Assessment of Proximate Compositions and Functional Properties of Blends of Broken Rice and Wheat Flours

Research Article

Assessment of Proximate Compositions and Functional Properties of Blends of Broken Rice and Wheat Flours

Ishfaq Ahmed*, Ihsan Mabood Qazi and Suraiya Jamal

Department of Food Science and Technology, The University of Agriculture Peshawar, Khyber Pakhtunkhwa, Pakistan.

Abstract | This study was carried out to investigate the influence of incorporating wheat flour (WF) on broken rice flour (BRF) at different concentrations (0, 20, 40, 60, 80 and 100 g/100 g) on the proximate compositions and functional properties. It was found that percent protein (8.93–12.25%), ash (0.52–1.01%) and moisture contents (4.47–7.09%) showed significant (P < 0.05) increase, while fat content (1.41-1.17%) showed significant (P < 0.05) decrease by blending WF with BRF. Similarly, water solubility index (WSI), water absorption index (WAI) and swelling power (SP) showed significant (P < 0.05) decrease as the concentration of wheat flour in the blends increases. The values for WAI, WSI and SP were 4.73–6.18 g/g, 1.98–3.99% and 5.35–6.81 g/g, respectively. The blending of WF with BRF had substantially improved the proximate compositions and functional properties, which could be used in the enhancement of the nutritional quality of the value added products; processed by the addition of them.

Received | January 30, 2016; Accepted | June 29, 2016; Published | August 17, 2016

Correspondence | Ishfaq Ahmed, Department of Food Science and Technology, The University of Agriculture Peshawar-Pakistan; Email: [email protected]

Citation | Ahmed, I., I.M. Qazi and S. Jamal. 2016. Assessment of proximate compositions and functional properties of blends of broken rice and wheat flours. Sarhad Journal of Agriculture, 32(3): 142-150.

DOI | http://dx.doi.org/10.17582/journal.sja/2016.32.3.142.150

Keywords | Broken rice flour, Wheat flour, Blends, Proximate composition, Functional properties

Introduction

Rice (Oryza sativa L.) is the second most important staple food in the world after wheat (Jamal et al., 2016; Singh et al., 2005). Each year, approximately 600 million tons of rice is produced globally. China is the world’s largest producer of rice and produces 205.46 million tons annually (Reddy and Bhotmange, 2013; Giddel and Jivan, 2007). While, the production of rice in Pakistan is about 6 million tons annually (FBS, 2012), and it accounts 2.7%, and 0.6% of the worth in agriculture and gross domestic production, respectively (Memon, 2013). Rice flour constitutes 7% protein, 78% carbohydrates and 0.4–0.8% fat (Laureys, 1999), and also provides B vitamins; riboflavin, niacin, and thiamin in a considerable amount (Fresco, 2005). Some peoples are allergic to gluten and wheat flour causes celiac disease in such peoples, hence, rice flour is consumed to minimize the risk of allergic effect (Torbica et al., 2010). It is consumed as a staple food in many parts of Asia and has been widely employed for industrial and scientific purposes as a major gluten-free flour base (Park et al., 2012; Ahmed et al., 2015). In 2009, the largest consumer of rice was China consuming 156.3 million metric tons of paddy equivalent (29.4% of the world consumption) and India consuming 123.5 million metric tons of paddy equivalent (23.3% of the world consumption). Between 1961 and 2002, per capita consumption of rice increased by 40% (FAO, 2012). Considering the importance of rice in the diet, a variety of product such as cooked grains, puddings, desserts, noodles etc. are made from it (Ahmed et al., 2015; Inglett et al., 2005). Recently, rice flour is being employed in functional food, extruded products, coating agent, processing aid, emulsifiers, water binders, flavour carriers and fat replacer (Jamal et al., 2016; Inglett et al., 2005).

The quality characteristics of rice grains are nutritional profile, appearance, cooking and eating properties (Jamal et al., 2016; Juliano et al., 1990). However, rice flour lack gluten, which confines it use for developing many types of products (Gallagher et al., 2004). The elasticity, cohesiveness, mixing behaviour and resistance to stretch of rice dough is poor than wheat dough, hence, give low viscoelastic and cohesive structure (Cham and Suwannaporn, 2010). The quality parameters of the rice products depend mostly on the physicochemical properties (Bhattacharya et al., 1999). Flour obtained from different varieties of rice exhibited variation in term of amylose, amylopectin, lipid, protein and ash contents, which affect the thermal, pasting, cooking and functional properties of the final product (Jamal et al., 2016; Wang and Wang, 2004). Milling also affects the flour properties, as dry milled rice flour showed higher water hydration as well as soluble loss compared to wet milled rice flour and is attributed to the higher level of starch damage (Heo et al., 2013).

Wheat (Triticum spp.) is one of the oldest crops and has been cultivated all over the world. The majority of the world nations used it as a staple food. Therefore, a substantial amount of vegetable protein in the human diet is provided by wheat (Uthayakumaran and Wrigley, 2010). Approximate composition of wheat flour comprises of 8 to 13% protein, 1.0% soluble protein, 72% carbohydrates, 1.5% fat, 2.5% sugar, 0.5% minerals and 12 to 13% moisture (Oberoi et al., 2007). The wheat kernel contains embryo which is a concentrated source of minerals, protein and vitamins while the endosperm is a starch storage portion of the kernel (Bozzini, 1988). Glutenin and Gliadin are the main protein fractions, which are water insoluble and form a gluten network on hydration. The starch granules and gluten matrix form a strong network by acting as filler particles (Edwards et al., 2002). This enables dough to form a very unique cohesive and viscoelastic texture, which aids bread making and other food applications such as pasta, biscuits, noodles, cakes, soups etc. (Uthayakumaran and Wrigley, 2010; Li and Vasanthan, 2003).

On the other hand, blending of different flours lead to very unusual cohesive and elastic behaviours, and physical modifications that cannot be ascribed only to the final compositions and mixing proportions of the blends (Lin et al., 2002). Though, it is believed to have happened due to the different solubility and swelling properties of the starches present in the flour mixtures (Chen et al., 2003a). However, the bonding among the molecules of the different flour blends is yet not known (Lin et al., 2002). Reconstitution of different flours either increases or decreases the compositions up to certain extent, which affect the quality attributes of final products (Gianibelli et al., 2005). The influence of blending wheat flour with non-waxy and waxy rice flours was investigated by Huang and Lai (2010). The water absorption capacity of the dough was found to increase mainly because of the smaller granule size of rice starches in the flour, which provides a larger surface area for hydration. At the same time, the dense packaging of starch granules and gluten matrix also improved the water holding capacity of the dough. Functional properties represent the interaction between the structure, composition, molecular conformation and physicochemical characteristics of the food components with the subsequent environment in which it exists and is determined by chemical and physical means (Siddiq et al., 2009). Even though broken rice comprises of the substantial amount of rice sold in the marketplace at a very cheap rate and is deemed as a very low-quality product. The aim of this research work involved the collection of data on the proximate compositions and functional properties of this underutilized rice flour and also to find out the effect of blending WF on the aforementioned properties. The present study has great significance regarding the utilization of the underutilized broken rice along with wheat flour in food industries in order to produce natural, nutritious, cheap and acceptable functional foods. It also gives information regarding manufacturing of different products by using various concentrations of the raw materials. This information is helpful for the manufacturing of different value added products from broken rice.

Materials and Methods

Broken rice grains of Super Basmati 385 and whole wheat flour were procured from the flour mill located in Board bazaar Peshawar, Pakistan. Broken rice was considered as waste materials in the flour mill. The present study was carried out in Food Technology laboratory, The University of Agricultre, Peshawar, Pakistan.

Flour Preparation from Broken Rice

The impurities in broken rice kernels were first cleaned and then ground into flour via a Laboratory mill (THOMAS-Wiley, Model 4. USA). The obtained flour was next passed through a sieve of 100 mesh size (0.1µm). Likewise, wheat flour was also passed from the same mesh sieve to get flour with uniform particle size. The flour samples were then packed in airtight plastic bags and were kept in a refrigerator until any further analysis (Heo et al., 2013).

Blending Formulation

After that, Wheat flour (WF) was mixed with broken rice flour (BRF) at different concentrations including; 20, 40, 60, 80 and 100g / 100g on dry weight basis, using electric balance (Table 1). The color of BRF changed from white to creamy white with the addition of WF. All the treatments were analyzed for proximate compositions and functional properties.

Table 1: Blending formulation of broken rice flour (BRF) and wheat flour (WF)

| S.No | Samples | Broken Rice flour (g) | Wheat flour (g) |

| 01 | BRF:WF(100:00) | 100 | 00 |

| 02 | BRF:WF(80:20) | 80 | 20 |

| 03 | BRF:WF(60:40) | 60 | 40 |

| 04 | BRF:WF (40:60) | 40 | 60 |

| 05 | BRF:WF(20:80) | 20 | 80 |

| 06 | BRF:WF (00:100) | 00 | 100 |

Proximate Analysis of Flour Samples

The percent ash, moisture, crude fat and protein content of BRF, WF and their blends were analyzed following the method of AOAC (2012). The samples were taken in three replications for each analysis.

Functional Properties of Flour

All the treatments were analyzed in term of water solubility index (WSI), water absorption index (WAI) and swelling power (SP). The WSI, WAI and SP were determined by following the procedure conducted by Thumrongchote et al. (2012).

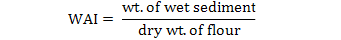

Water Absorption Index (WAI) and Water Solubility Index (WSI)

Fully dried 1.0 g flour samples were dissolved in 6.0 ml distilled water. The mixtures were then placed in a shaking water bath at 80oC for 30 min. It was then put in a centrifugation machine, which was adjusted at 2500 rpm for 10 min. After centrifugation, the supernatants were put into a pre-weighed Petri-dish and were placed in an oven at 105oC for 10 hr. The dried samples were weighed using electric balance. While, the wet sediments that remained at the bottom of the Petri-dish were weighed directly. The WAI and WSI were determined by using the formula given below:

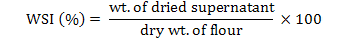

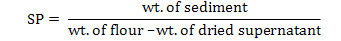

Swelling Power (SP)

Flour samples (500 mg) were accurately weighed and put in a pre-weighed empty centrifuge tube. Distil water (15 ml) was decanted into the tube. Afterward, the centrifuge tubes were placed in a shaking water bath that has been adjusted at 80oC for 30 min. The samples were then placed in a centrifugation machine at 4000 rpm for 20 min. The supernatants were collected and put into pre-weighed Petri-dishes and placed in an oven at 105oC until constant weight was acquired. The dried supernatants were weighed, while the remaining sediments at the centrifuge tube were weight without drying. The SP of all the flour samples were calculated by using the following formula:

Statistical Analysis

All the results were analyzed in a completely randomized design (CRD) via one-way (ANOVA) procedures with three replications. Mean values were separated by Least Significance Difference (LSD) test (Steel and Torrie, 1997) and data were analyzed using the software Statistix 8.1.

Results and Discussions

Proximate Composition of Flours

Food proximate composition is usually studied to analyze the nutrient profile and also it amount by percentage or weight in the sample. It is very important in order to obtain a good outlook of the nutritional advantages of that particular food product in the eating regime. It was found in the present study that blends of wheat and broken rice flours hold appreciable quantities of beneficial nutrients needed for maintaining normal body activities, as presented in Table 2.

Table 2: Effect of blending wheat flour in various proportions on proximate composition of broken rice flour

| Treatments | Moisture (%) | Ash (%) | Protein (%) | Fat (%) |

| BRFWF(100:00) | 4.47±0.03 d | 0.52±0.02 e | 8.93±0.09 f | 1.41±0.00 a |

| BRFWF(80:20) | 4.54±0.18 d | 0.68±0.05 d | 9.45±0.02 e | 1.33±0.00 b |

| BRFWF(60:40) | 5.61±0.06 c | 0.79±0.06 cd | 9.98±0.01 d | 1.28±0.00 c |

| BRFWF(40:60) | 5.71±0.11 c | 0.85±0.09 bc | 10.81±0.01 c | 1.25±0.00 d |

| BRFWF(20:80) | 5.90±0.97 b | 0.96±0.16 ab | 11.31±0.01 b | 1.18±0.00 e |

| BRFWF(00:100) | 7.09±0.07 a | 1.01±0.03 a | 12.25±0.01 a | 1.17±0.00 f |

The values in the column followed by different letters are significantly different from each other (P < 0.05)

In the respective figures, the results indicated that the incorporation of wheat flour in broken rice flour at different levels resulted significant increase in percent ash, percent moisture, ash and protein contents, except crude fat content that decreased significantly (P < 0.05). Moisture, ash, crude protein and fat content were found in the range of 4.47-7.09%, 0.52-1.01%, 8.93-12.25% and 1.17-1.41% respectively, having least value for BRF:WF (100:00) and highest value for BRF:WF (00:100), while fat content was maximum in BRF:WF (100:00) and vice versa (Figure 1, 2, 3 and 4).

Figure 1: Effect of blending wheat flour in various proportions on mean moisture content (%) of broken rice flour (P < 0.05)

Figure 2: Effect of blending wheat flour in various proportions on mean ash content (%) of broken rice flour (P < 0.05)

In the earlier studies conducted by Thumrongchote et al. (2012) on various rice varieties, the values for moisture content was found in the range of 5.00 to 5.88%. In contrast, Nura et al. (2011) found rather higher moisture content in rice flour (8.50–8.58%). Jamal et al. (2016) determined moisture content of 5.46 to 7.08% in rice flour obtained from various Pakistani aromatic and non-aromatic rice varieties. On the other hand, Akanbi et al. (2011) and Yadav et al. (2014) determined a moisture content of 4.65 to 8.50% in wheat flour. Processing time, temperature and milling method influence the drying of flour samples (Luh and Mickus, 1991).

Figure 3: Effect of blending wheat flour in various proportions on mean protein content (%) of broken rice flour (P < 0.05)

Figure 4: Effect of blending wheat flour in various proportions on mean fat content (%) of broken rice flour (P < 0.05)

Moreover, fiber content of the flour also influences the moisture content. Flour containing higher fiber content show higher moisture content and vice versa (Maneju et al., 2011). The increase in the proportion of wheat flour causes an increase in moisture content of the blends, which is explained by Martinez et al. (2009), who found that the addition of wheat flour in non-glutinous flour lead to a rise in protein content, which eventually lead to a stronger gluten matrix. Consequently, causes resistance in the separation of moisture during the process of dehydration. Moisture content exceeding 20 percent is not desirable for storing flour, as it accelerates the microbial growth (Akanbi et al., 2011).

The values of the ash content of rice flour are similar with the findings of Han et al. (2011), Thumrongchote et al. (2012) and Nura et al. (2011), who found a value ranging from 0.32 to 0.77%. However, Jamal et al. (2016) found rather higher ash content (0.48-1.23%) in flour obtained from various rice varieties. On the other hand, Ngozi (2014) and Han et al. (2013) found relatively higher ash content (0.86 to 2.29%) in wheat flour. Variation in cereal sources, varieties and milling method influence the flour ash content. Milling method effect in a way as it removes the bran content of the grain, as ash content is highly concentrated in the bran (Kaur et al., 2012; Islam et al., 2012; Han et al., 2011).

The results obtained in term of the protein content of rice flour closely agreed with Jamal et al. (2016), Fari et al. (2011) and Han et al. (2011). They found a protein content of 6.84 to 11.18% in various rice varieties. However, the protein content of wheat flour was found to be relatively higher than rice flour and ranged from 11.65 to 14.93% (Ngozi, 2014; Han et al., 2013). The variation in protein content in different rice varieties might be due to the variation in genetic makeup (Han et al., 2011). Protein and starch molecules are bound together to form a strong network, which effects the flour pasting properties. Higher concentration of protein contains greater binding sites for attachment with starch content. The stronger network enables it to hold a higher amount of water (Rosniyana and Hazila, 2013; Chung et al., 2012; Martinez et al., 2009). The aleurone layer of cereal grains contain higher protein content, which is removed during dry milling, subsequently minimizes the protein content (Perez et al., 2009). The present findings for crude fat content are similar to that of Fari et al. (2011) and Han et al. (2011). Their observed values ranged from 0.56–2.17 percent. On the other hand, a lower content of fat (0.27–0.30%) was recorded in different non-glutinous rice varieties by Thumrongchote et al. (2012). However, wheat flour obtained from different varieties had a fat content in the range of 1.31 to 3.23% (Ngozi, 2014). Broken rice flour had a considerably lower fat content as compared to non-broken rice samples. During parboiling, the oil content diffuses out from germ to the bran, consequently causes a reduction in fat content of broken rice flour (Zecchinelli and Fossati, 1983). Generally, higher fat content was found in rice bran among other cereal brans (Kaur et al., 2012). The fat content of flour has significant importance, as it affects the shelf life of a product. High fat content negatively affects the storage stability and quality characteristic of the final products due to the issue of causing rancidity and thereby minimizing storage life (Ihekoronye and Ngoddy, 1985).

Figure 5: Effect of blending wheat flour in various proportions on mean water absorption index (g/g) of broken rice flour (P < 0.05)

Functional Properties

The flour functional properties are extremely important to develop a product, as it indicates the quantity of water needed to develop optimum dough and also indicates the properties and behavior of flour with the addition of water (Islam et al., 2012). Flour functional properties i.e. WAI, WSI, and SP of different treatments are presented in Figures 5, 6 and 7, respectively. With the increase in the levels of wheat flour in the blends, the WAI, WSI and SP decreased.

Figure 6: Effect of blending wheat flour in various proportions on mean water solubility index (%) of broken rice flour (P < 0.05)

Figure 7: Effect of blending wheat flour in various proportions on mean swelling power (g/g) of broken rice flour (P < 0.05)

The values regarding WAI, WSI and SP of flours differed significantly (P < 0.05) as shown in Table 3. Pure broken rice flour exhibited highest WAI (6.18 g/g), WSI (3.99%) and SP (6.81 g/g) as compared to other treatments. However, pure wheat flour exhibited lowest WAI (4.73 g/g), WSI (1.98%) and SP (5.35 g/g), respectively. The obtained values for WAI are in accordance with the results of Jamal et al. (2016), Thumrongchote et al. (2012) and Heo et al. (2013), who found the values of 5.38-6.26 g/g, 6.0–8.0 g/g and 3.3–5.0 g/g respectively. On the other hand, Chandra and Samsher (2013) determined a value of 1.92 g/g and 1.40 g/g in term of WAI of rice and wheat flours, respectively. The addition of wheat flour with rice flour causes a reduction in the WAI of the flour (Ammar et al., 2009). It was reported in earlier studies that higher level of starch damage in cereal flour is directly associated with WAI. As the level of damages starch increases, higher would be the water absorption capacity. Similarly, the smaller granule size of rice starch exhibit higher WAI compared to larger granule size of wheat flour (Nura et al., 2011; Chiang and Yeh, 2002). Variation in carbohydrate, fat, protein, fiber and amylose contents of flours also affect the WAI (Chandra and Samsher, 2013; Maneju et al., 2011). Higher level of fiber and starches in flour might also be responsible for higher WAI (Chandra and Samsher, 2013). Differences in varieties, particle sizes and starch granule structures affect the WAI of the flour (Nura et al., 2011).

Table 3: Effect of blending wheat flour in various proportions on functional properties of broken rice flour

| Treatments | Water absorption index (g/g) |

Water solubility Index (%) |

Swelling power (g/g) |

| BRFWF(100:00) | 6.18±0.02 a | 3.99±0.01 a | 6.81±0.01 a |

| BRFWF(80:20) | 5.47±0.02 b | 3.95±0.02 b | 6.00±0.02 b |

| BRFWF(60:40) | 5.20±0.02 c | 3.31±0.01 c | 5.94±0.02 c |

| BRFWF(40:60) | 5.16±0.03 c | 2.96±0.02 d | 5.57±0.02 d |

| BRFWF(20:80) | 5.06±0.04 d | 2.34±0.01 e | 5.53±0.01 e |

| BRFWF(00:100) | 4.73±0.01 e | 1.98±0.02 f | 5.35±0.02 f |

The values in the column followed by different letters are significantly different from each other (P < 0.05)

The observed values for WSI of rice flour are in accordance with the findings (0.6–7.94%) of Heo et al. (2013), Thumrongchote et al. (2012) and Wadchararat et al. (2006). On the other hand, wheat flour exhibited less WSI (Yadav et al., 2014). Likewise, the water solubility of flour increases with the increase in damaged starch level (Yadav et al., 2014). It was also established that WSI rises due to the increase in temperature, as the temperature showed a direct relationship with the WSI (Wadchararat et al., 2006). Heo et al. (2013) studied the influence of milling on functional properties of the flour and found an increase in WSI due to the degradation of starch granules.

The present results of SP are similar with the observation made by Thumrongchote et al. (2012), Fari et al. (2011) and Wadchararat et al. (2006), as they found an SP of 5.82–16.23 g/g in rice flour. However, Yadav et al. (2014) found an SP of 6.5 g/g in the case of native wheat flour. The SP of wet and dry milled rice flour at 100oC and 25oC were 3.8 g/g, 12.6 g/g and 4.7 g/g, 10.9 g/g, respectively (Heo et al., 2013). Consequently, it was concluded that processing temperature and milling methods can alter the flour SP due to starch degradation. However, the SP of the flour is also linked with the protein content. The higher protein content in flour lead to the reduction in SP, as it embed the starch granules together to form a stiff protein network which subsequently restrict imbibitions of water (Rosniyana and Hazila, 2013).

Conclusions

It was found from the present study that the various blends of wheat and rice flours differed significantly in term of functional properties and proximate compositions. The proximate composition (percent ash, crude protein and moisture content) and functional properties (WAI, WSI and SP) increased significantly. However, percent fat reduced significantly with the increase in the concentration of wheat flour in the blends. This study provided the useful and fundamental information for the better understanding of broken rice and wheat flours as well as their blends. So it is recommended that value added product concerning health and nutritional aspects could be developed using suitable blends having some limitations with rice flour alone.

Authors’ Contribution

All the authors contributed in the execution of the research study. Ishfaq Ahmed was the main investigator of the study. Dr. Ihsan Mabood Qazi assisted him in research design, technical writing and compilation of the manuscript. Suraiya Jamal assisted in sample collection, laboratory work and data analysis.

References

Ahmed, I., I.M. Qazi and S. Jamal. 2015. Quality evaluation of noodles prepared from blending of broken rice and wheat flour. Starch/Starke. 67: 905-912. http://dx.doi.org/10.1002/star.201500037

Akanbi, T.O., S. Nazamid, A.A. Adebowale, A. Farooq and A.O. Olaoye. 2011. Breadfruit starch wheat flour noodles: preparation, proximate compositions and culinary properties. Int. Food Res. J. 18:1283-1287.

Ammar, M.S., A.E. Hegazy and S.H. Bedeir. 2009. Using of taro flour as partial substitute of wheat flour in bread making. World J. Dairy Food Sci. 4(2):94-99.

AOAC. 2012. Official methods of analysis. The Association of Official Analytical Chemists. 19th (Eds.), Arlington, USA.

Bhattacharya, M., S.Y. Zee and H. Corke. 1999. Physicochemical properties related to quality rice noodles. J. Cereal Chem. 76: 861-867. http://dx.doi.org/10.1094/CCHEM.1999.76.6.861

Bozzini, A. 1988. Origin, distribution and production of durum wheat in the world. In: G. Fabriani & C. Lintas (Eds.), Durum Chemistry and Technology. American Association of Cereal Chemists, USA. Pp. 1-16.

Cano, M.P., and B. Ancos. 2005. Advances in use of high pressure to processing and preservation of plant. p. 291. In: Barbosa-Ca´ novas, G.V., Tapia, M.S., Cano, M.P. (eds.), Novel Food Processing Technologies. CRC Press, New York, USA.

Cham, S., and P. Suwannaporn. 2010. Effect of hydrothermal treatment of rice flour on various rice noodles quality. J. Cereal Sci. 51:284-291. http://dx.doi.org/10.1016/j.jcs.2010.01.002

Chandra, S., and Samsher. 2013. Assessment of functional properties of different flours. Afr. J. Agri. Res. 8:4849-4853.

Chen, J.J., V.M.F. Lai and C.Y. Lii. 2003a. Effects of compositional and granular properties of pasting viscosity of rice starch blends. J. Starch. 55:203-212. http://dx.doi.org/10.1002/star.200390039

Chiang, P.Y. and A.I. Yeh. 2002. Effect of soaking on wet-milling of rice. J. Cereal Sci. 35(1):85-94. http://dx.doi.org/10.1006/jcrs.2001.0419

Chung, H.J., A. Cho and S.T. Lim. 2012. Effect of heat-moisture treatment for utilization of germinated brown rice in wheat noodle. J. Food Sci. Technol. 47:342-347. http://dx.doi.org/10.1016/j.lwt.2012.01.029

Demirkesen, I., B. Mert, G. Sumnu and S. Sahin. 2010. Rheological properties of gluten-free bread formulations. J. Food Eng. 96:295-303. http://dx.doi.org/10.1016/j.jfoodeng.2009.08.004

Edwards, N.M., J.E. Dexter and M.G. Scanlon. 2002. Starch participation in durum dough linear viscoelastic properties. Cereal Chem. 79:850-856. http://dx.doi.org/10.1094/CCHEM.2002.79.6.850

FAO (FAOSTAT). 2012. Food Balance Sheets, Commodity Balances, Crops Primary Equivalent.

Fari, M.J.M., D. Rajapaksa and K.K.D.S. Ranaweera. 2011. Quality characteristics of noodles made from selected varieties of Sri Lankan rice with different physicochemical characteristics. J. Nat. Sci. Found. Sri Lanka. 39:53-60. http://dx.doi.org/10.4038/jnsfsr.v39i1.2923

Federal Bureau of Statistics, Government of Pakistan. 2012.

Fresco, L. 2005. Rice is life. J. Food Compos. Anal. 18:249-253. http://dx.doi.org/10.1016/j.jfca.2004.09.006

Fu, B.X. 2008. Asian noodles: History, classification, raw materials, and processing. Food Res. Int. 41:888-902. http://dx.doi.org/10.1016/j.foodres.2007.11.007

Gallagher, E., T.R. Gormley and E.K. Arendt. 2004. Recent advances in the formulation of gluten free cereal-based products. Trends Food Sci. Technol. 15:143-152. http://dx.doi.org/10.1016/j.tifs.2003.09.012

Gianibelli, M.C., M.J. Sissons and I.L. Batey. 2005. Effect of source and proportion of waxy starches on pasta cooking quality. Cereal Chem. 82:321-327. http://dx.doi.org/10.1094/CC-82-0321

Giddel, M.R., and Jivan A.P. 2007. Waste to wealth, potential of rice husk in India a literature review. International Conference on Cleaner Technologies and Environmental Management PEC, Pondicherry, India.

Han, H.M., J.H. Cho and B.K. Koh. 2011. Processing properties of Korean rice varieties in relation to rice noodle quality. J. Food Sci. Biotechnol. 20:1277-1282. http://dx.doi.org/10.1007/s10068-011-0176-5

Han, L., Y. Zhou, E. Tatsumi, Q. Shen, Y. Cheng and L. Li. 2013. Thermo-mechanical properties of dough and quality of noodles made from wheat flour supplemented with different grades of tartary buckwheat (Fagopyrum tataricum Gaertn.) flour. Food Bio. Proces. Technol. 6:1953-1962. http://dx.doi.org/10.1007/s11947-012-0831-8

Heo, S., S.M. Lee, J.H. Shim, S.H. Yoo and S. Lee. 2013. Effect of dry- and wet-milled rice flours on the quality attributes of gluten-free dough and noodles. J. Food Eng. 116:213-217. http://dx.doi.org/10.1016/j.jfoodeng.2012.11.017

Huang, Y.C. and H.M. Lai. 2010. Noodle quality affected by different cereal starches. J. Food Eng. 97:135-143. http://dx.doi.org/10.1016/j.jfoodeng.2009.10.002

Ihekoronye, A.I., and Ngoddy, P.O. 1985. Integrated good science and technology for the tropics. Macmillan Publishers Ltd., London and Basingstoke. Pp. 15-22.

Inglett, G.E., S.C. Peterson, C.J. Carriere and S. Maneepun. 2005. Rheological, textural, and sensory properties of Asian noodles containing an oat cereal hydrocolloid. J. Food Chem. 90:1-8. http://dx.doi.org/10.1016/j.foodchem.2003.08.023

Islam, M.L.J.T., M.S.U. Din, M. Syduzzaman and M.M. Hoque. 2012. Physico-chemical and functional properties of brown rice (Oryza sativa L.) and wheat (Triticum aestivum L.) flour and quality of composite biscuit made thereof. J. Kri. Found. The Agriculturists. 10:20-28. http://dx.doi.org/10.3329/agric.v10i2.13135

Jamal, S., I.M. Qazi and I. Ahmed. 2016. Comparative studies on flour proximate compositions and functional properties of selected Pakistani rice varieties. Proc. Pak. Acad. Sci. 53(1):47-56.

Jobling, S. 2004. Improving starch for food and industrial applications. Curr. Opin. Plant Bio. 7:210-218. http://dx.doi.org/10.1016/j.pbi.2003.12.001

Juliano, B.O., C.M. Perez and M. Kaosa. 1990. Grain quality characteristics of export rice in selected markets. J. Cereal Chem. 67:192-197.

Kaur, G., S. Sharma, H.P.S. Nagi and B.N. Dar. 2012. Functional properties of pasta enriched with variable cereal brans. Food Sci. Technol. 49(4):467-474. http://dx.doi.org/10.1007/s13197-011-0294-3

Laureys, C. 1999. A natural choice for texture: Rice derivatives. National starch and chemical, comparison of cerebind, rice flour, purity W and national, personal communication. 78-148.

Li, J.H., and T. Vasanthan. 2003. Hypochlorite oxidation of field pea starch and its suitability for noodle making using an extrusion cooker. Food Res. Int. 36:381-386. http://dx.doi.org/10.1016/S0963-9969(02)00230-2

Lin, S.Y., Y.T. Liu, J.J. Chen and C.Y. Lii. 2002. The influential factors of pasting behavior on Chinese Water Chestnut/Corn starch blends. Taiwan. J. Agri. Chem. Food Sci. (Chinese). 40:357-369.

Luh, B.S., and R.R. Mickus. 1991. Broken rice. In: Rice utilization. Vol. II. 2nd Ed. (ed. B.S. Luh). Van Nastrand Reinhold, New York. http://dx.doi.org/10.1007/978-1-4899-3754-4

Maneju, H., C.E. Udobi and J. Ndife. 2011. Effect of added brewers dry grainon the physic chemical, microbial and sensory quality of wheat bread. Am. J. Food Nutr. 1(1):39-43. http://dx.doi.org/10.5251/ajfn.2011.1.1.39.43

Martinez, O.M., S.S. Ayerdi, E.A. Acevedo, I. Goñiand and L.A.B. Pérez. 2009. Unripe banana flour as an ingredient to increase the undigestible carbohydrates of pasta. Food Chem. 113(1):121-126. http://dx.doi.org/10.1016/j.foodchem.2008.07.035

Memon, N.A. 2013. Rice: Important cash crop of Pakistan. J. Excl. Rice. Pp. 21.

Ngozi, A.A. 2014. Effect of whole wheat flour on the quality of wheat-baked bread. Global J. Food Sci. Technol. 2(3):127-135.

Nura, M., M. Kharidah, B. Jamilah and K. Roselina. 2011. Textural properties of laska noodle as affected by rice flour particle size. J. Int. Food Res. 18:1309-1312.

Oberoi, D.P.S., D.S. Sogi and B.S. Gill. 2007. Noodle Processing Technology. Bev. Food World. 34: 68-70.

Park, S., K.Y. Haand M. Shin. 2012. Properties and qualities of rice flours and gluten-free cupcakes made with higher-yield rice varieties in Korea. Food Sci. Biotechnol. 21:365-372. http://dx.doi.org/10.1007/s10068-012-0048-7

Singh, N., L. Kaur, N.S. Sodhi and K.S. Sekhon. 2005. Physicochemical, cooking and textural properties of milled rice from different Indian rice cultivars. Food Chem. 89:253-259. http://dx.doi.org/10.1016/j.foodchem.2004.02.032

Perez, E., M. Baragano, M. Arteaga and M. Schroeder. 2009. Proximal composition and categorization by the amylose content of rice varieties. J. Rev. Facul. Agron. 35:94-99.

Qazi, I.M., S.K. Rakshitand, T. Tran. 2011. Effect of physic- chemical properties of tropical starches and hydrocolloids on the gels texture and noodles water retention ability. J. Starch. 63:558-569. http://dx.doi.org/10.1002/star.201000140

Reddy, D.K., and M.G. Bhotmange. 2013. Isolation of Starch from Rice (Oryza Sativa L.) and its Morphological Study using Scanning Electron Microscopy. Int. J. Agri. Food Sci. Technol. 4:859-866.

Rosniyana, A., and K.K. Hazila. 2013. Nutritional properties and organoleptic acceptability of traditionalcakes made from mr 220 rice flour. J. Trop. Agri. Food Sci. 41(1):41-52.

Siddiq, M., M. Nasir, R. Ravi, K.D. Dolan and M.S. Butt. 2009. Effect of defatted maize germ addition on the functional and textural properties of wheat flour. Int. J. Food Properties. 12:860-870. http://dx.doi.org/10.1080/10942910802103028

Steel, R.G.D., and J.H. Torrie. 1997. Principles and Procedures of Statistics. With special Reference to the Biological Sciences. J. Biometr. 4:207-208.

Thumrongchote, D., T. Suzuki, K. Laohasongkram and S. Chaiwanichsiri. 2012. Properties of mon-glutinous Thai tice glour: Effect of rice variety. J. Pharm. Biol. Chem. Sci. 3:150.

Torbica, A., M. Hadnad-ev and T. Dapcˇevic´. 2010. Rheological, textural and sensory properties of Gluten-free bread formulations based on rice and buckwheat flour. Food Hydrocol. 24:626-632. http://dx.doi.org/10.1016/j.foodhyd.2010.03.004

Uthayakumaran, S., and C.W. Wrigley. 2010. Wheat: characteristics and quality requirements. In: Wrigley, C.W., I.L. Batey (Eds.), Cereal grains assessing and managing quality. Woodhead Publishing Ltd. New Delhi. 59-111. http://dx.doi.org/10.1533/9781845699529.2.59

Varavinit, S., S. Shobsngob, W. Varanyanond, P. Chinachoti and O. Naivikul. 2003. Effect of amylose content on gelatinization, retrogradation and pasting properties of flours from different cultivars of Thai rice. Starch/Stärke. 55:410-415. http://dx.doi.org/10.1002/star.200300185

Wadchararat, C., M. Thongngam and O. Naivikul. 2006. Characterization of pregelatinized and heat moisture treated rice flours. Kasetsart J. Nat. Sci. 40:144-153.

Wang, L. and Y.J. Wang. 2004. Application of high intensity of ultrasound and surfactants in rice starch isolation. J. Cereal Chem. 81:104-144. http://dx.doi.org/10.1094/CCHEM.2004.81.1.140

Yadav, B.S., R.B Yadav, M. Kumar and B.S. Khatkar. 2014. Studies on suitability of wheat flour blends with sweet potato, colocasia and water chestnut flours for noodle making. LWT- Food Sci. Technol. 57(1):352-358.

Zecchinelli, P., and G. Fossati. 1983. Comparison of crude lipid and total lipid in broken and non-broken rice. Rivista della societa italiana di Scienza dell. Alimentazione. 12(3):173-176.

To share on other social networks, click on any share button. What are these?