Effect of Various Toasting Conditions of Full Fat Soybean on Nutritive Value and Growth Performance in Broiler Chickens

Research Article

Effect of Various Toasting Conditions of Full Fat Soybean on Nutritive Value and Growth Performance in Broiler Chickens

M. Mansoor Javed*, M. Aslam Mirza, M. Aziz ur Rehman and M. Saif ur Rahman

Institute of Animal and Dairy Sciences, University of Agriculture, Faisalabad, Pakistan.

Abstract | This experiment was conducted to check the effect of various processing conditions on the nutritive value of full-fat soybean (FFSB), apparent metabolizable energy (AME), nitrogen retention and growth in broiler chickens. Full-fat soybean was prepared by subjecting dehulled soybean to different temperatures i.e. 90°C, 100°C and 110°C for various resident tines i.e., 15 min, 30 min and 45 min in a multitier commercial toaster. Each product was analyzed for proximate composition, pepsin digestibility, KOH solubility and urease activity prior to inclusion in the experimental diets. A day old Cobb-500 broiler birds (n=432) were purchased commercially. Nine iso-caloric as well as iso-nitrogenous experimental formulations as starter diets (CP 22 %, ME 3000 Kcal/kg), grower diets (CP 20.5 %, ME 3075 Kcal/kg) and finisher diets (CP 19 %, ME 3150 Kcal/kg) were formed as per nutritional recommendations for Cobb-500 and assigned to 36 replicates (four replicates/treatment) employing 3×3 factorial arrangement under the completely randomized design. Each replicate had 12 birds. The trial lasted for 35 days. No effect of toasting temperature and resident time (P>0.05) was noted on feed intake during starter phase (day 1-10). Body weight gain and feed conversion ratio (FCR) were significantly (P<0.05) positively affected in response to diets having FFSB processed at 90°C for 45 minutes. Processing FFSB at 90°C for 15 minutes resulted in lowest weight gain, while poor FCR was observed in the birds fed FFSB processed at 110°C for 45 minutes. Extending the toasting time from 15 to 45 min improved FCR at 90°C. The AME and AMEn values were non-significant (P>0.05) across dietary treatments. Similar trend was observed for digestibility of ether extract (P>0.05). Nitrogen retention was higher (P<0.05) in the birds fed on diets having FFSB processed at 90°C for 45 min. Pancreatic hypertrophy was observed histologically in birds having feed formulations with FFSB processed at lowest temperature for shortest time duration. It was inferred that toasting FFSB at various temperatures could affect growth performance and digestibility parameters in broiler chickens.

Received | January 10, 2022; Accepted | August 29, 2022; Published | December 14, 2022

*Correspondence | M. Mansoor Javed, Institute of Animal and Dairy Sciences, University of Agriculture, Faisalabad, Pakistan; Email: linkmansoor@outlook.com

Citation | Javed, M.M., M.A. Mirza, M.A. Rehman and M.S. Rahman. 2022. Effect of various toasting conditions of full fat soybean on nutritive value and growth performance in broiler chickens. Sarhad Journal of Agriculture, 38(5): 252-262.

DOI | https://dx.doi.org/10.17582/journal.sja/2022/38.5.252.262

Keywords | Full-fat soybean, Toasting, Broiler, Performance, Apparent metabolizable energy, Digestibility

Copyright: 2022 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

It is widely accepted that raw soybean (SB) cannot be used in broiler diets, because it contains various anti-nutritional factors such as trypsin and protease inhibitors affect the overall growth performance of birds adversely (Ebrahimi-Mahmoudabad and Taghinejad-Roudbaneh, 2011). Zahid (2017) reported that feeding raw SB inhibited growth performance, reduced feed efficiency (FE) and pancreatic hypertrophy. Gilani et al. (2005) reported that feeding raw SB reduced growth rate, FE and led to pancreatic enlargement, decreased availability and digestibility of amino acids. Perez-Maldonado et al. (2003) reported that use of raw SB diet reduced daily weight gain and FE due to the prevalence of trypsin inhibitor (Gu et al., 2010) that led to reduction in protein digestibility from 20-40% leading to wastage of dietary protein (Caine et al. 1998).

The anti-nutritional factors of the raw SB are TI, glycinin, lectins, β-glycinin, oligosaccharides, saponins and phytic acid (Van-Eys, 2012). The major anti-nutritional that possesses damage to the birds are TI. Various heat processes i.e. extrusion, toasting, autoclaving, roasting and cooking are widely applied to destroy the TI. Processing of SB is critical in terms of destruction of the anti-nutritional factors and protein quality. Van-Eys (2012) reported that heating SB in the presence of moisture could affect quality of protein as proteins are sensitive to temperature. When meal is heated in the presence of moisture for longer duration of time it triggers Mailard reaction which affects the availability of amino acids, thus affecting the quality of meal (Anderson-Hafermann et al., 1992). So, optimum processing is required to keep the quality of SB intact. Toasting of FFSB could serve the purpose. When FFSB is passed through toaster it is exposed to heat and moisture. Optimum combination of temperature and resident time is required to avoid over-processing or under processing of meal. Over processing could lead to compromised protein quality in terms of amino acids availability, while under processing fails to destroy anti-nutritional factors. Hence, in order to achieve highest protein quality along with maximal inactivation of negatively affecting anti-nutritional factors coming from full-fat soybean, it is necessary to process the meal at optimal heating temperatures (Ari et al., 2017).

This present research was scheduled to analyze the effect of different conditions of toasting i.e. toasting temperature and resident time on the nutritive value of full-fat soybean in terms of growth performance and carcass response of broiler birds.

Materials and Methods

All procedures followed to conduct this experiment were approved by Advance Studies and Research Board (ASRB), University of Agriculture Faisalabad (UAF), Pakistan.

Preparation of toasted full-fat soybean

Toasted soybean (full-fat) products were developed at Hi-Tech Edible Oil Mills Private LTD, Sahiwal, Pakistan using multi desk toaster/conditioner provided with jacketed and open steam at 90°C, 100°C and 110°C. At each toasting temperature FFSB was toasted for 15 min, 30 min and 45 min, so that we got nine FFSB products. Soybean seeds were cleaned, de-hulled and then flaked to a thickness of .30-.38 mm prior the toasting process. Full-fat soybean products prepared were analyzed for proximate composition following (AOAC, 2010). All samples were also tested for KOH solubility (Araba and Dale, 1990), urease activity and pepsin digestibility Mertz et al. (1984).

Table 1: Proximate composition and quality parameters of toasted full-fat soybean.

|

Parameter (%) |

Full-fat soybean |

||||||||

|

90.15* |

90.30 |

90.45 |

100.15 |

100.30 |

100.45 |

110.15 |

110.30 |

110.45 |

|

|

DM |

92.6 |

92.3 |

92.5 |

92.1 |

92.1 |

91.9 |

92.5 |

91.9 |

91.7 |

|

CP |

35.7 |

35.4 |

35.7 |

35.7 |

35.4 |

36.3 |

36.5 |

36.8 |

35.7 |

|

EE |

23.2 |

22.7 |

22.3 |

22.7 |

22.4 |

21.1 |

22.7 |

22.4 |

22.3 |

|

CF |

3.5 |

3.4 |

3.5 |

3.4 |

3.7 |

3.8 |

3.8 |

3.7 |

3.8 |

|

Ash |

5.7 |

5.5 |

5.6 |

5.5 |

5.3 |

5.7 |

5.6 |

5.6 |

5.8 |

|

KOH solubility |

89.1 |

86.5 |

81 |

85.5 |

80.5 |

74.97 |

74.28 |

73.03 |

72 |

|

Pepsin digestibility |

93.3 |

92.4 |

88.2 |

90 |

87.6 |

79.3 |

72 |

76.7 |

73.3 |

|

Urease activity |

0.94 |

0.35 |

0.05 |

0.15 |

0.1 |

0.02 |

0 |

0.03 |

0 |

*Temperature in ºC, time in minutes.

Experimental diets, birds and housing

Three experimental formulations as starter diets (CP 22 %, ME 3000 Kcal/kg), grower diets (CP 20.5 %, ME 3075 Kcal/kg) and finisher diets (CP 19%, ME 3150 Kcal/kg) were formed as per dietary recommendations set out for Cobb-500 broiler chicken. Each diet contained only FFSB as major protein source. Nine FFSB processing products prodcued were fed in a way that each FFSB product was fed to one treatment group. Total of four hundred and thirty two (n=432) broiler chicks delievered from a commercial hatchery (Olympia Chicks Pvt. Limited) were randomly divided into 36 replicates having twelve birds per replicate in such a way that each dietary treatment group had four replicates. Ingredient and nutrient composition of the diets is given in Tables 2 and 3. The birds were kept on solid concrete floor, which was covered with the 2 inch layer of rice husk as bedding material. Each bird was allowed a floor space of 0.75 ft2 in a 4×3 square feet pen placed in an environmentally controlled experimental house. Local vaccination schedule was floowed to vaccine birds against infectious bronchitis (IB) on 3rd day, infectious bursal disease (IBD) on 12th day and Newcastle disease (ND) on day 17th and 28th day of the trial. Experimental diets were fed in three phases i.e. starter (1st-10th day), grower ( 11th-21st day) and finishar day (22nd-35th day). Exoerimental pens were provided with the round bottom feeders. Water was supplied round the clock with a nipple drinking system. The temperature of the experimental shed was maintained at 33°C during first week with the reduction of 3°C in first week and 2°C aftrewards. Twenty lux light was provided for twenty three hours with one hour dark every day following 23:1 light to dark schedule.

Nutrient digestibility assay

A nutrients digestibility test was performed on day 10th, 21st and 35th of the experiment. For this purpose, 1% acid insoluble ash by (Celite®) was added in the experimental diets being fed as an external marker. For each replicate polythene sheets were thoroughly spread on floor on day 9th, 19th and 32nd to collect the droppings every 3 hours on day 11th, 21st and 35th for whole day long. Plastic cups were used to transfer those collected samples which were then kept into ice box immediately before their final storage in freezer at -10°C temperature. Then after thawing these stored samples, the fecal samples were pooled in pen and heat dried through hot-air oven at a temperature of 65°C. Afterwards, the dried samples were finally ground to 0.5 mm sieve size. These processed samples were then again kept in freezer at -10°C temperature till the further analysis were done. Various analyses including CP, DM, CF, N, GE, EE and Ash were done on diets. Micro Kjeldahl apparatus was used for testing the fecal samples for their nitrogen content, AIA following Vogtmann et al. (1975). Further, Parr oxygen bomb calorimeter was used for GE analysis (Parr Instrument Co. Moline, IL).

Table 2: Ingredient composition of experimental.

|

Ingredients |

Starter |

Grower |

Finisher |

|

Maize |

45.2 |

49 |

56 |

|

Rice Polishings |

8.0 |

7 |

4 |

|

Full-fat soybean |

32 |

34.03 |

36.39 |

|

Soybean meal |

10 |

5 |

- |

|

Calcium carbonate |

0.84 |

0.93 |

0.87 |

|

di-Calcium phosphate |

1.5 |

1.77 |

1.54 |

|

Sodium chloride |

0.3 |

0.3 |

0.3 |

|

Sodium bicarbonate |

0.13 |

0.13 |

0.13 |

|

Lysine sulphate, 55% |

0.4 |

0.32 |

0.3 |

|

DL- Methionine, 99.5% |

0.32 |

0.25 |

0.22 |

|

L-Threonine, 99% |

0.15 |

0.11 |

0.09 |

|

Vitalink®a |

0.05 |

0.05 |

0.05 |

|

Nutrimin®b |

0.05 |

0.05 |

0.05 |

|

Choline Chloride, 70% |

0.06 |

0.06 |

0.06 |

|

Celite®c |

1.00 |

1.00 |

1.00 |

|

Total |

100.00 |

100.00 |

100.00 |

aEach kg of vitalink® supplied the following: Vitamin A, 20000 KIU; Vitamin D3, 5400 KIU; Vitamin E, 48000 mg; Vitamin K3, 4000 mg; Vitamin B1, 4000 mg; Vitamin B2, 9000 mg; vitamin B6, 7600 mg; vitamin B12, 20 mg; niacin, 60000 mg; pantothenic acid, 20000 mg; folic acid, 1600 mg; biotin, 200 mg). bEach kg of nutrimin® supplied the following: iron, 10000 mg; zinc, 120000 mg; manganese, 140000 mg; copper, 12000 mg; iodine, 1800 mg; cobalt, 400 mg; and selenium, 360 mg . cA product of Verenium Corporation, San Diego, CA, USA

Table 3: Nutrient composition of experimental diets.

|

Nutrients (%) |

Starter |

Grower |

Finisher |

|

ME (kcal/kg) |

3000 |

3086 |

3172 |

|

CP |

22 |

20.5 |

19.0 |

|

EE |

9.5 |

10.3 |

10.40 |

|

CF |

4.45 |

4.25 |

3.80 |

|

Ca |

0.94 |

0.84 |

0.76 |

|

Av. P |

0.45 |

0.42 |

0.38 |

|

Na |

0.22 |

0.2 |

0.20 |

|

Cl |

0.2 |

0.22 |

0.22 |

|

Dig. Lys |

1.22 |

1.10 |

1.00 |

|

Dig. M + C |

0.89 |

0.79 |

0.73 |

|

Dig. Thr |

0.82 |

0.74 |

0.67 |

|

Dig. Trp |

0.22 |

0.21 |

0.19 |

|

Dig. Arg |

1.32 |

1.22 |

1.10 |

|

Dig. Val |

0.86 |

0.79 |

0.74 |

|

Dig. Ile |

0.78 |

0.69 |

0.64 |

|

Dig. Leu |

1.58 |

1.48 |

1.42 |

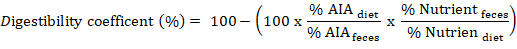

Following relationship was used to measure the digestibility of nutrients:

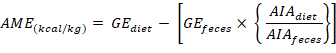

Calculation of AME for the diets was done by relationship as follows:

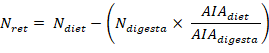

Factor 8.22 kcal/g was employed to adjust the apparent metabolisable energy to the zero N retention (Hill and Anderson, 1958). Also as, AMEn = AME- (8.22 × Nret). Therefore, for calculating the Nret , following formula was used as given by Bolarinwa and Adeola (2012).

Growth performance

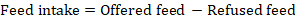

Digital weighing balance was used to record the body weight of experimental birds on the day of their arrival to the farm as well as at the end of each growth phase. Feed intake (FI) of birds for whole phase was determined by the formula as follows:

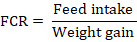

FCR was calculated by dividing the total feed intake with the weight gained during that phase as given by the following formula:

Carcass response

On day 35th, two birds/replicate were slaughtered to record the carcass response (Mushtaq et al., 2013). Feathers were removed after slaughtering and evisceration was done. In carcass response; dressing percentage, carcass, breast and thigh weights were determined. Relative weights of internal organs like gizzard, liver and pancreas were also recorded.

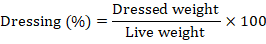

Dressing (%)

The dressing percentage was determined by dividing the dressed weight (without internal organs i.e., gizzard, heart and liver) with live weight as follows:

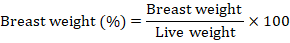

Breast weight (%)

Breast weight (%) was determined by dividing the breast weight (g) of the birds with corresponding live weight (g) as follows:

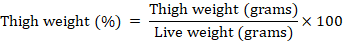

Thigh weight (%)

Thigh weight (%) was determined by dividing thigh weight of the birds with live weight of birds as follows:

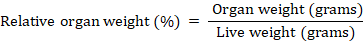

Relative organ weights (%)

Relative organ weights (%) were determined by dividing respective organ weight with the live weight as follows:

Statistical analysis

The results of the study were statistically analyzed through Minitab 17.1 giving the linear model procedures (Minitab Inc., State College, PA). The study was 3×3 factorial experiment hence applied to compeltely randomised (CRD). Four replicate measurments done on each sample. Means were compared by Tukey’s honestly significant difference test. Tukey’s HSD test was used to separate the significant mean values (Steel et al., 1997).

Results and Discussion

The proximate composition of toasted FFSB is given in Table 1. Full-fat soybean analyses showed that it contained almost 89% dry matter, 36% CP, 3.29% crude fiber, 22.5% EE and 5.23% ash. Pepsin digestibility ranged from 73.3% to 93.3%. Urease activity (∆pH) was 0.00 to 0.94 for various full-fat soybean products. Urease activity is a useful assay in determining that either soybean meal is adequately heated to deactivate the trypsin inhibitors, but it does not tell the excessive heating (Herkelman et al., 1991). Although the rise in pH level between 0.05 and 0.20 of urease activity are considered optimum, but urease activity index below 0.05 does necessarily mean that soybean meal is over processed (Waldroup et al., 1985; Araba and Dale, 1990). Potassium hydroxide (KOH) solubility of protein is an indicator of overheating of soybean meal (Herkelman et al., 1991). In the soybean meal trials, the KOH solubility values below the 75% has been shown to be indicator of overheating of soybean meal (Webster et al., 2003). The urease activity and KOH solubility of full-fat soybean processed at various temperatures and resident times show the adequacy of the processing in terms of under or over processing.

Growth performance

Starter phase (days 1-10): The basic parameters to analyze growth performance in poultry birds are determined by calculating the body weight gain, feed intake (FI) and FCR at end of the starter phase (day 1-10). The results are mentioned in Table 4. Feed intake was non-responsive to the main effects of toasting time and resident temperature, while interaction of resident time and temperature has significant (P<0.05) effect on FI. Lowest feed intake was observed in the birds fed FFSB toasted at 90°C for 15 minutes, while FI was highest in the birds fed toasted FFSB at 110°C for 45 minutes. All other dietary treatments remained the same in terms of FI. In agreement to our study for main effect of toasting time and temperature, Onwumelu et al. (2012) reported that feed intake was similar in the birds fed various levels of toasted FFSB. As full-SB is processed for anti-nutritional factors, contents of trypsin inhibitors almost reaches to zero, trypsin free FFSB is considered as safe for chicken feeding. In current study, similar feed intake for processed FFSB at various temperatures and resident time is indicating that processed FFSB didn’t affected feed intake. Zahid (2017) reported reduced feed intake with the dietary inclusion of raw FFSB in diets of broiler chickens. The reduction of feed intake was attributed to presence of trypsin inhibitor contents in FFSB.

Body weight gain (BWG) of birds in starter phase as a response to experimental diets was observed to be statistically significant (P<0.05) for interaction effect of toasting temperature and resident time, while main effects of time and temperature remained unchanged (P>0.05). Increased BWG was seen in chicks fed FFSB toasted at 90°C for 45 minutes. Lowest body weight was observed in the birds fed FFSB toasted at 90°C for 15 minutes. This could be attributed to the under processing of full-fat SB. The birds fed toasted FFSB at 110°C for 45 minutes also shown lower body weight gain. This fact was maybe due to over processing of FFSB.

Table 4: Effect of toasting full-fat soybean on performance of broiler chickens.

|

Items |

1-10 d |

11-21 d |

|||||

|

Temp (°C) |

Time (min) |

FI |

WG |

FCR |

FI |

WG |

FCR |

|

90 |

289 |

242 |

1.19a |

939 |

592 |

1.59 |

|

|

100 |

299 |

242 |

1.24ab |

968 |

594 |

1.57 |

|

|

110 |

302 |

237 |

1.28b |

934 |

574 |

1.64 |

|

|

SEM |

4.83 |

4.05 |

0.02 |

12.9 |

10.30 |

0.03 |

|

|

15 |

298 |

234 |

1.26 |

954 |

584 |

1.62 |

|

|

30 |

294 |

244 |

1.20 |

957 |

586 |

1.62 |

|

|

45 |

300 |

244 |

1.25 |

930 |

590 |

1.56 |

|

|

SEM |

4.83 |

4.05 |

0.02 |

12.9 |

10.30 |

0.03 |

|

|

90 |

15 |

279b |

217d |

1.29bc |

926ab |

559cd |

1.65bc |

|

30 |

294ab |

246abc |

1.20ab |

981a |

594abcd |

1.65bc |

|

|

45 |

292ab |

262a |

1.11a |

909b |

623a |

1.47a |

|

|

100 |

15 |

306a |

236bcd |

1.29bc |

986a |

585abcd |

1.64bc |

|

30 |

292ab |

254ab |

1.15a |

981a |

621ab |

1.51ab |

|

|

45 |

299ab |

237bcd |

1.26bc |

939ab |

578abcd |

1.56abc |

|

|

110 |

15 |

294ab |

249abc |

1.19ab |

949ab |

608abc |

1.56abc |

|

30 |

296ab |

234cd |

1.27bc |

910b |

545d |

1.68bc |

|

|

45 |

315a |

232cd |

1.36c |

944ab |

570bcd |

1.66c |

|

|

SEM |

8.37 |

7.01 |

0.04 |

22.4 |

17.8 |

0.05 |

|

|

P-values |

|||||||

|

Temp |

0.13 |

0.67 |

0.05 |

0.14 |

0.32 |

0.37 |

|

|

Time |

0.41 |

0.14 |

0.25 |

0.28 |

0.90 |

0.35 |

|

|

Temp * Time |

0.33 |

0.01 |

0.01 |

0.03 |

0.01 |

0.04 |

|

Feed conversion ratio of the birds fed toasted at various temperatures for different resident times remained unchanged for main effect on resident time, while FCR was significantly different (P<0.05) for main effect of processing temperature and interaction effects toasting temperature and resident time. In response to the toasting temperature, best FCR was observed in the birds fed with the diet having toasted FFSB processed at 90°C as compared to other temperatures. In response of interaction effect of various toasting temperatures and toasting times, the birds on such feeds having toasted FFSB processed at 90°C for 45 minutes showed best FCR. While the birds on such feeds having FFSB processed at 110°C for 45 minutes expressed worst FCR among other dietary treatments.

Grower phase (days 11-21): The basic parameters to analyze growth performance at end of the grower phase (day 11-21) in poultry birds are determined by calculating the body weight gain, feed intake (FI) and FCR. The results are mentioned in Table 4. Feed intake was non-responsive to the main effects of toasting time and resident temperature, while interaction effect of resident time and temperature has significant (P<0.05) effect on FI. Lowest feed intake was observed in the birds those were fed FFSB toasted at 90°C for 45 minutes and 110°C for 30 minutes.

Body weight gain (BWG) of birds in growing phase as a response to experimental diets was observed to be statistically significant (P<0.05) for interaction effect of toasting temperature and resident time, while main effects of time and temperature remained unchanged (p>0.05). Higher BWG resulted in experimental groups fed FFSB toasted at 90°C for 45 minutes. Lowest body weight was observed in the birds fed FFSB toasted at 110°C for 30 minutes. This could be attributed to the over processing of full-fat SB.

Feed conversion ratio of the birds fed toasted at various temperatures for different resident times remained unchanged for main effect of toasting temperature and resident time of full-fat SB, while FCR was significantly different (P<0.05) for interaction effects of toasting temperature and resident time. In response to interaction effect of toasting temperatures and toasting times, the birds on such feeds having toasted FFSB processed at 90°C for 45 minutes showed best FCR. While the birds on such feeds having FFSB processed at 110°C for 45 minutes expressed worst FCR among other dietary treatments.

Finisher phase (days 21-35): The basic parameters to analyze growth performance at end of the finishing phase (days 22-35) in poultry birds are determined by calculating the body weight gain, feed intake (FI) and FCR. The results are mentioned in Table 5. Feed intake was non-responsive (P>0.05) to main and interaction effects of toasting times and resident temperatures of soybean (full-fat).

Body weight gain (BWG) of birds in finisher phase as a response to experimental diets was observed to be significant statistically (p<0.05) for the main effects of toasting temperature as well as interaction effect of toasting temperature along with resident time, while main effects of toasting time affected the weight gain non-significantly (p>0.05). Higher (p<0.01) weight gain was shown by the birds receiving FFSB toasted at 100°C. In interaction effect, higher (p<0.05) BWG was seen in the treatment groups getting formulations of toasted FFSB processed at 90°C for 45 minutes, 100°C for 15 minutes and 100°C for 45 minutes. The treatment groups of FFSB toasted at 110°C for 45 minutes had lowest (P<0.05) BWG. This could be attributed to the over processing of FFSB.

Table 5: Effect of toasting full-fat soybean on performance of broiler chickens.

|

Items |

21-35 d |

1-35 d |

|||||

|

Temp (°C) |

Time (min) |

FI |

WG |

FCR |

FI |

WG |

FCR |

|

90 |

1987 |

936ab |

2.13ab |

3214 |

1770ab |

1.82ab |

|

|

100 |

1968 |

977a |

2.02a |

3235 |

1814a |

1.79a |

|

|

110 |

1956 |

908b |

2.15b |

3193 |

1720c |

1.86b |

|

|

SEM |

43.5 |

19.3 |

0.04 |

44.2 |

23.0 |

0.02 |

|

|

15 |

1990 |

940 |

2.11 |

3238 |

1759 |

1.84 |

|

|

30 |

2016 |

950 |

2.13 |

3268 |

1780 |

1.84 |

|

|

45 |

1905 |

930 |

2.06 |

3137 |

1759 |

1.78 |

|

|

SEM |

43.7 |

19.3 |

0.04 |

44.2 |

23.0 |

0.02 |

|

|

90 |

15 |

1945 |

887c |

2.17ab |

3149 |

1664b |

1.89bc |

|

30 |

2086 |

924b |

2.26b |

3363 |

1764ab |

1.90c |

|

|

45 |

1931 |

997a |

1.95a |

3131 |

1882a |

1.67a |

|

|

100 |

15 |

2001 |

982a |

2.03ab |

3292 |

1803ab |

1.83abc |

|

30 |

1957 |

924b |

1.95a |

3229 |

1884a |

1.72ab |

|

|

45 |

1947 |

997a |

2.07ab |

3184 |

1756ab |

1.81abc |

|

|

110 |

15 |

2030 |

954ab |

2.12ab |

3273 |

1810ab |

1.81abc |

|

30 |

2004 |

916b |

2.18ab |

3211 |

1695ab |

1.90c |

|

|

45 |

1836 |

853c |

2.15ab |

3095 |

1665b |

1.87bc |

|

|

SEM |

75.8 |

33.5 |

0.06 |

76.5 |

39.9 |

0.04 |

|

|

P-values |

|||||||

|

Temp |

0.88 |

0.05 |

0.02 |

0.79 |

0.02 |

0.07 |

|

|

Time |

0.18 |

0.78 |

0.31 |

0.10 |

0.78 |

0.11 |

|

|

Temp * Time |

0.53 |

0.04 |

0.01 |

0.34 |

0.01 |

0.01 |

|

Feed conversion ratio was different (P<0.05) in the birds fed FFSB toasted at various temperatures, while similar (P>0.05). FCR was observed in response to resident times. Interaction effect of toasting temperature and resident temperature was also significant. Best FCR was observed in the fed with the diets having FFSB toasted at 90°C for 45 minutes and 100°C for 30 minutes.

Overall performance (days 1-35): The basic parameters to analyze growth performance at end of the finishing phase (days 22-35) in poultry birds are determined by calculating the body weight gain, feed intake and FCR. The results are mentioned in Table 5. Bird’s feed intake (FI) remained unresponsive (p>0.05) to main effects and interaction effects of toasting temperature and resident time of FFSB indicating that processing conditions had no effect on feed consumption of broiler chickens.

Table 6: Effect of toasting on AME, N ret, AMEn and nutrients digestibility in broiler chickens (day 10).

|

Items |

AME (Kcal/kg) |

N ret (%) |

AMEn (kcal/kg) |

Digestibility (%) |

|||

|

Temp (°C) |

Time (min) |

CP |

EE |

||||

|

90 |

2957.3 |

2.83a |

2934.0 |

76.61 |

79.67 |

||

|

100 |

2963.2 |

2.78ab |

2940.3 |

78.11 |

80.16 |

||

|

110 |

2960.9 |

2.55b |

2938.6 |

75.69 |

80.36 |

||

|

SEM |

29.5 |

0.02 |

29.4 |

1.05 |

0.13 |

||

|

15 |

2969.5 |

2.77a |

2946.1 |

77.51 |

79.98 |

||

|

30 |

2948.5 |

2.68b |

2926.0 |

76.10 |

80.04 |

||

|

45 |

2963.5 |

2.71ab |

2940.8 |

76.80 |

80.18 |

||

|

SEM |

29.5 |

0.02 |

29.4 |

1.05 |

0.13 |

||

|

90 |

15 |

2944.1 |

2.77ab |

2921.3 |

73.83b |

79.22 |

|

|

30 |

2957.4 |

2.83ab |

2934.2 |

76.10ab |

79.89 |

||

|

45 |

2970.4 |

2.90a |

2946.6 |

79.91a |

79.91 |

||

|

100 |

15 |

2989.4 |

2.87ab |

2965.6 |

79.93a |

79.97 |

|

|

30 |

2953.6 |

2.76ab |

2930.9 |

78.98a |

80.02 |

||

|

45 |

2946.8 |

2.72ab |

2924.4 |

75.41b |

80.45 |

||

|

110 |

15 |

2948.7 |

2.67ab |

2926.1 |

78.78a |

80.74 |

|

|

30 |

2947.6 |

2.45b |

2925.9 |

73.23b |

80.20 |

||

|

45 |

2986.3 |

2.53ab |

2963.8 |

75.07b |

80.13 |

||

|

SEM |

51.1 |

0.04 |

50.9 |

1.82 |

0.23 |

||

|

P-values |

|||||||

|

Temp |

0.99 |

0.01 |

0.98 |

0.28 |

0.00 |

||

|

Time |

0.87 |

0.02 |

0.88 |

0.64 |

0.58 |

||

|

Temp*Time |

0.95 |

0.51 |

0.96 |

0.03 |

0.04 |

||

Means with different superscripts differed significantly (P>0.05).

Body weight gain was observed significantly different in the dietary treatment groups having toasted FFSB being prepared at various temperatures, while main effect of resident time had no impact on BWG of the birds. The interaction effect of toasting temperature and resident time influenced the BWG of the birds fed processed full-fat SB. Higher (p<0.05) weight gain was expressed in groups fed FFSB toasted at 100°C, while in interaction effect BWG was significantly (P<0.05) high in groups fed with feed formulations having toasted FFSB processed at 90°C for 45 minutes.

Table 7: Effect of toasting on AME, N ret, AMEn and nutrients digestibility in broiler chickens (day 21).

|

Items |

AME (Kcal/kg) |

N ret (%) |

AMEn (kcal/kg) |

Digestibility (%) |

|||

|

Temp (°C) |

Time (min) |

CP |

EE |

||||

|

90 |

3078.2 |

2.52b |

3057.5 |

77.90 |

79.48 |

||

|

100 |

3087.9 |

2.58ab |

3066.6 |

77.98 |

80.75 |

||

|

110 |

3087.3 |

2.62a |

3065.8 |

77.31 |

81.11 |

||

|

SEM |

29.1 |

0.02 |

29.1 |

0.80 |

0.84 |

||

|

15 |

3083.2 |

2.55b |

3061.6 |

77.75 |

80.72 |

||

|

30 |

3083.2 |

2.54b |

3062.6 |

78.11 |

80.44 |

||

|

45 |

3086.7 |

2.63b |

3065.7 |

77.34 |

80.19 |

||

|

SEM |

29.1 |

0.02 |

29.1 |

0.80 |

0.84 |

||

|

90 |

15 |

3072.4 |

2.52ab |

3051.4 |

75.71b |

78.84 |

|

|

30 |

3090.1 |

2.48b |

3069.8 |

77.55ab |

78.70 |

||

|

45 |

3072.2 |

2.58ab |

3051.2 |

80.44a |

80.93 |

||

|

100 |

15 |

3080.7 |

2.69ab |

3058.6 |

78.19a |

80.75 |

|

|

30 |

3089.3 |

2.57ab |

3068.1 |

79.87a |

81.34 |

||

|

45 |

3093.6 |

2.50b |

3073.0 |

75.90b |

80.18 |

||

|

110 |

15 |

3087.9 |

2.44a |

3065.4 |

79.34ab |

82.58 |

|

|

30 |

3084.8 |

2.60ab |

3063.4 |

76.93b |

81.29 |

||

|

45 |

3089.3 |

2.51b |

3068.7 |

75.68b |

79.45 |

||

|

SEM |

50.5 |

0.04 |

50.3 |

1.39 |

1.45 |

||

|

P-values |

|||||||

|

Temp |

0.96 |

0.04 |

0.97 |

0.82 |

0.37 |

||

|

Time |

0.99 |

0.04 |

0.99 |

0.80 |

0.90 |

||

|

Temp* Time |

0.99 |

0.02 |

0.99 |

0.03 |

0.43 |

||

Means with different superscripts differed significantly (P>0.05).

Feed conversion of the birds was significant for the main effect of toasting temperature of full-fat SB, while no difference (p>0.05) was expressed by dietary groups fed with formulations having FFSB processed at different resident times. Interaction effect of toasting temperature and resident time was significant. Best FCR was observed in the birds fed toasted FFSB at 90°C for 45 minutes. This may be attributed to the quality of full-fat soybean. The KOH solubility of meal indicates the over or under processing of meal. The optimum KOH solubility range is 78-85%, less or above than that is correlated with over or under heating. When meal is overheated the quality of FFSB is decreased in terms of crude protein and amino acids, as the temperature rise during toasting mailard reaction occur resultantly reducing the available amino acid contents. Erdaw et al. (2017) replaced commercial soybean meal with raw FFSB at 0, 10 or 20%. They showed that increasing the level of raw FFSB meal had no significant effect on body weight gain. Nematallah et al. (2015) conducted a study in which five levels of FFSB (0, 4, 6, 10 and 12%) were used in broilers diet and reported that weight gain during overall trial period was not affected by the treatments. MacIsaac et al. (2005) explained that providing 15% FFSB (roasted) to the birds in their feed resulted in better (p<0.05) FCR than that of those birds which were on control diets.

Table 8: Effect of toasting on AME, N ret, AMEn and nutrients digestibility in broiler chickens (day 32).

|

Items |

AME (Kcal/kg) |

N ret (%) |

AMEn (kcal/kg) |

Digestibility (%) |

|||

|

Temp (°C) |

Time (min) |

CP |

EE |

||||

|

90 |

3164.3 |

2.25 |

3145.7 |

79.22 |

81.67 |

||

|

100 |

3134.2 |

2.30 |

3115.2 |

80.21 |

80.77 |

||

|

110 |

3156.0 |

2.25 |

3137.5 |

78.06 |

81.36 |

||

|

SEM |

37.2 |

0.02 |

37.2 |

0.97 |

0.72 |

||

|

15 |

3154.8 |

2.29 |

3136.2 |

77.55 |

80.96 |

||

|

30 |

3155.1 |

2.26 |

3136.2 |

80.11 |

82.43 |

||

|

45 |

3144.6 |

2.26 |

3125.8 |

79.84 |

80.41 |

||

|

SEM |

37.2 |

0.02 |

37.2 |

0.97 |

0.72 |

||

|

90 |

15 |

3177.0 |

2.17 |

3159.1 |

77.02b |

80.91 |

|

|

30 |

3164.4 |

2.27 |

3145.7 |

79.87a |

81.69 |

||

|

45 |

3151.5 |

2.32 |

3132.4 |

80.80a |

82.41 |

||

|

100 |

15 |

3131.7 |

2.37 |

3112.4 |

76.72b |

80.62 |

|

|

30 |

3130.1 |

2.32 |

3111.0 |

82.55a |

82.70 |

||

|

45 |

3140.8 |

2.24 |

3122.2 |

81.37a |

78.99 |

||

|

110 |

15 |

3146.4 |

2.34 |

3127.2 |

78.90ab |

81.34 |

|

|

30 |

3169.2 |

2.20 |

3151.2 |

77.94b |

82.91 |

||

|

45 |

3152.3 |

2.21 |

3134.1 |

77.37b |

79.84 |

||

|

SEM |

64.4 |

0.04 |

64.4 |

1.69 |

1.25 |

||

|

P-values |

|||||||

|

Temp |

0.84 |

0.14 |

0.84 |

0.31 |

0.67 |

||

|

Time |

0.97 |

0.53 |

0.97 |

0.14 |

0.14 |

||

|

Temp * Time |

0.99 |

0.01 |

0.99 |

0.26 |

0.43 |

||

Means with different superscripts differed significantly (P>0.05).

Nutrient digestibility

Crude protein: Crude protein was analyzed for its digestibility determination at 10th, 21st, 35th days of starter, grower and finisher phases respectively. The results are shown in Table 6-8. At the end of starting phase, digestibility of crude protein remained the same for main effects of toasting temperature and resident times. The interaction effects of toasting temperature and resident time was significant (p<0.05), increased digestibility of proteins was observed in experimental birds fed with the diets having FFSB processed at 90°C for 45 minutes and FFSB processed at 100°C for 15 minutes and 30 minutes. Digestibility coefficient values of protein were lower in experimental birds provided with the feed formulations having toasted full-fat processed at 110°C for 30 minutes. Similar trend of crude protein digestibility was observed during growing phase. During growing phase, digestibility of crude protein was similar for main effects toasting temperature and resident time of FFSB, while interaction effect was significant (p<0.05). Higher digestibility was seen in poultry birds receiving diets with full-fat soybean processed at 90°C for 45 minutes. Whereas, soybean (full-fat) toasted for 45 minutes at 110°C showed low digestibility of CP in the birds.

Table 9: Effect of toasting on carcass response in broiler chickens.

|

Items |

Carcass yield |

Breast yield |

Thigh yield |

Abdominal fat pad |

Pancreas |

|

|

Temp (°C) |

Time (min) |

|||||

|

90 |

60.51 |

36.70 |

9.17 |

2.21 |

3.26b |

|

|

100 |

60.57 |

37.75 |

9.14 |

2.10 |

3.04ab |

|

|

110 |

61.30 |

37.85 |

9.02 |

2.33 |

2.86a |

|

|

SEM |

||||||

|

15 |

60.47 |

36.96a |

9.33 |

2.09 |

3.24b |

|

|

30 |

60.93 |

38.20b |

9.10 |

2.21 |

2.98a |

|

|

45 |

60.98 |

37.15ab |

9.28 |

2.33 |

2.94a |

|

|

SEM |

||||||

|

90 |

15 |

58.77 |

34.81a |

9.27 |

2.03 |

4.36b |

|

30 |

61.17 |

38.70b |

9.11 |

2.39 |

3.30b |

|

|

45 |

61.61 |

36.94a |

9.12 |

2.20 |

3.02ab |

|

|

100 |

15 |

60.95 |

37.99a |

9.18 |

2.03 |

3.88b |

|

30 |

60.03 |

38.01a |

8.89 |

2.16 |

2.92ab |

|

|

45 |

60.72 |

37.23a |

9.04 |

2.10 |

2.93ab |

|

|

110 |

15 |

61.68 |

37.29a |

9.04 |

2.22 |

2.98ab |

|

30 |

61.59 |

38.08a |

9.16 |

2.42 |

2.76a |

|

|

45 |

60.63 |

38.18a |

9.11 |

2.34 |

2.86ab |

|

|

SEM |

||||||

|

P-values |

||||||

|

Temp |

0.35 |

0.09 |

0.23 |

0.37 |

0.15 |

|

|

Time |

0.63 |

0.08 |

0.12 |

0.36 |

0.24 |

|

|

Temp * Time |

0.03 |

0.07 |

0.14 |

0.98 |

0.40 |

|

*means with different superscripts differ significantly (P<0.05)

In finishing phase, increased CP digestibility was observed in experimental groups getting diets of full-fat soybean processed at 100°C for 30 minutes. Main effects of toasting temperature and resident time were remained un-effected (P>0.05). Lower CP digestibility was observed in the birds fed with diets having FFSB processed at 90°C for 15 minutes. Lower CP digestibility was expressed by the experimental birds provided with feeds of FFSB processed at 90°C for 15 minutes. This fact was may be due to the fact that FFSB remained under process due to lower temperature and short temperature. MacIsaac et al. (2005) reported un-processed FFSB contain high trypsin inhibitor content. Higher trypsin inhibitor content reduces the enteric proteolytic activity leading to reduced protein digestibility.

Ether extract: Ether extract was analyzed for its digestibility coefficient determination at the end of each phase i.e., at 10th, 21st and 35th day. The results are shown in Tables 6-8. Digestibility coefficient of ether extract remained un-affected (P>0.05) during all phases.

Apparent metabolisable energy: Apparent metabolisable energy (AME) contents were determined at end of each growth phase, starter (day 10th), grower (day 21st) and finisher (day 35th). Apparent matabolisable energy remained unchanged during all phases, indicating that processing of FFSB had no effect on AME of broiler chickens.

Nitrogen retention: Nitrogen retention was also analyzed at 10th, 21st and 35th days. Results are shown in Tables 6-8. During starter phase, main and interaction effect of toasting temperature and resident times of full-fat SB. Nitrogen retention was similar for FFSB processed at 90°C and 100°C, while birds receiving feed formulations of toasted full-fat soybean at 110°C expressed lower nitrogen retention. This fact may be attributed to the over processing and low protein quality in terms of amino acid availability due to browning of FFSB. Birds fed with the diets having FFSB processed at 110°C for 30 minutes had lower Nret. During growing phase, main effects and interaction effects of toasting temperature and resident times of FFSB remained significant (P<0.05). In response to toasting temperature, lower retention of N was expressed in the experimental birds receiving the feed formulations having FFSB toasted at 90°C. The birds fed with the diets having processed of FFSB for 45 minutes had higher (P<0.05) Nret as compared to the birds fed full-fat soybean toasted for 15 and 30 minutes. The interaction effect of FFSB toasted at 110°C for 15 minutes had lower Nret as compared to the other dietary interaction effect of toasting temperature and resident times. During finishing phase Nret remained same (P>0.05) for main and interaction effect of toasting temperature and resident time of FFSB.

Apparent metabolizable energy (AMEn) corrected for nitrogen: Apparent metabolizable energy as being corrected for nitrogen content (AMEn) was measured at the end of each growth phase, i.e., at day 10th (starter phase), at day 21st (grower phase) and at day 35th (finishing phase) and their results are shown in Tables 6-8. During all phases AMEn of the birds remained the same for various dietary treatments. Main and interaction effects of toasting temperature and resident times had no effect on AMEn of birds fed with the diets having variously processed FFSB.

Carcass response

Carcass response was examined to check the carcass, thigh, and breast yield at 35th day i.e., end of the finishing phase. The results are elaborated in Table 9. Carcass yield, breast yield, thigh yield and abdominal fat pad were affected non-significantly (P>0.05) with experimental diets having processed FFSB included at various temperatures for different resident times. Weight of pancreas was significantly different (P<0.05) for various dietary treatments. Maximum weight of pancreas was observed in the birds fed FFSB processed at 90 °C for 15 minutes. Main effects of toasting temperature and resident time were also significant, weight of the pancreas decreased as processing temperature increased. Main effect of time was also significant (P<0.05), weight of pancreas decreased with increasing the processing time.

Conclusions and Recommendations

It was concluded that resident time and toasting temperature of FFSB had significant effect on performance of broiler chickens. Processing FFSB at 90°C for 45 min could improve the growth performance in broiler chickens.

Acknowledgements

This project was funded by Higher Education Commission (indigenous Ph.D. fellowship program, phase II, batch IV, H.E.C., Islamabad, Pakistan).

Novelty Statement

In this trial we have studied various processing conditions of FFSB using local conditions of Pakistan. Processed FFSB could provide excellent replacement for soybean meal and soybean oil in commercial broiler diets.

Author’s Contribution

Muhammad Mansoor Javed: Executed the research work and wrote the paper.

Muhammad Aslam Mirza: Designed the research work and supervised the research.

Sai fur Rehman: Helped in statistical analysis of collected data.

Aziz ur Rahman: Contributed in description and arranging of manuscript.

Conflict of interest

The authors have declared no conflict of interest.

References

Anderson-Hafermann, J.C., Y. Zhang, C.M. Parsons, and T. Hymowitz. 1992. Effect of heating on nutritional quality of conventional and kunitz trypsin inhibitor-free soybeans. Poult. Sci., 71: 1700–1709. https://doi.org/10.3382/ps.0711700

AOAC, 2010. Official methods of analysis. Association of Official Analytical Chemists, Gaithersburg, MD.

Araba, M. and N.M. Dale. 1990. Evaluation of protein solubility as an indicator of under processing of soybean meal. Poult. Sci., 69: 1749–1752. https://doi.org/10.3382/ps.0691749

Ari, M.M., B.A. Ayanwale and T.Z. Adama. 2017. Evaluation of different processing methods of soya beans (glycine max) on its nutritive value and the performance of broilers: a qualitative selection approach for extension. Int. J. Livest. Prod., 8: 113–124. https://doi.org/10.5897/IJLP2017.0371

Bolarinwa, O.A., and O. Adeola. 2012. Energy value of wheat, barley, and wheat dried distillers’ grains with solubles for broiler chickens determined using the regression method. Poult. Sci., 91: 1928-1935. https://doi.org/10.3382/ps.2012-02261

Caine, W.R., M.W. A. Verstegen, W.C. Saver and S. Taminga. 1998. Effect of protease treatment of soybean meal on content of total soluble matter and crude protein and levels of soybean trypsin inhibitors. Anim. Feed Sci. Technol., 71: 177-183. https://doi.org/10.1016/S0377-8401(97)00139-9

Ebrahimi-Mahmoudabad, S.R., Taghinejad-Roudbaneh, M., 2011. Investigation of electron beam irradiation effects on anti-nutritional factors, chemical composition and digestion kinetics of whole cottonseed, soybean and canola seeds. Rad. Phys. Chem., 80(12): 1441-1447. https://doi.org/10.1016/j.radphyschem.2011.08.003

El-Faham, A.I., N.G.M. Ali, and M.A.M. Abdelaziz. 2016. Effect of using full-fat soy-bean in broiler diets on performance, carcass parts, meat composition, bone traits and economic efficiency. Egypt. Poult. Sci., 36: 755-766. https://doi.org/10.21608/epsj.2016.168805

Erdaw, M.M., M.M. Bhuiyan and P.A. Iji. 2017. Response of broiler chicks to non-steamor steam-pelleted diets containing raw, full-fat soybean meal. J. Appl. Poult. Res., 26: 260–272. https://doi.org/10.3382/japr/pfw070

Gilani, G.S., K.A. Cockell, and E. Sepehr. 2005. Effects of antinutritional factors on protein digestibility and amino acid availability in foods. J. AOAC Int., 88(3): 967-987. https://doi.org/10.1093/jaoac/88.3.967

Gu, C., H. Pan, Z. Sun, and G. Qin. 2010. Effect of soybean variety on anti-nutritional factors content, and growth performance and nutrients metabolism in rat. Int. J. Mol. Sci., 11: 1048–1056. https://doi.org/10.3390/ijms11031048

Han, Y., C.M. Parsons and T. Hymowitz. 1991. Nutritional evaluation of soybeans varying in trypsin inhibitor content. Poult. Sci., 70: 896–906. https://doi.org/10.3382/ps.0700896

Herkelman, K.L., G.L. Cromwell, and T.S. Stahly. 1991. Effects of heating time and sodium metabisulfite on the nutritional value of full-fat soybeans for chicks. J. Anim. Sci., 69: 4477-4486. https://doi.org/10.2527/1991.69114477x

MacIsaac, J.L., K.L. Burgoyne, D.M. Anderson, and B.R. Rathgeber. 2005. Roasted full-fat soybeans in starter, grower, and finisher diets for female broiler Turkeys. J. App. Poult. Res., 14(1): 116-121. https://doi.org/10.1093/japr/14.1.116

Mertz, E.T., M.M. Hassen, W.C. Cairns, A.W. Kirleis, L. Tu and J.D. Axtell. 1984. Pepsin digestibility of proteins in sorghum and other major cereals. Proc. Natl. Acad. Sci., 81(1): 1-2. https://doi.org/10.1073/pnas.81.1.1

Mushtaq, M.M.H., T.N. Pasha, M. Akram, T. Mushtaq and R. Parvin. 2013. Growth performance, carcass traits and serum mineral chemistry as affected by dietary sodium and sodium salts fed to broiler chickens reared under phase feeding system. Asian-Australas. J. Anim. Sci., 26: 1742–1752. https://doi.org/10.5713/ajas.2013.13266

Nematallah, G.M.A., M.H.S. El-Sanhoury and M.A.M. Abdelaziz. 2015. Full-fat soybean as an energy source in broiler chicken diets. Egypt. Poult. Sci., 35: 277-289.

Onwumelu, I.J., J.C. Okonkwo and O.J. Akpodiete. 2012. Growth response of broiler chickens fed graded levels of yeast treated raw soya bean and full fat soya bean. Acta Agric. Sloven., 100: 47-57.

Parsons, C.M., K. Hashimoto, K.J. Wedekind and D.H. Baker. 1991. Soybean protein solubility in potassium hydroxide: An in vitro test of an in vivo protein quality. J. Anim. Sci., 69: 2918–2924. https://doi.org/10.2527/1991.6972918x

Perez-Maldonado, R.A., P.F. Mannion and D.J. Farrell. 2003. Effects of heat treatment on the nutritional value of raw soybean selected for low trypsin inhibitor activity. Br. Poult. Sci., 44(2): 299-308. https://doi.org/10.1080/0007166031000085463

Steel, R.G.D., J.H. Torrie and D.A. Dickie. 1997. Principles and procedures of statistics. A biometric approach. 3rd ed. McGraw-Hill Book Publishing Company, Toronto, Canada.

Van Eys, J.E., 2012. Manual of quality analyses for soybean products in the feed industry, 2nd edition. U.S. Soybean Export Counc.

Vogtmann, H., H. Pfirter, and A. Prabucki. 1975. A new method of determining metabolisability of energy and digestibility of fatty acids in broiler diets. Br. Poult. Sci., 16: 531-534. https://doi.org/10.1080/00071667508416222

Waldroup, P.W., B.E. Ramsey, H.M. Hellwig, and N.K. Smith. 1985. Optimum processing for soybean meal used in broiler diets. Poult. Sci., 64: 2314–2320. https://doi.org/10.3382/ps.0642314

Webster, M.J., R.D. Goodband, M.D. Tokach, J.L. Nelssen, S.S. Dritz, J.C. Woodworth, M. De La Llata, and N.W. Said. 2003. Evaluating processing temperature and feeding value of extruded-expelled soybean meal on nursery and finishing pig growth performance. J. Anim. Sci., 81: 2032–2040. https://doi.org/10.2527/2003.8182032x

Zahid, M., 2017. Effect of substitution of solvent extracted soybean meal with raw full-fat soybean on the growth parameters in finishing broilers. MSc. Hons. thesis. University of Agriculture, Faisalabad, Pakistan.

Zhang, Y., C.M Parsons, K.E. Weingartner and W.B. Wijeratne. 1993. Effects of extrusion and expelling on the nutritional quality of conventional and Kunitz trypsin inhibitor-free soybeans. Poult. Sci., 72: 2299–2308. https://doi.org/10.3382/ps.0722299

Zhang, Y., C.M. Parsons and T. Hymowitz. 1991. Effect of soybeans varying in trypsin inhibitor content on performance of laying hens. Poult. Sci., 70: 2210–2213. https://doi.org/10.3382/ps.0702210

To share on other social networks, click on any share button. What are these?