Performance Evaluation of Downdraft Gasifier with Syngas Cleaning System

Performance Evaluation of Downdraft Gasifier with Syngas Cleaning System

Sidrah Ashfaq1, Muhammad Nadeem1*, Muhammad Yamin1, Talha Afzal1, Muhammad Waqar Akram1, Rabia Anam1 and Ali Mehboob2

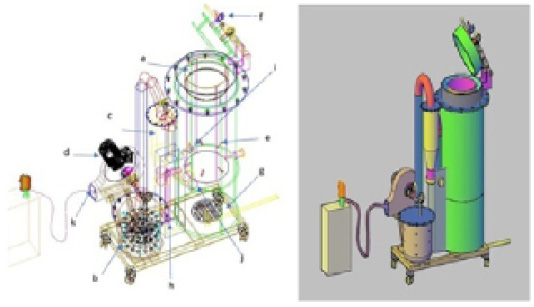

Isometric view gasifier system; A) Gasifier reactor, B) Hybrid biomass filter, C) Cyclone sepatator, D) Suction system, E) Nozzles, F) Pressure safety valve, G) Circular grate, H) Air entry valve, I) Firing valve, J) Ash removal prot, K) Gas exit prot.

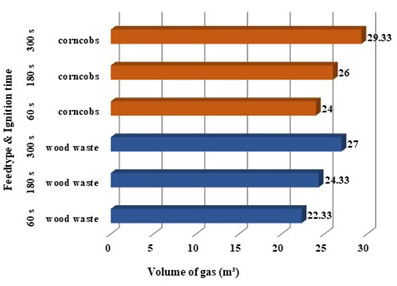

Volume osf gas produces in response to treatments.

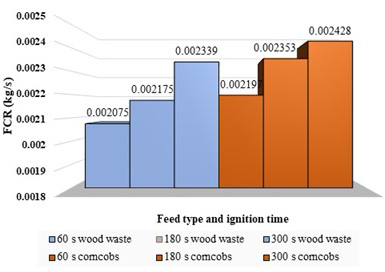

Fuel consumption rate with respect to treatments.

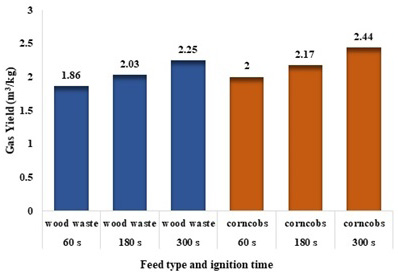

Effect of feed type and ignition time on gas yield.

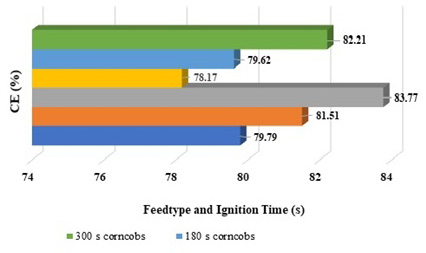

Cleaning unit efficiency with respect to treatments.

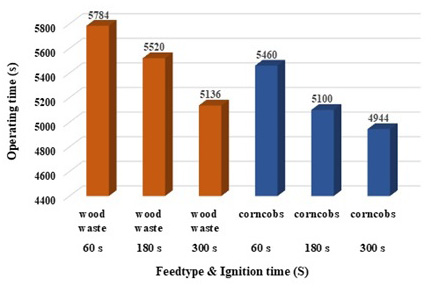

Operating time in response to treatments.