Advances in Animal and Veterinary Sciences

Research Article

Adaptability of Dairy Cows to Individual Quarter Milking System after Changing from Tying to Loose Housing System

Shehadeh Kaskous1, Abdelaziz Fadlelmoula2, 3*

1Department of Animal Science, Faculty of Agriculture, Damascus University, Syria, Expert at the Siliconform GmbH Company, Schelmengriesstrasse 1, D-86842 Türkheim, Germany; 2Department of Genetics and Animal Breed, Faculty of Animal Production, University of Khartoum, P.O.Box: 3213314, Shambat-Sudan; 3Department of Biology, Faculty of Sciences and Arts, Alkamel, University of Jeddah, P.O.Box: 110 21931 Alkamel-KSA.

Abstract | The study was conducted during the period June-September 2013, to study the pattern of adaptability of dairy cows to milking using the individual quarter milking system (MultiLactor) when changing from tying to loose housing system. Daily milk yield and milk quality over a period of two months were tested. A total of 30 Brown-Swiss dairy cows at Türkheim dairy farm-Germany were used in the study. Cows were at different parities and stages of lactation. Collected data were processed using SAS program (SAS, 1999). The study found that the average milk yield rate in the first milking was 77.38±2.40% after changing from conventional to MultiLactor milking system and the individual milk yield rate varied from 47 to 106% of the expected milk yield before the changeover. Milk yield in the first three days after changing was decreased and then increased to the normal values of the expected milk yield before the changeover. Fat and protein contents were not significantly varied during the experimental period after the changeover. Lactose content of the milk showed a significant continuous increase during the study period. Somatic cell count (SCC) in milk decreased during the experimental period and reached the lowest values (114x103/ml) at day 58. Three weeks after the change, urea showed the lowest concentration (10-15 mg/100ml). The result concluded that quarter single tube is more convenient after changing the conventional milking system.

Keywords | Adaptability, Dairy cows, Milk composition, MultiLactor

Editor | Kuldeep Dhama, Indian Veterinary Research Institute, Uttar Pradesh, India.

Received | February 23, 2015; Revised | March 15, 2015; Accepted | March 16, 2015; Published | March 22, 2015

*Correspondence | Abdelaziz Fadlelmoula, Department of Biology, Faculty of Sciences and Arts, University of Jeddah, P.O.Box: 110, 21931 Alkamel-KSA; Email: abdelazizfadlelmoula@gmail.com

Citation | Kaskous S, Fadlelmoula A (2015). Adaptability of dairy cows to individual quarter milking system after changing from tying to loose housing system. Adv. Anim. Vet. Sci. 3(4): 225-232.

DOI | http://dx.doi.org/10.14737/journal.aavs/2015/3.4.225.232

ISSN (Online) | 2307-8316; ISSN (Print) | 2309-3331

Copyright © 2015 Kaskous and Fadlelmoula. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Introduction

It has been demonstrated that management of dairy cows in relation to the variation of environmental factors is a complex physiological process. The development of the milk yield and quality during changing the process of milking technology is reflected in a degree of physiological adaptability to the new milking system (Sandrucci et al., 2007 and Tancin et al., 2006). Such a practice is of great importance for the welfare of cows and thus for a good adaptability to the milking parlour, so that daily milking will be done fast, gently as possible and a complete removal of milk from the udder is guaranteed. Kanswohl et al. (2012) showed that milk removal is optimal during the milking process, whenever the cow has been well prepared and the milking system meets the adaptability requirements of the cow. Fahr and Lengerken (2003) reported that the modern design of milking machines ensures certain requirements in order to maintain the performance in a healthy udder, excluding health impairments and obtain the milk and milk content largely unaffected.

Now a days the goal of milking is to gain the total quantity of milk as quick as possible, complete and with maximal protection to the udder (Schallenberger, 2002; Tröger, 2004; Bruckmaier, 2008; Kaskous and Bruckmaier, 2011 and Kanswohl et al., 2012). However, both human and animals require a high degree of adaptability due to change of housing. It was found that the ability to adapt a cow to an automatic milking system (AMS) after the change from conventional milking parlor is varied, and the milk yield in first automatic milking day varied between 8 and 96% less than the expected before the changeover (Weiss, 2004). These results clearly demonstrated that a significant disturbance of milk ejection can occur due to the negative reaction of the animal to the change. Recently, many milking machines are on the market to provide modern technology at a high standard level, but not always fit to all herds, as animals respond individually, since the physiological control mechanisms in animals cannot be modified. Milking equipment and routine need to be adjusted according to the animal physiological mechanism to achieve optimal milk removal (Bruckmaier, 2013) and must not be uncomfortable or even painful to the cow (Kaskous, 2014a). MultiLactor was developed and practically used in the field. A conclusion was drawn out, that MultiLactor in comparison with the conventional milking systems is more convenient in term of positive stimulation effect (Müller et al., 2011). Moreover, it was noticed that MultiLactor has improved the daily milk yield and quality compared to the conventional milking system as protein content was increased and the somatic cell number was significantly reduced (Kaskous, 2014a and Kaskous, 2014b). It has been found that on comparing in the same conditions, milking with MultiLactor milking system to the milking with the conventional milking system, no change was observed with regard to fat and protein contents, value of electric resistance and SCC (Müller, et al., 2013). Fahr and Lengerken (2003) reported that milking machine type highly influencing milk yield and quality. Spolders et al. (2004) indicated that fat content of cow milk was significantly lower in automatic milking system compared to conventional milking system. Therefore, the changing period from the tying housing with conventional milking system to loose housing with separate milking parlor at the same place is of paramount importance to be investigated. The aim of the present study is to examine the adaptability of dairy cows in a MultiLactor milking system after changing from tying to loose housing systems with respect to milk yield and quality.

Materials and Methods

Experimental Farm and Animals

The study was carried out in a practice dairy farm in Türkheim (Bavaria) from June to September 2013. 30 dairy cows of the Brown cattle breed were used during the changing period from conventional pipeline milking machine to quarter individual milking system (MultiLactor).

At the beginning of the experiment, cows were housed in a conventional tying stall (with pipeline milking system), lying surface is covered with rubber mat, bedding is used and manure is manually removed twice a day. After the changing, the same animals were kept in a lying boxes loose housing, where the milking place (tandem milking parlour) is isolated separately and equipped with MultiLactor milking system. The lying surface was divided in lying boxes for each animal. A slatted walk floor space was left outside the lying surface where feeding utensil were found. Laying surface was covered with natural materials.

Before changing, cows were at the following stages of lactation:

Mixed concentrate ration and raw diet was fed according to the performance of each cow. Cows were proved to be healthy throughout the course of the experiment, except for hoof problems that were observed for over a week after changing to loose housing.

Milking Systems

A conventional pipeline milking system, with a high level milk line was installed in the first stable. Milk withdrawn by the force of the system vacuum from the four quarters just behind the udder via a milking cluster and then pumped into the milk tank.

The milking parlour type, in which the MultiLactor milking system is built, is a tandem milking parlour with 10 bays (2x5). The quarter individual milking system derives milk from the udder quarters in four individual tubes. Cows were kept and milked in individual boxes parallel to milking corridor. The characteristics and properties of the used milking in the two systems are compiled in Table 1.

Table 1: Characteristics and properties of conventional and MultiLactor Milking Systems

|

Characteristics |

Conventional milking System |

MultiLactor Milking system |

|

Milking parlor type |

pipeline milking parlor |

tandem milking parlor (2x5) |

|

Milking vacuum (kPa) |

45 |

32-34 |

|

Pulsation rate (cycles/min) |

60 |

60 |

|

Pulsation ratios |

60/40 |

60/40 |

|

Pulsation type |

changing pulsation |

sequential pulsation |

|

Air inlet |

continuously in the claw |

periodic air inlet |

|

Cleaning (C) and disinfection (D) of the milk machine |

after milking, only (C). |

after each cow milked and after milking (C+D) |

Milking Routine

Using both systems; cows were milked twice a day at 6:30 and 16:30. Milking with pipeline milking system began with fore-milking, cleaning the udder and teats and manual stimulation of the udder, after that attaching the milking unit. At the end of milking, the milking unit was manually removed and the teats were dipped.

With MultiLactor milking system was performed another milking routine. After the fore milking and cleaning the udder and teats are done, swing the milking unit directly in front of the cow’s udder. The teats cups were individually manually attached to teats. Subsequent to this step, the system is started on the control display and the pre-stimulation began. The pre-stimulation is structured to be intensively activated for 50s with aid of a mechanical actuator stimulating that vibrate the teats. This step takes place before the beginning of the milking process. After the end of milking the teats cups were automatically retracted and fully automatically cleaned and disinfected and the teats dipped.

Milk Yield and Composition

Recording of milk yield and collection of 50 ml of milk sample were carried out from each cow in involved in the experiment. This procedure took place after milking in the conventional milking system, 10 days before changing from tying to loose housing. Tying housing has a continuous electronic milk flow meter (LactoCorder, WMB. Balgach, Switzerland). And after the changing, recording of daily milk yield was started from day 1-day 16, then weekly until day 58 of lactation. Data extracted from the MultiLactor program for each cow in each milking. In the meantime; milk samples were collected (50 ml) per week from the 9th to the 58th day after the changeover for each cow in each milking. Analysis of milk components (fat%, protein%, Lactose%, number of somatic cell counts (SCC)/ml and urea mg/100 ml) was carried out in the laboratory of Milchprüfring Bayern (Bavaria). Table 2 summarized these procedures.

Table 2: Experiment Procedures and Days

|

Procedure |

Days |

|

Milking with pipeline milking system (tying housing) |

0* |

|

Milking in tandem milking parlor (loose housing) |

1.2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 23. 30. 37. 44. 51. 58 |

|

Milk sampling |

9. 16. 23. 30. 37. 44. 51. 58 |

*Day 0=milking with pipeline milking system 10 days before the changeover to MultiLactor milking system

Statistical Analysis

Data was subjected to statistical analysis with the aid of SAS statistical package (SAS, 1999). Least square means and standard error for the effect of milking system on milk yield and composition were computed. The results were presented in form of line graphs.

Results and discussion

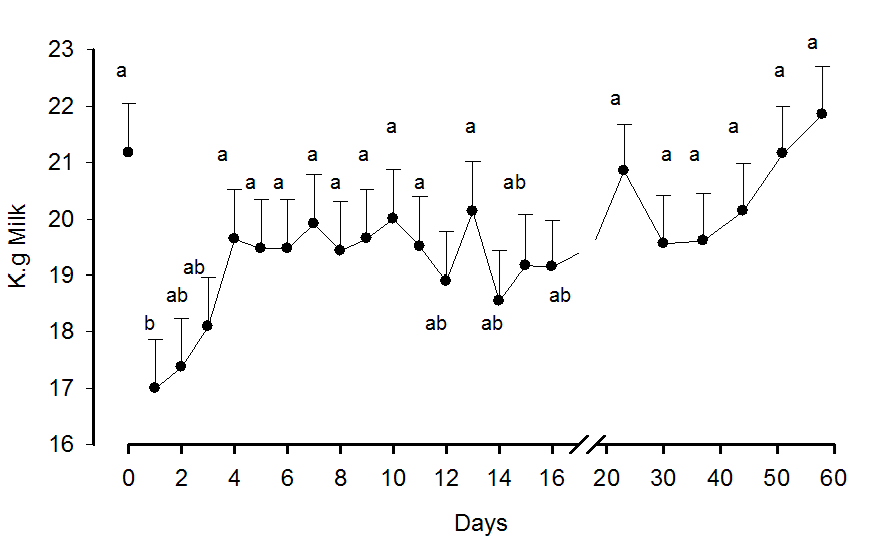

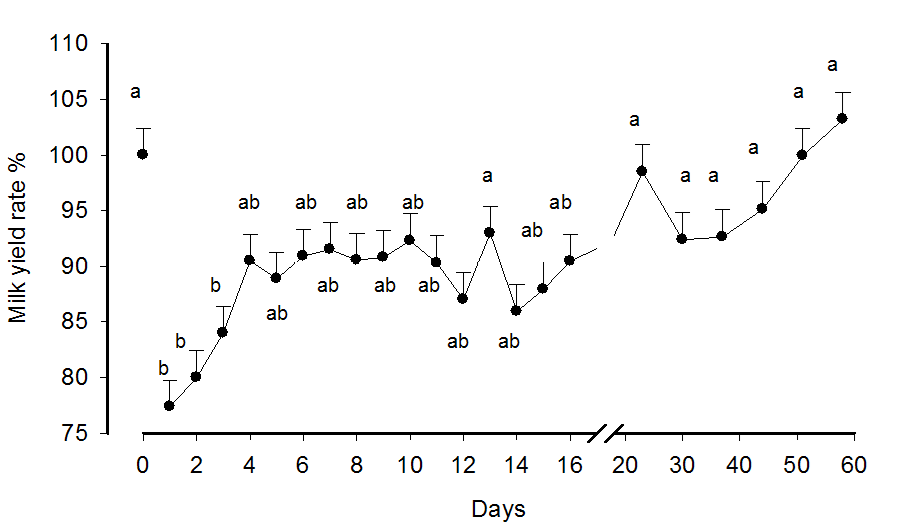

Figure 1, 2, 3, and 4 show the results of the development of milk yield and composition of the studied cows during the changing period from conventional pipeline to the quarter individual milking system (MultiLactor). Figure 1 clearly showed a significant decrease (P<0.05) in daily milk yield on the first day of milking with MultiLactor milking system compared to pipeline milking system before the changeover. The values were afterwards at 16.99 ± 0.87 and previously at 21.17 ± 0.87 kg milk/day. This corresponds to a production rate of 77.38 ± 2.40% of the first output value as shown in Figure 2. This indicates the variation of cows in the reaction to MultiLactor in the first day, consequently milk yield ranged between 47-106% of the expected milk yield before the changeover.

Figure 1: Daily milk yield after changing from the conventional pipeline milking system to tandem milking system with MultiLactor. (Day 0=10 days before the start of new milking system MultiLactor)

Means with different letters (a, b) are significantly different (P<0.05).

After that the daily milk yield increased continuously and reached on day 4 a production rate of 90.49 ± 2.40% (Figure 2), and thereafter the milk yield remained almost the same until 16 days after the changeover with approx 19.15 ± 0.83 kg milk/day and then the daily milk yield increased slightly and reached at the end of the experiment (day 58), the higher values of about 21.85 ± 0.86 kg milk/day. This corresponds to a production rate of 103.21 ± 2.43% in relation to the milk yield before the changeover. However, the development of daily milk yield was found to have the same tendency in both the morning and evening milking. That is, the values were lower in the first three days, and then increased again and reached the initial values on day 16 of the experiment.

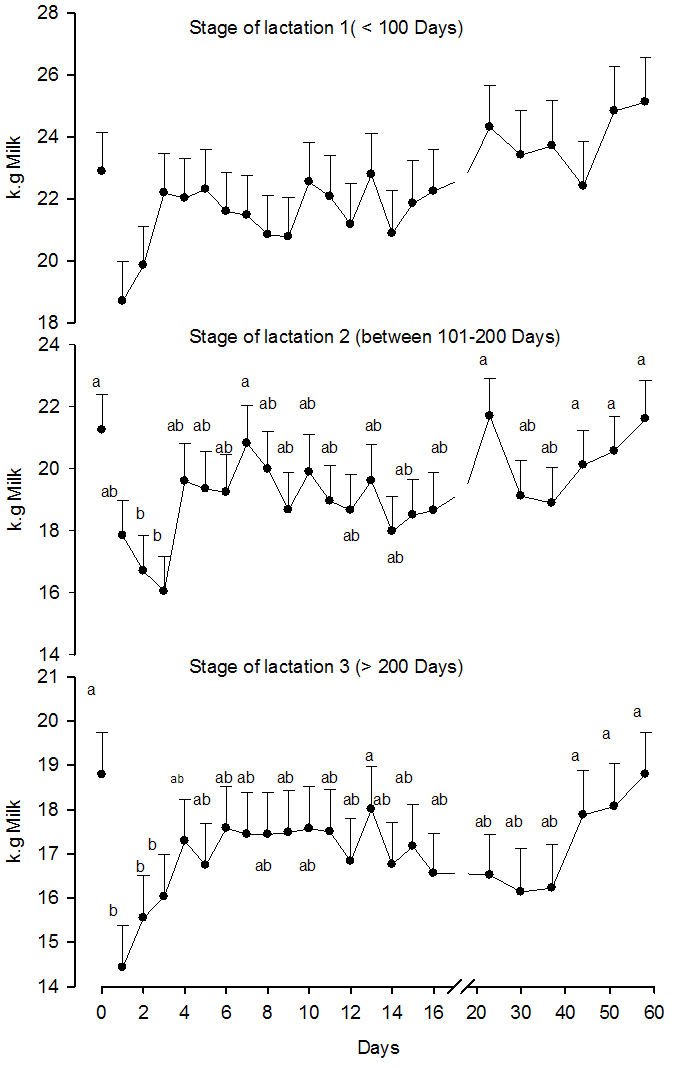

Figure 3 explained the effect of stage of lactation on daily milk yield after application of MultiLactor milking system which was found to be insignificantly different during the first stage of lactation, whereas in the second and third stage of lactation the effect was significant. Daily milk yield decreased in the first three days after changeover and then increased to the level before the application of the new milking system. This could be attributed to the effect of changeover of housing and milking system which cause serious disturbance in milk ejection reflex. Moreover, it was noticed that the application of MultiLactor milking system when changing from tying housing with pipeline milking system to loose housing with tandem milking parlor was found to be advantageous to overcome the decline of the yield during the adaptation period. Similar conclusion was attained by Weiss et al. (2004).

Figure 2: Daily milk yield rate % after changing from the conventional pipeline milking system to tandem milking system with MultiLactor. (Day 0 = 10 days before the start of new milking system MultiLactor).

Means with different letters (a, b) are significantly different (P<0.05).

Kaskous (2014a) noticed an increase in milk yield when changing from conventional milking system to MultiLactor milking system at similar conditions (loose housing). Danner (1989) found a significantly higher milk yield in loose housing compared to tying housing. Added to that the practical experience of scientists and farmers agreed that the changeover from tying to loose housing can lead to some management problems, among which decrease milk yield, hoof problem and lameness which may reach up to 30% of the herd (Wolkerstorfer, 2006). Earlier Andreae (1973), Schubert et al. (1982), Bakken et al. (1988) and Köll (2004) concluded that cows in loose housing had a significantly less clinical disease, fertility problems and shorter calving interval, but the average amount of milk was significantly lower than the amount produced by cows in tying housing.

Figure 3: Development of milk production after changing from the conventional pipeline milking system to tandem milking system with MultiLactor in relation to the stage of lactation. (Day 0=10 days before the start of new milking system MultiLactor)

Means with different letters (a, b) are significantly different (P<0.05).

Klug et al. (2006) argued that the higher milk production in tying housing system could be due intensive individual cow care and individual feeding; at the same time in loose housing system, growing horns could negatively affect the metabolic rate of the cow on expenses of milk yield.

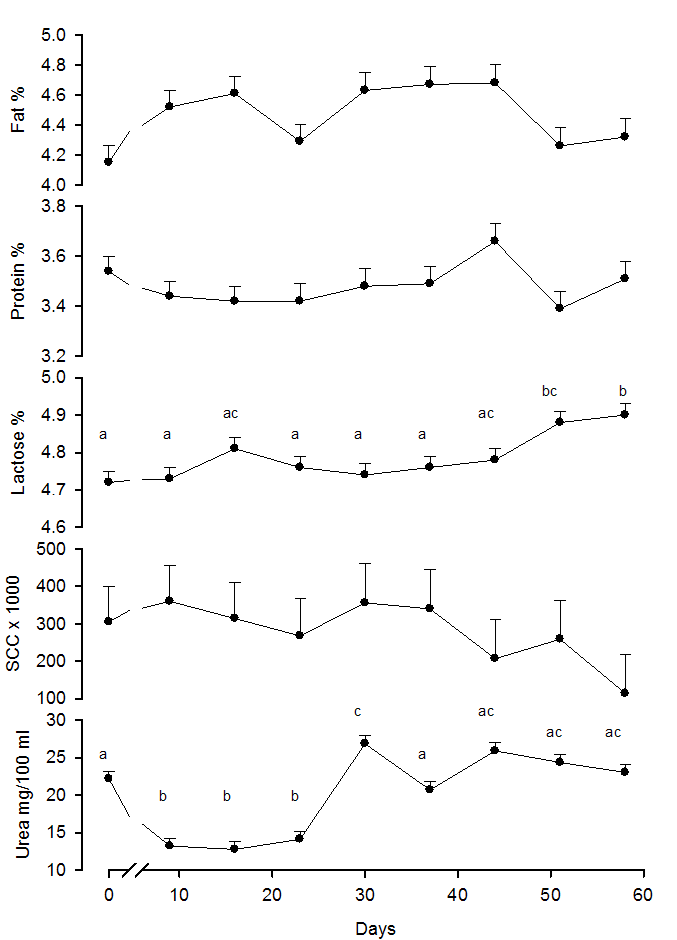

Results of statistical analysis of milk quality showed that fat content after the application of MultiLactor milking system was insignificantly different compared to value before the changeover. The values ranged between 4.15 ± 0.11 and 4.68 ± 0.12% during the period of the experiment. The same findings were observed for protein content after application of MultiLactor milking system and the values varied between 3.39 ± 0.07 and 3.66 ± 0.07% (Figure 4).

Figure 4: Development of milk components after changing from the conventional pipeline milking system to tandem milking system with MultiLactor. (Day 0=10 days before the start of new milking system MultiLactor)

Means with different letters (a, b) are significantly different (P<0.05).

Streit and Ernst (1989) and Köll (2004), (14) found that the value of fat in milk of cows in loose housing was significantly higher compared to those in tying housing depending on the breed. In contrast to that was the result of Kaskous (2014a), he found that the protein content in individual quarter milk after changeover from conventional milking system to MultiLactor milking system was significantly increased (from 3.26 to 3.34%), but the fat content after changeover unchanged (3.95 to 3.94%). Gustafson et al. (1993) observed a significantly higher protein content in milk of cows in tying housing without free walk compared to those with free walk. Weber et al. (1993) and Olesen et al. (1999) conducted a study on changeover of dairy cows from conventional to organic milk production farm, they found that the protein content of organic milk was significantly lower than that of conventional milk, but fat content in the study of the former was not differ significantly.

It could be noticed from the results (Figure 4) that lactose content of the milk showed a significant continuous increase after the application of MultiLactor milking system. The values reached on day 58 of the experiment a maximum level of about 4.90 ± 0.03%. This could be attributed to the fact that the udder was healthy, milk synthesis has gone well and the metabolic energy was sufficient for the anabolism of lactose in the udder.

Figure 4 demonstrated that the SCC in milk decreased gradually during the course of the experiment and reached the lowest values at day 58 with 114.05 ± 105.49 x103 cells / ml without significant differences. This finding could be explained in the context that, not only the housing system (tying or loose housing) but also the milking system affects the SCC in the milk. Accordingly, Valde et al. (1997) found no significant difference in SCC in cow milk in tying and loose housing. But in loose housing farms significantly less mastitis cases were encountered than in tying housing farms. Gustafson (1993) in his study of the health status of two groups with and without free walking in the same tying housing; found that during the first stage of lactation the SCC were significantly higher in milk of cows in tying system without free walk than the other group. However, during the remaining of lactation no difference in SCC was observed. Weber et al. (1993) and Weller and Cooper (1996) found a higher cell count in milk of some organic dairy farms compared to conventional farms.

Since SCC in this study tends to decrease in milk; the reasons could be due to good hygienic conditions no detection of stress factors during the changeover. It is known that the level of SCC greatly vary with the cleanliness of the milking system due to bacterial contamination. The MultiLactor milking system used in this experiment seem to protect the udder. The transfer of pathogens between cows and within the milking unit between the teats cups is not possible, since the MultiLactor consisted of four single milk tubes without a milking claw and is automatically cleaned after each milking from outside and inside, disinfected and rinsed. Moreover, the system worked with low milking vacuum of 32-34 kPa, which play a good role in the health of the udder. Consequently, SCC decreased significantly in the milk during the course of the experiment. Similar conclusion was reported by Kaskous (2014a) in his field study; as the SCC decrease from 289.09±45 to 211.05±47 x103 cell/ml when changing from conventional to MultiLactor milking system.

The milk urea content in this study showed a significantly decreasing trend below the normal level during the first 3 weeks after the changeover to MultiLactor milking system. Thereafter the values increased to reach the normal level of between 20 and 30 mg/100 ml of milk (Figure 4). Milk urea content is primarily a measure of the evaluation of feed raw protein. The low concentration of urea content in milk (10 - 15 mg/100 ml milk) detected during the 3 weeks after the changeover is probably could be connected with the feed intake. Richardt (2004) claimed that the amount of fed protein, SCC and days in lactation could directly influence the limit values of urea in milk.

Conclusions

The study concluded that the system (MultiLactor) is more suitable for the changeover from tying to loose housing. The suitability can be observed in form of physiological correction of milk, creating optimal working conditions, good stimulation of milk reflex, allow optimal automatic finishing of milking with smooth detachment of the milking unit and automatic disinfection of teats cups between milking and dipping of teats. The decrease in performance due to changeover can be avoided by training cows for a period of a week for easy adaptation to the new barns and milking parlour. This can be done by practicing intermittent housing and milking of animals in the new barns and parlour. An intensive and keen claw care is recommended before changing from tying to loose housing to avoid hoof problems that may appear later in the loose house.

Conflict of interest

Authors declared that they have no conflict of interest.

References