Ranking of Internet of Things (IOT) Applications in Dairy Cattle Industry Productivity: A Multi Criteria Decision Making Approach and Thematic Analysis

Ranking of Internet of Things (IOT) Applications in Dairy Cattle Industry Productivity: A Multi Criteria Decision Making Approach and Thematic Analysis

Sumei Zeng and Yong Zhang*

Key Laboratory of Animal Genetics, Breeding and Reproduction in the Plateau Mountainous Region, Ministry of Education, Guizhou University, Guiyang, 550025, China

Guizhou Provincial Key Laboratory of Animal Genetics, Breeding and Reproduction, Guizhou University, Guiyang, 550025, China

College of Animal Science, Guizhou University, Guiyang 550025, China

ABSTRACT

Experiences in different countries show that applying technical and advanced knowledge in the production sectors is the basis of growth and development in the agricultural sector. The advent of Internet of Things (IOT) as an emerging digital technology has led to a new direction of innovative research in the field of animal husbandry. IOT technology has a variety of applications in the economic productivity of the livestock and poultry industry. The purpose of this study is to identify and rank IOT applications in dairy cattle industry productivity with a multi-criteria decision making approach and using the Complex Proportional Assessment (COPRAS) method. Evaluation indicators were selected by theme analysis method based on the opinion of managers working in industries that are using IOT. The research method is applied in terms of purpose and is descriptive in terms of data collection tools. The results showed that Detection of Insemination Time (DIT) and Early Detection of Diseases (EDD) applications are more important, respectively.

Article Information

Received 21 May 2022

Revised 29 May 2022

Accepted 07 June 2022

Available online 25 November 2022

(early access)

Published 28 July 2023

Authors’ Contribution

SZ collected the samples. SZ and YZ analysed the data. YZ conducted the experiments and analysed the results. Both authors discussed the results and wrote the manuscript.

Key words

Digital technologies, Animal husbandry, Cattle farms, COPRAS, Decision matrix

DOI: https://dx.doi.org/10.17582/journal.pjz/20220521050533

* Corresponding author: zym13711405338@126.com

0030-9923/2023/0005-2121 $ 9.00/0

Copyright 2023 by the authors. Licensee Zoological Society of Pakistan.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

INTRODUCTION

Productivity growth directly increases agricultural and animal husbandry income and indirectly increases production as well as food supply, which in turn reduces food prices, and as income increases in agriculture and animal husbandry, so does demand for non-agricultural goods and services, and this will increase employment in the non-agricultural sector. Hence, the whole society can benefit from productivity growth in the agricultural sector. On the other hand, declining per capita food production over several years can lead to a recession in an area, and if the government does not support increased production, the recession could worsen (Nkamleu, 2004).

One of the ways to achieve productivity growth resources in the field of agriculture and animal husbandry is to increase the use of new Information and Communication Technologies (ICT) as digital innovation (Walter et al., 2017; GeSI, 2016). The Internet of Things (IOT) paradigm as one of these new digital innovations has enabled objects to connect at any time and place by anything or anyone using a set of advanced and interconnected technologies such as mobile and wireless communication, Nano, radio wave detection and intelligent sensors (Biggs et al., 2016). The term was officially introduced by the International Telecommunication Union (ITU) in 2005 (Rayes and Salam, 2017) and was added to Gartner’s technology maturity cycle in 2011 as an emerging technology (Gartner, 2011). The growth of the number of devices in IOT was about 14 billion in 2014 and 50 billion in 2020 (Kocovic et al., 2017). It is therefore expected to generate significant economic and social benefits through cost savings, value creation, improved productivity and economic growth (Thierer and Castillo, 2015). There is no consensus among various industries on the number of vertical IOT markets (Rayes and Salam, 2017) and its applications are very diverse and numerous, so that today we can see its impact on all levels of daily life, including individuals, businesses and society (Vermesan and Friess, 2014a).

In general, Improvements in livestock nutrition and comfort can increase dairy cattle performance. However, there are still various factors such as disease, low diagnosis of insemination times and reproductive health problems that negatively affect the overall economic performance of the dairy cattle industry. These factors are reflected in reduced milk production, the premature elimination of potentially valuable cows, and long calving intervals, which will reduce the number of calves born by each cow (De Maturana et al., 2007). There are several challenges in cattle farm, some of which are high need for labor, failure to diagnose sick livestock and high treatment costs, production decline, existence of thermal stress, lack of accurate and timely identification of estrus livestock, lack of warning system and crisis identification in livestock, and sometimes theft of livestock.

Monitoring and response operations against the four main parameters, body temperature, mobility rate, number of ruminants, location of cows, can be used to improve disease status and increase reproductive performance and livestock safety. Timely detection and inoculation of estrus cows is one of the most important parameters to increase livestock fertility and is important for efficient production management (Walker et al., 1996). Automated activity monitoring systems are important tools for estrus detection (Fricke et al., 2014) and manufacturers who have installed these systems were satisfied with their performance (Michaelis et al., 2013). Misdiagnosis of estrus may lead to insemination of cows that are not estrus or to inseminate at a time when it is not conducive to pregnancy (Law et al., 2009). Another parameter is heat stress as one of the main problems in cow farms. Heat stress caused by hot environment is one of the main factors that has a negative effect on production, reproduction and health of dairy cows (Bernabucci et al., 2010). In a comprehensive study by Hansen (2007) the destructive effects of heat stress on oocyte growth and maturation, premature embryo death, and fetal or placental growth were explained. The next parameter is ruminant activity, which has been proposed as a reagent for the overall health of livestock (Paudyal et al., 2018). Ruminant measuring devices are now available and have been successfully validated, indicating a strong link between visual observations and data reported by the technology (Schirmann et al., 2009). Therefore, with low rumination, health of cows can be identified and disease can be identified in early stages. The next parameter is mobility rate such that estrus, health, moving speed and location of livestock can be tracked by monitoring livestock movement and prevented theft of livestock.

Therefore, it is necessary to have an intelligent system based on IOT technology in cattle farms so that information about body temperature, mobility rate, number of ruminants and location of cows can be sent to the processing center without interruption and online and the processing center can also provide the necessary solution for the cattle farmer to overcome the problem in order to improve the disease situation, increase reproductive performance and livestock safety. Availability of real-time data helps to search for estrus using mobility rate monitoring, monitor livestock health using number of ruminants and body temperature, prevent diseases, and timely identify and relieve heat stress that is highly damaging to livestock.

The present study focuses on IOT applications in dairy cattle industry productivity and IOT use in cattle farms, some of which will be explored in later sections of this article. Previous articles have investigated IOT applications in dairy cattle industry productivity on a variety of topics, but economically there is no article that identifies and ranks these applications in dairy cattle industry productivity. This is while the greatest impact of IOT on the animal husbandry sector emerges in the economic approach. Therefore, there is a need to examine this issue more closely. Given the dairy cattle industry’s need to use IOT, the present study focuses on that what are IOT applications in dairy cattle industry economically? This provides a complete economic perspective on IOT applications in dairy cattle industry productivity. Due to budget constraints and available resources, livestock and poultry industry farmers cannot implement all these applications in their livestock. Therefore, it is checked that: Which of these applications has a higher priority for implementation in the dairy cattle industry? What are the appropriate criteria for ranking these applications? and based on that, what are the most important applications? This helps cattle farmers to make better and more accurate decisions about using IOT in the dairy cattle industry.

The structure of this article is as follows: The second section examines the research background. In the third section, the research method is described. The implementation process of the complex proportional assessment (COPRAS) method and analyzing the data is described in the fourth section, and using this method, the applications are ranked. In this section, the ranking criteria are extracted based on the theme analysis method. The last section also summarizes and concludes.

Each object with IOT technology consists of 3 main layers (sections): measurement layer, network layer (data transfer), and application layer (data storage and use) (Miorandi et al., 2012).

Measurement layer deals with technologies such as radio-frequency identification (RFID), wireless sensor network (WSN) and near-field communication (NFC). RFID technology is the first and most primitive example of connecting objects to each other (Welbourne et al., 2009). This technology is a wireless identification system that can exchange data by transferring information between a label attached to a product, object, card, etc., and a reader devise. This system uses electronic and electromagnetic signals to read and write data without direct contact (Cardullo, 2003). This technology plays an important role in agriculture and animal husbandry; For example, this technology can be used to monitor agricultural and livestock products, food supply chain, track quality control and evaluate the life cycle of products (Welbourne et al., 2009). WSN consists of a large number of sensor nodes that are widely distributed in an environment and collect information. This network transmits information wirelessly. In addition to one or more sensors, each node in WSN is typically equipped with a radio transmitter and receiver (or any other wireless telecommunications device), a small monitor, and a power source (usually a battery). These networks, in addition to monitoring and control, are used in monitoring, identifying and tracking agricultural and livestock products (Welbourne et al., 2009). NFC is a wireless communication device between two adjacent devices that is used for short distances (maximum several centimeters). This is an alternative method of transferring information and files between two mobile devices using Bluetooth, which, unlike Bluetooth, does not require time to search for nearby devices and can be used simply by moving the second device closer. In this technology, QR-code information is exchanged between two devices (Tzounis et al., 2017).

Network layer is the ability to network in one of the main core of IOT devices. Just as the internet is an interface between humans, in IOT, inhuman beings and objects are interconnected. Wireless sensor nodes interact with physical objects or the environment, communicate with nearby nodes or ports and build networks to send data remotely for storage, analysis and knowledge generation (Gubbi et al., 2013). For wireless communications, there are conventions that make it easy to network devices. These conventions include: ZigBee, ONE-NET, Sigfox, Wireless HART, and ISA100.11a (Suhonen et al., 2012). In recent years, Bluetooth connectivity with low power consumption and Wi-Fi has also developed (Tzounis et al., 2017).

Application layer is the most important part of IOT. This layer can suggest the most appropriate action to a user or send the most appropriate signal to an operator and start or stop it. In fact, it is the most external layer that a user can interact with; such as software or applications installed on a smartphone that the user can use to monitor or manage an IOT system. For example, a farmer can remotely set up an irrigation system on her farm or turn on frost control systems. In the future agriculture, IOT can connect many devices such as sensors, machines, weather stations, data storage devices, RFID scanners, smartphones, tablets, and more. Big data is created due to the instantaneous production of millions of data. Due to the high volume of big data, today only cloud spaces due to their unlimited capacity can store all this information. In the modern future scenario, the stored data will be analyzed and corrected online, and systems based on artificial intelligence will be used to extract knowledge from the information collected from objects (Sawant et al., 2014).

IOT can affect the entire dairy cattle industry. First, it can increase dairy cattle industry productivity; Second, it can use resources effectively; Third, it can make management process visible to improve information transparency in dairy cattle industry; Fourth, it can manage dairy cattle industry in real time; and finally, it can make management process completely agile and integrated. IOT affects dairy cattle industry productivity in husbandry sector. In husbandry sector, IOT is used not only to monitor and control dairy cattle but also to monitor and control the environment of these cattle. This technology has even been used to monitor livestock grazing farms (Fig. 1, Bhargava et al., 2015). Wireless sensors are also used to track animals and analyze their behavior (Huircan et al., 2010; Kwong et al., 2012; Asikainen et al., 2013) and to monitor odors and hazardous gases (Nadimi et al., 2012; Mamduh et al., 2012). Figure 1 shows an example of an IOT system in open-air livestock farming.

Many articles on the subject have dealt with IOT technical issues in dairy cattle industry. For example, Dieng et al. (2017) in their research discussed cattle rustling in the African region and utilizing IOT system to prevent it. They provided a prototype in this area and tried to identify abnormal situation in herd using IOT. Research has also been conducted on development of an IOT platform as a real-team monitoring system for voluntary weighing of cattle (Mirmanov et al., 2021). The researchers used a custom data processing algorithm in the system. Their results showed that IOT platform provided for livestock farmers is useful as a control tool. Benhai et al. (2015) in a scientometric survey reviewed research on IOT and livestock management. They discussed the extent of IOT knowledge development in livestock management and studied the process of developing research in this field. This research showed that from 2012 onwards there is a significant increase in the development of IOT knowledge in livestock management debate.

According to the mentioned studies, IOT can provide various services to dairy cattle industry and livestock farms. Taking advantage of these opportunities offered by IOT in livestock farms requires accurate identification of its applications in dairy cattle industry. To rank the applications, we need criteria based on which we can distinguish between the applications. Expert opinions are used to identify the criteria. Experts, given the current state of the technology as well as familiarity with dairy cattle industry in China, can provide more detailed opinions in this area, which helps to look at this issue from a localization perspective. However, the purpose of this article is not to localize the applications. Therefore, the main gap in the research is the lack of an approach to identify the priorities of IOT in dairy cattle industry productivity, which is addressed in this article. To analyze the opinions of experts, thematic analysis as well as the COPRAS method are used, which are described in detail in the following sections.

MATERIALS AND METHODS

Considering that this research is an applied research and the purpose of this research is to rank IOT applications in dairy cattle industry productivity, first the effective criteria for ranking IOT applications in dairy cattle industry productivity have been selected as measurement and ranking criteria. These criteria were extracted by experts from the China Information and Communication Technology Association, livestock and poultry operators using IOT, and the use of a theme analysis approach. This approach and its implementation method are described in the next section. After identifying some of these criteria based on the articles and sharing it with experts and obtaining their opinions, thematic analysis approach was used for framing. The most important of IOT applications in dairy cattle industry productivity were also identified. These cases were based on articles.

The mentioned applications were extracted by reviewing various articles on IOT applications in dairy cattle industry productivity, and the experts were asked to add below the questionnaire if they know of another application in addition to the above, but no new case was added. Then, using a questionnaire design, the score of each application was collected by the experts based on each criterion, and finally, using the COPRAS technique, the applications were ranked. In this study, the statistical population is composed of experts from the China Information and Communication Technology Association and livestock and poultry operators who are using IOT. The data used in this study were collected in 2021 through a questionnaire with 5 multiple choice questions based on the Likert scale. The collected data were analyzed using the COPRAS method and finally the priority of each application was determined. The COPRAS method has been used in various articles, which shows the importance of this method among multi-criteria decision making methods (Liou et al., 2016; Roy et al., 2019). Also, given that IOT is a new field, so it is necessary to make decisions with controlled risk in this area that the COPRAS method tries to reduce the decision risk using the comparative advantage measurement method. For this reason, this method was used to control the risk of decision making. The COPRAS method is described below.

The COPRAS method is one of the compromise methods that was first introduced in 1994 by (Zavadskas et al., 1994). Although about two decades have passed since the introduction of this method, but the use of this method has gone through an upward trend and is used in all scientific disciplines (Ayrim et al., 2018). The advantage of this method over other methods is the simplicity of the steps, considering all data of one criterion and the separation of positive and negative criteria. In this method, different options are evaluated independently in terms of multiple criteria (not pairwise comparison) and ranked based on purpose. In this paper, the options are the same as IOT applications in dairy cattle industry and the criteria are identified based on expert opinion and thematic analysis. The COPRAS method process is as follows:

Step 1: Identify the options for prioritizing between them; the number of these options is assumed m. In this article, at this stage we use the existing articles and as mentioned our options in this article are the same applications identified.

Step 2: Find the most important criteria for decision makers to distinguish between the options; their number is assumed n. In this article, at this stage we will use the expert opinions and thematic analysis, which are described in detail in the next section. Twenty-five experts participated in this section.

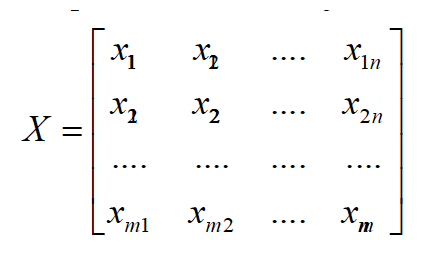

Step 3: Create an X decision matrix based on information obtained in the previous steps and expert’s opinions; this matrix is as follows, where xij is the value of the i-th option based on the j-th criterion.

Step 4: Integrate the decision matrices obtained from the opinions of various experts; To aggregate and obtain the final decision matrix, geometric mean is used in matrices elements obtained from the opinions of different decision makers. There is no need to do this step if there is only one decision maker.

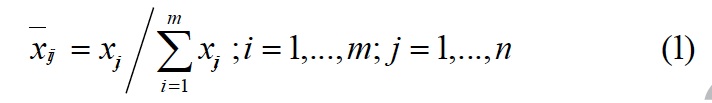

Step 5: Normalize the decision matrix; Equation 1 is used to normalize the decision matrix:

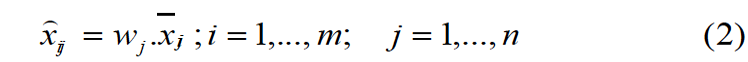

Step 6: Calculate the balanced decision matrix; To calculate this matrix, Equation 2 is used, in which wj is the weight and significance of the j-th criterion.

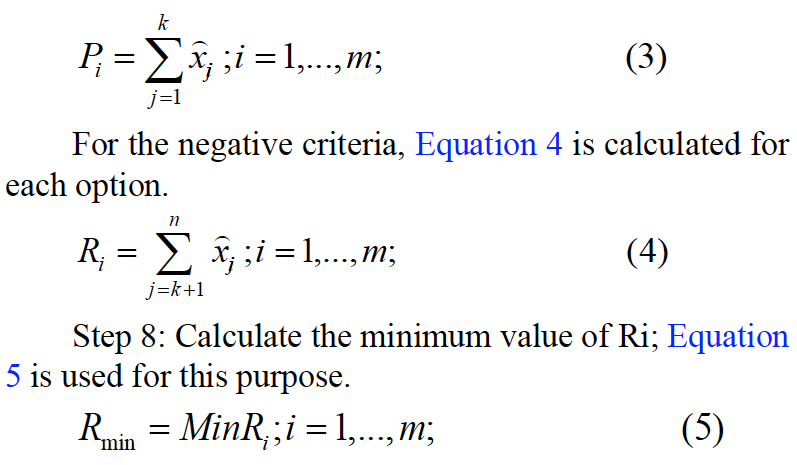

Step 7: Calculate the values of each option according to the positive and negative criteria; given that the criteria are different from each other, some are desirable when they take more (such as profit, income, etc.), and some are desirable when they take less (such as cost, risk, etc.). The first category of criteria is called positive criteria and the second category of criteria is called negative criteria. Suppose the first k criteria are positive and the rest are negative. For the positive criteria, Equation 3 is calculated for each option.

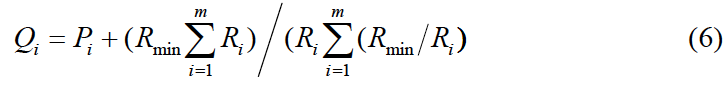

Step 9: Calculate the relative importance of each option; the relative importance of each option is given by Equation 6.

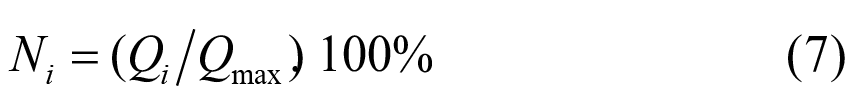

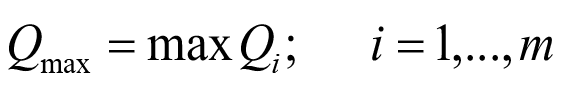

Step 10: Rank the options based on the value obtained in the previous step; The option with a higher Qi value is a better option. Equation 7 can be used to calculate and obtain the degree of desirability of each option.

Where;

The next section describes the implementation process of the selected method (COPRAS) and describes in detail the steps used to priority IOT applications in dairy cattle industry productivity.

RESULTS AND DISCUSSION

In this part of the present study, implementing the important steps of the COPRAS method is described and at the end, an analysis of the results is presented.

Step 1: Identification of IOT applications in dairy cattle industry productivity

At IOT conference, Vannieuwenborg et al. (2017) published the results of their research on design and evaluation of an intelligent cattle monitoring system from an economic and technical perspective. In this study, the researchers described a system design method based on IOT technology. Economic and strategic issues were also considered in this system. The project focuses on four different applications that affect the overall economic performance of dairy cattle, including: Early diagnosis of diseases, detection of insemination time, prediction of calving time, and location and identification of dairy cattle.

Early diagnosis of diseases (EDD)

EDD in cattle farm is very important. Various common diseases of dairy cattle such as mastitis, lameness, ketosis and metritis account for a large share of economic losses of livestock farms due to the prevalence of the disease itself as well as their direct effect on milk production and elimination rates of livestock. Other costs imposed by these diseases include: removal of milk due to drug residues, veterinary and pharmaceutical costs as well as additional labor costs. In addition, these diseases affect the fertility rate of livestock, which can lead to fewer calves and therefore longer calving intervals. Monitoring physiological or behavioral parameters such as temperature, activity level obtained from livestock velocity and position data helps in automated analysis and interpretation of these data. Precision dairy-monitoring technologies (PDMT) can be useful in diagnosing disorders at the level of a cow (Helwatkar et al., 2014). Examples of disease indicators include behavioral changes, fever, lower activity levels, less drinking water, and changes in ruminant behavior. Since the PDMT system does not provide any biochemical confirmation for the disease, the system will not be able to determine exactly what disease the cow is suffering from.

Detection of insemination time (DIT)

Estrus diagnosis is key to proper reproductive function because it directly affects the total number of calves born per year and total milk production. Detecting this event is a challenging task and has a time limit. In this regard, it is necessary to carefully observe the physical behavior of livestock (for example, standing, jumping and barking other cows). In addition, most of these events can be easily missed because they occur overnight and are only visible for a period of 6 to 36 h (Sumon-Shahriar et al., 2015). Currently, there are several tools and techniques that are widely used to more accurately diagnose estrus, but their average success rate is 50% (Inchaisri, 2011). Therefore, implementing a PDMT system that is able to improve estrus detection rates while reducing labor requirements will be beneficial to the overall economic performance of cattle farm.

Prediction of calving time (PCT)

Problems during calving increase the risk of stillbirth, mortality and elimination of cattle, as well as the overall risk of disease. Depending on the severity of the problem, research shows that it can cost around € 150 to € 600 per case (McGuirk et al., 2007). Therefore, the exact time of calving must be determined. Past research projects (Rutten et al., 2017) have shown that calving time can be detected by sensor systems installed on cattle that integrate information on mobility, behavior, temperature and tail position of cattle.

Location and identification of dairy cattle (LIDC)

Another application of the system is the location and identification of livestock. Because locating livestock is currently a time-consuming process, certainly in large herds, PDMT systems have a high potential to reduce the time required to locate a particular livestock. Through a mobile app, rancher can get real-time close-up information of a cow. Also, through the app, rancher can scan a cow wirelessly to get all livestock information and cow calendar. Regarding livestock location, since this application is enabled by the technology required for the first application (early detection of diseases), no additional system components are required except mobile application.

Step 2: Identification of the industrial IOT criteria

In this step, the effective criteria for selecting IOT applications were identified through interviews with 25 experts who had sufficient experience and knowledge in this field, as well as reviewing theoretical literature and thematic analysis method. At this stage, the codes obtained from the interviews were regularly placed in the form of the main themes, and all the coded data related to each of the themes were identified and collected. By re-examining and refining the themes further, attempts were made to make the themes separate, non-repetitive, and large enough to contain a set of ideas presented in different sections of the text. From the total codes obtained by interviewing experts and theme analysis method, 15 sub-criteria are classified into three main criteria: capabilities, advantages and challenges of industrial IOT, which can be seen in Table I.

Table I. Results of interviews analysis and identifying industrial IOT prioritization indicators.

|

Row |

Main criteria |

Sub-criteria |

|

1 |

Capabilities |

Artificial intelligence |

|

2 |

Relationship |

|

|

3 |

Sensors |

|

|

4 |

Active employment |

|

|

5 |

Use of low equipment |

|

|

6 |

Advantages |

Technology optimization |

|

7 |

Customer employment |

|

|

8 |

Reduction of additional items |

|

|

9 |

Improved data collection |

|

|

10 |

Work processes improvement |

|

|

11 |

Challenges |

Complexity |

|

12 |

Privacy |

|

|

13 |

Security |

|

|

14 |

Compatibility |

|

|

15 |

Flexibility |

Step 3: Decision matrices based on the opinions of each expert

Experts from the China Information and Communication Technology Association (ICT) and operators on IOT farms are the most important resources that can help effectively rank IOT applications in dairy cattle industry productivity. Data and information were collected through a questionnaire and then, using the collected information, the COPRAS decision matrix was formed. The scoring values of the applications were determined using the Likert scale, which is one of the most common measurement scales in research based on a questionnaire.

Step 4: Formation of the aggregate decision matrix

At this step, by aggregating the completed questionnaires, the aggregated decision matrix was created (Table II).

Table II. Aggregate decision matrix.

|

Applications |

Criteria |

|||

|

LIDC |

PCT |

DIT |

EDD |

|

|

6.20 |

3.17 |

4.65 |

2.54 |

Artificial intelligence |

|

1.33 |

3.06 |

6.19 |

3.97 |

Relationship |

|

4.64 |

4.51 |

4.33 |

6.02 |

Sensors |

|

2.54 |

2.28 |

7.21 |

6.11 |

Active employment |

|

7.45 |

2.67 |

7.55 |

1.87 |

Use of low equipment |

|

4.18 |

5.69 |

5.13 |

5.79 |

Technology optimization |

|

5.57 |

4.81 |

2.18 |

4.23 |

Customer employment |

|

6.96 |

7.23 |

4.72 |

3.13 |

Reduction of additional items |

|

4.27 |

3.05 |

6.34 |

7.06 |

Improved data collection |

|

6.58 |

4.88 |

1.95 |

6.44 |

Work processes improvement |

|

7.77 |

7.28 |

2.86 |

4.25 |

Complexity |

|

2.82 |

6.69 |

7.39 |

2.66 |

Privacy |

|

1.73 |

5.66 |

6.16 |

2.48 |

Security |

|

4.32 |

7.71 |

5.08 |

4.75 |

Compatibility |

|

5.19 |

8.11 |

4.12 |

7.14 |

Flexibility |

DIT, detection of insemination time; EDD, early detection of diseases; LIDC, location and identification of dairy cattle; PCT, prediction of calving time.

Also, by aggregating the opinions of experts, the importance of each criterion in decision making was determined in accordance with Table III.

Steps 5-9: Calculations

Since all these steps are related to mathematical calculations and do not add value to the article and only add more pages to the article, these calculations are omitted.

Step 10: Ranking of the applications based on the calculations performed

In this step, we want to rank IOT applications in dairy cattle industry productivity (EDD, DIT, PCT, LIDC) based on industrial IOT criteria (artificial intelligence, relationship, sensors, active employment, use of low equipment, technology optimization, customer employment, reduction of additional items, improved data collection, work processes improvement, complexity, privacy, security, compatibility, flexibility). The larger the criteria value, the higher the ranking of that option in that ranking. The option that has the best possible case, as an ideal option, always has the highest value. The evaluation results of the Coopers model for ranking and the degree of desirability of IOT applications in dairy cattle industry productivity are shown in Table IV.

Our results show that DIT is more important than other applications. Estrus diagnosis directly affects cattle farm economic performance and failure to diagnose it properly leads to fewer calves per year and less milk production due to reduced milk production after calving. The IOT system is expected to reduce the working time and increase the estrus detection rates by up to 80%. These results are consistent with a report published by Rutten et al. (2013), may even be somewhat conservative. Also, considering that the use of IOT increases the productivity and efficiency of industries, it was predictable that this application would achieve a high position in this ranking.

The second priority is dedicated to EDD. Since the IOT system does not include biochemical analyzes, it will be difficult to distinguish between different diseases, with the exception of lameness, which is a movement disorder and is visible. Because fever in livestock is an indicator for a number of diseases, cow fever will be monitored in this system. The expected effect of implementing an IOT system on cattle farms is to diagnose very common diseases of dairy cattle. These conditions include mastitis, lameness, ketosis, and inflammatory uterus.

Table III. Importance of each criterion based on the consolidated opinions of experts.

|

Reduction of additional items |

Customer employ-ment |

Technology optimization |

Use of low equip-ment |

Active employ-ment |

Sensors |

Relation-ship |

Artificial intelligence |

Criteria |

|

0.179 |

0.114 |

0.234 |

0.104 |

0.147 |

0.186 |

0.131 |

0.265 |

Criterion importance |

|

Flexibility |

Compatibility |

Security |

Privacy |

Complexity |

Work processes improve-ment |

Improved data collection |

Criteria |

|

|

0.116 |

0.212 |

0.288 |

0.164 |

0.135 |

0.125 |

0.109 |

Criterion importance |

Table IV. Applications ranking results.

|

Desirability (%) |

Qi |

Ranking |

Applications |

|

100% |

0.67 |

Rank 1 |

DIT |

|

84% |

0.61 |

Rank 2 |

EDD |

|

70% |

0.56 |

Rank 3 |

LIDC |

|

40% |

0.29 |

Rank 4 |

PCT |

LIDC and PCT are applications that are ranked third and fourth, respectively, based on COPRAS results. Birth monitoring, observation, and possible assistance during the birth process can reduce the prevalence and consequences of a difficult birth. The IOT system warns the farmer as an indicator for the calving moment. This reduces the number of unnecessary examinations and saves labor. In addition, the likelihood of side effects will be reduced, which will reduce the total cost of veterinary services and increase milk production and reproduction rates. Although significant costs of examinations are reduced, the overall effect of IOT on dystocia is small.

Conclusion

Today, cattle farms face major problems such as high labor force demand, Failure to diagnose sick livestock and high treatment costs, drop in production, existence of thermal stress, lack of accurate and timely identification of estrus livestock, and lack of warning system and crisis identification in livestock and sometimes theft of livestock. As new algorithmic technologies, sensors, and WSN nodes have been able to have positive effects on production efficiency, quality improvement, and productivity, this sector is still unable to overcome existing challenges. IOT, through the convergence of technologies such as big data, cloud computing, Block-chain and so on, has been able to have a tremendous impact on vertical markets by creating data-driven products and services, creating new business models, and improving decisions. Therefore, it can be claimed that IOT, by providing solutions in line with productivity indicators, is able to empower cattle farms to overcome these challenges.

This research, which was conducted with the aim of helping dairy cattle industry decision makers to use IOT, can direct IOT-related investments in the dairy cattle industry. IOT numerous and costly applications in dairy cattle industry productivity, along with limited financial, knowledge and human resources in livestock farms, make us need a way to identify the most important priorities in this area for implementation in the dairy cattle industry. The present study has identified IOT applications in dairy cattle industry productivity and used the COPRAS method to rank the applications. The results of this study showed that DIT with a significance of 0.67 has the highest rank among the options and EDD with a significance of 0.61 and LIDC with a significance of 0.56 are in the second and third ranks, respectively. Also, PCT with a significance of 0.29 is of the least importance.

Based on the knowledge of the authors, so far, no ranking of IOT applications in dairy cattle industry productivity has been done. Our results can be a beacon for managers and operators of the dairy cattle industry. These results can be used in many dairy cattle farms and reduce production costs and increase the quality of their products. Other researchers can use new methods to assess the value that each of these applications adds to society (people and industries), and predict the value added of each of these applications using futures studies-based approaches in this field. Also, due to the differences among livestock farms in different industries, researchers can study livestock related to each industry and identify and rank IOT applications in them. Also, the use of IOT in livestock farms, such as related architecture, data storage, processing of collected data and so on, has many technical issues that could be the subject of some future research.

Statement of conflict of interest

The authors have declared no conflict of interest.

References

Asikainen, M., Haataja, K., and Toivanen, P., 2013. Wireless indoor tracking of livestock for behavioral analysis. In: 2013 9th international wireless communications and mobile computing conference, IWCMC, pp. 1833-1838. https://doi.org/10.1109/IWCMC.2013.6583835

Ayrim, Y., Atalay, K.D., and Can, G.F., 2018. A new stochastic MCDM approach based on COPRAS. Int. J. Inform. Tech. Decis. Making, 17: 857-882. https://doi.org/10.1142/S0219622018500116

Benhai, X., Liang, Y., Xiaohua, P., and Zhengang, Y., 2015. Review on application of internet of things technology in animal husbandry in China. Tran. Chinese Soc. Agric. Eng., 31.

Bernabucci, U., Lacetera, N., Baumgard, L.H., Rhoads, R.P., Ronchi, B., and Nardone, A., 2010. Metabolic and hormonal acclimation to heat stress in domesticated ruminants. Animal, 4: 1167-1183. https://doi.org/10.1017/S175173111000090X

Bhargava, K., Ivanov, S., and Donnelly, W., 2015. Internet of nano things for dairy farming. In: Proceedings of the second annual international conference on nanoscale computing and communication. Nanocom, 15: 1-2. https://doi.org/10.1145/2800795.2800830

Biggs, P., Garrity, J., LaSalle, C., and Polomska, A., 2016. Harnessing the internet of things for global development. ITU J. (Geneva), https://doi.org/10.2139/ssrn.2588129

Cardullo, M., 2003. Genesis of the versatile RFID tag. RFID J., pp. 110-131. (Please check journal name).

De Maturana, E.L., Legarra, A., Varona, L., and Ugarte, E., 2007. Analysis of fertility and dystocia in Holsteins using recursive models to handle censored and categorical data. J. Dairy Sci., 90: 2012-2024. https://doi.org/10.3168/jds.2005-442

Dieng, O., Diop, B., Thiare, O. and Pham, C., 2017. A study on IoT solutions for preventing cattle rustling in African context. ICC, pp.153-161. https://doi.org/10.1145/3018896.3036396

Fricke, P.M., Giordano, J.O., Valenza, A., Lopes, G.J., Amundson, M.C., and Carvalho, P.D., 2014. Reproductive performance of lactating dairy cows managed for first service using timed artificial insemination with or without detection of estrus using an activity monitoring system. J. Dairy Sci., 97: 2771-2781. https://doi.org/10.3168/jds.2013-7366

Gartner, 2011. Internet of things added to the 2011 hype cycle. Retrieved from Postscapes: https://www.postscapes.com/internet-of-things-added-to-the-2011-hype-cycle/.

GeSI, 2016. How digital solutions will drive progress towards the sustainable development goals. Global e-Sustainability Initiative, Brussels.

Gubbi, J., Buyya, R., Marusic, S., and Palaniswami, M., 2013. Internet of things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst., 29: 1645-1660. https://doi.org/10.1016/j.future.2013.01.010

Hansen, P.I., 2007. In: Current therapy in large animal theriogenology (eds., R.S. Youngquist and W.R. Threlfall), 2nd edn. Saunders-Elsevier, St Louis, MO. pp. 431-441.

Helwatkar, A., Riordan, D. and Walsh, J., 2014. Sensor technology for animal health monitoring. Int. J. Smart Sens. Intell. Syst. Proc. 8th Int. Conf. Sens. Technol. Liverpool, UK, 7: 266-271. https://doi.org/10.21307/ijssis-2019-057

Huircan, J.I., Munoz, C., Young, H., Von Dossow, L., Bustos, J. and Vivallo, G., 2010. ZigBee-based wireless sensor network localization for cattle monitoring in grazing fields. Comput. Electron. Agric., 74: 258-264. https://doi.org/10.1016/j.compag.2010.08.014

Inchaisri, C., 2011. Bio-economic modeling to support insemination decisions in dairy cows. Proc. natl. Acad. Sci. U. S. A., (Vol and Pages?).

Kocovic, P., Behringer, R., Ramachandran, M., and Mihajlovic, R., 2017. Emerging trends and applications of the internet of things. IGI Global, Hershey PA, https://doi.org/10.4018/978-1-5225-2437-3

Kwong, K.H., Wu, T.T., Goh, H.G., Sasloglou, K., Stephen, B., and Glover, I., 2012. Practical considerations for wireless sensor networks in cattle monitoring applications. Comput. Electron. Agric., 81: 33-44. https://doi.org/10.1016/j.compag.2011.10.013

Law, R.A., Young, F.J., Patterson, D.C., Kilpatrick, D.J., Wylie, A.R.G., and Mayne, C.S., 2009. Effect of dietary protein content on estrous behavior of dairy cows during early and mid-lactation. J. Dairy Sci., 92: 1013-1022. https://doi.org/10.3168/jds.2008-1179

Liou, J.J., Tamošaitienė, J., Zavadskas, E.K. and Tzeng, G.H., 2016. new hybrid Copras-G Madm Model for improving and selecting suppliers in green supply chain management. Int. J. Prod. Res., 54: 114-134. https://doi.org/10.1080/00207543.2015.1010747

Mamduh, S.M., Shakaff, A.Y.M., Saad, S.M., Kamarudin, K., Kamarudin, L.M., and Zakaria, A., 2012. Odour and hazardous gas monitoring system for swiftlet farming using wireless sensor network (WSN). Chem. Eng. Trans., 30: 331-336.

McGuirk, B.J., Forsyth, R., and Dobson, H., 2007. Dobson economic cost of difficult calving in the United Kingdom dairy herd. Vet. Rec., 161: 685-687. https://doi.org/10.1136/vr.161.20.685

Michaelis, I., Hasenpusch, E. and Heuwieser, W., 2013. Estrus detection in dairy cattle; changes after the introduction of an automated activity monitoring system? Tierarztl. Prax. Ausg. G. Grosstiere Nutztiere, 41: 159-165. https://doi.org/10.1055/s-0038-1623167

Miorandi, D., Sicari, S., De Pellegrini, F., and Chlamtac, I., 2012. Internet of things: Vision, applications and research challenges. Ad. Hoc. Netw., 10: 1497-1516. https://doi.org/10.1016/j.adhoc.2012.02.016

Mirmanov, A., Alimbayev, A., Baiguanysh, S., Nabiev, N., Sharipov, A., Kokcholokov, A. and Caratelli, D., 2021. Development of an IOT platform for stress-free monitoring of cattle productivity in precision animal husbandry. Adv. Sci. Tech. Eng. Syst. J., 6: 501-508. https://doi.org/10.25046/aj060155

Nadimi, E.S., Jørgensen, R.N., Blanes-Vidal, V., and Christensen, S., 2012. Monitoring and classifying animal behavior using ZigBee-based mobile ad hoc wireless sensor networks and artificial neural networks, Comput. Electron. Agric., 82: 44-54. https://doi.org/10.1016/j.compag.2011.12.008

Nkamleu, G.B., 2004. Productivity growth, technical progress and efficiency change in African agriculture. Afr. Dev. Rev., 16: 203-222. https://doi.org/10.1111/j.1467-8268.2004.00089.x

Paudyal, S., Maunsell, F.P., Richeson, J.T., Risco, C.A., Donovan, D.A. and Pinedo, P.J., 2018. Rumination time and monitoring of health disorders during early lactation. Animal, 12: 1484-1492. https://doi.org/10.1017/S1751731117002932

Rayes, A., and Salam, S., 2017. Internet of things-from hype to reality. Spring International Publication. https://doi.org/10.1007/978-3-319-44860-2

Roy, J., Sharma, H.K., Kar, S., Zavadskas, E.K., and Saparauskas, J., 2019. An extended COPRAS model for multi-criteria decision-making problems and its application in web-based hotel evaluation and selection. Econ. Res. Ekon. Istra., 32: 219-253. https://doi.org/10.1080/1331677X.2018.1543054

Rutten, C.J., Velthuis, A.G.J., Steeneveld, W. and Hogeveen, H., 2013. Invited review: Sensors to support health management on dairy farms. J. Dairy Sci., 96: 1928-1952. https://doi.org/10.3168/jds.2012-6107

Rutten, C.J., Kamphuis, C., Hogeveen, H., Huijps, K., Nielen, M., and Steeneveld, W., 2017. Sensor data on cow activity, rumination, and ear temperature improve prediction of the start of calving in dairy cows. Comput. Electron. Agric., 132: 108-118. https://doi.org/10.1016/j.compag.2016.11.009

Sawant, S.A., Adinarayana, J., and Durbha, S.S., 2014. Krishi Sense: A semantically aware web enabled wireless sensor network system for precision agriculture applications. Int. Geosci. Remote Sens. Symp. Proc., pp. 4090-4093. https://doi.org/10.1109/IGARSS.2014.6947385

Schirmann, K., Keyserlingk, M.A., Weary, D.M., Veira, D.M., and Heuwieser, W., 2009. Technical note: Validation of a system for monitoring rumination in dairy cows. J. Dairy Sci., 92: 6052-6055. https://doi.org/10.3168/jds.2009-2361

Suhonen, J., Kohvakka, M., Kaseva, V., Hamalainen, T.D., and Hannikainen, M.H., 2012. Low-power wireless sensor networks: Protocols. Services and applications, Springer. https://doi.org/10.1007/978-1-4614-2173-3

Sumon-Shahriar, M.D., Smith, D., Rahman, A., Henry, D., Bishop-Hurley, G., Rawnsley, R., Freeman, M., and Hills, J., 2015. Heat event detection in dairy cows with collar sensors: An unsupervised machine learning approach. IEEE SENSORS, pp. 1-4. https://doi.org/10.1109/ICSENS.2015.7370528

Thierer, A., and O’Sullivan, A., 2015. Projecting the growth and economic impact of the internet of things. George Mason University, Mercatus Center, VA, USA, pp. 1-10.

Tzounis, A., Katsoulas, N., Bartzanas, T., and Kittas, C., 2017. Internet of things in agriculture, recent advances and future challenges. Biosyst. Eng., 164: 31-48. https://doi.org/10.1016/j.biosystemseng.2017.09.007

Vannieuwenborg, F., Verbrugge, S., and Colle, D., 2017. Designing and evaluating a smart cow monitoring system from a technoeconomic perspective. 2017 Internet of Things Business Models, Users, and Networks, Copenhagen, pp. 1-8. https://doi.org/10.1109/CTTE.2017.8260982

Vermesan, O., and Friess, P., 2014a. Internet of things from research and innovation to market deployment. Riv. Publicaion.

Walker, W.L., Nebel, R.L. and McGilliard, M.L., 1996. Time of ovulation relative to mounting activity in dairy cattle. J. Dairy Sci., 79: 1555-1561. https://doi.org/10.3168/jds.S0022-0302(96)76517-7

Walter, A., Finger, R., Huber, R., and Buchmann, N., 2017. Opinion: Smart farming is key to developing sustainable agriculture. Proc. natl. Acad. Sci., 114: 6148–6150. https://doi.org/10.1073/pnas.1707462114

Welbourne, E., Battle, L., Cole, G., Gould, K., Rector, K., and Raymer, S., 2009. Building the internet of things using RFID: The RFID ecosystem experience. IEEE Int. Comput., 13: 48-55. https://doi.org/10.1109/MIC.2009.52

Zavadskas, E.K., Kaklauskas, A., and Sarka, V., 1994. The new method of multi-criteria complex proportional assessment of projects. Technol. Econ. Dev. Econ., 1: 131-139.

To share on other social networks, click on any share button. What are these?