Exploring Potential of Mechanical Transplanting of Rice in Punjab, Pakistan

Research Article

Exploring Potential of Mechanical Transplanting of Rice in Punjab, Pakistan

Nadeem Akmal1, Abid Hussain1*, Muhammad Yousaf2, Waqar Akhtar1 and Hassnain Shah1

1Social Sciences Research Institute, PARC-National Agricultural Research Centre, Islamabad, Pakistan; 2Plant Sciences Division, Pakistan Agricultural Research Council, Islamabad, Pakistan.

Abstract | Rice is an important food grain crop in Pakistan. However, the country stands far behind in the South Asian region in mechanization of the crop. Currently, rice farming in Pakistan is in transition, with the coexistence of conventional and mechanized farming. In this reference public sector is supporting rice farmers through the knowledge dissemination and service provision in the country for the mechanization of rice crop. In this article economic comparison of mechanical and conventional rice sowing methods in the rice-wheat cropping zone of the Punjab province has been made by applying economic analysis technique. As, Basmati-Super and Basmati- 386 are main rice varieties grown in the country. Thus, this study is based on data of 46 purposively selected farmers for the crop season 2021, including 30 and 16 farmers of Basmati-386 and Basmati-Super, respectively. Cost comparison of the crop produced through mechanical and conventional manual transplanting techniques revealed that costs of raising the nursery and its transplanting through mechanical method are higher than conventional sowing method by 13.55 percent and 2.33 percent, in case of Basmati Super and Basmati-386, respectively. While, all other cost items of the crop production are more or less the same across both methods. Thus, it is reaffirmed that mechanical transplanting of rice (MTR) is labour saving, and more productive than conventional sowing method. Productivity of Basmati-Super and Basmati-386 rice crop palnted through MTR at sample farms were higher than conventionally transplanted crops by 12.23 and 10.56 percent, respectively. In case of Basmati 386, benefit-cost ratios of crops sown through mechanical and conventional methods are 1.40 and 1.28, respectively. Similarly, for Basmati-Super benefit-cost ratios of crops sown through mechanical and conventional methods are 1.44 and 1.33, respectively. Furthermore, MTR can be adopted on all soil types. Thus, MTR technique has obvious advantage over conventional rice sowing method. The technique has the potential to be adopted on wider scale. However, mechanical, technical and financial backups for importers, entrepreneurs and service providers are needed to be devised. Agronomists should conduct research to compare suitability of different planting materials for nursery sowing in trays. Similarly, experiments should be carried out to find out optimal irrigation and fertilizer application levels for mechanically transplanted crop.

Received | March 20, 2023; Accepted | September 15, 2023; Published | June 28, 2023

*Correspondence | Abid Hussain, Social Sciences Research Institute, PARC-National Agricultural Research Centre, Islamabad, Pakistan; Email: abid.parc@gmail.com

Citation | Akmal, N., A. Hussain, M. Yousaf, W. Akhtar and H. Shah. 2023. Exploring potential of mechanical transplanting of rice in Punjab, Pakistan. Pakistan Journal of Agricultural Research, 36(2): 169-182.

DOI | https://dx.doi.org/10.17582/journal.pjar/2023/36.2.169.182

Keywords | Adoption, Benefit-cost Ratio, Economic analysis, Mechanized sowing, Productivity, Rice, Punjab

Copyright: 2023 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Rice is a major crop of Pakistan with an annual production of 9.3 million tons (GOP, 2022). It is an important food crop in the country, and has a sizable contribution in country’s foreign exchange earnings. In the year 2020-21, Pakistan exported basmati rice of more than US$ 800 million and earned a valuable foreign exchange of USD 2 billion from the rice export (REAP, 2021). The introduction of new varieties and improving management practices over time have enhanced yield to some extent. Still, rice productivity is low i.e., 2.64 tons per hectare in Pakistan compared to the world average of 4.71 tons per hectare (GOP, 2022; FAOSTAT, 2020). Due to conventional farming practices and low use of innovative technology, the country faces serious yield gap issues (FAO, 2012; Hussain, 2014; Aslam et al., 2016). Kahliq et al. (2019) reported that there is a yield gap of thirty-three percent in rice in Gujranwala district. The yield gap can be narrowed with efficient management practices like mechanical transplanting of rice (MTR) and direct seeding instead of using the traditional puddling method. The rice transplanting method is the crucial element of rice cultivation (Islam, 2016).

Currently, rice farming in Pakistan is in transition, with the coexistence of traditional and mechanized farming. Mechanized use of inputs and resources directly bear on timeliness and precision in the crop production operations, increase in production and productivity, higher income generation, reduction in crops and food losses, reduction in drudgery, and improvement in the farming work environment. Agricultural mechanization plays a strategic role in improving agricultural production and productivity in developing countries (Naseer et al., 2020). The main constraint in increasing agricultural productivity includes the non-availability of agricultural machinery at the right time on affordable prices to the farming community (GOP, 2020). Compared to the regional nations, agricultural mechanization in Pakistan is considered under-prioritized, relying mainly on tractors and specific land-preparing instruments as the sector’s lack of technological orientation (FAO, 2012).

One of the major constraints of farm mechanization is smallholding. The average farm size in Pakistan is small (about 1.0 ha), and small and marginal landholdings (less than 2.0 ha) account for 85% of landholdings. Mechanizing small and non-contiguous groups of small farms is against ‘economies of scale’ for individual ownership of farm machinery (Naseer et al., 2020). Thus, small size and scattered holdings of the farmers stand in the way of mechanization. As a result of this, farm machinery generally remains underutilized. Farm machinery can also increase yield and reduce the need for labour, although the requirement of significant capital investment often prevents small farmers from buying machinery (Akram et al., 2020). In this scenario, it is desirable to use small-scale and cost-effective agricultural machinery according to the farm size. The government of Pakistan has launched some programs to promote mechanization in agricultural enterprises. In this regard, the government is providing subsidies for mechanical rice transplanters. Some private entrepreneurs are also promoting this technology by importing new and used trans-planters from Japan and Korea. The varying capacity of these transplanters suits small to large holder farmers. MTR is considered a viable technique for increasing productivity due to labour savings, prompt and timely transplantation, and optimal plant density (Kumar et al., 2015). Rice transplanting done manually requires about forty percent of the total labour requirement of rice production (Sangeetha and Baskar, 2015). While, MTR takes one-fourth of the total labour requirement of the rice production under traditional system (Saha et al., 2021). However, mechanical transplanting systems improves yield, enhances labor efficiency, maintains optimal plant density and enables operational timeliness (Islam, 2016; Umar et al., 2022).

The Agricultural research and development initiatives have encouraged the transformation in agriculture sector with increasing mechanization. Crop enterprise has shifted its labour-intensive practices to cost-effective mechanized crop management methods. The mechanized management methods vary among the crops due to varying crop cultivation practices. The sowing of rice crop has been a manual activity worldwide for a longer period of time. Though majority of the farmers in rice-growing countries have shifted themselves to MTR mainly due to labour shortage and rice productivity prospects. While, rice-growing farmers in Pakistan are still stuck or convinced with the conventional way of rice sowing.

In Pakistan, rice is the second most essential food crop, after wheat, and livelihood source for the millions of farm households. However, the crop is facing significant yield reduction due to climate change. In this reference, low yield regions are more vulnerable in the country (Khan et al., 2021). On the other hand, in rice farming, machinery, fuels, agrochemicals and animal labour share 1.8, 30.7, 66.6 and 0.8 percent in greenhouse gas (GHG) emissions. Emissions from tubewell irrigation systems is the highest in comparison with canal and rain-fed systems. They also reported a positive and statistically significant relationship between rice yield and GHG emission (Maraseni et al., 2009). Similarly, Azam et al. (2021) reported that performance of Pakistan’s agriculture sector in carbon emission structure and intensity is average. They stated that spatiotemporal evolution of energy use in Pakistan in the decade (of 2006 to 2016) has revealed that the country has become more energy efficient due to improvement in the economy. They further specified that the use of advanced technologies in the production process has increased energy consumption per unit of GDP, resulting in a reduction in carbon emissions.

In the country, agriculture, forestry and other land use (AFOLU) sector accounted for thirty-seven percent of total GHG emissions in 2017. Out of this, agriculture sub sector shared thirty-four percent in total GHG emissions. Enteric fermentation (livestock) and agricultural soils are the main sources of GHG emissions in the agriculture sub-sector. Livestock shares seventy-four percent in GHG emissions from agriculture. Similarly, agricultural soils, manure management, rice cultivation and crop residue burning share about 16.3, 7.3, 2.0, and 0.4 percent in the GHG emissions. Over time (1994 to 2017), the GHG emissions from AFOLU increased linearly, possibly due to the consistent growth in livestock population and use of synthetic fertilizers (Mir et al., 2021).

Niazi (2003) argued that land tenure, its use and degradation are interlinked in Pakistan. Uneven access to land engenders intensification of its use; small holders intensively use their small holdings to pay for self-subsistence and cost of production, along with tenants are to manage rent on the land. While, large landholders tend to adopt practices like over/ under irrigation, low use of soil ameliorating inputs, and delay in farm operation etc. which cause land degradation from depletion of essential soil nutrition and salinity. Greenhouse gas emissions badly affected the production of cotton, wheat and rice crops in Pakistan. While, energy consumption exerts the positive impact on the production of cotton, wheat and rice in Pakistan. Thus, mechanized rice farming is expected to have net positive impact on rice production in the country and may improve the sustainable use of natural resources.

The rice-wheat (RW) zone of Punjab province is the major aromatic rice producing area of the country. Foreseeing the labour shortage in the agricultural sector in the RW zone and productivity enhancement prospects of mechanized rice farming, PARC scientists have initiated MTR at farmers’ fields in Gujranwala district under the PSDP Productivity Enhancement of Rice project that was initiated in the year 2020. There is a gap for socioeconomic evidence regarding compatibility, viability, social acceptability and feasibility of different options being promoted by public and private sector in general and mechanized transplanting of rice in particular. This research study has been designed to gauge the adoption and contribution of MTR in enchancing the crop yield and farmers’ profitability in the RW production system of Punjab, Pakistan. As per official statistics, the rice-wheat zone of the Punjab, comprised of Gujrat, Mandi Bahauddin, Sialkot, Gujranwala, Hafizabad, Sheikhupura, Nankana Sahib and Lahore districts; shares 29.5 percent in total rice area and 24.4 percent production of rice in Pakistan, respectively (GOP, 2022a, b; Khaliq et al., 2019). Furthermore, the adoption of MTR has started earlier in the zone than other rice producing areas of the country. Likewise, adoption of the method is more wide spread in Gujranwala and Sheikhupura districts as compared to other districts in the zone. Thus, these districts in the zone were considered as the study area. Following are specific objectives of the study to study socioeconomic characteristics of the adopters of MTR; to conduct economic comparison of MTR with conventional sowing; to explore the adoption determinants and contribution of MTR in comparison to conventional rice sowing method; to find the constraints in the adoption and use of MTR at the farm level; to provide feedback to researchers for enhancing the effectiveness of MTR, and suggest policy measures to promote MTR.

Materials and Methods

The study is based on primary data of 46 rice farmers for the crop season 2021, including 30 and 16 farmers of Basmati 386 and Basmati-Super varieties, respectively. In the first step to undertake this research study, higher management of PSDP funded project ‘Productivity Enhancement of Rice’ was contacted to get firsthand knowledge about the mechanical transplanting of rice (MTR). In the second step, a draft survey tool was prepared. That was pre-tested and finalized for field survey use. In the next step, PSDP project management was asked for the list of adopters of mechanized rice sowing method. The farmers were contacted through telephone calls, and the one willing to give feedback about the technology were interviewed through face-to-face method by the research team in March 2022. In this way, purposive sampling was used and farmers belonged to Gujranwala and Sheikhupura districts in rice-wheat zone of Punjab were interviewed. Details of villages by tehsil and districts are given in Table 1.

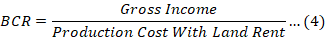

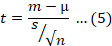

Service providers of mechanized rice transplanting, entrepreneurs/ importers of new and used walk after and ride type transplanters, nursery sowing machines, nursery trays and spare parts were also contacted to obtain their views about promotion of the technology through informal interviews. Most of these were located on Eminabad road, GT road, Ali Pur By Pass, Ali Pur Chowk, Gujranwala; Verpal Chatha, Wazirabad, Gujranwala and Wahndo Road, Eminabad, Gujranwala. Similarly, the offices of Agriculture Extension Departments of Gujranwala and Maridkay-Sheikhupura, and Adoptive Research Gujranwala were also visited and survey team held detailed discussions with them to get opinion of district level officers about the technology adoption prospects. In the same way, agricultural service providers (ASPs) were also contacted to get their views about the adoption prospects of MTR through informal interviews. IBM SPSS Statistics 20 software is used for determination of descriptive statistics and statistical analysis along with MS-Excel for economic analysis. Following are details of the economic analysis. Net income of the farmers excluding land rent and with land rent are determined by expression 1 and 2, respectively. Similarly, benefit cost ratios excluding land rent and with land rent are obtained by expressions 3 and 4, respectively. Student t-test was determined to make statistical comparisons of cost items and productivity of MTR with conventional rice sowing through expression 5. Farmers perceptions about the future adoption of mechanized rice farming in relevance to technology related aspects and constraining factors in adoption are analyzed by using the scale given in section i and ii of Table 2.

Where m = mean, µ = theoretical value, s= standard deviation and n = variable set size.

Results and Discussion

Socioeconomic characteristics of the farmers

Sample adopters of the mechanical transplanting of rice (MTR) were in the middle age group, with mean age of 46 years and standard deviation of 13 years (Table 3). Umar et al. (2022) studied the adoption of MTR in rice-wheat zone of Punjab and unveiled based on the demographic profile of the farmers that farmers in young age have less inclination towards rice planting and MTR adoption. Sample farmers for this study have ample crop farming experience, with a mean of 21 years and standard deviation of 14 years. Adaptors of mechanized rice farming are mostly educated up to

Table 1: Sample distribution by villages in the study area.

|

Districts |

Tehsils |

Villages |

Sample size (n) |

|

Sheikhupura |

Sheikhpura |

Hardeo |

1 |

|

Muridkay |

Goth Haji Faqair, Pindi Bhattian and Resear Sabota |

3 |

|

|

Gujranwala |

Gujranwala |

Amanabad, Bajumal, Datey Wali Ferozwala, Khaliqpur, Nundpur and Nongra |

14 |

|

Kamoki |

Kot Rehmat Khan and Laopur |

7 |

|

|

Nowshera |

Chung, Nokrian and Philoke |

8 |

|

|

Wazirabad |

Bhuma Batt, Dargahi Wala, Kalair Uch, Kot Proay and Verpal Chatta |

13 |

|

|

Total |

46 |

||

secondary school (28%) and higher secondary school and above (36%). While, twelve percent of them were illiterate. Adopters of the technology have large operational holdings, as mean operational holding of the sample farmers was 41.47 acre, including owned land of 26.98 acre i.e., sixty-five percent of operational area.

Table 2: Scale for farmers perceptions about future adoption of mechanized rice farming.

|

I. Scale for perceptions in relevance to the technology related aspects |

Value range |

|

No opinion |

≤ 0.83 |

|

Strongly disagree |

0.84-1.66 |

|

Disagree |

1.67-2.50 |

|

Slightly agree |

2.51-3.33 |

|

Agree |

3.34-4.17 |

|

Strongly agree |

4.18-5.00 |

|

II. Scale for constraining factors in adoption |

|

|

Not a constraint |

1.00-1.79 |

|

Slight constraint |

1.80-2.59 |

|

Moderate constraint |

2.60-3.39 |

|

Serious constraint |

3.40-4.19 |

|

Very serious constraint |

4.20-5.00 |

Table 3: Socioeconomic characteristics of sample farmers.

|

i. Age and experience (Years) |

|

|

Age (years) |

46 ± 13 |

|

Farming experience (Year) |

21 ± 14 |

|

ii. Education level (Percent) |

|

|

Illiterate |

12 |

|

Up to middle |

24 |

|

Matric/ Secondary school |

28 |

|

Intermediate/ Higher secondary school and above |

36 |

|

iii. Land holding (Acres) |

|

|

Owned |

26.98 |

|

Cultivated |

26.42 |

|

Shared in |

0.04 |

|

Shared out |

0.00 |

|

Leased in |

15.35 |

|

Leased out |

0.34 |

|

Operational |

41.47 |

Eighty percent of sample farmers reported to own tractors. They were well equipped with other farm implements, including cultivators (80%), trolleys (60%), disc harrows (58%) and rotavators (52%). Sixteen percent of the sample farmers also reported to have rice nursery sowing and planting machines each. All the sample farmers reported availability of pumped water at their farms. Moreover, seventy-six percent of the farmers reported to have access to canal water. Most of them (93%) reported seasonal availability of canal water. Availability of canal water with weekly, fortnightly and monthly intervals was reported by twenty-six, forty-four and thirty percent of the farmers, respectively. Mean time allocation per acre was reported 26 minutes with a requirement of water for 3.46 hours per acre for pre-sowing irrigation of the rice crop of 3.5 hours per acre. Sixty-seven percent of the farmer reported to have electricity connections at their farms for pumping ground water, twenty-nine percent reported to use peter engines and four-percent have solar pumps. Analysis of socioeconomic characteristics of the farmers revealed that the farmers in middle age, having high levels of education, having ample experience in crop farming, possessing large land holdings, equipped with tractor and other farm implements are main adopters of the MTR. Umar et al. (2022) also stressed to convince rice farmer having formal education, ownership of their lands and tubewell to irrigate the crop to adopt MTR.

Area allocation to rice varieties

Area allocation to rice crop at sample farms averaged at 36.5 acre. Basmati super and basmati 386 are main varieties planted by the farmers, with mean area of 17.7 acre (48% of rice area) and 10.6 acre (29% of rice area) per farm, respectively. Basmati 515, Kainat, 1509 and other varieties were planted at 2.8, 1.7, 1.0 and 2.7 acre, respectively, with area allocation per farm in percentage term of 8, 5, 3 and 7, respectively. As Basmati Super and Basmati 386 are the main rice varieties in the rice-wheat zone, thus are largely transplanted through MTR method. Fifty-six percent area of Basmati-386 (6.0 acre) and eighteen percent of Basmati Super (3.2 acre) per farm was planted through MTR method. While, thirteen percent area of all other varieties (1.1 acre) was planted through mechanical method.

Economics of mechanical and conventional rice transplanting methods for basmati super

Cost comparison of the crop produced through mechanical and conventional transplanting techniques for Basmati Super are presented in Table 4. Cost of nursery and transplanting for MTR method is higher than conventional sowing method by 13.55 percent (Rs. 1171 per acre) and difference is statistically

Table 4: Itemized cost and yield comparison of mechanical with conventional sowing method (Basmati Super) Rs./acre.

|

Mechanical |

Conventional |

Difference |

Standard deviation |

t value |

Sig. |

|

|

Land preparation cost |

9928 |

10241 |

-313 (-3.05) |

873 |

-1.43 |

0.173 |

|

Nursery and transplanting cost |

9813 |

8642 |

1171 (13.55) |

2362 |

1.98 |

0.066*** |

|

Irrigation cost |

8330 |

8319 |

11 (0.13) |

389 |

0.11 |

0.911 |

|

Fertilizers’ cost |

11242 |

11269 |

-27 (-0.24) |

1416 |

-0.08 |

0.941 |

|

Plant protection cost |

4549 |

4386 |

163 (3.70) |

480 |

1.35 |

0.196 |

|

Labour cost |

4452 |

4394 |

58 (1.33) |

124 |

1.62 |

0.132 |

|

Harvesting cost |

5656 |

5453 |

203 (3.72) |

813 |

1.00 |

0.333 |

|

Mark up, marketing cost and land tax |

3694 |

3491 |

203 (5.81) |

436.5 |

1.23 |

0.112 |

|

Yield (40 Kgs) |

35.8 |

31.9 |

3.9 (11.93) |

2.2 |

7.01 |

0.000* |

Note: Figures in parenthesis are percentage difference over conventional method * and *** are significant at 1 and 10 percent levels, respectively.

Table 5: Benefits comparison of mechanical with conventional sowing method (Basmati Super) Rs./acre.

|

Mechanical |

Conventional |

Difference |

Percent change |

|

|

Production cost |

57664 |

56195 |

1469 |

2.61 |

|

Land rent |

20500 |

20500 |

0 |

0 |

|

Production cost with land rent |

78164 |

76695 |

1469 |

1.92 |

|

Yield |

35.8 |

31.9 |

3.9 |

12.23 |

|

Rice paddy value @ 2166 per 40 kg |

77543 |

69095 |

8447 |

12.23 |

|

Dry stalk value |

3063 |

3063 |

0 |

0 |

|

Production cost per 40 kg including land rent |

2183 |

2404 |

-221 |

-9.19 |

|

Production cost per 40 kg excluding land rent |

1611 |

1762 |

-151 |

-8.56 |

|

Gross income |

80606 |

72158 |

8447 |

11.71 |

|

Net income excluding land rent |

22942 |

15963 |

6978 |

43.71 |

|

Net income with land rent |

2442 |

-4537 |

6978 |

-153.82 |

|

Benefit cost ratio excluding land rent |

1.40 |

1.28 |

0.12 |

8.86 |

significant at 10 percent level. However, all other cost items of rice crop production are quite similar across both methods. While, MTR method has clear advantage over conventional method, mean yield of sample farmers was higher by 11.93 percent (3.9 mound per acre) than conventional method. Increase in the yield due to MTR over conventional method was much less than potential yield enhancement claimed by the Directorate of Agriculture, Gujranwala i.e. 20-25 mound per acre. The results of present study are in line with that of Farooq et al. (2001), they reported that five to six mounds higher grain yield is obtained whenever transplanting is done through MTR over manual transplanting with same level of inputs. Similarly, Singh et al. (2006) reported that MTR method offered 23.04 percent higher yield over manual method. Increase in yield in MTR method is generally attributed to transplanting of younger seedlings with appropriate spacing and depth, early tillering, development of more panicles on earlier tillers, long panicles, extended active leaf life and decreased rate of leaf are reduction (Yao et al., 2000).

Comparison of total cost of production and benefits of MTR method vis-à-vis conventional method per acre are presented in Table 5. Total costs of production per acre excluding land rent were Rs.57,664 and 56,195 through mechanical and conventional methods, respectively. Thus, cost of production of mechanical method was little higher than conventional method by 2.61 percent (Rs.1469 per acre). While, both yield and value of paddy produced through MTR method and gross income were higher than that of conventional method by 12.23% each and 11.71%, respectively. The results are similar to Singh et al. (2006) and Manes et al. (2013), who stated that MTR increased yield over conventional manual method. As the prices of paddy rice were much low in year 2021, with mean of Rs. 2166 per 40 kg for sample farmers, profitability of the crop by considering land rent as cost item was considerably low in case of MTR method, and was negative in case of conventional method. While, excluding land rent, it was Rs.22,942 per acre in case of MTR method and Rs.15,963 in conventional sowing method. Benefit-cost ratios of crops grown through MTR and conventional methods are found to be 1.40 and 1.28, respectively. The results are in line with Bohra and Kumar (2015), who reported that MTR gave the highest benefit cost ratio of 2.86 among various rice sowing methods viz. manual transplanting, MTR, direct seeding of sprouted and dry seedings.

Economics of mechanical and conventional rice transplanting methods for Basmati-386

Similar to Basmati Super variety of rice, cost comparisons of Basmati-386 variety of the crop produced through mechanical transplanting of rice (MTR) and conventional transplanting techniques divulged that except cost of nursery transplanting, all cost items are not much different across sowing techniques (Table 6). While, as was the case with Basmati Super, cost of nursery and transplanting for MTR method is higher than conventional sowing method by 2.33 percent (Rs.544 per acre) and difference is statistically significant at 5 percent level. While, mean yield of MTR was 10.58 percent (5.1 mounds per acre) higher than conventional sowing method.

Comparison of total cost of production and benefits of MTR method vis-à-vis conventional method per acre for Basmati-386 are presented in Table 7. Total costs of production per acre excluding land rent were Rs.59,891 and 58,693 through MTR and conventional methods, respectively. Thus, cost of production of MTR was little higher than conventional method by 2.04 percent (Rs.1198 per acre). Though, value of paddy produced through MTR method and gross income were higher than that of conventional method by 10.56% and 10.46%, respectively. Prices of paddy rice of variety Basmati-386 were Rs. 1561 per 40 kg, profitability of the crop by considering land rent as cost item was considerably low in case of MTR method, and even negative in case of conventional method. Whereas, excluding land rent, it was Rs.26,639 per acre in case of MTR method and Rs.19,645 in conventional sowing method. Benefit-cost ratios of crops sown through MTR and conventional methods are found to be 1.44 and 1.33, respectively.

Table 6: Itemized cost and yield comparison of mechanical with conventional sowing method (Basmati-386) Rs./acre.

|

Mechanical |

Conventional |

Mean difference |

Standard deviation |

t value |

Sig. |

|

|

Land preparation cost |

11269 |

11177 |

92 (0.83) |

470.68 |

1.00 |

0.327 |

|

Nursery and transplantation cost |

8846 |

8302 |

544 (6.56) |

1190.94 |

2.33 |

0.028** |

|

Irrigation cost |

8375 |

8365 |

10 (0.12) |

365.30 |

0.14 |

0.892 |

|

Fertilizers’ cost |

13131 |

13129 |

2 (0.01) |

807.52 |

0.01 |

0.990 |

|

Plant protection cost |

4398 |

4245 |

154 (3.62) |

464.10 |

1.69 |

0.103 |

|

Labour cost |

4518 |

4481 |

37 (0.83) |

168.94 |

0.96 |

0.350 |

|

Harvesting cost |

4846 |

4731 |

115 (2.44) |

588.35 |

1.00 |

0.327 |

|

Mark up, marketing cost and land tax |

4508 |

4263 |

245 (5.74) |

278.00 |

0.98 |

0.278 |

|

Yield (40 Kgs) |

53.4 |

48.3 |

5.1 (10.58) |

2.18 |

11.97 |

0.000* |

Note: Figures in parenthesis are percentage difference over conventional method * and ** are significant at 1 and 5 percent levels, respectively.

Table 7: Benefits comparison of mechanical with conventional sowing method (Basmati-386) Rs./ acre.

|

Mechanical |

Conventional |

Mean difference |

Percent change |

|

|

Production cost |

59891 |

58693 |

1198 |

2.04 |

|

Land rent |

20500 |

20500 |

0 |

- |

|

Production cost with land rent |

80391 |

79193 |

1198 |

1.51 |

|

Yield (40 Kgs) |

53.4 |

48.3 |

5.1 |

10.56 |

|

Rice paddy value @ 1561 per 40 kg |

83357 |

75396 |

7961 |

10.56 |

|

Dry stalk value |

3173 |

2942 |

231 |

7.84 |

|

Production cost per 40 kg including land rent |

1505 |

1640 |

-134 |

-8.18 |

|

Production cost per 40 kg excluding land rent |

1122 |

1215 |

-94 |

-7.70 |

|

Gross income |

86530 |

78338 |

8192 |

10.46 |

|

Net income excluding land rent |

26639 |

19645 |

6994 |

35.60 |

|

Net income with land rent |

6139 |

-855 |

6994 |

-818.01 |

|

Benefit cost ratio excluding land rent |

1.44 |

1.33 |

0.11 |

8.25 |

Table 8: Perceptions in relevance to technology related aspects (n=46).

|

Percentage |

Mean |

|||||||

|

No opinion |

Strongly disagree |

Dis-agree |

Slightly agree |

Agree |

Strongly agree |

Value |

Scale |

|

|

Yield advantage |

0 |

2 |

2 |

32 |

32 |

32 |

3.89 |

Agree |

|

Labour saving |

0 |

4 |

2 |

32 |

38 |

23 |

3.74 |

|

|

High conviction / satisfaction |

2 |

11 |

6 |

34 |

36 |

11 |

3.23 |

Slightly agree |

|

Advantage over traditional practice |

0 |

30 |

4 |

19 |

34 |

13 |

2.96 |

|

|

Crop stand is good |

2 |

32 |

11 |

21 |

32 |

2 |

2.55 |

|

|

Suitability for specific soil type |

9 |

43 |

9 |

11 |

15 |

15 |

2.26 |

Disagree |

|

Ease in using the technology |

2 |

43 |

23 |

0 |

30 |

2 |

2.19 |

|

|

Less weed infestation |

9 |

32 |

47 |

13 |

0 |

0 |

1.64 |

Strongly disagree |

|

Water saving |

4 |

57 |

36 |

2 |

0 |

0 |

1.36 |

|

Scale: Mean Value range: No Opinion= 0-0.83, Strongly Disagree= 0.84-1.66, Disagree= 1.67-2.50, Slightly Agree=2.51-3.33, Agree= 3.34-4.17, Strongly Agree= 4.18-5.00

Farmers perceptions about future adoption of mechanized rice farming

In accordance with the results of field survey about productivity gain through MTR for both Basmati Super and Basmati-386 varieties, sample farmers perceive that mechanical transplanting of rice results into higher yield than conventional manual sowing and other methods like Direct Sowing of Rice (DSR) through drill or broad casting etc. (Table 8). Ninety-six percent of the sample farmers reported that MTR method results in to higher productivity. They perceive that it is a labour saving technology and help to overcome labour shortage issue for planting of the crop on time. Similarly, rice growers perceive that the technology has significant advantage over traditional practice, results into good crop stand, and they are convinced with overall performance of the technology. The results are in line with Umar et al. (2022) they reported that MTR is time-efficient, reduces labour requirements, gives better plant population and provides more yield as compared to conventional planting. In the same way, Kumar et al. (2015) found that MTR offers a viable alternative for timely transplanting, it is labour saving, and gives ideal number of plants, all of which help to increase the productivity. Fifty-five percent of the farmer reported that MTR results into good crop stand as plant density/ number of plants per unit area are higher than conventional method of transplanting. Similarly, Hayashi et al. (2006) also reported that higher plant density in flooded rice crop increases grain yield. Thus, higher plant density achieved through MTR results in higher grain yield in favourable flooded conditions. While, farmers perceive that technology is not soil specific i.e., it can be equally adopted at all soil types in rice-wheat cropping zone of the province. Like in Pakistan, MTR is gaining popularity in Bangladesh as reported by Hossen et al. (2022). They stated that it is cost-effective and operation-friendly. Through, its use seedlings can be planted while maintaining plant and line spacing, both of which are crucial for increasing yield. Mechanized planting is somehow tough to adopt as compared to conventional planting method, 59% farmers reported hardship in its use. They perceive that the crop grown through MTR is more prone to weed infestation as light irrigations at early crop stage may often results in growth of weeds in the crop. They also reported that MTR does not have considerable impact on water requirements of the crop vis-à-vis conventional sowing method.

Constraining factors in adoption of mechanical transplanting

As far as technical factors of adoption of MTR are concerned, farmers perceive that non-existence of local manufacturing industry is a serious constraint as reported by 57 percent of the respondents (Table 9-I). While, non-availability of transplanting services, high prices of transplanters, and difficulty in preparation of nursery in trays etc. as well as all extension related factors are rated moderate constraints in wide scale adoption (Table 9-II). The results are in line with Umar et al. (2022), they reported that higher cost of laser levelling, difficulty in repair/ maintenance of mechanical transplanters, non-availability of spare parts, unskillfulness of labour for nursery raising machines, lack of proper training regarding MTR, high prices of transplanting machines, difficulty in raising

Table 9: Constraining factors in mechanical transplanting (n=46).

|

Constraints |

Types |

Mean |

|||||

|

Not a constraint |

Slight |

Moderate |

Serious |

Very serious |

Value |

Scale |

|

|

I. Technical factors (%) |

|||||||

|

Lack of local manufacturing |

6 |

6 |

13 |

57 |

17 |

3.72 |

Serious constraint |

|

Non-availability of transplanters |

17 |

15 |

15 |

36 |

17 |

3.21 |

Moderate constraints |

|

High prices of transplanters |

17 |

19 |

4 |

45 |

15 |

3.21 |

|

|

Nursery preparation in trays |

9 |

15 |

36 |

32 |

9 |

3.17 |

|

|

Death possibility of seedlings/ Riskier |

4 |

34 |

36 |

23 |

2 |

2.85 |

|

|

Difficult to use the technology |

19 |

49 |

19 |

11 |

2 |

2.28 |

|

|

Lodging of crop |

64 |

26 |

11 |

0 |

0 |

1.47 |

Not a Constraint |

|

Soil suitability |

77 |

11 |

6 |

6 |

0 |

1.43 |

|

|

II. Extension factors (%) |

|||||||

|

Lack of attention of mass media |

11 |

17 |

11 |

51 |

11 |

3.34 |

Moderate constraints |

|

Lack of extension literature |

15 |

17 |

17 |

47 |

4 |

3.09 |

|

|

Extension workers’ lack of knowhow |

11 |

28 |

26 |

34 |

2 |

2.89 |

|

|

Farmers’ lack of awareness among |

15 |

32 |

15 |

36 |

2 |

2.79 |

|

|

Farmers’ lack of knowledge |

15 |

38 |

11 |

30 |

6 |

2.74 |

|

|

Farmers’ lack of conviction |

34 |

28 |

17 |

21 |

0 |

2.26 |

|

|

III. Financial factors (%) |

|||||||

|

Farmers’ poor financial resource base |

17 |

2 |

13 |

38 |

30 |

3.62 |

Serious constraint |

|

Lack of credit facilities for purchase of machine |

17 |

11 |

13 |

38 |

21 |

3.36 |

Moderate constraints |

|

Lack of adequate credit to buy other inputs |

17 |

4 |

40 |

32 |

6 |

3.06 |

|

Scale Mean Value range: Not a Constraint=1-1.79, Slight Constraint= 1.80-2.59, Moderate Constraint= 2.60-3.39, Serious Constraint=3.40-4.19, Very Serious Constraint=4.20-5.00

seedlings and nursery management for MTR are main constraints in the adoption, in decreasing order of importance. Extension related factors by rank value include; lack of attention of mass media, lack of extension literature, lack of know-how on part of extension workers and farmers etc. Farmers’ poor financial resource base is perceived a serious constraint in the adoption (Table 9-III). While, lack of credit facility for purchase of transplanters and lack of adequate credit supplies for purchase of related inputs are ranked moderate constraints in the adoption.

Import of new and used mechanical nursery sowing machines and rice transplanters

Complete nursery transplanting unit is comprised of three machines viz. soil/ planting material mixing machine, nursery tray planting machine and mechanical transplanter. Furthermore, there are two types of both nursery tray planting machines viz. platform type and crawling type, as well as of mechanical transplanters viz. walk after type and riding type. Most of the entrepreneurs dealing in sales business of mechanical transplanters reported to start business seven or eight years ago i.e. back in year 2014 or 2015. They reported to import few units of walk after type 4-row mechanical transplanters with one or two units of nursery tray planting machines, in the first season either from China or Korea. They reported that nursery raised in trays becomes ready for transplanting in 18-25 days. The number of tillers per plant are even more than double as compared to usual 40-day old nursery which is prepared in open fields. They further stressed that laser land levelling is a prerequisite for mechanical transplanting of rice (MTR).

Hassan et al. (2022) evaluated different planting methods for rice crop in the RW zone and reported that the mechanical transplanting of rice proved to perform best in terms of meeting recommended plant population, yield and yield parameters of rice crop. Mechanical transplanters have fix line to line distance of 12 inches, while plant to plant distance can be maintained at 4, 6 and 8 inches. Thorough mechanical transplanters 0.120 million rice plants can be transplanted per

Table 10: Specifications and prices of rice nursery transplanting machines in Year 2022.

|

Transplanters’ specification |

Labour requirement (men/day) |

Reported capacity (acre/day) |

Reported capacity per season of 30 days (acre) |

Price during rice season (Rs. Million) |

Expected working life (years) |

|

6-row riding type |

4 or 5 |

7-8 |

200-250 |

2.36 to 2.70* 4.70** 0.45*** 0.40**** |

6-8 6-8 3 2 |

|

8-row riding type |

4 or 5 |

12-14 |

400-450 |

0.85*** 0.80**** |

3 2 |

|

4-row walk after type |

2 |

4 |

120 |

0.44* |

3 |

|

6-row walk after type |

2 |

6 |

180 |

0.57* |

3 |

|

8-row walk after type |

5 |

7 |

210 |

1.80*** |

3 |

* New units imported from Korea/China, ** New unit imported from Japan *** Used units imported from Japan **** Used units imported from Korea.

acre, while it has capability to transplant 2 or 3 plants per hill. Currently, rice transplanters having 4 and 6 rows specification are imported from China, Korea and Japan. According to estimates currently there are 40 to 50 thousand rice nursery transplanters in the country. Approximately half of these are being used for agricultural service provision. About one-hundred trays are required to plant one acre of the rice crop. Seed requirement for Basmati-386 variety and Basmati-Super are 7-8 kg and 10 kg per acre, respectively. Similarly, optimization of seeding rate significantly affects the growth, yield and related traits of fine basmati rice. He concluded that 90-gram seed per tray improve the grain yield by enhancing number of productive tillers and grain weight of fine basmati rice. Entrepreneurs reported that normally three men are needed to optimize working of nursery sowing machine. Specification, labour requirement to operate, reported capacity area per day and per season along with machine prices are given in Table 10. Though, prices of imported machines vary greatly with made year and origin of import. It was reported that in Kharif season of year 2021 about 200 to 300 units were sold in the surveyed market. Under PSDP Productivity Enhancement of Rice project these machines were provided to farmers on 50 percent subsidy in year 2020, and 70 percent subsidy in year 2021 and 2022. While in year 2022, subsidy on nursery sowing machines was 50 percent.

Fuel requirements of these machines ranged from 2 to 2.5 liter per hour. Six-row riding type machine can plant one acre in one hour, while 8-row riding type machine can plant one acre in 45 minutes. A few of the entrepreneurs also reported to import and market petrol engine machines along with diesel engine operated units, however they reported to abandoning import of petrol engine machines due to low efficiency and other tehnical faults. There is a consistent increase in sale of the mechanical transplanters overtime. Similarly, area under MTR has increased many folds. Entrepreneurs involved in the marketing of rice transplanters believe that in next 4 to 5 years most of the rice crop (70-80%) will be planted through machines in the rice growing belt of the province.

Issues in mechanical transplanting, its benefits and future prospects

Initially there were few flaws in the use of the technology; use of non-sieved clay, nursery trays’ quality and resultant difficulty in uprooting of the nursery from trays were main issues. Similarly, time for transplanting is critical and was difficult to manage, precise land levelling was another issue. Generally, farmers don’t level and prepare land properly, and they usually blame that service providers don’t transplant the nursery properly. In the same way, impurity in seed of specific varieties resultant mixing in the transplanted nursery was another issue at the time of introduction of the technology. However, farmers instead of relying on seed managed by service providers, started to provide seed to them on their own for planting nursery and issue has been resolved. In the year 2020-21, labour availability was high due to outbreak of Covid-19 pandemic, thus sales and use of mechanized transplanting machinery were comparatively low. Used/ reconditioned imported machines need maintenance cost of Rs.0.08 to 0.20 million at the start of sowing season and in season maintenance cost of Rs.0.05 million. It is reported that second-hand eight-line units imported from Japan have capacity of transplanting rice nursery at seven acre daily, usually five labourers are needed for daily machine operation, with wage rate of Rs.1000 per day, including one operator, one helper for refilling trays and three men for supplying nursery. Machine operation is not difficult; thus, farm workers and tractor operators have gained operational know-how through their own working experience.

‘Still Platform’ and ‘Crawling’ type nursery sowing machines were priced Rs.0.85 million and Rs. 0.4 million in year 2022. It is reported that crawling type machine is more successful than platform type machine. Expected operational lives of these machines are more than five years each. Maintenance cost of nursery sowing machine is about 20 thousand per year. Crawling type machine requires 480-Volt current, and can be operated with electric power or 2.5 KW generator with a fuel consumption of 0.5-liter per hour. Silt (bhal) is commonly used as tray material, mostly without sieving. However, it should also be sieved with 6 mm strainer. By using platform type machine six to seven thousand trays can be sown in two days by using 10-man days; including 4 labourors to sieve and fill the clay in trays on first day and 6 labourors on next day for sowing the seed in filled trays. While, by using compost as planting material twelve to fourteen thousand trays can filled by same number of labourors in two days. Thus, considering wage rate of Rs.700 per day, labour cost of sowing is about Rs.1.07 and Rs.0.64 per tray with use of clay and compost as planting material, respectively. In 272.25 square feet area (1 marla), 100 to 136 trays measuring 1 x 2 foot can be placed. While a crawling type machine needs three labourers for its optimal use. A tray costs about Rs.30 to 35 with expected life of 3-4 years. While, if these are used twice a year i.e. both for coarse and fine varieties, then expected life would be two years. Low germination rate in plastic trays and water stress in initial one to two weeks after transplanting nursery plants in field, due to probable rise in temperature are issues in MTR. Irrigation level in the paddy fields during this time period is much crucial, as high level of irrigation may sink the young nursery plants, while low level of irrigation may result in plant wilting, hence cause stress on the growth of the crop. Though, by using mechanical transplanters, nursery sized 12-inch can be transplanted; however, Agriculture Service Providers prefer to transplant nursery sized 9-inch. Thus, water stress at this stage can be solved by using nursery sized 12-inch. Occasionally, ASPs keep speed of transplanters little high to cover large areas in less time, thus transplant nursery improperly with less than optimal level number of plants per unit area. Thus, farmers having their own transplanting machines can easily gain recommended number of plants per acre by keeping desired consistently slow speed of the machine. Alternatively, to increase vigor of the nursery plants they can use 200 trays with same quantity seed rate as used for 100 trays for planting one-acre area.

Similarly, frequent disorders in used/ reconditioned machines and non-availability of spare parts are other problems. Though, farmers are contented that in MTR less labour is required for the crop production with clear advantage of yield enhancement. However, these issues result into lack of conviction on part of the farmers and adopter for large scale adoption. Currently, availability of spare parts in not an issue. Two entrepreneurs in the surveyed area reported sales of Chinese origin spare parts, while one entrepreneur reported that components of used Korean machines that are not sold in first season of import, are used as spare parts in the next season. It is believed that water and nutrient requirement of mechanically transplanted crop is always more due to higher plant population per unit area than conventionally transplanted crop. Similarly, lack of knowledge about complete production package results into the crop production issues and low productivity.

Limitations of the study

There may be some possible limitations in this study. Though this study is based on reasonable sample size; however, study findings should be taken with little caution, as it has been carried out to cover a research area or technology, which is comparatively new in Pakistan. Limited number of studies in the country’s context are available on the topic. Thus, thorough review of available literature has been made before designing the survey toll used for the study. It is hoped that findings of the study would be useful for policy planners, development practitioners, researcher, academia, agricultural service providers, farmers and other relevant stakeholders. Findings of this research study can be used as a basis in designing future research endeavors to explore new dimensions of adoption of MTR in the country. Similarly, views of the entrepreneurs involved in import and sales business of mechanical transplanters, spare parts, and service provision should be taken carefully to draw workable options, as these may be biased to some extent.

Conclusion and Recommendations

Mechanical transplanting of rice (MTR) is a labour saving and more productive than conventional transplanting method. Farmers are conversant with the use of mechanical transplanters, but still they are not sure about consistency in the performance of MTR due to risk factors involved in its adoption. Access to service provision and affordability of the farmers to purchase the machines are issues in adoption of MTR. In case MTR, intensive crop care is required for first 10-15 days after transplanting due to comparatively small size of nursery plants i.e. light irrigation and draining are required on daily basis during first two weeks. Though the number of plants per unit area is greater in MTR, still input use is quite same as in conventional method i.e. complete production technology of MTR does not exist. Few of the Agricultural Service Providers are not skillful and availability of spare parts is still a genuine issue. However, most of the farmer reported that there is more possibility of wider adoption of the mechanical transplanting method, while remining six percent have mixed views in this reference. Following are a few recommendations based on findings of the study; PSDP project management and provincial extension departments should organize hands on rice nursery sowing in trays training for farmers, PSDP project management or concerned departments are required to develop criteria for import of used machine, so that these can also be included in the project for subsidy provision to the farmers. Tax on import of mechanical transplanting machine should be reduced, which is being charged at 17%. Similarly, provision of mechanical, technical and financial backups to importers, entrepreneurs and service providers is needed. Laser levelling is a prerequisite for mechanical transplanting of rice thus its large-scale adoption in the RW zone should also be promoted through public support. Special Facilitation Centers (SFCs) for promotion of MTR may also be established to assist importers, entrepreneurs, agricultural service providers and farmers. Agronomists should conduct experiments on comparative analysis of nursery germination and growth in clay/ bhal, compost and other soil types/ planting materials. In the same way, irrigation and fertilizer requirements of mechanically transplanted crop should also be determined, as number of plants are more than double per unit area of conventionally transplanted crop. Similarly, role of the agricultural extension department in promotion of the MTR should also be studied and encouraged.

Acknowledgement

The authors are extremely indebted to the management of PSDP-Productivity Enhancement of Rice for extending technical and financial support for this research study. In this reference, support provided by scientific and field staff of the PARC Rice Research Station, Kala Shah Kaku-Sheikhupura during field survey conducted for the study is highly commendable. The authors are obliged to officers of Agriculture Extension/ Adoptive Research Department of Gujranwala and Maridkay-Sheikhupura to share their expert opinion about the adoption prospects of the technology. Private sector entrepreneurs involved in MTR bussiness in the Rice-Wheat zone, including Meskay & Femtee, Chakwal Traders & Chairman Sons etc., and rice farmers are recognized for taking time out of their busy schedule to provide feedback about the technology.

Novelty Statement

Rice crop is in a state of transition from conventional to mechanized farming due to unavailability of labour for the crop production practices, specifically for nursery transplanting and the crop harvesting. It is claimed that MTR enables, operational timeliness, requires less labour, maintain optimal plant density and increases the rice productivity. In this perspective, there is an information gap about the adoption, economic gains and promotion of mechanical transplanting of the crop in the country. The research study is first detailed effort to fill the existing research gap. The findings will be helpful in upscaling of mechanical transplanting of the crop in country.

Author’s Contribution

Nadeem Akmal: Conceived the research idea, did field survey instrument development, pretesting of field survey instrument, data analysis and wrote first draft.

Abid Hussain: Field survey instrument development, pretesting of field survey instrument, data analysis and entry, literature review, wrote and finalized the manuscript.

Muhammad Yousaf: Technical guidance at each and every step of the research process.

Waqar Akhtar: Review of literature, data editing and entry

Hassnain Shah: Guidance in field survey instrument development and informal survey in the study area.

Conflict of interest

The authors have declared no conflict of interest.

References

Akram, M.W., N. Akram, H. Wang, S. Andleeb, K. Rehman, U. Kashif and S.F. Hassan. 2020. Socioeconomics determinants to adopt agricultural machinery for sustainable organic farming in Pakistan: A multinomial probit model. Sustainability, 12(23): 9806. https://doi.org/10.3390/su12239806

Aslam, M., 2016. Agricultural productivity current scenario, constraints and future prospects in Pakistan. Sarhad J. Agric., 32(4): 289-303. https://doi.org/10.17582/journal.sja/2016.32.4.289.303

Azam, M., S. Nawaz, Z. Rafiq and N. Iqbal. 2021. A spatial-temporal decomposition of carbon emission intensity: a sectoral level analysis in Pakistan. Environ. Sci. Pollut. Res., 28: 21381-21395.

Bohra, J.S. and R. Kumar. 2015. Effect of crop establishment methods on productivity, profitability and energetics of rice (Oryza sativa)-wheat (Triticum aestivum) system. Indian Agric. Sci., 85(2): 217-223. https://doi.org/10.56093/ijas.v85i2.46502

FAO, 2012. The state of food and agriculture. Food and Agriculture Organization of the United Nations. Rome, Italy.

Farooq, U., A.D. Sheikh, I. Muhammad, A. Bashir and Z. Anwar. 2001. Diffusion possibilities of mechanical rice transplanters. Int. J. Agric. Biol., 3(1): 17–18.

FAOSTAT, 2020. World rice yield. Food and Agriculture Organization of the United Nations. Rome, Italy.

GOP, 2020. Pakistan Economic Survey 2019-20. Finance Division. Government of Pakistan, Islamabad.

GOP, 2022. Pakistan Economic Survey 2021-22. Finance Division. Government of Pakistan, Islamabad.

GOP, 2022a. Agricultural Statistics of Pakistan 2021-22. Economic Wing, Ministry of National Food Security and Research, Government of Pakistan, Islamabad.

GOP, 2022b. Kharif Crops Estimates, Crop Reporting Service, Agriculture Department Government of Punjab, Lahore.

Hassan, U., L. Ali, M. Yonus, W. Qamar, T. Chauhdhary and I. Hassan. 2022. Evaluation of planting methods for rice in rice-wheat zone of Sheikhupura, Pakistan. J. Arable Crops Market, 4(2): 89-95. https://doi.org/10.33687/jacm.004.02.4498

Hayashi, S., A. Kamoshita and J. Yamagishi. 2006. Effect of planting density on grain yield and water productivity of rice (Oryza sativa L.) grown in flooded and non-flooded fields in Japan. Plant Prod. Sci., 9(3): 298-311. https://doi.org/10.1626/pps.9.298

Hossen, M.A., M.M. Shahriyar, S. Islam, H. Paul and M.M. Rahman. 2022. Rice transplanting mechanization in Bangladesh: Way to make it sustainable. Agric. Sci., 13(2): 130-149. https://doi.org/10.4236/as.2022.132011

Hussain, A., 2014. An analysis of technical efficiency of wheat farmers in Punjab. Unpublished Ph.D. thesis. Department of Economics and Agricultural Economics. PMAS-Arid Agriculture University, Rawalpindi, Pakistan.

Islam, A.S., 2016. Mechanized rice transplanting in Bangladesh. Bangladesh Rice Research Institute, Gazipur.

Khaliq, T., D.S. Gaydon, M.J.M. Cheema and U. Gull. 2019. Analyzing crop yield gaps and their causes using cropping systems modelling–A case study of the Punjab rice-wheat system, Pakistan. Field Crops Res., 232: 119-130. https://doi.org/10.1016/j.fcr.2018.12.010

Khan, N.A., Q. Gao and M. Abid. 2021. Mapping farmers vulnerability to climate change and its induced hazards: Evidence from the rice-growing zones of Punjab, Pakistan. Environ. Sci. Pollut. Res., 28: 4229-4244. https://doi.org/10.1007/s11356-020-10758-4

Kumar, R., V. Sharma and S. Singh. 2015. Comparative performance of mechanical transplanting and direct seeding of rice. Agric. Eng., 2: 23-31.

Manes, G.S., A. Dixit, A. Singh, J.S. Mahal and G. Mahajan. 2013. Feasibility of mechanical transplanter for paddy transplanting in Punjab. Agric. Mech. Asia Africa Latin Am., 44: 14-17.

Maraseni, T.N., S. Mushtaq and J. Maroulis. 2009. Greenhouse gas emissions from rice farming inputs: A cross-country assessment. J. Agric. Sci., 147(2): 117-126. https://doi.org/10.1017/S0021859608008411

Mir, K.A., C. Park, P. Purohit and S. Kim. 2021. Comparative analysis of greenhouse gas emission inventory for Pakistan: Part II agriculture, forestry and other land use and waste. Adv. Climate Change Res., 12(1): 132-144. https://doi.org/10.1016/j.accre.2021.01.003

Naeem, A. and M. Hussain. 2022. Mechanical transplanting of rice (Urdu Booklet). Farm Training and Adaptive, Research Directorate of Agriculture, Gujranwala.

Naseer, M.A.U.R., M. Ashfaq, A. Razzaq and Q. Ali. 2020. Comparison of water use efficiency, profitability and consumer preferences of different rice varieties in Punjab, Pakistan. Paddy Water Environ., 18(1): 273-282. https://doi.org/10.1007/s10333-019-00780-9

Niazi, T., 2003. Land tenure, land use, and land degradation: A case for sustainable development in Pakistan. J. Environ. Dev., 12(3): 275-294. https://doi.org/10.1177/1070496503255485

REAP, 2021. Rice export association of Pakistan. Sadiq Plaza, The mall, Lahore. https://reap.com.pk/

Saha, R., P.S. Patra and A.S. Ahmed. 2021. Impact of mechanical transplanting on rice productivity and profitability. A review. Int. J. Econ. Plants, 8(4): 226-230. https://doi.org/10.23910/2/2021.0418d

Sangeetha, C. and P. Baskar. 2015. Influence of different crop establishment methods on productivity of rice. A review. Agric. Rev., 36(2): 113-124. https://doi.org/10.5958/0976-0741.2015.00013.6

Singh, K.K., S.K. Lohan, A.S. Jat and T. Rani. 2006. New technologies of planting rice for higher production. Res. Crops, 7(2): 369-371.

Umar, M., S. Ali, A. Ali, M.K. Bashir, N. Nawaz, M.H. Khan and A. Riaz. 2022. Adoption of mechanical transplanting of rice (MTR) among rice growers in the rice-zone of Punjab, Pakistan. J. Arable Crops Market, 4(1): 21-29. https://doi.org/10.33687/jacm.004.01.4435

Yao, Y.M., M.X. Shen and H. Sun. 2000. Effect of transplanting of rice seedling in pots on growth characteristics and yield single cropping late rice. Jiangsu Agric. Sci., 34(1): 13–15.

Zohaib, A., M. Hussain, I. Ahmad and A. Bashir. 2020. Effect of seeding rate for mat type nursery on growth, yield and economic efficacy of mechanically transplanted fine basmati rice. Pak. J. Agric. Res., 35(1): 21-28. https://doi.org/10.17582/journal.pjar/2022/35.1.21.28

To share on other social networks, click on any share button. What are these?