Characteristics of Pork Quality as Influenced by Gamma Irradiation: A Meta-Analysis Approach

Research Article

Characteristics of Pork Quality as Influenced by Gamma Irradiation: A Meta-Analysis Approach

Endy Triyannanto1, Danung Nur Adli2, Diah Pratiwi3, Lukman Hakim3, Selma Noor Permadi3, Taufik Kurniawan3, Angga Maulana Firmansyah3, Lina Ivanti3, Dinar Suksmayu Saputri3, Mohammad Miftakhus Sholikin4, Hari Hariadi5, Tri Ujilestari3, Teguh Wahyono3*

1Faculty of Animal Science, Universitas Gadjah Mada, Sleman 55281, Indonesia; 2Faculty of Animal Science, Universitas Brawijaya, Malang 65145, Indonesia; 3Research Center for Food Technology and Processing, National Research and Innovation Agency (BRIN), Gunungkidul 55861, Indonesia; 4Research Center for Animal Husbandry, BRIN, Bogor 16915, Indonesia; 5Research Center for Appropriate Technology, BRIN, Subang, 41213, Indonesia.

Abstract | An overview of the application of gamma irradiation for pork preservation has not been published in any of the studies. This meta-analysis study aims to elucidate the influence of gamma irradiation on texture properties, lipid and protein peroxidation, microbiological aspects, and sensory characteristics aspects in pork. 52 experiments from 21 studies were compiled into an extensive database. The irradiation dose varied between 0 and 50 kGy during the meta-analysis. A mixed-model technique was applied to perform the meta-data analysis, with the gamma irradiation dose considered as fixed effects and the different research (articles) as random effects. Gamma irradiation reduced hardness, gumminess, and chewiness of pork (p < 0.01). Meanwhile, gamma irradiation increases pH values at 0 and 7 d after storage. Furthermore, redness (a*) value increases with increasing irradiation dose (p < 0.01). As expected, gamma irradiation significantly increased thiobarbituric acid-reactive substances (TBARS) and peroxide-oxygen value (POV) (p < 0.01). Meanwhile, total aerobic bacteria, coliform, and lactic acid bacteria (LAB) decreased after irradiation treatment (p < 0.01). In conclusion, even though it can decontaminate pathogenic microbes, gamma irradiation can affect the texture, change color, increase oxidation parameters, and reduce the sensory parameters of pork products.

Keywords | Gamma irradiation, Meat, Meta-analysis, Pork, Quality

Received | March 16, 2024; Accepted | May 21, 2024; Published | July 10, 2024

*Correspondence | Teguh Wahyono, Research Center for Food Technology and Processing, National Research and Innovation Agency (BRIN), Gunungkidul 55861, Indonesia; Email: tegu021@brin.go.id

Citation | Triyannanto E, Adli DN, Pratiwi D, Hakim L, Permadi SN, Kurniawan T, Firmansyah AM, Ivanti L, Saputri DS, Sholikin MM, Hariadi H, Ujilestari T, Wahyono T (2024). Characteristics of pork quality as influenced by gamma irradiation: a meta-analysis approach. J. Anim. Health Prod. 12(3): 348-359.

DOI | http://dx.doi.org/10.17582/journal.jahp/2024/12.3.348.359

ISSN (Online) | 2308-2801

Copyright: 2024 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

INTRODUCTION

Pork is an essential meat commodity worldwide besides chicken products (Yan et al., 2024). The demand for pork and its production is expected to increase continuously. The protein content of beef, pork, poultry, and sheep is projected to increase by 5.9%, 13.1%, 17.8%, and 15.7%, respectively, by the year 2030 (OECD-FAO, 2021). The increase was primarily a result of rising demand from various Asian nations. Several financially strong Asian countries, including China, Philippines, Thailand, and Vietnam, have noticed a rise in per capita pork consumption. Vietnam is expected to become the top consumer in this category (OECD-FAO, 2018). As the pork trade increases globally, accurate preservation technology is essential to support this growth. Curate preservation technology is essential to support growth as the pork trade increases globally.

Within a few decades, pork preservation techniques can be implemented biologically using essential oils (Hao et al., 2023; Liu et al., 2023), edible film/coating (Khruengsai et al., 2024; Sun et al., 2021; Wei et al., 2023) and/or chitosan (Guo et al., 2022; Wan et al., 2024). Meanwhile, physical preservation methods are carried out using Co60 gamma (Ham et al., 2017; Li et al., 2017), electron beam (Chen et al., 2023; Lei et al., 2021; Yim et al., 2019) and x-ray irradiation (Ji et al., 2022; Shin et al., 2014). Irradiation is a feasible and effective non-thermal intervention approach for decontaminating meat products. Utilizing high-energy gamma rays or accelerated electrons to irradiate meat products may improve its shelf-life and prevent the growth of pathogenic microorganisms (Zhang et al., 2020). Irradiation has the potential to accomplish the following: (1) enhance food safety and prevent the risk of foodborne illnesses; (2) extend the shelf life of numerous perishable products; and (3) reduce the probability of postprocessing contamination for untouched, packaged products (Ibrahim, 2013). Gamma and electron beam irradiation are commonly used due to their efficacy and lack of residue.

A comprehensive review of studies on food irradiation is required to determine the focus of future research on radiation application. Future studies on food irradiation should focus on discovering new technologies and uses, resolving areas of uncertainty and disagreement, and enhancing existing knowledge of the impact of irradiation on food (Indiarto et al., 2023). A meta-analysis study is required to fully investigate the utilization of irradiation in pork products. Various meta-analysis studies on food irradiation have been conducted with regard to various animal products (Dimov and Popova, 2022; Ujilestari et al., 2023; Wahyono et al., 2023; Wahyono et al., 2024a; Wahyono et al., 2024b). A previous study by Wahyono et al. (2024b) reported that irradiation with electron beam increases lipid peroxidation, reduces microbiological parameters, and diminishes overall acceptability. Instead has no effect on the color of the pork products. Meta-analysis studies related to gamma radiation on pork have never been reported. Gamma irradiation for pork products still needs to be studied as an alternative to electron beam. Therefore, this meta-analysis study aims to elucidate the influence of gamma irradiation on texture properties, lipid and protein peroxidation, microbiological aspects, and sensory characteristics aspects in pork.

MATERIALS AND METHODS

Ethical Approval

The present meta-analysis study did not require any ethical clearance. The Preferred Reporting Items for Systematic Review and Meta-Analysis (PRISMA) criteria were strictly adhered to in this research (Page et al., 2021).

The strategy of literature search

Raw meta-data were compiled from published studies evaluating the effect of gamma irradiation on texture properties, lipid and protein peroxidation, microbiological aspects, and sensory characteristics aspects in pork. We searched for articles published between 2000 and 2023 in PubMed, Google Scholar, Scopus, and Crossref using the keywords “gamma,” “irradiation,” and “pork.” We checked the reference lists of each article to identify any possibly relevant papers that were not found during the initial search.

Database compilation

Articles were selected according to the specified criteria: (1) The investigation was published in peer-reviewed journals; (2) Investigations applied gamma irradiation instead of electron beam or x-ray; (3) The irradiation dosage was identified, and (4) raw meat or its products that were processed were employed as the subject material. Fig. 1 displays information about the studies chosen for this meta-analysis. The comprehensive database included 21 articles that contain 52 experiments (Table 1). The compiled data description is available in the results section.

The studies investigated in our meta-analysis focused on the impact of gamma irradiation on many aspects of pork meat, including textural characteristics, color, oxidation parameters, microbiological loads, and sensory properties. Studies utilizing electron beam irradiation or x-ray sources, excluding gamma sources, were not included in the study.

The texture parameters include hardness, springiness, cohesiveness, gumminess, and chewiness. The color parameters studied were lightness (L*), redness (a*), and yellowness (b*). Oxidation parameters consist of thiobarbituric acid-reactive substances (TBARS), peroxide-oxygen value (POV), and total volatile base nitrogen (TVBN). The microbiological loads assessed were total aerobic bacteria, coliform, and lactic acid bacteria. The sensory evaluation

Table 1: Studies included in the meta-analysis of the effects of gamma irradiation on the characteristics of pork

| No. | Reference | Meat sample | Dosage (kGy) | Additional treatment | Parameters reported |

| 1 | Ham et al. (2017) | Cooked pork sausage | 0; 2.5; 5; 7.5; and 10 | Cooked | pH; Hunter color; texture properties; TBARS |

| 2 | Li et al. (2017) | Fresh pork | 0; 3; 5; and 7 | No treatment | Hunter color; sensory evaluation; TBARS |

| 3 | Fadhel et al. (2016) | Pork loins | 0; 1; 1.5; and 3 | No treatment and marinated | Hunter color; TBARS; LAB |

| 4 | Kim et al. (2014) | Ground meat and fat | 0; and 10 | No treatment | pH; Hunter color; texture properties; sensory evaluation |

| 5 | Dussault et al. (2012) | Pork sausage | 0; and 1.5 | Refrigerated; and fermented with 0.5% dextrose | pH; and LAB |

| 6 | Kim et al. (2012) | Fermented pork sausage | 0; 0.5; 1; 2; and 4 | No treatment | pH; Hunter color; TBARS; TVBN; coliform; LAB |

| 7 | Choi et al. (2011) | Pork sausage | 0; 5; and 10 | No treatment; addition of 0.3% onion powder; 0.3% garlic powder; and 0.5% kimchi powder | pH; Hunter color; texture properties; sensory evaluation; oxidation parameters |

| 8 | Cheng et al. (2011) | Chilled pork | 0; 2; 4; 5; 6; 8; and 10 | No treatment | TBARS; POV |

| 9 | Galán et al. (2011) | Pork sausage | 0; 2; 3; and 4 | No treatment; addition of 0.6; 1.2; and 2.4 mg folic acid/100 mg sample | Hunter color; texture properties; sensory evaluation |

| 10 | Kim et al. (2009) | Pork patty | 0; 2; 4; 6; and 8 | No treatment; addition of fucoidan; and laminarin | Hunter color; TBARS; total aerobic bacteria |

| 11 | Sinanoglou et al. (2009) | Fresh pork meat | 0; 1; 2.5; and 4.7 | Vacuum packaging | Hunter color |

| 12 | Song et al. (2009) | Minced pork | 0; 5; 10; 15; and 20 | No treatment | Hunter color; texture properties; sensory evaluation; TBARS; total aerobic bacteria |

| 13 | Oh et al. (2008) | Porky jerky | 0; 3; 5; 7; and 10 | No treatment | Hunter color; sensory evaluation; TBARS |

|

14 |

Kang et al. (2007) | Pork patty | 0; and 3 | Packaging variation (aerobic and vacuum); and coating variation (no coating, coated with pectin-based materials, and coated with pectin-based material containing 0.5% green tea powder) | Sensory evaluation |

| 15 | Lee et al. (2006) | Pork rib steak | 0; 10; 20; 30; 40; and 50 | Marinated and precooked | TBARS; total aerobic bacteria |

| 16 | Kanatt et al. (2005) | Pork salami | 0; 1; 2; and 3 | No treatment | Sensory evaluation; TBARS |

| 17 | Lee et al. (2005) | Hamburger steak (chilled pork, pork back fat) | 0; 5; 10; and 20 | No treatment; addition of 200 g rosemary; 500 g rosemary; and butylated hydroxyanisole (BHA) | Texture properties; TBARS; total aerobic bacteria; coliform |

| 18 | Davis et al. (2004) | Pork loins | 0; 2.2; and 4.4 | No treatment or injected with 13% final added weight with a brine composed of 3.04% sodium tripolyphosphate, 2.17% sodium chloride, and 20.8% potassium lactate | Hunter color; TBARS |

| 19 | Ahn et al. (2004) | Pork sausage | 0; and 5 |

Packaging variation (aerobic, vacuum, CO2, N2, or CO2/N2) |

Hunter color |

| 20 | Byun et al. (2001) | Pork sausage | 0; 3; and 5 | Salted and washed | Coliform |

| 21 | Jo et al. (2001) | Pork sausage | 0; 4.5; 10; and 20 |

No treatment; addition of 0.2% chitosan oligomer; and 156 ppm NaNO2 |

pH; Hunter color; sensory evaluation |

TBARS: thiobarbituric acid reactive substances (mg MDA/kg); TVBN: total volatile base nitrogen (mg N/100 g sample); POV: peroxide value (meq peroxide/kg); LAB: lactic acid bacteria (Log CFU/g).

criteria comprised color, flavor, tenderness, taste, juiciness, texture, off-odor, and overall acceptance on a scale of 0-10.

Statistical Analysis

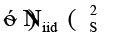

This meta-analysis applied a mixed model approach (Sauvant et al., 2008; St-Pierre, 2001). The gamma irradiation dose was considered a fixed effect, whereas study differences were treated as random effects. The following mathematical model is:

The dependent variable is represented by Yijk , overall mean value is represented by μ, the random effect of the ith study is represented by si, considered to have a mean of 0 and variance, following a normal distribution,  , the fixed effect of the jth τ factor is represented by τj, the random interaction between the ith and jth levels of the τ factor is represented by sτij assumed to a normal distribution

, the fixed effect of the jth τ factor is represented by τj, the random interaction between the ith and jth levels of the τ factor is represented by sτij assumed to a normal distribution , the overall value of the fixed effect (Y to X) of the linear regression coefficient is represented by β1, The overall quadratic regression coefficient value of Y on X (a fixed effect) is represented by β2, Xij and

, the overall value of the fixed effect (Y to X) of the linear regression coefficient is represented by β1, The overall quadratic regression coefficient value of Y on X (a fixed effect) is represented by β2, Xij and  represents the continuous values of the predictor variable in linear and quadratic forms, respectively, the random effect of the study on the regression coefficient of Y to X is represented by bi, assumed to follow a normal distribution with mean 0 and variance

represents the continuous values of the predictor variable in linear and quadratic forms, respectively, the random effect of the study on the regression coefficient of Y to X is represented by bi, assumed to follow a normal distribution with mean 0 and variance , and the residual value stemming from unpredictable errors is represented by eijk.

, and the residual value stemming from unpredictable errors is represented by eijk.

All statistical analysis were performed using R version 3.6.3 with “nmle” library (Pinheiro et al., 2020). Coefficient of determination (R2), root means square error (RMSE), and p-value were used as model statistics. p < 0.01 and p < 0.05 were used as staitistically significant. Meanwhile, a p-value ranging from 0.05 to 0.10 was considered as a statistically significant tendency.

RESULTS

Description about the selected studies

Descriptions of the articles included in this research are presented in Table 1. There are seven categories of pork products mentioned in 21 papers: pork sausage (8 papers), fresh pork (6 papers), pork patty (2 papers), pork steak (2 papers), chilled pork (1 paper), pork salami (1 paper), and pork jerky (1 paper). Regarding gamma irradiation doses for treatments, only four papers applied dosages over 10 kGy. The treatment consists mainly of graded dosages ranging from 0 to 10 kGy. Supplementary treatment was applied to pork product samples in addition to irradiation. Eight papers lack additional treatment. Additional treatments could include variations in packaging (Ahn et al., 2004; Kang et al., 2007; Sinanoglou et al., 2009), antioxidants (Choi et al., 2011; Galán et al., 2011; Kang et al., 2007; Lee et al., 2005), polymers (Jo et al., 2001), or chemical additives (Davis et al., 2004; H. J. Kim et al., 2009).

Influence of gamma irradiation on texture properties

The effect of gamma irradiation on texture properties in pork is presented in Table 2. Present meta-analysis findings reported that gamma irradiation reduced hardness, gumminess, and chewiness of pork (p < 0.01). Meanwhile, springiness was increased after irradiation tereatment (p < 0.05). Gamma irradiation did not affect cohesiveness. Gumminess (kg) = 0.494 + (-0.011X) + 0.001X2; n = 27; p = 0.002; RMSE = 0.012; R2 = 1.

Table 2: Effect of gamma irradiation on texture properties of pork

| Parameter | Unit | n | Intercept | SE Intercept | Slope | SE Slope | p-value | RMSE |

R2 |

| Hardness | kg | 53 | 0.868 | 0.113 | -0.006 | 0.002 | 0.001 | 0.048 | 0.98 |

| Springiness | - | 27 | 0.988 | 0.033 | 0.007 | 0.002 | 0.016 | 0.072 | 0.47 |

| Cohesiveness | - | 43 | 0.397 | 0.046 | -0.001 | 0.001 | 0.101 | 0.021 | 0.98 |

| Gumminess | kg | 27 | 0.494 | 0.283 | -0.011 | 0.003 | 0.003 | 0.012 | 1.00 |

| Chewiness | kg | 32 | 1.250 | 0.669 | -0.056 | 0.012 | 0.001 | 0.214 |

0.98 |

SE: standard error; RMSE: root mean square error; R2: The proportion of variance in a dependent variable that an independent variable can explain (bigger is better).

Table 3: Effect of gamma irradiation on pH and Hunter color of pork

| Parameter | Unit | n | Intercept | SE Intercept | Slope | SE Slope | p-value | RMSE |

R2 |

| pH | - | ||||||||

| 0 day | 33 | 6.208 | 0.123 | 0.010 | 0.003 | 0.001 | 0.036 | 0.99 | |

| 7 days | 12 | 6.354 | 0.062 | 0.018 | 0.007 | 0.044 | 0.029 | 0.92 | |

| 14 days | 12 | 6.215 | 0.101 | 0.040 | 0.023 | 0.147 | 0.113 | 0.65 | |

| L* (lightness) - | |||||||||

| 0 day | 96 | 60.712 | 2.621 | 0.068 | 0.035 | 0.058 | 1.230 | 0.99 | |

| 7 days | 18 | 53.812 | 1.152 | 0.063 | 0.346 | 0.858 | 2.464 | 0.18 | |

|

14 days |

12 | 55.023 | 1.797 | -0.229 | 0.393 | 0.575 | 2.066 | 0.51 | |

| a* (redness) - | |||||||||

| 0 day | 111 | 6.818 | 0.831 | 0.068 | 0.022 | 0.003 | 0.809 | 0.96 | |

| 7 days | 18 | 6.675 | 3.407 | 0.785 | 0.106 | 0.001 | 0.646 | 0.99 | |

| 14 days | 12 | 9.229 | 5.270 | 0.733 | 0.095 | 0.001 | 0.465 | 0.99 | |

| b* (yellowness) - | |||||||||

| 0 day | 88 | 10.171 | 0.842 | 0.028 | 0.019 | 0.152 | 0.688 | 0.96 | |

| 7 days | 10 | 12.260 | 3.481 | 0.226 | 0.104 | 0.073 | 0.547 |

0.99 |

|

SE: standard error; RMSE: root mean square error; R2: The proportion of variance in a dependent variable that an independent variable can explain (bigger is better).

Table 4: Effect of gamma irradiation on TBARS, POV and TVBN

| Parameter | Unit | n | Intercept | SE Intercept | Slope | SE Slope | p-value | RMSE |

R2 |

| TBARS | mg MDA/kg | ||||||||

| 0 day | 91 | 0.774 | 0.200 | 0.043 | 0.009 | 0.001 | 0.265 | 0.920 | |

| 7 days | 22 | 1.245 | 0.916 | 0.060 | 0.005 | 0.001 | 0.172 | 0.992 | |

| 14 days | 16 | 1.600 | 1.544 | 0.057 | 0.003 | 0.001 | 0.122 | 0.998 | |

| POV | meq peroxide/kg | 9 | 2.833 | 1.372 | 0.537 | 0.129 | 0.006 | 1.171 | 0.772 |

| TVBN | mg N/100 g sample | 17 | 6.493 | 3.226 | -0.003 | 0.028 | 0.910 | 0.562 |

0.989 |

TBARS: thiobarbituric acid reactive substances; TVBN: total volatile base nitrogen; POV: peroxide value; SE: standard error; RMSE: root mean square error; R2: The proportion of variance in a dependent variable that an independent variable can explain (bigger is better).

Influence of gamma irradiation on pH and Hunter color

Gamma irradiation increase pH value of pork at 0 and 7 days after storage (p < 0.05; Table 3). Regarding Hunter color parameters, L* and b* values of pork at 0 and 7 days after storage did not affect by gamma irradiation treatment. Furthermore, a* value increase with increasing irradiation dose (p < 0.01).

Influence of gamma irradiation on lipid and protein oxidation

Table 4 shows the effects of gamma irradiation on TBARS, POV and TVBN. Gamma irradiation significantly increased TBARS value of pork at 0, 7, and 14 days of storage (p < 0.01). Furthermore, POV value at 0 days storage also increased after irradiation treatment (p < 0.01). Mean

Table 5: Effect of gamma irradiation on microbial loads of pork

| Parameter | Unit | n | Intercept | SE Intercept | Slope | SE Slope | p-value | RMSE |

R2 |

| Total aerobic bacteria | Log CFU/g | 53 | 1.991 | 0.298 | -0.093 | 0.022 | 0.001 | 1.609 | 0.000 |

| Coliform | Log CFU/g | 27 | 1.997 | 0.375 | -0.146 | 0.041 | 0.002 | 1.387 | 0.000 |

| Lactic acid bacteria | Log CFU/g | 17 | 1.866 | 0.812 | -0.464 | 0.135 | 0.005 | 0.511 |

0.894 |

CFU: Colony Forming Unit’s; SE: standard error; RMSE: root mean square error; R2: The proportion of variance in a dependent variable that an independent variable can explain (bigger is better).

Table 6: Effect of gamma irradiation on sensory evaluation of pork

| Parameter | Unit | n | Intercept | SE Intercept | Slope | SE Slope | p-value | RMSE |

R2 |

| Color | - | 45 | 7.066 | 0.325 | -0.064 | 0.024 | 0.012 | 0.491 | 0.791 |

| Flavor | - | 44 | 7.172 | 0.267 | -0.153 | 0.026 | 0.001 | 0.403 | 0.816 |

| Tenderness | - | 11 | 8.179 | 0.100 | -0.021 | 0.006 | 0.011 | 0.061 | 0.866 |

| Taste | - | 38 | 5.968 | 0.180 | -0.097 | 0.024 | 0.000 | 0.425 | 0.627 |

| Juiciness | - | 9 | 8.028 | 0.118 | -0.017 | 0.009 | 0.133 | 0.087 | 0.735 |

| Texture | - | 33 | 7.049 | 0.262 | -0.290 | 0.081 | 0.002 | 0.378 | 0.740 |

| Off odor | - | 25 | 3.906 | 0.719 | 0.298 | 0.054 | 0.001 | 0.595 | 0.903 |

| Overall acceptance | - | 70 | 7.560 | 0.289 | -0.203 | 0.036 | 0.001 | 0.464 |

0.842 |

SE: standard error; RMSE: root mean square error; R2: The proportion of variance in a dependent variable that an independent variable can explain (bigger is better).

while, TVBN value at 0 days storage was not affected by gamma irradiation. TBARS at 0 days (mg Malondialde hyde/kg) = 0.774 + 0.043X + 0.001X2; n = 91; p = 0.001; RMSE = 0.265; R2 = 0.92.

Influence of gamma irradiation on microbial loads

The results of meta-analysis study summarized the effects of gamma irradiation on microbial load parameters are presented in Table 5. Total aerobic bacteria, coliform, and LAB decreased after gamma irradiation (p < 0.01).

Influence of gamma irradiation on sensory evaluation

Gamma irradiation treatment resulted in a decrease in texture, flavor, taste, and overall acceptance of pork (p < 0.01; Table 6). Furthermore, color and tenderness also decreased as the gamma irradiation dose increased (p < 0.05). Meanwhile, off-odor parameter was increased after irradiation treatment (p < 0.01). Gamma irradiation did not affect juiciness value.

DISCUSSIONS

Influence of gamma irradiation on texture properties

An essential aspect of eating quality that directly affects consumer preferences is the meat product’s texture profile (Abeyrathne and Nam, 2022). Except for cohesiveness, the profile of hardness, gumminess, chewiness, and springiness is affected by gamma irradiation. Alteration in texture properties is assumed to be related to structural changes in pork protein following treatment. The reduction of hardness in pork meat could be associated to the decreasing collagen content. Following gamma irradiation treatment, there was a significant decrease in the soluble collagen mass fraction (Sant et al., 2022). Myofibrillar protein content in meat decreases as the radiation dose is increased. It changes the secondary structure, which modifies the myofibrillar protein’s functional characteristics (Indiarto et al., 2023). The shrinkage of the myofibrils and consequent constriction of the sarcomeres observed in the meat microstructure may be the reason for the texture changes (Galán et al., 2010). According to Indiarto et al. (2023), irradiation can also denature protein molecules. The gumminess value of the pork will be impacted by this mechanism, which will make it firmer. Ionizing radiations may have an impact on protein denaturation, as may interactions between proteins that have been denatured by various radiation types (Kim et al., 2020). Some crosslinks might develop during the radiation, resulting in the formation of bonds among proteins and free amino acids and the formation of protein-protein complexes that have the potential to significantly alter the structure of meat (Galán et al., 2010). Our meta-analysis showed that irradiation doses of 5.7 and 3.7 kGy could alter the gumminess and texture of pork.

In addition to its effect on protein linkages, Choi et al. (2011) reported that irradiation influences meat’s moisture content. This mechanism has been suggested to affect the texture of meat because radiation induced the loss of water-holding capacity. According to reports, protein denaturation causes muscle fiber diameter to rise, which reduces meat’s water holding capacity (Huang et al., 2023). After the muscle falls to the crucial limit (about 40% moisture content), gamma irradiation will increase the disappearance of both bound and free water (Zu et al., 2022). Similar results were reported by Choi et al. (2011), Galán et al. (2011) and Lee et al. (2005). The muscle fiber membrane’s structural integrity has been damaged after irradiation, leading to a decrease in the meat’s ability to retain water (Pelicia et al., 2015).

Influence of gamma irradiation on pH and Hunter color

The pH value of pork increased significantly following irradiation on day 0 and 7 of storage, but remained unchanged until day 14. It is interesting to note that, in our previous meta-analysis study (Wahyono et al., 2024), the pH value of pork products did not change following electron beam irradiation. The reason for this difference can be attributed to the fact that the gamma irradiation mechanism possesses more capability for penetration compared to the electron beam (Mine & Yekta, 2009). Variations in the ability to penetrate will lead to variations in the physicochemical characteristics of the samples. However, due to its high penetrating capability, gamma ray irradiation may exhibit more efficacy in decreasing bacterial populations when compared to electron beam irradiation (Park et al., 2010). The preservation procedure, which is the main objective of irradiation, works optimally when the pH level is steady. The pH level is a critical factor in regulating the duration for which meat products can be stored without getting spoiled (Wahyono et al., 2024b). It is crucial to note that although irradiation does not directly affect the pH of meat, pH variations remain possible due to several factors like storage conditions, methods of processing, and the type of meat. According to Ham et al. (2017), altering the pH of irradiated pork products has minimal to minor impacts on their quality properties.

The color of the pork meat is an essential indicator of quality in the market. Ohene-Adjei et al. (2004) reported that oxidation could theoretically result in a mechanism that affects the pigmentation of meat. Initial irradiation generated materials that were darker (L* value decreased), redder (a* value increased), and yellower (b* value decreased). Pork, a conventional type of “red” meat, appears pink to red in its raw form but undergoes a color change to a lighter shade when cooked (Keeton & Dikeman, 2017). Beef has a higher concentration of myoglobin, while poultry has a lower concentration. Lamb and pork contain an intermediate amount of myoglobin (American Meat Science Association, 2023). According to this information, the impact of gamma irradiation on the color of pork is mostly affected by the redness value parameter (a*). Our meta-analysis study confirms these findings. Meanwhile, there were no significant changes reported in the lightness (L*) and yellowness (b*) values.

The increase in redness value (a*) is correlated with the increase in pH value as explained previously. The rise in pH value is due to of the oxidation reaction happening to myoglobin following gamma irradiation. The mechanism of myoglobin oxidation may result in the synthesis of metmyoglobin, a substance that has a brown color and is less acidic compared to myoglobin (Faustman et al., 2010; Liu et al., 2021). The myoglobin molecule in meat is naturally sensitive to energy input from irradiation treatment, which can lead to changes in meat color. This can result in the generation of brown, green, and bright red pigments (Zhou et al., 2010). In addition to oxidizing compounds (hydroxyl radicals), aqueous electrons, and hydrogen atoms are produced as well during the radiolytic degradation of water molecules (Brewer, 2004; C. Li et al., 2017). Additionally, Kim et al. (2013) stated that the red color value of meat could be altered by irradiation treatment because of nitrosoheme pigment destruction. Nitrosoheme is responsible for the pink or red color observed in fresh meat. Upon destruction, the meat may exhibit a more brownish or grayish color. However, the impact of irradiation on the redness value also depends on the additional treatment of the meat. Irradiation decreases the redness (a*) value in meat that had been handled with modified atmospheric packing, as shown by Ahn et al. (2004). Additionally, the addition of folic acid has the same effect, as demonstrated by Galan et al. (2011).

Influence of gamma irradiation on lipid and protein oxidation

Color changes associated with the oxidation of myoglobin are also used as an indicator of lipid oxidation. MetMb-H2O2 and ferryl myoglobin have been identified as effective accelerators for lipid oxidation in meat (Faustman et al., 2010). The TBARS assay is a widely used method for measuring lipid oxidation in fish and meat products. Malonaldehyde (MDA) is an aldehyde that develops after unsaturated fatty acids have been broken down (Abeyrathne et al., 2021). Key factors that contribute to the oxidation and rancidity of pork meat and meat-based products are the phospholipids and triglycerides that are found in meat (Abeyrathne & Nam, 2022). The application of irradiation, along with the inclusion of antioxidants, can be utilized in the pork industry to develop a high-quality product that has an extended shelf-life (Ibrahim, 2013). In our meta-analysis, we included studies that combined irradiation treatment with other interventions to minimize oxidation. These interventions included packaging (Kang et al., 2007; Sinanoglou et al., 2009), antioxidants (Choi et al., 2011; Galán et al., 2011; Kang et al., 2007), and chitosan (Jo et al., 2001). However, the TBARS value showed an increase following irradiation, although at lower levels compared to the lack of any additional treatment. This trend was also observed in previous meta-analysis on electron beam treatment (Wahyono et al., 2024b).

POV, along with TBARS, is a key factor in assessing the presence of lipid peroxidation in pork following gamma irradiation. Irradiation induces the formation of free radicals in water, which generates a chain reaction of free radicals and enhances the process of lipid auto-oxidation in meat (Yan et al., 2024). Increases in POV value may be influenced by the irradiation dose, and the storage conditions following to irradiation (Li et al., 2023). Our meta-analysis discovered that the application of gamma irradiation, beginning at a dosage of 10 kGy, has an immediate effect on elevating the POV value. Similar to our previous findings in electron beam technique (Wahyono et al., 2024b), the trend of POV rises in pork following gamma irradiation is consistent with TBARS value. The POV value of pork is significantly impacted by variations in pH levels and the production of free radicals after gamma irradiation. Catalytic activity (temperature, pH, metal ions, and free radicals) is essential for the highly complicated chemical process of autoxidation, which also includes the self-programming reaction of radicals (Amaral et al., 2018).

The breakdown of proteins and other nitrogen-containing substances due to spoiling mechanisms leads to the production of organic amines, which are referred to as total volatile basic nitrogen (TVBN) (Bekhit et al., 2021). The metabolic activities of bacteria and other microbes naturally found in meat involve the breakdown of proteins into volatile nitrogen molecules (Hwang et al., 2022). Our meta-analysis study showed that there was no alteration in TVBN levels following irradiation treatment. Gamma irradiation is believed to inhibit the activity of pathogenic bacteria, which in effect inhibits the production of TVBN. As a result, there is no rise in TVBN levels during the gamma irradiation process. Nevertheless, various studies have shown that TVBN levels increased after irradiation treatment (Chen et al., 2023; Kim et al., 2013). The increase of TVBN is impacted not only by microbial activity but also by protein degradation. Many kinds of nitrogen-containing compounds are produced during the degradation of proteins, such as volatile amines and ammonia (Kim et al., 2012).

Influence of gamma irradiation on microbial loads

Total aerobic bacteria, coliforms, and lactic acid bacteria were significantly decreased, which is in line with the initial objectives of gamma irradiation. Following gamma irradiation treatment, microbial populations remained undetected in various studies (Kim et al., 2009; Kim et al., 2012; Lee et al., 2006; Song et al., 2009). The current meta-analysis showed that irradiation treatment at doses of 27.39 and 12.97 kGy was associated with an elimination in the total number of aerobic bacteria and coliforms, respectively. Gamma irradiation exhibits bactericidal effects through two different mechanisms such as 1) a direct method, by attacking DNA; or 2) an indirect mechanism, by reacting with water and developing reactive oxygen species (Correa et al., 2019). Regarding mechanism number two, the evidence provided in the present study is a finding of an oxidation reaction, which is shown by the Hunter color redness (a*) parameter and lipid peroxidation. Initial flora, degree of contamination, storage period, and temperature are all factors in the growth of meat decomposition bacteria (Byun et al., 2001). Our meta-analysis study has shown that gamma irradiation is a highly successful method for sterilizing pork from various sources, treatments, and storage conditions. Gram-positive and gram-negative microbial pathogens exhibit various levels of radiosensitivity, although both can be effectively eliminated through irradiation (Wahyono et al., 2024a). Based on its primary purpose of eliminating pathogens, irradiation treatment can be used in combination with different methods such as herbal additives, smoking, marination, and frozen storage (Fadhel et al., 2016; Dimov and Popova, 2022; Kim et al., 2014).

The present meta-analysis study shows that gamma irradiation effectively decreases the total levels of coliform in pork products. Similar findings were also found for samples of chicken and ruminant meat (Kanatt et al., 2010; Oliveira et al., 2009; Yim et al., 2023). It is important to note that gamma irradiation also eliminates lactic acid bacteria, which play a role in the marination and preservation of meat. Therefore, it is essential to employ an appropriate technique to anticipate it. Fadhel et al. (2016) showed that the irradiation technique can be effectively integrated with meat marination. Even though numerous species of lactic acid bacteria are harmful to meat (Brugnini et al., 2021).

Influence of gamma irradiation on sensory evaluation

Consumer acceptance of irradiated pork products is ultimately determined by sensory evaluation, which is a crucial concluding parameter. As previously explained, the texture of pork (including its hardness, gumminess, chewiness, and springiness) has been affected by gamma irradiation, consequently, consumers’ collective evaluation scores on texture have been decreased. Theoretically, changes in the texture of pork can be attributed to the following factors: 1) a decrease in the formation of soluble collagen protein and myofibril protein (Galán et al., 2010; Sant et al., 2022); 2) a decrease in the water binding activity (Huang et al., 2023; Pelicia et al., 2015); and 3) an increase in the rate of lipid oxidation (Alahakoon et al., 2015).

The results of our meta-analysis indicated that gamma irradiation had a negative impact on flavor, taste, and tenderness (p < 0.05). Irradiation of pork lipids and proteins caused oxidation reactions that changed these three sensory parameters. The production of aldehydes, esters, ketones, hydrocarbons, lactones, and furans through lipid oxidation has been identified as a possible cause of rancid flavors (Henry, 2009; Li et al., 2017). Following lipid oxidation, an increase of off-flavors is also accompanied by the formation of an unpleasant odor. Lipid oxidation and oxidative breakdown of proteins (amino acids) caused by irradiation, together with the formation of new volatile compounds resulting from their interactions, are significant factors contributing to the development of off-odors in irradiated materials (Wang et al., 2022). Irradiation produces volatile sulfur molecules that are responsible for the unusual odor of meat (Henry, 2009). The breakdown of nucleotides is also responsible for the changes in taste observed in irradiated meat, a fact that has been confirmed by electronic tongue data (Feng and Ahn, 2021). A rise in off-odor, along with a decrease in taste, texture, and color, will subsequently reduce the overall acceptability parameters. The fact that irradiated meat products produce radiolytic off-flavors and odors is a primary cause of the decline in all sensorial acceptability (Ham et al., 2017).

CONCLUSION

Our meta-analysis findings confirm that a decrease in sensory qualities, alteration in redness (a*), and increased oxidation parameters are critical negative effects of gamma radiation on pork. Meanwhile, the main objective of microbiological decontamination has been accomplished. Effective strategies must be established in place to minimize the negative effects of gamma irradiation on consumer perception.

ACKNOWLEDGEMENTS

We are thankful for the kind support from Research Center for Food Technology and Processing, National Research and Innovation Agency (BRIN) as an institutional platform that supports collaboration between researchers.

CONFLICT OF INTEREST

The authors declare there is no conflict of interest.

novelty statement

As an alternative to electron beam technique, gamma irradiation in pork products requires further investigation. Meta-analysis studies related to gamma radiation in pork have not been published to thus far. The novelty aspect of this research is that we present a comprehensive report on the effects of gamma-ray irradiation on the quality of pork.

AUTHORS CONTRIBUTION

Triyannanto designed the experiment, funding acquisition, writing – original draft, and supervision; Nur Adli performed conceptualization, data analysis, and validation; Pratiwi performed project administration, and writing – original draft; Hakim conducted data interpretation, and methodology; Permadi performed data curations, methodology, and validation; Kurniawan performed data curation, and data analysis; Firmansyah performed data curation, and data analysis; Ivanti performed writing – original draft and validation; Saputri performed data analysis, validation, and writing – review and editing; Sholikin designed the experiment, data analysis, visualization, and writing – review and editing; Hariadi performed data curation, software, and writing – original draft; Ujilestari performed data curations, methodology, and validation; Wahyono performed conceptualization, data curation, writing – original draft, writing – review and editing, supervision, and project administration.

REFERENCES

Abeyrathne EDNS, Nam K, Ahn DU (2021). Analytical methods for lipid oxidation and antioxidant capacity in food systems. Antioxidants, 10(10): 1–19. https://doi.org/10.3390/antiox10101587

Abeyrathne EDNS, Nam KC (2022). Impact of irradiation in meat quality on pork sausage products using hot and cold carcasses, stored at different aging temperatures. J. Agri. Life Sci. 56(1): 39–47. https://doi.org/10.14397/jals.2022.56.1.39

Ahn HJ, Kim JH, Jo C, Lee JW, Yook HS, Kim HY, Byun MW (2004). Combined effects of gamma irradiation and a modified atmospheric packaging on the physicochemical characteristics of sausage. Radiat. Phys. Chem. 71(1–2): 53–56. https://doi.org/10.1016/j.radphyschem.2004.04.006

Alahakoon AU, Jayasena DD, Jung S, Kim SH, Kim HJ, Jo C (2015). Effects of electron beam irradiation and high pressure treatment combined with citrus peel extract on seasoned chicken breast meat. J. Food Process. Preserv. 39(6): 2332–2339. https://doi.org/10.1111/jfpp.12480

Amaral AB., Solva MVD, Lannes SCDS (2018). Lipid oxidation in meat: Mechanisms and protective factors - a review. Food Sci. Technol (Brazil) 38: 1–15. https://doi.org/10.1590/fst.32518

American Meat Science Association (2023). Chemistry of fresh meat color. American Meat Science Association. Illinois: Champaign. https://doi.org/10.1016/j.meatsci.2005.02.016

Bekhit AEDA, Holman BWB, Giteru SG, Hopkins DL (2021). Total volatile basic nitrogen (TVB-N) and its role in meat spoilage: A review. Trends Food Sci. Technol. 109: 280–302. https://doi.org/10.1016/j.tifs.2021.01.006

Brewer S (2004). Irradiation effects on meat color - A review. Meat Sci. 68(1): 1–17. https://doi.org/10.1016/j.meatsci.2004.02.007

Brugnini G, Rodríguez S, Rodríguez J, Rufo C (2021). Effect of UV-C irradiation and lactic acid application on the inactivation of listeria monocytogenes and lactic acid bacteria in vacuum-packaged beef. Foods 10(6). https://doi.org/10.3390/foods10061217

Byun MW, Lee JW, Jo C, Yook HS (2001). Quality properties of sausage made with gamma-irradiated natural pork and lamb casing. Meat Sci. 59(3): 223–228. https://doi.org/10.1016/S0309-1740(01)00062-6

Chen W, Yang J, Huang N, Zhang Q, Zhong Y, Yang H, Liu W, Yue Y (2023). Effect of combined treatments of electron beam irradiation with antioxidants on the microbial quality, physicochemical characteristics and volatiles of vacuum-packed fresh pork during refrigerated storage. Food Control 14: 109480. https://doi.org/10.1016/j.foodcont.2022.109480

Cheng A, Wan F, Xu T, Du F, Wang W, Zhu Q (2011). Effect of irradiation and storage time on lipid oxidation of chilled pork. Radiat. Phys. Chem. 80: 475-480. https://doi.org/10.1016/j.radphyschem.2010.10.003

Choi SM, Choi JH, Choi YS, Kim HW, Kim HY, Lee MA, Hwang KE, Lee JW, Kim CJ (2011). Effects of kimchi powder on the quality properties of emulsion type sausage made with irradiated pork meat. Korean J. Food Sci. Anim. Resour. 31(5): 649–657. https://doi.org/10.5851/kosfa.2011.31.5.649

Correa W, Brandenburg J, Behrends J, Heinbockel L, Reiling N, Paulowski L, Schwudke D, Stephan K, Martinez-de-Tejada G, Brandenburg K, Gutsmann T (2019). Inactivation of bacteria by γ-irradiation to investigate the interaction with antimicrobial peptides. Biophys. J. 117(10): 1805–1819. https://doi.org/10.1016/j.bpj.2019.10.012

Davis KJ, Sebranek JG, Huff-Lonergan E, Ahn DU, Lonergan SM (2004). The effects of irradiation on quality of injected fresh pork loins. Meat Sci. 67(3): 395–401. https://doi.org/10.1016/j.meatsci.2003.11.011

Dimov K, Popova T (2022). A meta-analysis of the effect of gamma irradiation on chicken meat quality: Microbiology and colour. Food Sci. Appl. Biotechnol. 5(2): 160–172. https://doi.org/10.30721/fsab2022.v5.i2.185

Dussault D, Benoit C, Lzcroix M (2012). Combined effect of ɤ-irradiation and bacterial-fermented dextrose on microbiological quality of refrigerated pork sausages. Radiat. Phys. Chem. 81: 1098-1102. https://doi.org/10.1016/j.radphyschem.2011.11.031

Fadhel YB, Leroy V, Dussault D, St-Yves F, Lauzon M, Salmieri S, Jamshidian M, Vu DK, Lacroix M (2016). Combined effects of marinating and γ-irradiation in ensuring safety, protection of nutritional value and increase in shelf-life of ready-to-cook meat for immunocompromised patients. Meat Sci. 118: 43–51. https://doi.org/10.1016/j.meatsci.2016.03.020

Faustman C, Sun Q, Mancini R, Suman SP (2010). Myoglobin and lipid oxidation interactions: Mechanistic bases and control. Meat Sci. 86(1): 86–94. https://doi.org/10.1016/j.meatsci.2010.04.025

Feng X, Ahn DU (2021). Effect of irradiation on the quality parameters of raw beef. Iowa State University Animal Industry Report 17 (1). https://doi.org/10.31274/air.12043

Galán I, García ML, Selgas MD (2010). Effects of irradiation on hamburgers enriched with folic acid. Meat Sci. 84(3): 437–443. https://doi.org/10.1016/j.meatsci.2009.09.013

Galán I, García ML, Selgas MD (2011). Irradiation is useful for manufacturing ready-to-eat cooked meat products enriched with folic acid. Meat Sci. 87(4): 330–335. https://doi.org/10.1016/j.meatsci.2010.11.007

Guo Q, Ren CW, Cai JH, Zhang CY, Li YT, Xu B, Farooq MA (2022). The synergistic inhibition and mechanism of epicatechin gallate and chitosan against methicillin-resistant Staphylococcus aureus and the application in pork preservation. LWT, 163: 113575. https://doi.org/10.1016/j.lwt.2022.113575

Ham YK, Kim HW, Hwang KE, Song DH, Kim YJ, Choi YS, Song BS, Park JH, Kim CJ (2017). Effects of irradiation source and dose level on quality characteristics of processed meat products. Radiat. Phys. Chem. 130: 259–264. https://doi.org/10.1016/j.radphyschem.2016.09.010

Hao Y, Kang J, Guo X, Sun M, Li H, Bai H, Cui H, Shi L (2023). pH-responsive chitosan-based film containing oregano essential oil and black rice bran anthocyanin for preserving pork and monitoring freshness. Food Chem. 403(20): 134393. https://doi.org/10.1016/j.foodchem.2022.134393

Henry FC (2009). Irradiation effects on meat: a review. Rev. Cienc. Agrar. 32(2): 255–262.

Huang X, You Y, Liu Q, Dong H, Bai W, Lan B, Wu J (2023). Effect of gamma irradiation treatment on microstructure, water mobility, flavor, sensory and quality properties of smoked chicken breast. Food Chem. 421: 136174. https://doi.org/10.1016/j.foodchem.2023.136174

Hwang SH, Lee JH, Nam TG, Koo M, Cho YS (2022). Changes in physicochemical properties and bacterial communities in aged Korean native cattle beef during cold storage. Food Sci. Nutr. 10(8): 2590–2600. https://doi.org/10.1002/fsn3.2864

Indiarto R, Irawan AN, Subroto E (2023). Meat Irradiation: a comprehensive review of its impact on food quality and safety. Foods 12(9). https://doi.org/10.3390/foods12091845

Ji J, Allahdad Z, Sarmast E, Salmieri S, Lacroix M (2022). Combined effects of microencapsulated essential oils and irradiation from gamma and X-ray sources on microbiological and physicochemical properties of dry fermented sausages during storage. LWT 159: 113180. https://doi.org/10.1016/j.lwt.2022.113180

Kanatt SR, Chander R, Sharma A (2005). Effect of radiation processing on the quality of chilled meat products. Meat Sci. 69: 269-275. https://doi.org/10.1016/j.meatsci.2004.07.006

Kanatt SR, Rao MS, Chawla SP, Sharma A (2010). Shelf-life extension of convenience meat products sold in Indian supermarkets by radiation processing. Radiat. Phys. Chem. 79(12): 1259–1263. https://doi.org/10.1016/j.radphyschem.2010.07.008

Kang HJ, Jo C, Kwon JH, Kim JH, Chung HJ, Byun MW (2007). Effect of a pectin-based edible coating containing green tea powder on the quality of irradiated pork patty. Food Control 18(5): 430–435. https://doi.org/10.1016/j.foodcont.2005.11.010

Keeton JT, Dikeman ME (2017). “Red” and “white” meats-terms that lead to confusion. Animal Front. 7(4): 29–33. https://doi.org/10.2527/af.2017.0440

Khruengsai S, Phoopanasaeng P, Sripahco T, Soykeabkaew N, Pripdeevech P (2024). Application of chitosan films incorporated with Zanthoxylum limonella essential oil for extending shelf life of pork. Int. J. Biol. Macromol. 129703. https://doi.org/10.1016/j.ijbiomac.2024.129703

Kim HJ, Choi JI, Park JG, Song BS, Kim JH, Yoon Y, Kim CJ, Shin, MH, Byun MW, Lee JW (2009). Effects of combined treatment of gamma irradiation and addition of fucoidan/laminarin on ready-to-eat pork patty. Korean J. Food Sci. Anim. Resour. 29(1): 34–39. https://doi.org/10.5851/kosfa.2009.29.1.34

Kim HJ, Jung S, Yong HI, Bae YS, Kang SN, Kim IS, Jo C. (2014). Improvement of microbiological safety and sensorial quality of pork jerky by electron beam irradiation and by addition of onion peel extract and barbecue flavor. Radiat. Phys. Chem. 98: 22–28. https://doi.org/10.1016/j.radphyschem.2014.01.003

Kim HJ, Kang M, Yong HI, Bae YS, Jung S, Jo C (2013). Synergistic effects of electron-beam irradiation and leek extract on the quality of pork jerky during ambient storage. Asian-Australas. J. Anim. Sci. 26(4): 596–602. https://doi.org/10.5713/ajas.2012.12580

Kim IS, Jo C, Lee KH, Lee EJ, Ahn DU, Kang SN (2012). Effects of low-level gamma irradiation on the characteristics of fermented pork sausage during storage. Radiat. Phys. Chem. 81(4): 466–472. https://doi.org/10.1016/j.radphyschem.2011.12.037

Kim TK, Hwang KE, Ham YK, Kim HW, Paik HD, Kim, YB, Choi YS (2020). Interactions between raw meat irradiated by various kinds of ionizing radiation and transglutaminase treatment in meat emulsion systems. Radiat. Phys. Chem. 166. https://doi.org/10.1016/j.radphyschem.2019.108452

Lee JW, Park KS, Kim JG, Oh SH, Lee YS, Kim JH, Byun MW (2005). Combined effects of gamma irradiation and rosemary extract on the shelf-life of a ready-to-eat hamburger steak. Radiat. Phys. Chem. 72(1): 49–56. https://doi.org/10.1016/j.radphyschem.2004.01.003

Lei YJ, Chen SW, Jing YY, Zhang Y, Han X, Liu WL (2021). Effect of electron beam irradiation on the preservation of fresh pork. Mod. Food Sci. Technol. 37(10): 136–144. https://doi.org/10.13982/j.mfst.1673-9078.2021.10.0242

Li C, He L, Jin G, Ma S, Wu W, Gai L (2017). Effect of different irradiation dose treatment on the lipid oxidation, instrumental color and volatiles of fresh pork and their changes during storage. Meat Sci. 128: 68–76. https://doi.org/10.1016/j.meatsci.2017.02.009

Li G, Lin, P, Li Y, He Y, Liu Z (2023). Quality and stability evaluation of Guizhou spicy chicken treated with gamma irradiation during the storage period. Food Sci. Nutr. 00: 1–12. https://doi.org/10.1002/fsn3.3232

Liu F, Yu C, Guo S, Chiou BS, Jia M, Xu F, Chen M, Zhong F (2023). Extending shelf life of chilled pork meat by cinnamaldehyde nano emulsion at non-contact mode. Food Pack. Shelf Life 37. https://doi.org/10.1016/j.fpsl.2023.101067

Liu Q, Long Y, Zhang YF, Zhang ZY, Yang B, Chen CY, Huang LS, Su Y (2021). Phenotypic and genetic correlations of pork myoglobin content with meat colour and other traits in an eight breed-crossed heterogeneous population. Animal 15(11). https://doi.org/10.1016/j.animal.2021.100364

OECD-FAO (2018). Chapter 6. Meat. In AGRICULTURAL OUTLOOK 2018-2027. Rome pp. 149–162.

OECD-FAO. (2021). Chapter 6: Meat. In Agricultural Outlook 2021-2030. Rome pp. 163–177. http://dx.doi.org/10.1787/agr-outl-data-

Oh JS, Han IJ, Park JG, Park JN, Song BS, Kim JH, Byun MW, Chun SS, Lee JW (2008). Effect of gamma irradiation on physicochemical and sensory properties of restructured pork jerky. J. Korean Soc. Food Sci. Nutr. 37(3): 362-366. https://doi.org/10.3746/jkfn.2008.37.3.362

Ohene-Adjei S, Bertol T, Hyun Y, Ellis M, McKeith FK, Brewer MS (2004). Effect of vitamin E, low dose irradiation, and display time on the quality of pork. Meat Sci. 68(1): 19–26. https://doi.org/10.1016/j.meatsci.2003.08.016

Page MJ, McKenzie JE, Bossuyt PM, Boutron I, Hoffmann TC, Mulrow CD, Shamseer L, Tetzlaff JM, Akl EA, Brennan SE, Chou R, Glanville J, Grimshaw JM, Hróbjartsson A, Lalu MM, Li T, Loder EW, Mayo-Wilson E, McDonald S, McGuinness S, Stewart LA, Thomas LA, Tricco J, Welch AC, Whiting VA, Moher D (2021). The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. The BMJ 372. https://doi.org/10.1136/bmj.n71

Park JG, Yoon Y, Park JN, Han IJ, Song BS, Kim JH, Kim WG, Hwang HJ, Han SB, Lee JW (2010). Effects of gamma irradiation and electron beam irradiation on quality, sensory, and bacterial populations in beef sausage patties. Meat Sci. 85(2): 368–372. https://doi.org/10.1016/j.meatsci.2010.01.014

Pelicia K, Garcia EA, Molino AB, Santos GC, Vieira Filho JA, Santos TA, Berto DA (2015). Chicken Meat submitted to gamma radiation and packed with or without oxygen. Braz. J. Poultry Sci. 17(2): 255–262. https://doi.org/10.1590/1516-635x1702255-262

Pinheiro J, Bates D, DebRoy S, Sarkar D, Authors D, Heisterkamp S, Van Willigen B, Ranke J (2020). Linear and Nonlinear Mixed Effects Models Description. Available from: https://cran.r-project.org/web/packages/nlme/nlme.pdf. Retrieved on 02-01-2024

Sant NJ, Proffen BL, Murray, MM (2022). Effects of radiation dose and nitrogen purge on collagen scaffold properties. J. Biomater. Appl. 36(6): 1011–1018. https://doi.org/10.1177/08853282211047683

Sauvant D, Schmidely P, Daudin JJ, St-Pierre NR (2008). Meta-analyses of experimental data in animal nutrition. Animal 2(8): 1203–1214. https://doi.org/10.1017/S1751731108002280

Shin MH, Lee JW, Yoon YM, Kim JH, Moon BG, Kim JH, Song BS (2014). Comparison of quality of bologna sausage manufactured by electron beam or x-ray irradiated ground pork. Korean J. Food Sci. Anim. Resour. 34(4): 464–471. https://doi.org/10.5851/kosfa.2014.34.4.464

Sinanoglou VJ, Konteles S, Batrinou A, Mantis F, Sflomos K (2009). Effects of gamma radiation on microbiological status, fatty acid composition, and color of vacuum-packaged cold-stored fresh pork meat. J. Food Prot. 72(3): 556–563. https://doi.org/10.4315/0362-028X-72.3.556

St-Pierre NR (2001). Invited review: Integrating quantitative findings from multiple studies using mixed model methodology. J. Dairy Sci. 84(4): 741–755. https://doi.org/10.3168/jds.S0022-0302(01)74530-4

Sun Y, Zhang M, Bhandari B, Bai B (2021). Nanoemulsion-based edible coatings loaded with fennel essential oil/cinnamaldehyde: Characterization, antimicrobial property and advantages in pork meat patties application. Food Control 127 https://doi.org/10.1016/j.foodcont.2021.108151

Ujilestari T, Damayanti E, Sholikin MM, Febrisiantosa A, Permadi SN, Ivanti L, Jayanegara A, Wahyono T (2023). A meta-analysis of the effects of gamma irradiation on biochemical and physical characteristics of honey. IOP Conf. Ser. Earth Environ. Sci. 1230(1). https://doi.org/10.1088/1755-1315/1230/1/012053

Wahyono T, Firmansyah AM, Febrisiantosa A, Setiyawan AI, Karimy MF, Trinugraha AC, Ujilestari T, Sholikin MM, Benita AM, Jayanegara A (2023). Thiobarbituric Acid Reactive Substances (TBARS) and quality of poultry meat as affected by electron beam irradiation: A meta-analysis study. Developing Modern Livestock Production in Tropical Countries: 34–38. https://doi.org/10.1201/9781003370048-9

Wahyono T, Benita AM, Pratama IM, Palupi GR, Sadewo H, Hariadi H, Sholikin MM, Henry, Aviyani S, Damayanti E (2024a). Effect of gamma irradiation and evaporation on physicochemical, antibacterial, and antioxidant activity of selected high-quality herbal honey. Radiat. Phys. Chem. 214: 111263. https://doi.org/10.1016/j.radphyschem.2023.111263

Wahyono, T, Ujilestari T, Sholikin MM, Muhlisin M, Cahyadi M, Volkandari SD, Triyannanto E (2024b). Quality of pork after electron-beam irradiation: A meta-analysis study. Vet. World, 17(1): 59–71. https://doi.org/10.14202/vetworld.2024.59-71

Wan Y, Wang X, Yang L, Li Q, Ma L, Bai T, Zheng X, Wang X (2024). Anti Staphylococcus aureus activity of shikonin @ chitosan nanoemulsion and its effect on the storage quality of pork. Food Control 158: 110203. https://doi.org/10.1016/j.foodcont.2023.110203

Wang Q, Dong K, Wu Y, An F, Luo Z, Huang Q, Wei S (2022). Exploring the formation mechanism of off-flavor of irradiated yak meat based on metabolomics. Food Chem.: X 16: 100494. https://doi.org/10.1016/j.fochx.2022.100494

Wei Z, Huang L, Feng X, Cui F, Wu R, Kong Q, Sun K, Gao J, Guo J (2023). Development of functional, sustainable pullulan-sodium alginate-based films by incorporating essential oil microemulsion for chilled pork preservation. Int. J. Biol. Macromol. 253(9). https://doi.org/10.1016/j.ijbiomac.2023.127257

Yan, Y, Zhu X, Lu A, Yang X, Yu J, Qu J, Zhu M, Wang W (2024). Effect of 60Co-γ-irradiation on the degradation of β-agonists residues and the quality of fresh pork during refrigeration. Food Control 160: 110362. https://doi.org/10.1016/j.foodcont.2024.110362

Yim DG, Jo C, Mahabbat A, Park JY, Lee SY, Nam KC (2019). Combined effect of aging and irradiation on physicochemical quality of pork shoulder. Food Sci. Anim. Resour 39(3): 510–519. https://doi.org/10.5851/kosfa.2019.e46

Yim DG, Kim HJ, Kim SS, Lee HJ, Kim JK, Jo C (2023). Effects of different X-ray irradiation doses on quality traits and metabolites of marinated ground beef during storage. Radiat. Phys. Chem. 202: 110563. https://doi.org/10.1016/j.radphyschem.2022.110563

Zhang M, He L, Li C, Yang F, Zhao S, Liang Y, Jin G. (2020). Effects of gamma ray irradiation-induced protein hydrolysis and oxidation on tenderness change of fresh pork during storage. Meat Sci. 163: 108058. https://doi.org/10.1016/j.meatsci.2020.108058

Zhou GH, Xu XL, Liu Y (2010). Preservation technologies for fresh meat - A review. Meat Sci. 86(1): 119–128. https://doi.org/10.1016/j.meatsci.2010.04.033

Zu XY, Li HL, Xiong GQ, Liao T, Yu YH, Qiu JH (2022). Gamma irradiation on moisture migration and lipid degradation of Micropterus salmoides meat. Radiat. Phys. Chem. 192(368). https://doi.org/10.1016/j.radphyschem.2021.109915

To share on other social networks, click on any share button. What are these?