermodynamic properties of bitter melon (Momordica charantia L.) leaves. Rev. Brasil. Engenh. Agricol. Ambient., 24(10): 707–712. https://doi.org/10.1590/1807-1929/agriambi.v24n10p707-712

Fauzie Jusoh, M., H. Sa’adiah, T. Abu Bakar, F.A. Abdullah, M. Khairul, H. Maidin, M. Firdaus and A. Muttalib. 2022. A scoping review of melon Manis Terengganu research perspective in Malaysia. https://doi.org/10.37231/jab.2022.13.2.294

Inyang, U.E., I.O. Oboh and B.R. Etuk. 2018. Kinetic models for drying techniques food materials. Adv. Chem. Eng. Sci., 8(2): 27–48. https://doi.org/10.4236/aces.2018.82003

Kamaruzaman, S.H., C.K.N.A.M. Che Ku Azman and N. Muhamad. 2022. Effect of drying temperatures on the functional properties and mineral content of immature Manis Terengganu melon. J. Biosci. Res., 19(SI-1): 295-301.

Leite, D.D.F., R.M.F. De Figueirêdo, A.J. De Melo Queiroz, L.S.L. Lima, Y.F. Paiva, D. Da Costa Santos, S.D.N. Silva, R.D.S. Silva and C.C. Costa. 2023. Citron melon peel flours: Drying kinetics and physicochemical evaluation. Notulae Botanicae Hortic. Agrobotanici Cluj-Napoca, 51(1): 12833. https://doi.org/10.15835/nbha51112833

Macedo, L.L., W.C. Vimercati, C. da Silva Araújo, S.H. Saraiva and L.J.Q. Teixeira. 2020. Effect of drying air temperature on drying kinetics and physicochemical characteristics of dried banana. J. Food Process Eng., 43(9): 1–10. https://doi.org/10.1111/jfpe.13451

Mamman, S., O.S. Musa, A.C. Sadiq, U. Saidu and O. Daniel. 2022. Proximate and elemental analysis of dried watermelon (Citrullus lanatus) seeds.

Morais, D.R., E.M. Rotta, S.C. Sargi, E.G. Bonafe, R.M. Suzuki, N.E. Souza, M. Matsushita and J.V. Visentainer. 2017. Proximate composition, mineral contents and fatty acid composition of the different parts and dried peels of tropical fruits cultivated in Brazil. J. Braz. Chem. Soc., 28(2): 308–318. https://doi.org/10.5935/0103-5053.20160178

Muhamad, N., N. Adillah and M. Redzuan. 2019. Effects of drying methods on the quality parameters of dried Manis Terengganu Melon (Cucumis melo). J. Agrobiotechnol., 10(101): 46–58.

Muhamad, N.W.S. and H.L. Hoon. 2018. Effect of drying temperatures and extraction solvents on total phenolic, flavonoid contents and antioxidant properties of immature Manis Terengganu Melon (Cucumis melo). J. Agrobiotechnol., 9(1S): 114–121.

Naderinezhad, S., N. Etesami, A.P. Najafabady and M.G. Falavarjani. 2016. Mathematical modeling of drying of potato slices in a forced convective dryer based on important parameters. Food Sci. Nutr., 4(1): 110–118. https://doi.org/10.1002/fsn3.258

Ong, Y.Q., S. Harith, M.R. Shahril, N. Shahidan and H. Hapidin. 2021. Polyphenolic profile and antioxidant activities of freeze-dried Melon Manis Terengganu peel extracts. Malays. Appl. Biol., 50(1): 181–188. https://doi.org/10.55230/mabjournal.v50i1.1506

Parikh, D.M., 2015. Vacuum drying: Basics and application. Chem. Eng. (United States), 122(4): 48–54.

Sanwiriya, P. and N. Suleiman. 2019. The effects of drying method and temperature on the nutritional quality of watermelon rinds. Int. Food Res. J., 26(3): 953– 958.

Siqueira, V.C., G.A. Mabasso, W.D. Quequeto, C.R. Da Silva, E.A.S. Martins and E.P. Isquierdo. 2020. Drying kinetics and effective diffusion of watermelon seeds. Res. Soc. Dev., 9(4): e16942887. https://doi.org/10.33448/rsd-v9i4.2887

Sramek, M., R.M. Schweiggert, A.V. Kampen, R. Carle and R. Kohlus. 2015. Preparation of high-grade powders from tomato paste using a vacuum foam drying method. J. Food Sci., 80(8): E1755–E1762. https://doi.org/10.1111/1750-3841.12965

Sroy, S., F.A. Miller, J.F. Fundo, C.L.M. Silva and T.R.S. Brandão. 2022. Freeze-drying processes applied to melon peel: Assessment of physicochemical attributes and intrinsic microflora survival during storage. Foods, 11(10): 1499. https://doi.org/10.3390/foods11101499

Stephenie, A.U., E.I. Obiora-Okafo and N.J. Nnamdi. 2021. Determination of drying characteristics of local seeds (melon and fluted pumpkin seeds): Drying kinetics models. J. Multidiscip. Eng. Sci. Technol., 8: 13819-13826.

Yang, L., Z. Hu, L. Yang, S. Xie and M. Yang. 2018. Hot-air drying characteristics and quality evaluation of bitter melon slice. Inmateh. Agric. Eng., 55(2): 53–62.

Zhao, D., K. An, S. Ding, L. Liu and Z. Xu. 2014. Two-stage intermittent microwave coupled with hot-air drying of carrot slices: Drying kinetics and physical quality. Food Bioproc. Technol., 7(8): 2308-2318. https://doi.org/10.1007/s11947-014-1274-1

To share on other social networks, click on any share button. What are these?