Pithecellobium dulce (PD) and Cassia senna alata (CA) Incorporated Food Packaging Films with Antioxidant Properties

Research Article

Pithecellobium dulce (PD) and Cassia senna alata (CA) Incorporated Food Packaging Films with Antioxidant Properties

Beenish Khanzada1*, Shagufta Jabeen2, Asif Ali1, Amna Fatimah1, Ishfa Zahid1, Esha Israr1, Arifa Iqbal1 and Ashas Waheed1

1Institute of Biochemistry, University of Sindh, Jamshoro, Pakistan; 2Department of Microbiology, University of Sindh, Jamshoro, Pakistan.

Abstract | Past practices of using medicinal plants as compounds to develop phyto-medicines has directed their more advanced use as active packaging as another way to preserve medicinal plants. The traditional plant extracts known for their antimicrobial or antioxidant properties can be incorporated in biopolymer based film forming solution to make active packaging films. This study contributes to comparative analysis of synthesis of biodegradable films from two biopolymers (i.e., starch and chitosan) with the additive effect of two medicinal plant extracts i.e., Pithecellobium dulce (PD) and Cassia senna alata (CA) using solvent casting technique. Fine homogenous and smooth surface films were the starch ones followed by chitosan. Prepared films were characterized using Fourier transform infrared spectroscopy (FTIR) to study the interactions between extract polyphenols with starch and chitosan. Water solubility analysis revealed the starch PD films with highest swelling degree, chitosan CA films with least water solubility and chitosan PD with least moisture content. In soil biodegradability analysis, starch PD films depicted highest weight loss (45%) in soil followed by chitosan CA films, proving the biodegradable character. DPPH assay displayed the highest free radical scavenging (32%) capacity of starch PD films followed by chitosan CA. For analysis of food quality effects, bread pieces were wrapped with these films and it was concluded that starch PD films displayed least weight loss (15%) of bread and maintained quality over one-week storage that was comparable to commercial plastic films.

Received | September 01, 2024; Accepted | September 25, 2024; Published | September 30, 2024

*Correspondence | Beenish Khanzada, Institute of Biochemistry, University of Sindh, Jamshoro, Pakistan; Email: beenish@usindh.edu.pk

Citation | Khanzada, B., S. Jabeen, A. Ali, A. Fatimah, I. Zahid, E. Israr, A. Iqbal and A. Waheed. 2024. Pithecellobium dulce (PD) and Cassia senna alata (CA) incorporated food packaging films with antioxidant properties. Pakistan Journal of Agricultural Research, 37(3): 338-344.

DOI | https://dx.doi.org/10.17582/journal.pjar/2024/37.3.338.344

Keywords | Phyto-assisted, Biodegradable packaging, Antioxidant activity, Shelf life, Solvent casting, Medicinal plants

Copyright: 2024 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Biopolymers based films offer several advantages as compared to conventional plastics such as lower cost, enhanced durability, biodegradability, non-abrasiveness, favorable mechanical properties, environmental friendly, and prolonged usage time. On the contrary, commercial plastic packaging films are non-biodegradable so the use is limited (Zakaria et al., 2024). Such active biopolymer based films have been proved as a renowned way to improve packaging quality by providing protection from ultra violet rays, microbial contamination or water. Many edible plant extracts are non-toxic and contain antioxidant and antimicrobial properties that’s why plant extracts are regarded as suitable additive for incorporation in food packaging films. Plant extracts contain secondary plant metabolites such as phenols and flavonoids that impart antimicrobial and antioxidant properties in a packaging film (Manzoor et al., 2023).

Pithecellobium dulce (PD), (commonly known as Jungle Jalebi or black bead tree), is an important medicinal plant, belonging to the family Fabaceae and is found in tropic areas like Asia, India and America. This plant has been reported to have anti-diabetic, anti-hyperlipidemic, antioxidant, anti-ulcer, nephron-protective, anti-diarrheal, anti-bacterial and anti-fungal properties. Pithecellobium dulce contain various flavonoids, alkaloids, saponins, coumarine, tannins, anthocyanin and triterpenoids (Mondal et al., 2024; Murugesan et al., 2019). Moreover, Cassia alata (CA; commonly known as candle brush, Senna alata) is another plant found in Indonesia, South Asia, France, India. Several studies have reported that Cassia alata plant leaves have strong anti-inflammatory, antioxidant and anti-fungal properties. Secondary metabolites such as alkaloids, saponins, steroids, flavonoids, and terpenoids have been found in Cassia alata (Colin et al., 2024). These important plants can be incorporated in biopolymer based films as additives due to above mentioned significant properties.

In smart bio-based packaging, plant extracts are added to biopolymer based composites to enhance physical and chemical strength of film and to add some biological properties. Potato starch is an applicable biopolymer, known for low gelatinization temperature, non-toxicity, good gel stability and low cost film preparation (Li et al., 2024). It is composed of amylose and amylopectin (joined by α-1, 4-glycosidic bonds) and amylopectin contributes to its gelling property and freeze-thaw stability (Park et al., 2024). In a recent study potato starch-based films were prepared with reinforcing effect of banana fibers for grapes packaging (Dutta and Sit, 2024). Chitosan is another positively charged polysaccharide which is an attractive choice for making edible film due to its biodegradable, bio-compatible, antimicrobial and non-toxic nature (Sarfraz et al., 2024). Studies have reported that the antimicrobial and antioxidant activity of chitosan films can be improved by incorporation of plant extracts such as pomegranate peel extract (de Almeida Soares and de Aquino Santana, 2024).

Therefore, our study aimed that incorporation of plant extracts i.e., Pithecellobium dulce (PD) and Cassia alata (CA) into starch and chitosan films may boost up the packaging properties of these biopolymers. Objectives of the current study include (1): Preparation of starch and chitosan films incorporated with PD and CA plant extracts (2). Characterization of films via FTIR (3). Evaluation of antioxidant activity, bio-degradability and water soluble properties of films (4). Effect of films on bread packaging.

Materials and Methods

P.D and C.A leaves were collected during September 2023 from the Sindh University Employees Society Jamshoro, Sindh, Pakistan. The specimens were identified by Dr. Noorulain, Department of Plant Sciences, University of Sindh Jamshoro.

Plant extract preparation

Leaves of both CA and PD plants were washed, dried and ground into powder. It was followed by maceration (i.e., soaking 5 g powder in 50 ml of methanol) and sonication. The extracts were filtered using Whatman #1 filter paper, concentrated in a rotary evaporator, dried and stored.

Starch was extracted from fresh potatoes whereas 90% de-acetylated chitosan powder was purchased from Chemsavers.

Film preparation

Solvent casting method was used for preparation of films (Khanzada et al., 2023). Starch powder (3% w/v) and chitosan powder (2% w/v) was dissolved in 50 ml of distilled water and 100 ml of 1% acetic acid respectively, with constant stirring at 90 °C. It was followed by the addition of glycerol (20% and 30% w/w, respectively), 1% PD and CA extracts and stirred at 70 °C for 30 min at 300 rpm. The solution was then poured in aluminum plates, placed in a preheated oven on 55°C and peeled off after 24 h

drying and conditioning.

FTIR analysis

The starch and chitosan films were directly placed on FTIR spectrometer and FTIR spectra were recorded spanning the wavenumber range of 4000-670 cm-1.

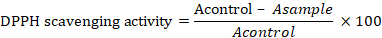

DPPH assay

The antioxidants activity of prepared films was evaluated using the DPPH assay (Zhang et al., 2024). 1mg DPPH powder was dissolved in 50 ml methanol, diluted to achieve an absorbance of approximately 0.9 at 517 nm. Samples of weight 100 mg (0.1g) were cut and placed in a test tubes containing 5 ml of methanol solution. Test tubes were covered with aluminum foil and were left for 24 hours for extract absorption in methanol. After 24 hours, 2 ml of the DPPH diluent was added and the mixture was allowed to react for 1hr in a dark environment. The absorbance was measured at 517 nm.

Acontrol refers to the absorbance value (approximately 0.9) of the DPPH diluent solution, while Asample represents the absorbance value of the test film.

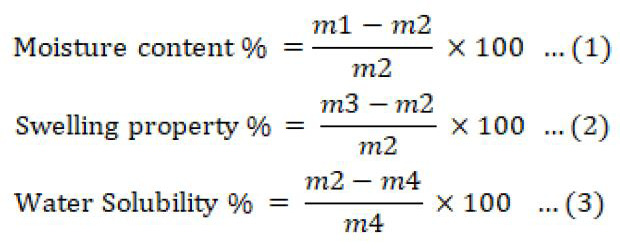

Water solubility

Solubility analysis of films was carried out using gravimetric method (Khanzada et al., 2023). 2x3 cm-2 film pieces were weighed (m1). Then, samples were oven-dried at 90°C (5 h) to get a constant dry mass (m2). Consequently, soaking of film samples in distilled water (25°C for 24 h) was done and then samples were taken out after attaining a constant mass (m3). Later, samples were oven-dried for 5 h (90°C) to reach a constant weight (m4). Following calculations were employed.

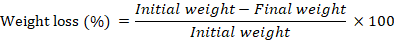

Biodegradability

The biodegradation capability of the prepared films was determined using the soil from the field of Institute of Biochemistry, University of Sindh Jamshoro, Pakistan. Films of 2 × 2 inch were covered up by soil in a pot at 2-inch depth for 7 days. Water spray to this soil was provided regularly after 7 days, samples were taken out and weight loss of the films were calculated as follows.

Food quality assay

Biodegradable films, commercial film, and bread slices were utilized. Fresh bread was sliced in circles, pre-weighed and wrapped in both type of films and one piece was left exposed to air as negative control. After 7 days, the packages were opened, and the bread slices were re-weighed. The variance between the initial and final weights indicated the weight loss.

Results and Discussion

Synthesis of biopolymer films

As compared to chitosan, starch films were seen to have good physical and mechanical strength and were smooth and homogenous. The photographs of synthesized biopolymer films are given in Figure 1. Thickness of the films was more in case of starch (130 µm) as compared to chitosan films (100 µm).

FTIR analysis

Prepared films were characterized using FTIR. The recorded spectra of the plant extract loaded films were compared to those of the control film (without extract), as shown in Figure 2.

The vibration peak of amide groups appeared at 1750 cm-1 in control starch film and this was shifted to 1500 cm-1 and 1650 cm-1 in the starch CA and starch PD films, respectively. Similarly, chitosan control film exhibited the absorption band corresponding to amide groups at 1600 cm-1 that was found to be shifted to 1500 cm-1 and 1650 cm-1 in chitosan PD and chitosan CA films, respectively. Chitosan CA film exhibited shifting of methyl group bending vibrations to 1300 cm-1 where as Chitosan PD showed shift of CO group vibrations to 1020 cm-1 as compared to control. The vibrations of CO groups were also found to be shifted to 1000 cm-1 in both extracts loaded starch films.

These changes may be attributed to the intermolecular rearrangement and modifications in the configuration of the primary chain. Furthermore, these peak alterations may be due to the combined influence of phenolic compounds present in the extract and the interactions between these compounds with the chitosan and starch chain structure (Gradinaru et al., 2023).

DPPH assay

Figure 3 shows the color change of DPPH and methanol solution with films immersion after 1 h, 3 h and 5 h. The results show that the starch (PD) film sample exhibited the highest DPPH scavenging activity i.e. 31.7% that was followed by chitosan (CA) i.e. 16.7% (Table 1). The incorporation of PD leaves extract significantly enhanced the free radical scavenging activity of the starch film. This enhancement is likely due to the release of polyphenols and flavonoids from the leaves extract, which have known antioxidant properties (do Nascimento et al., 2024; Nadira et al., 2022).

Table 1: DPPH percent scavenging of synthesized film.

|

Films |

Scavenging (%) |

|

Starch CA |

10.7 |

|

Starch PD |

31.7 |

|

Chitosan CA |

16.7 |

|

Chitosan PD |

2.9 |

Water solubility

Chitosan PD and Starch CA were found to have higher water solubility (50-55%). Film with higher solubility have the potential for developing active food packaging that can easily dissolve and release active agents (Taweechat et al., 2021). It was observed that chitosan PD film had the lowest moisture content and starch (PD) film have a highest swelling degree (%) among all films (Figure 4).

This could be attributed to strong molecular interactions or may be due to extract polyphenols having high hydrophilicity and they form hydrogen bonds with the hydroxyl group of starch, leading to an increase in the swelling degree (Zhai et al., 2024). Low moisture content of chitosan PD film suggests the formation of an inclusion complex between the chitosan matrix and the extract polyphenolic compounds through hydrogen bonding which may compete with the water molecules, limiting the matrix’s ability to bind with water (Homthawornchoo et al., 2022; Khanzada et al., 2023).

Biodegradability

Figure 5 shows the film appearance before and after degradation. The biodegradability results of film samples are shown in Figure 6 indicating that the starch PD film samples have high biodegradability rate i.e., 44.4% after a week. This biodegradability character of films may be due to the presence of plant extracts which provide additional nutrients for the micro-organisms, accelerating the degradation process and ultimately increasing the rate at which the biodegradable films break down into environmentally friendly product.

The specific effects of plant extracts on film biodegradation would depend on the composition of the extract and its interaction with the material (Wrońska et al., 2023). The specific effects of plant extracts on film biodegradation would depend on the composition of the extract and its interaction with the material.

Food quality

The bread pieces wrapped in biodegradable film showed acceptable texture, color and quality than those placed in open air. Figure 7 represent the results of changes in the appearance of bread pieces during one-week storage.

The bread pieces wrapped in biodegradable film showed acceptable texture, color and quality than those placed in open air. Starch and chitosan films loaded with PD extracts depicted least weight loss percentage as compared to other synthesized films (Table 2).

Table 2: Weight loss (%) in food quality assay.

|

Films |

Weight loss (%) of bread (after one week packaging) |

|

Starch CA |

34.8 |

|

Starch PD |

15.4 |

|

Chitosan CA |

34.8 |

|

Chitosan PD |

28.9 |

|

Chitosan control |

35.8 |

|

Commercial film |

11.1 |

This decreased weight loss of bread samples by PD loaded films was comparable to commercial films. The results are consistent with other assay findings, where starch PD films displayed highest percent scavenging and highest weight loss percentage in soil burial assay potentially contributing to their packaging aspects (Venkatesan et al., 2023).

Conclusions and Recommendations

Chitosan and starch based active films were synthesized successfully by incorporating PD and CA extracts. The prepared biopolymer based films (particularly starch PD films) exhibited good antioxidant activities, and biodegradability and were found to maintain quality of packaged bread samples. Therefore, such cost effective packaging films can be efficiently used for food packaging applications. However, future studies are needed to study their tensile, thermal and barrier properties for a better understanding of their packaging attributes.

Acknowledgements

We would like to acknowledge Prof. Dr Naseem Aslam Channa and Prof. Dr Ibtessam Tahir Ansari, institute of Biochemistry, University of Sindh Jamshoro for their help in FTIR and DPPH assay.

Novelty Statement

The medicinal plants used in our study i.e. Pithecellobium dulce (PD) and Cassia senna alata (CA) have never been incorporated as additives in either Chitosan or starch based food packaging films which contributes to novelty of this research.

Author’s Contributions

Beenish Khanzada: Conceptualization, supervision, writing, review and editing.

Shagufta Jabeen: Formal analysis, project administration.

Asif Ali: Investigation.

Amna Fatimah: Methodology.

Ishfa Zahid: Data curation.

Esha Israr: Validation.

Arifa Iqbal: Visualization.

Ashas Waheed: Resources.

Data availability

Data requested will be provided by corresponding author.

Funding statement

No funding was acquired by this study.

Conflict of interest

All authors declare no conflict of interest in publication of this article.

References

Colin, M.N., N.S.E. Claudiana, A.U. Kaffah, A.N. Hasanah and S. Megantara. 2024. Review on Cassia alata bioactive compounds: In silico, in vitro, and in vivo studies. Drug design, development and therapy, pp. 4427-4447. https://doi.org/10.2147/DDDT.S477679

de Almeida Soares, L. and L.C.L. de Aquino Santana. 2024. Physicochemical characterization, antioxidant and antimicrobial potential of biodegradable chitosan-based films containing pomegranate (Punica granatum L.) peel extract. J. Polym Environ., 32(4): 1729-1740. https://doi.org/10.1007/s10924-023-03063-x

do Nascimento, J.V., K.A. Silva, V.C. Giuliangeli, A.L.D. Mendes, L.P. Piai, R.N. Michels, T.C. Dal Bosco, G.R. Ströher and M.A. Shirai. 2024. Starch-PVA based films with Clitoria ternatea flower extract: Characterization, phenolic compounds release and compostability. Int. J. Biol. Macromol., 255: 128232. https://doi.org/10.1016/j.ijbiomac.2023.128232

Dutta, D. and N. Sit. 2024. Preparation and characterization of potato starch-based composite films reinforced by modified banana fibers and its application in packaging of grapes. Int. J. Biol. Macromol., 254: 127791. https://doi.org/10.1016/j.ijbiomac.2023.127791

Gradinaru, L.M., M. Barbalata-Mandru, A.A. Enache, C.M. Rimbu, G.I. Badea and M. Aflori. 2023. Chitosan membranes containing plant extracts: Preparation, characterization and antimicrobial properties. Int. J. Mol. Sci., 24(10): 8673. https://doi.org/10.3390/ijms24108673

Homthawornchoo, W., J. Han, P. Kaewprachu, O. Romruen and S. Rawdkuen. 2022. Green tea extract enrichment: Mechanical and physicochemical properties improvement of rice starch-pectin composite film. Polymers, 14(13): 2696. https://doi.org/10.3390/polym14132696

Khanzada, B., B. Mirza and A. Ullah. 2023. Chitosan based bio-nanocomposites packaging films with unique mechanical and barrier properties. Food Packag. Shelf Life, 35: 101016. https://doi.org/10.1016/j.fpsl.2022.101016

Li, H., J. Wang, Y. Liu, J. Chen, C. Wang, Y. Hu and K. Hu. 2024. Production of biodegradable potato starch films containing Lycium barbarum polysaccharide and investigation of their physicochemical properties. Food Packag Shelf Life, 44: 101320. https://doi.org/10.1016/j.fpsl.2024.101320

Manzoor, A., B. Yousuf, J.A. Pandith and S. Ahmad. 2023. Plant-derived active substances incorporated as antioxidant, antibacterial or antifungal components in coatings/films for food packaging applications. Food Biosci., 53: 102717. https://doi.org/10.1016/j.fbio.2023.102717

Mondal, P., D. Banerjee, P. Ghorai, S. Debnath and N. Pal. 2024. Natural Remedies in the Treatment of Peptic Ulcer: A. IRJPMS, 7(4), 24-38.

Murugesan, S., D.K. Lakshmanan, V. Arumugam and R.A. Alexander. 2019. Nutritional and therapeutic benefits of medicinal plant Pithecellobium dulce (Fabaceae): A review. J. Appl. Pharm. Sci., 9(7), 130-139. https://doi.org/10.7324/JAPS.2019.90718

Nadira, P., V.A. Mujeeb, P.M. Rahman and K. Muraleedharan. 2022. Effects of cashew leaf extract on physicochemical, antioxidant, and antimicrobial properties of N, O–Carboxymethyl chitosan films. Carbohydr. Polym. Technol. Appl., 3:100191. https://doi.org/10.1016/j.carpta.2022.100191

Park, H.J., D.H. Cho, H.J. Chung and S.T. Lim. 2024. Enhanced gelling property and freeze–thaw stability of potato, tapioca and corn starches modified by mild heating in aqueous ethanol solution. J. Sci. Food Agric., https://doi.org/10.1002/jsfa.13544

Sarfraz, M.H., S. Hayat, M.H. Siddique, B. Aslam, A. Ashraf, M. Saqalein, M. Khurshid, M.F. Sarfraz, M. Afzal and S. Muzammil. 2024. Chitosan based coatings and films: A perspective on antimicrobial, antioxidant, and intelligent food packaging. Prog. Org. Coat, 188: 108235. https://doi.org/10.1016/j.porgcoat.2024.108235

Taweechat, C., T. Wongsooka and S. Rawdkuen. 2021. Properties of banana (Cavendish spp.) starch film incorporated with banana peel extract and its application. Molecules, 26(5): 1406. https://doi.org/10.3390/molecules26051406

Venkatesan, R., S. Surya, S. Suganthi, M. Muthuramamoorthy, S. Pandiaraj and S.C. Kim. 2023. Biodegradable composites from poly (butylene adipate-co-terephthalate) with carbon nanoparticles: Preparation, characterization and performances. Environ. Res., 235: 116634. https://doi.org/10.1016/j.envres.2023.116634

Wrońska, N., N. Katir, M. Nowak-Lange, A. El Kadib and K. Lisowska. 2023. Biodegradable chitosan-based films as an alternative to plastic packaging. Foods, 12(18): 3519. https://doi.org/10.3390/foods12183519

Zakaria, M.R.S.B., M.B. Abid, A. Shamim, S.S. Suradi, N.B. Marsi and F.B. Kormin. 2024. A review on biodegradable composite films containing organic material as a natural filler. J. Inorg. Organomet. Polym. Mater., pp. 1-36.

Zhai, X., J. Han, L. Chang, F. Zhao, R. Zhang, W. Wang and H. Hou. 2024. Effects of starch filling on physicochemical properties, functional activities, and release characteristics of PBAT-based biodegradable active films loaded with tea polyphenols. Int. J. Biol. Macromol., 277: 134505. https://doi.org/10.1016/j.ijbiomac.2024.134505

Zhang, L., W. Wang, W. He, T. Du, S. Wang, P. Hu, B. Pan, J. Jin, L. Liu and J. Wang. 2024. A tailored slow-release film with synergistic antibacterial and antioxidant activities for ultra-persistent preservation of perishable products. Food Chem., 430: 136993. https://doi.org/10.1016/j.foodchem.2023.136993

To share on other social networks, click on any share button. What are these?