Performance Evaluation of Downdraft Gasifier with Syngas Cleaning System

Research Article

Performance Evaluation of Downdraft Gasifier with Syngas Cleaning System

Sidrah Ashfaq1, Muhammad Nadeem1*, Muhammad Yamin1, Talha Afzal1, Muhammad Waqar Akram1, Rabia Anam1 and Ali Mehboob2

1Faculty of Agricultural Engineering and Technology, University of Agriculture, Faisalabad; 2Department of Textile Engineering, School of Engineering and Technology, National Textile University, Faisalabad, Pakistan.

Abstract | Energy is a crucial factor and a capital of a country’s resources leading indicator. World’s energy focus is shifting towards alternate renewable, cheap and environment-friendly resources that can provide long-term sustainability for survival. Due to the fossil fuels depletion and their ever-growing cost, the need to shift focus towards renewable energy resources has increased a lot. To overcome the above-said problems, there is a need to look for a feasible and robust solution for thermal applications in remote areas. Biomass gasification proved to be one of the most efficient and clean waste-to-energy conversion processes in contrast to direct combustion of agricultural waste. Other than controlled burning of biomass, it can be subjected for different purposes like a thermal, synthesis of ethanol, engine running, and for fuel cell applications. An excessive amount of impurities like char, ash, tar, and particulate matter are making these syngas non-feasible for thermal or engine applications. To overcome the above-stated problem, a downdraft gasifier with cyclone separator and hybrid biomass filter was fabricated using locally available materials in the workshop of the Dept. of Farm Machinery and Power at the University of Agriculture, Faisalabad. Uniform distribution of 2.54-5.08 cm2 sizes of feedstock was used for gasification. Air was used as a gasifying agent. The reactor capacity was 0.19 m3. The values of performance parameters for wood waste and corncobs were recorded as fuel consumption rate (0.002195, 0.002323) kg-s-1, the volume of gas produced (24.56, 26.33) m3, operating time (5480, 5164) s, cleaning unit efficiency (81.79, 79.9) % and gas yield (2.04, 2.19) m3-kg-1.

Received | July 15, 2021; Accepted | January 21, 2022; Published | September 28, 2022

*Correspondence | Muhammad Nadeem, University of Agriculture, Faisalabad, Pakistan.; E-mail: ndmmuhammad@uaf.edu.pk

Citation | Ashfaq, S., M. Nadeem, M. Yamin, T. Afzal, M.W. Akram, R. Anam and A. Mehboob. 2022. Performance evaluation of downdraft gasifier with syngas cleaning system. Sarhad Journal of Agriculture, 38(4): 1322-1331.

DOI | https://dx.doi.org/10.17582/journal.sja/2022/38.4.1322.1331

Keywords | Downdraft gasifier, Gasification, Performance evaluation, Syngas cleaning

Copyright: 2022 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Everything, in essence, is about energy. Energy has a key role in the stability of a country and is at the forefront of social, environmental and financial security problems (Seyfang and Haxeltine, 2012). Energy streams have a crucial part in the evolving and financial advancement for a country. Being a developing nation, Pakistan is meeting with severe energy crisis, decelerating its economic development. Energy requirements in Pakistan are generally fulfilled by oil, liquefied gasoline, and natural gas resources. In electricity generation, these reserves contribute about 85 % of the total electricity generation (Kopyscinski et al., 2010). While the contribution of renewable reserves, nuclear and hydroelectric resources add up to 1.1 % and 9.2 % (Baloch et al., 2016).

Energy requirements are increasing day by day due to the high population of the country. Fossil reserves continued as the leading mover in universal economic growth during 21st century. But these oil deposits are diminishing very rapidly. The change in oil supplies is thus the only definitive choice for the dominant industrial field. Fossil fuels contributes almost 63 % of total world energy demand (Atilgan and Azapagic, 2015). Keeping in view the above stated problems, we cannot depend upon diminishing resources. Pakistan is blessed with the vast and widespread quantity of biomass which refers to the raw product obtained from any plant derived organic material (Ibrahim et al., 2011). Biomass is an inexpensive, renewable, and easyly-available energy source that can be used for internal combustion engines, compressor operation, and thermal power application. There are various types of biomass sources, such as energy crops, agro-industrial waste, agricultural crop residues, residential solid waste, and forest residues. The fuel value of total annual agricultural residue produces is projected to be 2.52 × 1012 GJ. Biomass is the fourth largest energy stream after three main fossil fuels (Kopyscinski et al., 2010). Global biomass production is assessed to be 146 BMT/year (Heinimö and Junginger, 2009).

In many developing countries, biomass accounts for meeting 50-90 % of total energy requirements (Massoud et al., 2009). Estimated amount of crop residues production in Pakistan is 3.17 BMT/year (Anwar et al., 2014). The total estimated energy potential from biomass in Pakistan is 50,000 GWh/year (Farooqui, 2014). Other applications may include home cooking, water heating and other important applications. With its positive features such as large abundance, ease in availability and low carbon emission, it meets all requirements of a good energy source. There are various ways of transforming biomass to energy, but primarily two key routes are used: thermochemical conversion and biochemical decomposition.

Thermochemical methods include processes like direct burning, pyrolysis, and gasification. Direct combustion is a typical process of disproportionate and least productive CO2 emissions. Out of these three processes, gasification is most effective, environmentally sustainable and has a high conversion rate compared to direct burning and pyrolysis. Biomass gasification is the most feasible owing to its higher thermal performance, the fast removal of contaminants and the output of gas from the fuel source (Calì et al., 2020). The gasification process produces lower levels of toxins compared to pyrolysis and carbonization. This mechanism is takes place at high temperatures (500-1400) °C with incomplete combustion resulting in the output of methane.

Biomass gasification is an energy conversion technique that generates heat as well as synthetic gas. This gas is then subjected for many applications thermal, running ICE, compressors, gas turbines and fuel cells for power generation (Buonomano et al., 2015). However, conventional methods for the biomass utilization include burning in the fields, domestic fuel, and industrial thermal applications. Direct burning of biomass at household is simply wastage of resources and deteriorating ozone layer by CO2 gas emission in the atmosphere (Choudhary et al., 2011).

Rather than direct combustion of biomass, it is a factual, viable, ecologically feasible choice to convert biomass to producer gas to diminish the hazardous substances addition into the atmosphere such as direct submission of heat, CO2, smoke, and various other pollutants. Also, direct burning of biomass is thermodynamically least efficient which means no other than but resource wastage (Zhu et al., 2019). The gas from central gasification plant could be distributed to various utilization stations. The prime benefit of gasification is the vision of changing dense carbonaceous fuel into clean producer gas in a way that it could retain (70-80) % chemical energy. It is also estimated that 1 kg of biomass can produce 2.5 m3 of synthetic gas upon gasification (Mustafa et al., 2017). Also, almost 4.5 m3 of air is required for the biomass gasification. For the process to run smoothly and to ensure the uniform gas flow through pipes and blower, it is optimistic to clean the primary impurities from the gas. This method is more flexible and efficient in areas of ample biomass feedstock (Kumar and Shukla, 2016).

The elemental analysis of syngas consists on mainly CO, H2, CO2, CH4 contents and the pollutants include char, ash particles, tar and traces of oil and water. In order to get clean gas, the product gas must be treated for its impurities and other toxic materials. Fan et al. (2020) examined the outcome of Torre faction pretreatment on gas generation and Tar production from CLG of crop residue which proved a resourceful approach for good quality gas produce. Thengane et al. (2019) showed in his research the benefits of using mixed gasification if high ash (biomass + Charcoal) for reduction in emissions. Thapa et al. (2017) also worked and developed the biomass filter for purification of synthetic gas produced by gasification process. A multiple cyclone separator design was also used for removal of fine particles from syngas (Hattingh et al., 2016). According to a study by Zhang et al. (2012), combination of mop fan and an electro filter best proves best for elimination of fine particles, tar and other impurities.

The main objectives of this research were fabrication and performance evaluation of syngas cleaning unit for downdraft gasifier. Biomass waste is one of the plentiful and readily available energy options. It is the need of the day to use certain sources of energy that have stayed unattended and make a major contribution and national energy production. In rural areas, biomass waste is abundant and is primarily used for direct burning purposes, contributing to loss of energy, environmental degradation, and other health problems. Agricultural waste and other solid biomass feedstock can be converted into a syngas that can be applied directly for thermal and heat applications. This syngas generates a portion of impurities like tar, moisture formation, dust and particulate matter and other impurities that need to be removed from the gas for smooth operation of reactor. Keeping in view the above-mentioned shortcomings faced in this technology, a gasifier reactor along with its cleaning unit comprises from cyclone separator and hybrid biomass filter was fabricated.

Material and Methods

Biomass gasification is a clean, imperishable with lowest CO2 emission. Keeping in view the shortcomings faced in this process, a downdraft gasifier reactor along with its cleaning units comprises of cyclone separator and hybrid biomass filter was fabricated in a way that it would remove most solid particulate matter, ash deposits, impurities like tar and moisture content from the producer gas (Szul et al., 2020). Hybrid biomass filter was fabricated with the aim to remove the tar and remaining impurities farther into exit pipe. Gasifier reactor along with cyclone separator and hybrid biomass filter was fabricated in the University of Agriculture, Faisalabad. Two different biomass feedstocks (wood waste & corncobs) along with three ignition times (60, 180, 300 s) were taken for measuring their effect on the following parameters. Performance of this gasifier system was examined with the parameters i.e. volume of gas produced, fuel consumption rate, operating time, tar removal efficiency and gas yield.

Detailed overview of downdraft gasifier

The downdraft gasifier mainly contains four main components reactor, cyclone separator, hybrid biomass filter and blower (Figure 1). The gasifier system was fabricated with mild steel (MS) sheet 1.52 mm thickness having weight 11.9 kg/m2. The reactor was made air tight and light weight. Size of reactor is provided for longer running and ease of drying from the internal heat of comigbustion. Primarily, four processes take part towards complete gasification reaction. With drying process in the top most section of gasifier reactor to evaporate the unwanted water vapors from the biomass to precede the process towards pyrolysis. This occurs as the feedstock is exposed to rising temperature in the gasifier. Both drying and pyrolysis reactions are endothermic taking up large portion of thermal energy produced from combustion. Subsequent temperature in drying is observed at 150 °C and in the pyrolysis zone up to 700 °C. In Pyrolysis, devolatization and breaking of the weaker chemical bonds occurs, releasing volatile gases such as tar vapors, methane, and hydrogen, along with producing a high molecular weight char which will undergo gasification reactions. In combustion zone, the volatile products and some of the char react with limited oxygen to form carbon dioxide (CO2), carbon monoxide (CO), and in doing so, provide the heat needed for subsequent gasification reactions and raising the temperature up to 1400 °C. In reduction, the remaining char reacts with CO2 and steam to produce CO and hydrogen (H2).

Temperature in the reduction zone lowers to 1100 °C with water-gas-shift and methanation. These are separate reversible gas phase reactions taking place simultaneously based on gasifier conditions. These are minor reactions which play a small role within in the gasifier. The produced syngas from reactor is drifted through cyclone separator of 100 mm internal diameter and barrel length of 304 mm with cone length of 154 mm. It has gas entering, gas exit and ash dropping pipes sections of 75 mm diameter. The coarser impurities dust, char, ash deposits and tar are eliminated from the gas with centrifugal action of cyclone vortex generated inside cyclone separator. This partial treated syngas is further treated via hybrid biomass filter made from consecutive layering of fine shavings of wood and corncobs. It has total length of 304 mm with three sieves of 279 mm diameter each distancing at 75 mm from each other. Gas entry is made through the bottom side of filter with a pipe of diameter of 75 mm and gas exit is provided with subsequent treatment through sieves towards the upward direction with a pipe of 50 mm diameter. Remaining tar, fine matter and water vapors from the syngas are removed in this filter. For the smooth and efficient running of gasifier system, moisture and particulate matter removal from syngas is the foremost requirement to prevent any fouling of blower due to tar deposit on its impeller.

Performance evaluation of downdraft gasifier system

Operating Time: The running time for the gasifier by filling the hopper in full capacity is called operating time. It was measured using smarphone stopwatch in seconds (Ojolo et al., 2012). It is denoted by Ot.

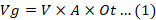

Volume of Gas: The volume of gas can be calculated in a simple way. The cross-sectional area and velocity of gas was recorded (West and Photiou, 2018). The gas velocity was measured at the exhaust side of the blower in (m/s). It is described with V. Flow rate of gas was calculated using this formula:

Where;

Vg: Gas volume (m3); V: Velocity of gas (m/s); A: Cross-sectional area of pipe (m2) and Ot: Operating time (s).

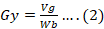

Gas Yield: Gas yield is the amount of gas produced from the gasification of per kilogram of biomass feedstock (Upadhyay et al., 2018). It was measured by dividing the total volume of gas by total weight of biomass feedstock.

Where;

Gy: Gas yield (m3/kg); Vg: Gas volume (m3) and Wb: Weight of feedstock (kg).

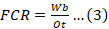

Fuel Consumption Rate: The fuel consumption rate is the amount of biomass feedstock used during gasification per unit of operational time (Grandhi et al., 2018).

Where;

FCR: Fuel consumption rate (kg/s ); Wb: Weight of biomass (kg); Ot: operating time (s).

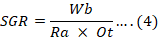

Specific Gasification Rate: The specific gasification rate is the quantity of biomass consumed per unit of operating time per unit of grate area. It was measured using the following equation (Ojolo et al., 2012).

Where;

SGR: Specific gasification rate (kg/s-m2); Wb: Weight of biomass feedstock (kg); Ot: Operating time (s).

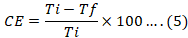

Cleaning Unit Efficiency: Tar removal efficiency of the cleaning unit is estimated by measuring the tar contents by gravimetric method prior and after cleaning of syngas (Awais et al., 2018). It is denoted as TRE in (%).

Where;

CE: Cleaning unit efficiency (%); Ti: Initial tar weight (mg) and Tf: Final tar weight (mg).

Experimental procedure

The study trials have been conducted to estimate the effeciency of gas cleaning unit and working of downdraft gasifier. Wood waste and corncobs were used as a gasifying source for the experiment. During the perfromance evaluation of downdraft gasifier system several other parameters like operation time, volume of gas produced, cleaning unit efficiency, gas yield and fuel consumption rate were assessed. The gasifier reactor should be completely filler up to its neck to remove any void space present in the reactor. Top lid and reactor perphery should be submerged with water to prevent entry of air frop top section. Air was used as a gasifying medium. Double walled reactor was used to provide air as a insulation medium. Cyclone seperator and biomass filter were used as cleaning unit for removal of unwanted materials. Diameter of cyclone was 100 mm with three openings. Gas is enetred horizontally and exited from a little higher point being at negative pressure. Ash and particulate deposits are collected in collection port and removed using dead cap. Whereas, hybrid biomass filter is designed on the basis of residence time of fuel in the reactor. It helps in removing water content and suspended impurities by using it’s three layers biomass sheets. Two gas inlets are provided at bottom while exit is at the top layer.This gasifier is a viable technology in providing hand to hand assistance in handling plentiful amount of biomass on rural scale for domestic applicatoion. Fixed amount of biomass was used for gasification with the help of digital weight balance. Anemometer was to measure the velocity of gas at the exit pipe of system. Gravimetric tar analysis was performed to measure tar before and after cleaning of syngas (Palma, 2013). A helical shaped cooper condenser was used to collect tar from the producer gas. The diameter of the helical spring was 9 mm and length of 3000 mm. The helical condenser was weighed initially and then immersed in chilled water to maintain temperature between 4 and 6 °C. The gas was then passed through the helical condenser where tar was condensed. Final weight of the helical condenser was noted. Tar collected in the helical condenser was collected and solubilized in acetone. Later, it was dried in the oven at temperature over 50 °C to evaporate the acetone.

Results and Discussion

Performance evaluation of gas cleaning unit

The syngas cleaning unit of downdraft gasifier was tested using two different biomass feedstock and at different operating conditions. Wood shavings and corncobs (pith) was used as two different feedstocks of varying characteristics. Air was used as a gasifying agent to oxidize the biomass inside the reactor. Feedstock was trialed at three consecutive intervals of ignition time to check the performance of gasification system. Three ignition time were set as (60, 180 & 300) s respectively. The measured data was statistically analyzed to observe the effect of ignition time and biomass feedstock on the performance parameters (Table 1).

Operating time of gasifier

The operating time of gasifier system significantly influences the working of a gasifier. 12 kg of biomass feedstock was used for filling the reactor. Time was recorded with the help of smartphone stopwatch in seconds. The feedstock should be uniform in size and it was crushed with the help of crusher into 1-2 in2 pieces. The moisture content of biomass feedstock was also kept minimum 12-14 % to obtain good quality of syngas and smooth running of system. Moisture content of the biomass feedstock was reduced with the help of oven dry method. Recommended moisture content range is below 20 %.

Moisture content was measured with the help of oven dry method. The velocity of gas was recorded with anemometer in regular intervals to calculate the mean average velocity of gas. For the less time the feedstock was ignited, operating time increased significantly. This was because the heat formation and the rate of pyrolysis process reduced to an extent to produce limited amount of char content and volatile matter production. Due to reduced char content combustion process produced a very less heat and resulting products from char, causing a certain delay in the uniformity of reactor smooth gas production.

Table 1: Measured data and efficiency of gas cleaning unit.

|

Sr # |

IT (s) |

FT |

Ot (s) |

Vg (m3) |

FCR (kg/s) |

SGR (kg/m2/s) |

Gy (m3/kg) |

CE (%) |

|

1 |

60 |

wood waste |

5784 |

22.33 |

0.002075 |

0.0692 |

1.86 |

79.79 |

|

2 |

180 |

wood waste |

5520 |

24.33 |

0.002175 |

0.0725 |

2.03 |

81.51 |

|

3 |

300 |

wood waste |

5136 |

27 |

0.002338 |

0.078 |

2.25 |

83.77 |

|

4 |

60 |

Pith |

5460 |

24 |

0.002197 |

0.0732 |

2.00 |

78.17 |

|

5 |

180 |

Pith |

5100 |

26 |

0.002352 |

0.0784 |

2.17 |

79.62 |

|

6 |

300 |

Pith |

4944 |

29.33 |

0.002427 |

0.0809 |

2.44 |

82.21 |

IT: Ignition Time; FT: Feed Type; Ot: Operating Time; Vg: Volume of Gas; FCR: Fuel Consumption Rate; SGR: Specific Gasification Rate; Gy: Gas Yield; CE; Cleaning Unit Efficiency.

And ultimately total operating time for less ignition time is increased. Operating time in case of wood waste was higher due to its higher bulk density in comparison of corncobs. As shown in Figure 2, the denser and uniform shape of corncobs, throat bridging was minimum, and a uniform downward movement of feed was established towards combustion and reduction zone. Ultimately, rate of chemical reactions was fast in case of corncobs rather than wood waste.

Volume of Gas produced from Gasifier

The volume of gas was estimated based on the velocity of gas at the exit side and by considering the operating time. Quantity and quality of gas produced during gasification had quite a vital role in estimating the overall efficiency of the gasifier system. Due to the minimization in the pyrolysis reactions, char content and volatile matter formation was lowered to certain level.

Reduced volatile matter and char content cause a deficiency in heat formation and the number of reactants (char) for combustion process. Heat released from exothermic reactions in the combustion zone was dropped to a level causing the minimum transformation of CO2 and H2O into CH4, CO and H2. Maximum gas production noted for treatment six 29.33 m3 was due to peak ignition time 300 s and the feedstock was corncobs that had lower bulk density that wood waste taking up less time to achieve uniformity in combustion (Figure 3). Also, soft materials increase gas production due to low thermal decomposition temperature. Shallow feed with maximum porosity of corncobs supports the chemical reactions inside combustion zone. It was established from the literature that thermal decomposition of corncobs began at lower temperature leading to faster reactivity in the chamber creating more amount of gas (Anukam et al., 2017).

Fuel Consumption Rate of Gasifier

Normally, gasifiers have (0.00055-0.0030) kg-s-1 of fuel consumption rate (Chawdhury and Mahkamov, 2011). Other important properties in explaining the rate of consumption are bulk density, size and uniformity distribution, moisture content and volatile matter in the biomass feedstock. The fuel consumption rate observed for three different ignition times (60, 180 & 300) s respectively showing the increasing trend in fuel consumption rate (0.002134, 0.002261 & 0.002383) kg-s-1 (Figure 4). Fuel consumption rate reported from the literature for wood waste was (0.0008611, 0.002778) kg-s-1 (Laohalidanond et al., 2017).

As less time, the feedstock was ignited, operating time increased significantly. With more ignition time, extra heat addition will lighten up thermal losses resulting in balancing the thermal deficient caused during process start up. The fuel consumption rate observed for two different biomass feedstocks (waste wood & corncobs) respectively showing the varying trend in fuel consumption rate (0.002195 & 0.002323) kg-s-1. This was due to varying properties of both biomass feedstocks. The very first reason of lower rate in case of wood waste is its higher bulk density. The shape of waste wood pieces resulting in excessive throat bridging. Also, proximate analysis of wood and corncobs had significant different portion of volatile matter, ash content and fixed carbon.

Gas Yield of Gasifier System

The quantity of gas yield observed for three different ignition times (60, 180 & 300) s accordingly presenting the growing pattern for gas yield (1.93, 2.09 & 2.33) m3-kg-1. Overdue ignition reduced the amount of heat produced during the initial stage to withstand drying and pyrolysis reactions. As the rate of pyrolysis reactions slowed down, char content and volatile matter formation was dropped to certain level. Reduced volatile matter and char content rooted for a deficit in temperature increase and the amount of char contents reduced to limit the combustion reactions. Temperature drop reduced the transformation of CO2 and H2O into CH4, CO and H2. Thus, gas production was reduced and vice versa.

The average gas yield obtained was 2.12 m3-kg-1. The gas yield accessed for two different biomass feedstocks (waste wood & corncobs) consequently displaying the dissimilar tendency in gas yield (2.04 & 2.19) m3-kg-1. Notable physical features of biomass feedstock (Figure 5) that had a strong impact on gas production rate are bulk density, softness, size of particles & shape. Thermal decomposition of wood waste occurred at lower temperature as compared to corncobs because corncobs has lower density. Thus, reducing gas yield. Also amount of oxygen in the wood waste largely deprived the reduction and combustion reactions from generating enough heat to remove oxygen from the final syngas composition. It was evident that gas yield reported from literature for wood waste and corncobs was (1.5, 2.0) m3-kg-1 (Omar et al., 2017).

More carbon content in the corncobs preceded the reaction towards higher carbon conversion efficiency, leading to more amount of gas produced per unit mass of feedstock. Due to the dense and uniform nature of corncobs minimizes the slagging, resulting in higher gas yield. Corncobs having higher volume of gas is due to their high volatile matter content, making their gasification process progress rapidly. The average gas yield was 2.12 m3- kg-1. Shallow feed with maximum porosity of corncobs supports the chemical reactions inside combustion zone.

Efficiency of Gas Cleaning Unit

The syngas cleaning unit comprises of cyclone separator and hybrid biomass filter was coupled with gasifier reactor. The syngas produced from the gasifier contain large amount of impurities that need to be cleaned by passing it through cleaning unit. Amount of tar present in the gas had a noteworthy part in determining the smooth running of the system. The cleaning unit efficiency detected for three diverse ignition times (60, 180 & 300) s consequently revealing the increasing trend for tar removal efficiency (78.97, 80.56 & 82.98) %. For a fixed amount of biomass feedstock, while the ignition time was reduced to 60 s, the temperature distribution inside the reactor was insufficient causing irregular drying and pyrolysis process to precede (Figure 6).

Elevation in the temperature inside the reactor consequently dropped and indirectly affecting the thermal cracking of tar in the oxidation zone (Basu, 2013). And the total amount of tar yield was increased and reducing the overall cleaning unit efficiency of the gas cleaning unit and vice versa.

The cleaning unit efficiency accessed for two unlike biomass feedstocks (waste wood & corncobs) exhibiting the alike leaning for tar removal efficiency (81.68 & 79.99) %. Thermal decomposition of wood waste occurred at higher temperature as equated to corncobs because corncobs has lower density. Thus, reducing tar content and increasing the tar separation efficiency. It was observed that cleaning unit efficiency was higher than already reported literature values of (72.74) % (Awais et al., 2018). Greater density of feedstock required more decomposition temperature of (900-1300) °C that aids up in tar products conversion into burnable gas constituents like CO, H2 and CH4 in the the reactor. Waste wood formed less tarry content in relation to corncobs. The tar generated for corncobs was more because it disintegrated at lesser temperature. But at this temperature the cracking of tarry products was not high enough as related to higher breakdown temperature of wood waste that also aids in higher cracking of tarry products.

Conclusions and Recommendations

The results of this study showed that operating time was found higher (5480 s) for wood waste (fuel) in contrast to corncobs (5164 s) resulting in longer running time of the system. Based on this result wood waste is more efficient as the recharging frequency decreases significantly. Moreover, cleaning efficiency (82.98 %) and fuel consumption (0.002383 kg-s-1) were found higher at maximum ignition time (300 s) as the tar cracking was enhanced by higher temperature inside the reactor. On the other hand, gas production from corncobs (26.33 m3) and wood waste (24.55 m3), higher for corncobs. Mean efficiency of the cleaning unit was observed at 80.84 % while gas yield for wood waste and corncobs were 2.04 m3-kg-1 and 2.19 m3- kg-1 respectively.

The study also suggested that gasification rate could be enhanced while tar yield could be decreased by adding the suitable catalyst in the hearth bed. Use of blended mixture of feed stocks may significantly enhance the gas production. The thermal efficiency of gasifier system could be tested with proper insolation to minimize conduction and radiation losses.

Novelty Statement

In present study, a novel downdraft gasifier with cyclone separator and hybrid biomass filter was fabricated. This technology will help in judicious use of biomass waste leading to energy and environment conservation.

Author’s Contribution

Sidrah Ashfaq: Planned and executed the study.

Muhammad Nadeem: Helped in execution of study and manuscript writing.

Muhammad Yamin and Talha Afzal: Evaluated the performance and carried out related computations and graphing.

Muhammad Waqar Akram: Helped in manuscript writing.

Rabia Anam: Helped in manuscript writing and graphing.

Ali Mehboob: Helped in reviewing the manuscript.

Conflict of interest

The authors have declared no conflict of interest.

References

Anukam, A., B. Goso, O. Okoh and N. Mamphweli. 2017. Studies on Characterization of Corn Cob for Application in a Gasification Process for Energy Production. J. Chem., 2017: 1-9. https://doi.org/10.1155/2017/6478389

Anwar, Z., M. Gulfraz and M. Irshad. 2014. Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: a brief review. J. Radiat. Res. Appl. Sc., 7: 163-173. https://doi.org/10.1016/j.jrras.2014.02.003

Atilgan, B. and A. Azapagic. 2015. Life cycle environmental impacts of electricity from fossil fuels in Turkey. J. Clean. Prod., 106: 555-564. https://doi.org/10.1016/j.jclepro.2014.07.046

Awais, E., W. Li, A. Arshad, Z. Haydar, N. Yaqoob and S. Hussain. 2018. Evaluating removal of tar contents in syngas produced from downdraft biomass gasification system. Int. J. Green Energy, 15 (12): 724-731. https://doi.org/10.1080/15435075.2018.1525557

Baloch, M.H., G.S. Kaloi and Z.A. Memon. 2016. Current scenario of the wind energy in Pakistan challenges and future perspective: A case study. Energy Rep., 2: 201-210. https://doi.org/10.1016/j.egyr.2016.08.002

Basu, P. 2013. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory: 3rd edition. Academic Press. USA. https://doi.org/10.1016/B978-0-12-396488-5.00007-1

Buonomano, A., F. Calise, M.D. D’accadia, A. Palombo and M. Vicidomini. 2015. Hybrid solid oxide fuel cells-gas turbine systems for combined heat and power: a review. Appl. Energy, 156: 32-85. https://doi.org/10.1016/j.apenergy.2015.06.027

Calì, G., P. Deiana, C. Bassano, S. Meloni, E. Maggio, M. Mascia and A. Pettinau. 2020. Syngas Production, Clean-Up and Wastewater Management in a Demo-Scale Fixed-Bed Updraft Biomass Gasification Unit. Energies, 13: 2594-2598. https://doi.org/10.3390/en13102594

Chawdhury, M.A. and K. Mahkamov. 2011. Development of a small downdraft biomass gasifier for developing countries. J. Sci. Res., 3: 51-51. https://doi.org/10.3329/jsr.v3i1.5613

Choudhary, M., M. Ghani, A. Munir, M. Iqbal and M. Umair. 2011. Fabrication and Evaluation of a Downdraught Gasifier Running with Biomass for Sustainable Agriculture. Pak. J. Life Soc. Sci., 9: 52-57.

Fan, Y., N. Tippayawong, G. Wei, Z. Huang, K. Zhao, L. Jiang, A. Zheng, Z. Zhao and H. Li. 2020. Minimizing tar formation whilst enhancing syngas production by integrating biomass torrefaction pretreatment with chemical looping gasification. Appl. Energy. 260: 114315. https://doi.org/10.1016/j.apenergy.2019.114315

Farooqui, S.Z. 2014. Prospects of renewables penetration in the energy mix of Pakistan. Renew. Sustain. Energy Rev., 29: 693-700. https://doi.org/10.1016/j.rser.2013.08.083

Grandhi, S., A. Gupta and M. Viswanadham. 2018. Design of lab-scale downdraft gasifier for biomass gasification. IOP Conference Series: Mater. Sci. Eng., 455 (012051). https://doi.org/10.1088/1757-899X/455/1/012051

Hattingh, M., I.J. Van Der Walt and F.B. Waanders. 2016. Comparison of Cyclone Design Methods for Removal of Fine Particles from Plasma Generated Syngas. Int. J. Mech. Mech. Eng., 11: 19-27.

Heinimö, J. and M. Junginger. 2009. Production and trading of biomass for energy-an overview of the global status. Biomass Bioenergy, 33: 1310-1320. https://doi.org/10.1016/j.biombioe.2009.05.017

Ibrahim, M., M. Yamin, G. Sarwar, A. Anayat, F. Habib, and S. Ullah. 2011. Tillage and farm manure affect root growth and nutrient uptake of wheat and rice under semi-arid conditions. Appl. Geochem., 26: S194-S197. https://doi.org/10.1016/j.apgeochem.2011.03.102

Kopyscinski, J., T.J. Schildhauer and S.M. Biollaz. 2010. Production of synthetic natural gas (SNG) from coal and dry biomass-A technology review from 1950 to 2009. Fuel, 89 (8): 1763-1783. https://doi.org/10.1016/j.fuel.2010.01.027

Kumar, S. and S. Shukla. 2016. A review on recent gasification methods for biomethane gas production. Int. J. Energy Eng., 6: 32-43.

Laohalidanond, K., N. Kongkaew and S. Kerdsuwan. 2017. Gasification Behavior Study of Torrefied Empty Corn Cobs. Energy Procedia, 138: 175-180. https://doi.org/10.1016/j.egypro.2017.10.146

Massoud, M.A., A. Tarhini and J.A. Nasr. 2009. Decentralized approaches to wastewater treatment and management: applicability in developing countries. J. Environ. Manage., 90: 652-659. https://doi.org/10.1016/j.jenvman.2008.07.001

Mustafa, A., R.K. Calay and M.Y. Mustafa. 2017. A Techno-economic Study of a Biomass Gasification Plant for the Production of Transport Biofuel for Small Communities. Energy Procedia, 112: 529-536. https://doi.org/10.1016/j.egypro.2017.03.1111

Ojolo, S., S.M. Abolarin and O. Adegbenro. 2012. Development of a Laboratory Scale Updraft Gasifier. Int. J. Manuf. Syst., 2: 21-42. https://doi.org/10.3923/ijmsaj.2012.21.42

Omar, M., A. Munir, M. Choudhary and A. Tanveer. 2017. Downdraft gasifier structure and process improvement for high quality and quantity producer gas production. J. Energy Inst., 91(6):1034-1044. https://doi.org/10.1016/j.joei.2017.07.005

Palma F. 2013. Modelling of tar formation and evolution for biomass gasification: A review. Appl. Energ., 111: 129-141. https://doi.org/10.1016/j.apenergy.2013.04.082.

Seyfang, G. and A. Haxeltine. 2012. Growing Grassroots Innovations: Exploring the Role of Community-Based Initiatives in Governing Sustainable Energy Transitions. Environ. Plan. C: Govt. Pol., 30 (3): 381-400. https://doi.org/10.1068/c10222

Szul, M., T. Iluk and A. Sobolewski. 2020. High-Temperature, Dry Scrubbing of Syngas with Use of Mineral Sorbents and Ceramic Rigid Filters. Energies, 13: 1528-1550. https://doi.org/10.3390/en13061528

Thapa, S., P. Bhoi, A. Kumar and R. Huhnke. 2017. Effects of Syngas Cooling and Biomass Filter Medium on Tar Removal. Energies. 10(3): 349-351. https://doi.org/10.3390/en10030349

Thengane, S.K., A. Gupta and S.M. Mahajani. 2019. Co-gasification of high ash biomass and high ash coal in downdraft gasifier. Bioresour Technol., 273: 159-168. https://doi.org/10.1016/j.biortech.2018.11.007

Upadhyay, D., A. Sakhiya, K. Panchal and R. Patel. 2018. Thermodynamic analysis of lignite gasification in the downdraft gasifier. J. Energy Env. Sustain., 5: 58-63. https://doi.org/10.47469/JEES.2018.v05.100058

West, T. and A. Photiou. 2018. Measurement of gas volume and gas flow. Anaesth. Intens. Care Med., 19 (4): 183-188. https://doi.org/10.1016/j.mpaic.2018.02.004

Zhang, W., H. Liu, I. Ul Hai, Y. Neubauer, P. Schröder, H. Oldenburg, A. Seilkopf and A. Kölling. 2012. Gas cleaning strategies for biomass gasification product gas. Int. J. Low-Carbon Technol., 7: 69-74. https://doi.org/10.1093/ijlct/ctr046

Zhu, Y., J. Liang, Q. Yang, H. Zhou and K. Peng. 2019. Water use of a biomass direct-combustion power generation system in China: A combination of life cycle assessment and water footprint analysis. Renew. Sustain. Energy Rev., 115: 109-396. https://doi.org/10.1016/j.rser.2019.109396

To share on other social networks, click on any share button. What are these?