Advances in Animal and Veterinary Sciences

Research Article

Antibacterial Activity of Enterococcus faecium and Propionibacterium sp. against Food-borne and Pathogenic Bacteria

Sallah A. Al-Hashedi1*, Mohamed F. Al-Helali2, Najeeb S. Al-Zoreky3, Sam S. Al-Dalali4, Nabil Q. Al-Hajj5, Naif A. Algabri6, Mohamed E. Abd El-Hack7, Mayada R. Farag8, Mahmoud Alagawany7*

1Central Labs, King Faisal University, P.O. Box 420, Al-Hassa, Saudi Arabia; 2Department Biology, Faculty of Science, Sana’a University, Sana’a, Yemen; 3Department Food Science and Nutrition, College of Agricultural and Food Sciences, King Faisal University, P.O. Box 400, Al-Hassa, Saudi Arabia; 4Department of Food Science and Technology, Faculty of Agriculture, Ibb University, Ibb, Yemen; 5Marine Science and Biological Research, Aden, P.O. Box 123, Aden, Yemen; 6Department of Pathology, Faculty of Veterinary Medicine, Thamar University, Yemen; 7Department of Poultry, Faculty of Agriculture, Zagazig University, Zagazig 44511, Egypt; 8Forensic Medicine and Toxicology Department, Faculty of Veterinary Medicine, Zagazig University, Zagazig 44511, Egypt.

Abstract | Bacteriocins are ribosomally synthesized antimicrobial polypeptides produced by some bacteria including selected lactic acid bacteria (LAB). The study conducted survey on traditional fermented dairy products and vegetables for presence of bacteriocin-producing bacteria. Bacteriocin genic LAB (1.62%) were isolated from samples were identified according to the standard phenotypical and biochemical tests. The standard well assay using indicator bacteria (L. monocytogenes ATCC 7644, Staphylococcus aureus ATCC 6538 and Lactococcus lactis subsp. Lactis ATCC 11955) were adopted to evaluate the inhibition spectra of substances produced by Enterococcus and Propionibacterium. The isolates showed similar or better activity than the nisin against indicators. The active principles produced by isolates were inhibited by proteases including α-Chymotrypsin. The protein nature of bacteriocins makes them vulnerable to common proteases of the digestive tract. Bacteriocins of the active isolates were affected by pH (4-6.5) and thermal treatments (65οC for 30 min).

Keywords | Lactic acid bacteria, Preservatives, Bacteriocins, Food-borne pathogens

Received | September 22, 2019; Accepted | November 12, 2019; Published | November 26, 2019

*Correspondence | M. Alagawany, Sallah A. Al-Hashedi, Department of Poultry, Faculty of Agriculture, Zagazig University, Zagazig 44511, Egypt; Central Labs, King Faisal University, P.O. Box 420, Al-Hassa, Saudi Arabia; Email: mmalagwany@zu.edu.eg, sahmad@kfu.edu.sa

Citation | Al-Hashedi SA, Al-Helali MF, Al-Zoreky NS, Al-Dalali SS, Al-Hajj NQ, Algabri NA, Abd El-Hack ME, Farag MR, Alagawany M (2019). Antibacterial Activity of Enterococcus faecium and Propionibacterium sp. against food-borne and pathogenic bacteria. Adv. Anim. Vet. Sci. 7(12): 1093-1100.

DOI | http://dx.doi.org/10.17582/journal.aavs/2019/7.12.1093.1100

ISSN (Online) | 2307-8316; ISSN (Print) | 2309-3331

Copyright © 2019 Al-Hashedi et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

INTRODUCTION

Lactic acid bacteria (LAB) and related microorganisms such as propionic acid bacteria are important microorganisms that are used in dairy and food industries. LAB and other food grade organisms have been subjected to intensive research due to their potential use as food preservatives (Stiles, 1996). Antimicrobial peptides (bacteriocins) produced by food-associated microorganisms can be used as natural preservatives. Bacteriocins are produced by numerous Grams-positive and Grams-negative bacteria (Tagg et al., 1976). Bacteriocins are ribosomally synthesized antimicrobial peptides or proteins with antagonistic activity (Cummins and Johnson, 1986; De Vuyst and Vandamme, 1994). They are consumed in LAB-fermented food and their actions result in desirable food characteristics, such as taste and appearance (eyeholes) in Swiss cheese. Thus, like LAB, they are a preferred source of antimicrobial agents that could be employed as new food preservatives because of their presumed non-toxicity for humans (Daeschel et al., 1990). Propionibacterium ssp. are able to produce a wide variety of biological compounds that enhance the human health like folic acid, proline, conjugated linoleic acid and vitamin B12 (De Freitas et al., 2015), and synthesize several different bio-protective compounds such as bacteriocins or antifungal compounds (Ojala et al., 2017). Moreover, many members of the dairy industry have a long history of safe use in food manufacturing. Propionibacterium shermanii produced a bacteriocin which is active mainly against gram-negative bacteria and crude preparation of the bacteriocin has been used commercially in preserving different food (Al-Zoreky et al., 1991; Lyon and Glatz, 1993). Some of those bacteriocins could be additional barriers to growth and survival of undesirable bacteria using the hurdle technology for making safer food products. Propionibacteria are gram-positive, short rods and catalase positive bacteria that grow under anaerobic condition (Wang et al., 2006; Berg’s manual, 1977), which ferment sugars and lactic acid to propionic acid, acetic acid and carbon dioxide (Walker and Phillips, 2007). The carbon dioxide production is crucial for the eye formation in hard cheeses involving propionibacteria, such as the Swiss-type cheeses (Wang et al., 2006). Nisin (lanthionine-containing bacteriocin), the bacteriocin produced by certain Lactococcus lactis ssp. Lactis, and has a molecular weigh of 3.5 KDa, has been commercially available in a concentrated form for use in food preservation since 1959 (Delves-Broughton et al., 1996). A commercial bacteriocin of P. shermanii has been also employed in food industry, in the U.S.A. and other countries, as a food-grade preservative (Al-Zoreky et al., 1991; Lyon and Glatz, 1993). The frequency of isolating LAB producing bacteriocins from traditional dairy products was lower than 2% (Al-Hashedi, 2007). Therefore, the aim of the present study was to isolate bacteriocin-producing LAB and propionibacteria from traditionally-made fermented dairy products and vegetables.

Materials and Methods

Microorganisms

Indicators for bacteriocin production by isolates and reference strains used in this study were maintained as frozen stocks at –20οC in APT/BHI broth with 10% (v/v) sterile glycerol. Working cultures were propagated in broth under appropriate condition (Table 1).

Samples

One hundred and twenty-eight food samples (buttermilk and cheeses) and vegetables samples of different food collected from local Yemeni markets were analyzed. They included traditional cheeses, fermented milk (buttermilk) and vegetables. The samples were kept refrigerated (icebox) during transportation to the laboratory. If necessary, they were maintained at 5οC for not more than 18 hours prior to microbiological tests.

Table 1: Indicator microorganisms and their strain numbers or sources.

| Growth condition |

Strain no./source |

Bacteria |

| Lactic Acid Bacteria (LAB) | ||

|

APTb, 35˚C |

210 | Lactobacillus bulgaricus |

| APT, 30˚C |

ATCCa 11955 |

Lactococcus lactis subsp. lactis |

| APT, 30˚C | C2 |

Lactococcus lactis subsp. lactis |

| APT, 30˚C | ATCC 19255 | Leuconostoc dextranicum |

| APT, 35˚C | 631 | Streptococcus thermophillus |

| BHI, 35˚C | B-287 | Micrococcus luteus |

| Pathogenic Bacteria | ||

| BHI, 35˚C |

ATCC 7644 |

Listeria monocytogenes |

| Scott A | Listeria monocytogenes | |

| BHI, 35˚C |

ATCC 6633 |

Bacillus subtilus |

| BHI, 35˚C |

ATCC 6538 |

Staphylococcus aureus |

| BHI, 35˚C |

ATCC 10536 |

Escherichia coli |

| BHI, 35˚C |

ATCC 10031 |

Klebsiella pneumoniae |

| BHI, 35˚C |

ATCC 9027 |

Pseudomonas aeruginosa |

| Yeasts | ||

| BHI, 30˚C | Y-1084 | Candida utilis |

| BHI, 30˚C | Y-139 | Saccharomyces cerevisiae |

aATCC, American Type Culture Collection, U.S.A.

b APT, All Purpose with Tween; BHI, Brain Heart Infusion medium.

Isolation of bacteriocin-producing bacteria

Samples of traditional dairy food were diluted with 0.1% peptone and aliquots were spread onto the surface of APT broth (Scharlau, Spain) with 1.5% agar. Spreaded plates were incubated anaerobically (GasPak with anaerobic atmosphere generation bags) at 30οC for 24-72 h. After incubation, representative colonies (up to 9 colonies per plate) were picked and separately activated in APT broth at 30οC for 24-96h. A loop-full of each isolated bacteria was streaked for purification in APT+1.5% agar followed by anaerobic incubation. Purified isolates were tested for bacteriocin production using the spot assay.

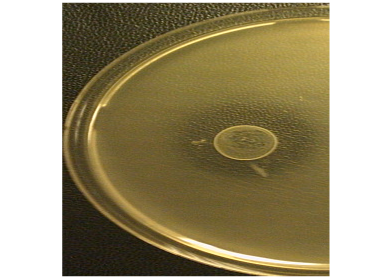

Agar spot test

According to Schillinger and Lücke (1989) the isolates were cultured in 10 ml APT broth at 30˚C for 24 h. Aliquots (5 µl) of the culture were spotted onto agar plates containing APT agar or Tryptic soy agar (TSA, Scharlau, Spain). After 48 h anaerobic incubation at 30˚C, each plate was overlaid with 5ml of BHI/APT soft agar (0.75%) inoculated with cell suspension of the indicator at a final concentration of ca. 105 CFU ml-1. The plates overlaid were incubated for 24 h to 48 h and the appearances of inhibitory zones around colonies of indicators were observed (Figure 1). The indicators (in soft agar overlay) were Lactococcus lactis subsp. lactis ATCC 11955, L. monocytogenes ATCC 7644 and E. coli ATCC 10536. The isolates which show inhibitory zone against one-indicator bacteria were checked for Gram positive stained (cocci/short or long rods) and catalase (negative/weak positive) and was taken as presumptive LAB or related genera.

Figure 1: Isolation of bacteriocin-producing lactic acid bacteria from buttermilk using Agar spot assay. Spot colonies were overlaid with the reference strain Lactococcus lactis subsp. lactis ATCC 11955.

Antimicrobial activity of isolates

The antimicrobial activity of cell-free supernatant (CFS) of isolates showing inhibition in the spot test was determined by agar well diffusion method (Tagg and McGiven, 1971). CFS was obtained from each active isolate (one presumptive LAB and two presumptive propionibacteria). The isolates were coded L1, P1 and P2, respectively. The propionibacterial cultures (P1and P2) were separately activated in Lactate broth (Ekinci and Barefoot, 1999) and APT broth. L1 was only activated in APT broth. Meanwhile, each isolate was cultured in a milk-based medium. All media were adjusted to pH 6.7 followed by incubation at 30˚C ±1 for 24 to 144 h. At each interval, growth media were centrifuged at 8700 g for 10 min at 5˚C (Sorvall® Instrument, U.S.A.). Supernatants were divided into two parts, unadjusted portion which was filter-sterilized (0.45 µm, Millipore, MA, USA) and the second portion adjusted to pH 6.5 with 5N NaOH followed by filter sterilization (0.45μm). Controls (uninoculated media) were adjusted to pH 4.0 (with 88% lactic acid) and filtered. Sterilized 100 ml APT broths containing 1.5% (w/v) agar, BHI and/or TSA agar were tempered to 48οC (water bath) prior to seeding or streaking with 1ml or 100µl of diluted active indicators (105 CFU/ml) listed in Table 1. Inoculated media were poured in Petri plates then left to harden. Wells (6 mm in diameter) were made in the agar with a sterile stainless steel rod filled with 100μl of CFS producer isolates. Plates were left undisturbed at room temperature for 30 min. to allow diffusion of CFS. Incubation was at 30 or 37οC ±1 for 9-48h until growth of indicators in controls was visible. Inhibition zones (including well diameter) were measured. Clear zones greater than 10mm were considered positive inhibition against the indicator. NisaplinTM (2.5% nisin; 1×106 IU nisin g-1 Danisco, Denmark) and Ampicillin were, respectively, reference bacteriocin and antibiotic Table 3.

Effect of cold storage on bacteriocins

Using Staphylococcus aureus ATCC 6538 as the indicator, CFS of isolates, which were producer in APT broth, pH 4.0 and 6.5, were stored under refrigeration (4οC) for two months prior to determine their antibacterial activity by well assay.

Effect of Proteolytic Enzymes

Bacteriocins produced by isolates (P1, P2 and L1) were treated with different proteases using Lewus et al. (1991) with modifications. Five μl portions of an active isolate were aseptically spotted on MRS agar and incubated an aerobically at 30οC for 48 h. Five μl aliquots of the enzyme (20 mg/ml) was spotted 3 mm from periphery of the spotted isolates. Plates were incubated at 37οC for 2h. Enzymes were protease type xv (Bacillus polymyxa), Pronase E (Streptomyces griseus), α-chymotrypsin (Bovine pancereas), amylase 20, pepsin and lipase (Type II), and all from Sigma (USA). Plates were overlaid with 5ml of soft agar (BHI) seeded with log10 4 cfu ml-1 L. monocytogenes Scott A. Boiled enzyme suspensions were used as negative controls. A negation of the zone of inhibition in the region of the enzyme confirmed the sensitivity of a bacteriocin to the proteolytic enzyme.

Bacteriocin titer

Titer of bacteriocin produced by one isolate (P2) was quantified by two-fold serial dilutions of Graciela et al. (1995) with a modification. The filter sterilized CFS of isolate (in milk-based media, 30˚C for 144h) were diluted in control milk-based media (non-fermented) treated similarly under the same conditions. Non-diluted CFS and diluted CFS (1/10, 1/20, 1/40, 1/80, 1/160, 1/320, 1/640) were separately placed in wells (100µl) in plates seeded with indicators. Plates were incubated aerobically at 30˚C for 9-24h and recording the highest dilution that produced distinct inhibitory zones. The titer of the bacteriocin was defined as the reciprocal of the highest dilution showing inhibition of the indicator lawn and was expressed in activity units per ml (AU ml-1).

Phenotypic characterization of isolates

The three isolates were identified to the genus level using the phenotypical and biochemical tests (Bergey’s Manual, 1977). After subcultured twice overnight in APT broth at 30°C, isolates were tested for Gram reaction, spore stain,

Table 2: Sensitivity of indicators and treatments to cell-free supernatant (CFS) of isolates using a well assay and treatments of CFS isolates.

|

Isolate code/ Reference bacteriocin(25µg/100µml) a |

Indicators bacteria and yeasts/Treatments | ||||

| Nisin | L1 | P2 | P1 | ||

| + | + | + | + |

Lactobacillus bulgaricus 210 |

Lactic Acid Bacteria (LAB) |

| + | + | + | + |

Lactococcus lactis ssp. lactis ATCC11955 |

|

| + | + | ─ | ─ |

Lactococcus lactis ssp. lactis C2 |

|

| + | + | ─ | ─ |

Leuconostoc dextranicum ATCC 19255 |

|

| + | + | + | + |

Streptococcus thermophillus 631 |

|

| + | + | ─ | ─ |

Listeria monocytogenes ATCC 7644 |

Gram Positive Bacteria |

| + | + | n.d. | n.d. |

Bacillus subtilus ATCC 6633 |

|

| + | + | + | + |

Staphylococcus aureus ATCC 6538 |

|

| ─ | + | + | + |

E. coli ATCC 10536 |

Gram Negative Bacteria |

| ─ | ─ | + | ─ |

Klebsiella pneumoniae ATCC 10031 |

|

| ─ | + | + | + |

Pseudomonas aeruginosa ATCC 9027 |

|

| ─ | ─ | ─ | ─ |

Candida utilis Y-1084 |

Yeasts |

| ─ | ─ | ─ | ─ |

Saccharomyces cerevisiae Y-139 |

|

| + | + | + | + |

Pasteurization at 65οC for 30 min. |

Treatments of CFS isolates |

| Storage at 4˚C for 2 months: | |||||

| + | + | + | + |

pH 4.0 |

|

| + | + | + | ─ |

pH 6.5 |

|

| + | + | + | + | Lecithin (0.1%) | |

a;–, no inhibition < 10mm; +, inhibition > 10mm; n.d., not done.

Table 3: Effects of growth media on inhibitor production by isolates using well assay of cell-free supernatant (CFS) produced by LAB isolates, inhibition zone (mm) a

|

Reference bacteriocin and antibiotic |

Media/ Isolates code/ Period of yield CFS | Indicators and pathogens | ||||||||

|

Ampicillin (20µg/ml) |

Nisin (25µg/ml) |

Lactate media | Milk based media | |||||||

| P2 | P1 | P2 | P1 | |||||||

| 5days | 48h | 5days | 48h | 5days | 48h | 5days | 48h | |||

| 22 | 17 | ─ | ─ | ─ | ─ | 19 | 12 | 12 | ─ |

Lactobacillus bulgaricus 210 |

| 18 | 16 | ─ | ─ | ─ | ─ | 18 | 12 | (12) | ─ |

Lactococcus lactis ssp. lactis ATCC 11955 |

| n.d. | 17 | ─ | ─ | ─ | ─ | 19 | ─ | (12) | ─ |

Leuconostoc dextranicum ATCC 19255 |

| 26 | 17 | ─ | ─ | ─ | ─ | 21 | 12 | 13 | ─ |

Streptococcus thermophillus 631 |

| 24 | 18 | ─ | ─ | ─ | ─ | 20 | 14 | 14 | 12 |

Listeria monocytogenes ATCC 7644 |

| n.d. | n.d. | 11 | ─ | ─ | ─ | 21 | 17 | 15 | 13 |

Micrococcus luteus B-287 |

| 22 | 16 | ─ | ─ | ─ | ─ | 18 | 14 | 15 | 14 |

Staphylococcus aureus ATCC 6538 |

| 11 | ─ | ─ | ─ | ─ | ─ | 16 | 15 | (12) | 16 |

E. coli ATCC 10536 |

| 23 | ─ | ─ | ─ | ─ | ─ | 20 | 12 | (12) | (11) |

Klebsiella pneumoniae ATCC 10031 |

| n.d. | ─ | 13 | ─ | 11 | ─ | 26 | 23 | 23 | 22 |

Pseudomonas aeruginosa ATCC 9027 |

a– , no inhibition (< 10mm(; ( ), not clear zone; n.d., not done.

catalase production, O2 requirement, growth at 10οC, 45οC and 50οC, and growth in APT broth containing 2, 4, and 6.5 % NaCl. Other tests used for identification were formation of H2S, motility, and production of indole in SIM medium, gelatin flow, Voges-Proskauer-Methyl-Read in MR-VP media, blood haemolysis, milk curding, action in litmus milk and assimilation of some carbohydrates.

Results

Isolation of bacteriocin-producing bacteria

Three isolates (1.62 % of total isolate) were isolated from 128 food samples (buttermilk and cheeses) and vegetables under this study. Those giving inhibition zones against Lactococcus lactis subsp. lactis ATCC 11955, L. monocytogenes ATCC 7644 and E. coli ATCC 10536 were selected based on the highest total inhibition diameter against indicators, using the spot assay (Figure 1).

Antimicrobial activity

Among the 3 isolates shown in Table 3 L1 had the highest inhibitory activity towards 10 out of 13 indicators (LAB, food-borne pathogens, and yeasts); the inhibition zones were wider (14- 20 mm) than those obtained with nisin against most species of LAB used as indicators (Table 2). The CFS of isolates coded (P1, P2 and L1) contained antimicrobial compounds inhibiting some food-borne bacteria that are important in the food industry (Bacillus subtilus, Listeria monocytogenes, and Staphylococcus aureus). Furthermore, CFS produced by P2 was active against Gram-negative bacteria (E. coli ATCC 10536, Klebsiella pneumonia ATCC 10031 and Pseudomonas aeruginosa ATCC 9027). Type of culture media and growth conditions influenced the inhibition pattern of LAB and propionibacterial isolated from traditionally-made fermented dairy products Table 3. In comparison with lactate, milk-based media were isolates produced inhibitory substance for the indicators, bacteriocin excretion by two isolates (P1 and P2) was blocked in lactate medium (Table 3).

Effects of thermal treatments, cold storage, pH and additives

CFS produced by three isolates were stable under storage in pH 4.0 at 4°C for 2 months, whereas only CFS produced by P2 and L1 isolates were stable upon storage in pH 6.5 at 4°C for 2months (Table 2).

Withstanding pasteurization (65°C for 30 minutes) and lecithin (0.1%) was a characteristic of the CFS produced by P1 , P2 and L1 (Table 2).

Effect of Proteolytic Enzymes

The antagonistic effects of CFS for the 3 isolates against the indicator (L. monocytogenes Scott A) were deserted upon treatment with various proteases; i.e. pepsin, proteases (E and type xv) and α-chymotrypsin. The exception was CFS of isolate P2, which was not degraded by pepsin and proteases (Table 4).

Table 4: Sensitivity of cell-free supernatant (CFS) of isolates to hydrolytic enzymes using Listeria monocytogenes Scott A as indicators

| Enzyme | Isolate code | |||||

| Lipase | Amylase |

α- Chymotrypsin |

Protease (type xv) |

Pronase E | Pepsin | |

| – | – | + | + | + |

+ a |

P1 |

| – | – | + | + | – | – | P2 |

| – | – | + | + | + | + | L1 |

a +, sensitive; –, not sensitive.

Bacteriocin titer

E. coli ATCC 10536 was more sensitive than Lactococcus lactis ssp. lactis ATCC11955 to bacteriocin (CFS) produced by P2. The activity units per milliliter was 1600 and 400 AU/ml, when used E. coli ATCC 10536 and Lactococcus lactis ssp. lactis ATCC11955 respectively (data not shown).

Table 5: Physiological and biochemical characteristics of the inhibitory isolates a

|

Isolate code |

Characteristics | |||

| P2 | L1 | P1 | ||

|

+Short rod |

+Cocci |

+Short rod |

Gram stain | |

| – | – | – | Spores | |

| ± | – | ± | Catalase | |

| Growth temperature: | ||||

| + | + | – |

10οC |

|

| n.d. | + | n.d. |

45οC |

|

| n.d. | – | n.d. |

50οC |

|

| Growth in APT with NaCl (%): | ||||

| + | + | + | 2 and 4 | |

| + | + | – | 6.5 | |

| – | n.d. | – | Gelatin liquefaction | |

| + | – | + | Voges-Proskauer | |

| – | – | – |

H2S production(SIM) |

|

| – | – | – | Indole production | |

| + | + | + | Methyl red | |

| – | – | – | Motility | |

| Acid/no curd | n.d. | Acid/curd |

Litmus milk at 30οC, 6days |

|

| + | + | + | Blood haemolysis (Beta) | |

|

c–(3.76) |

c+(4.55) |

c+(3.85) |

Milk coagulation (Final pH) | |

|

Carbohydrate (30οC, up to 7 days) |

||||

| + | + | + | Glucose | |

| + | + | + |

α- Lactose |

|

| + | + | + | Maltose | |

| + | + | + | Fructose | |

| ± | ± | + | Glycerol | |

| – | – | – | Inulin | |

| + | + | + | Lactate | |

| + | + | + | Mannitol | |

| + | + | ± | Sucrose | |

| – | – | – | Sorbitol | |

| P | E | P |

Genusb |

|

a+, positive; –, negative; n.d., not done; c, curd; ±, weak reaction; bP, Propionibacterium sp.; E, Enterococcus faecium.

Identification of isolates

Isolates L1 were gram-positive cocci, catalase-negative and homo-fermentative bacteria that did not grew at 50°C. They were able to grow in APT broth with 6.5 % NaCl. According to the Bergey’s manual (1977), L1 was identified as Enterococcus faecium (Table 5). Isolates P1 and P2 were gram-positive, non-motile short-rods, catalase weak-positive and hetero-fermentative that did not production indole and flow gelatin. Therefore, they were identified as Propionibacterium sp., according to the Bergey’s manual (1977).

DISCUSSION

Nisin was known for its activity only against gram positive bacteria, especially spores as reported in previous studies (De Vuyst and Vandamme, 1994; Darilmaz and Beyatli, 2012). Our results are in line with these of Yuksekdag et al. (2014) as they recorded that antimicrobial effects of Propionibacterium ssp. strains were more active against Gram negative strains. In addition, no inhibition was obtained against the 2 yeasts which were in a complete agreement with previous reports (Al-Hashedi, 2007). The resistance of gram negative bacteria to bacteriocins, such as nisin and other antibacterial substances was attributed to the outer membrane (lipopolysaccharide) which prevents binding of bacteriocins to the cell wall of those bacteria. The environmental factors such as media temperature and incubation time showed a profound effect on the yields of active bacteriocins (De Vuyst and Vandamme, 1994). Al-Hashedi (2007) stated that APT performed better than MRS media in bacteriocin production by the same LAB. Complex growth media are normally used for bacteriocin production (Parente and Hill, 1992).

For instance, acidocin B produced by Lactobacillus acidophilus M46 (ten Brink et al., 1994) stored at 4°C or - 20°C for at least three months did not loss its activity. Similarly, lactocin A was found to be stable in a solution containing 60% ethanol and 2.5 mM sodium phosphate (pH 7.3) at -20°C for several months (De Vuyst and Vandamme, 1994). Pediocin SJ-1 retained its activity after storage for 12 months at 4°C; pediocin PA-1 was stable for only 28 days at cold storage (Enan, 1995). In contrast, other classes of bacteriocin were not stable under refrigerating temperatures (1-4°C) or frozen storage (Enan, 1995). Most bacteriocins produced by LAB were stable at acidic pH (pH< 7) Hegazy (1999). In contrast, Pediocin AcH was active over a wider pH range (pH 2-9) (Bhunia et al., 1997). Carnocin U149 from Carnobacterium sp. was also stable under acidic conditions. Linocin M18 produced by Brevibacterium linens was similarly active at pH 3-12 (Hegazy, 1999). Bacteriocins considerably differ in their thermal stability. Withstanding temperatures between 60°C and 100°C for >30 minutes is reported for some bacteriocins, lactocin S, lactococcin A and plantaricin UG1 (Enan, 1995; Hegazy, 1999). Few bacteriocins such as plantaricin BN and pediocin PA1 were showed to be moderately thermostable and retained activity after treatment at 100°C for > 10 minutes (Lewus et al., 1991). Other bacteriocins (nisin, lactostrepcins, pediocin AcH, carnocin U149, sakacin M, lactocin B and Microgard) were resistant to 121°C for 15-20 minutes (AL-Zoreky et al., 1993; Hegazy, 1999). Heat stability is a very useful characteristic in the case of using bacteriocin as a food preservative, since many food-processing procedures involve heating steps.

The sensitivity of bacteriocin to proteases is a key criterion for the characterization of an inhibitor as a bacteriocin; it indicates the proteinaceous nature of bacteriocins (Tagg et al., 1976). Bacteriocins vary in their sensitivity to proteolytic enzymes. One bacteriocin may be degraded by proteinase k but not by proteinase E; the other bacteriocin may be degraded by various proteinases. Bifidocin B produced by Bifidobacteriurm bifidum was sensitive to protease IV, pronase E. proteinase k, and trypsin (Enan, 1995). Bacteriocins produced by Propionibacterium thoennii was digestion by proteinase K (Ben-Shushan et al., 2003).

In Conclusion, the present study showed different levels of isolates for inhibition foodborne bacteria, Bacteriocins of the active isolates were affected by pH, thermal treatments and food additives. It could be summarized that traditionally fermented dairy products are natural and valuable environmental sources for LAB producing bacteriocins inhibitory for undesirable pathogenic microorganisms in food. CFS of the identified isolates contained bacteriocins, which lost their inhibitory activity against indicators after treatment with α-chymotrypsin and other proteases. Thermal stability is a very useful characteristic in case of using thermostable bacteriocins as a food preservative, since many food-processing procedures involve heating steps.

Abbreviations

LAB: lactic acid bacteria; kDa: kilodalton unit; APT: all purpose with tween medium; BHI: brain heart infusion medium; TSA: tryptic soy agar; ATCC: American type culture collection; CFS: cell-free supernatant; IU: international unit; MIC; minimum inhibitory concentration.

Authors’ Contributions

NSA, SAA and MFA conceived and designed the experiments; SAA, NSA, SAA, NQA and NAA collected the traditional foods from local market and did the experiments, manuscript preparation; NSA and SAA analyzed the data and wrote this manuscript; Corresponding author SAA. All authors read and approved the final manuscript.

ACKNOWLEDGMENTS

We are grateful to Mr. Abdu Mohammad Al-Gradi General Director in Bajil Complex for Food Industries- Yemen Economical Corporation for his help.

Conflict of interest

The authors declare that no conflicts of interests exist.

REFERENCES