Parametric Analysis of the Mulching Depth of Oil Palm Fronds Achieved by Tractor Operated Mulcher

Parametric Analysis of the Mulching Depth of Oil Palm Fronds Achieved by Tractor Operated Mulcher

Bala Gambo Jahun1,2*, Muhammad Yamin2,3, Desa Bin Ahmad2, Muhammad Razif Mahdi2, Shamsuddin Suleiman4 and Salihu Ahmad Abdulkadir5

1Department of Agricultural and Bioresource Engineering Abubakar Tafawa Balewa University, PMB 0248, Bauchi State Nigeria; 2Department of Biological and Agricultural Engineering, Universiti Putra Malaysia 43400 Serdang, Selangor Darul Ehsan, Malaysia; 3Faculty of Agricultural Engineering and Technology, University of Agriculture, Faisalabad 38000, Pakistan; 4Department of Mechanical and Manufacturing Engineering, Universiti Putra Malaysia 43400, Serdang, Selangor Darul Ehsan, Malaysia; 5Department of Agricultural Engineering, Adamawa State Polytechnic Yola Nigeria.

Abstract | Pruning produces large quantities of waste from oil palm fronds (OPFs). During mulching of oil palm fronds, lifting angles of mulcher’s blades affect the mulching depth and may damage the shallow roots of oil palms. This study investigates the influence of blade lifting angles, tractor’s forward speed and tractor’s PTO speed in predicting mulching depth. Four blades with lifting angles of 0°, 60°, 120°, and 150°; 02 tractor’s PTO speeds of 540 and 1000 RPM and 03 tractor’s forward speeds of 1, 3, and 5 km/h were assessed for determining the effect on mulching depth in oil palm plantation. The results show that about 79 % of the mulching depth variance is explained by blade lifting angles, tractor’s forward speed and tractor’s PTO speed. Blade lifting angle of 120° at tractor’s PTO speed of 1000 RPM and tractor’s forward speed of 5 km/h offered the most suitable mulching depth of 14.10 cm. Tractor’s PTO speed was a major predictor of mulching depth in an oil palm plantation. Thus prescribed blade lifting angle and tractor’s forward speed must be adjusted for the attainment of shallow mulching depth. This will minimize the damage to the roots of oil palm while mulching oil palm fronds. Moreover, the developed multiple linear regression model can further be used for the adjustment of blade lift angles and tractor’s speed to achieve the required mulching depth during the field maintenance, replanting and access operation.

Received | March 12, 2020; Accepted | May 9, 2020; Published | May 20, 2020

*Correspondence | Bala Gambo Jahun, Department of Agricultural and Bioresource Engineering Abubakar Tafawa Balewa University, PMB 0248, Bauchi State Nigeria; Email: bgjahun@yahoo.com

Citation | Jahun, B.G., M. Yamin, D.B. Ahmad, M.R. Mahdi, S. Suleiman and S.A. Abdulkadir. 2020. Parametric analysis of the mulching depth of oil palm fronds achieved by tractor operated mulcher. Sarhad Journal of Agriculture, 36(2): 632-638.

DOI | http://dx.doi.org/10.17582/journal.sja/2020/36.2.632.638

Keywords | Blade lifting angles, Oil palm fronds, Tractor’s PTO speed, Tractor’s forward speed, Mulching depth

Introduction

The oil palm (Elaeis guineensis) is a tropical tree, known as the African oil palm found in West and Central Africa. It is one of two oil palm species in the Arecaceae or palm family. As a world’s second largest producer and exporter of palm oil among ten main exporters, Malaysia’s total plantation area occupies about 5.08 million hectares (Shamshiri et al., 2018). Only 10% of palm oil is processed in the oil palm mill and the other 90% is in the form of waste that produces the largest amount of biomass, estimated at 80 million dry tons per year (Abdullah et al., 2013).

During pruning and replanting activities, the oil palm fronds are stacked. Throughout the pruning activity, frond availability was calculated using an estimate of 10.4 tons ha-1, which currently yields an average of 6.97 million tons per year. Meanwhile, an estimate of 54.43 million tons of oil palm fronds per year will be available during the replanting period between 2007 and 2020 (Haafiz et al., 2014).

Currently, oil palm fronds and trunks generate environmental burdens as their present methods of discarding them are dangerous. It acts as habitat for insects, rodents and diseases that kill young seedlings and reduce yields, resulting in plant losses of 40% and 92% respectively as reported by Aljuboori (2013). Mulching is a technological technique of pulverizing and burying of oil palm residues on the soil, crushed oil palm residues and shredded trunks. It is mainly used to crush and pulverize residues and shredded trunks of oil palm fronds and to destroy insect and rodent inhabitants, diseases, reduced soil erosion and increased nutrients. The method can be applied to on-farm plant biomass (Andrejs, 2006; Bayala et al., 2012; Syrový et al., 2013).

The existing possibility of mulching devices to preserve surface residue pulverization depends primarily on the main active part of the tilt angle and geometry of the implementing blades (Raper, 2002). It was found that the disk type is better than the chisel type mulcher to mulch the crop residue. Using a disk model to run a mulcher at a deeper depth during mulching indicates better mulching efficiency but the energy consumption level was higher. This disc-type mulcher drawback prevented farmers from patronizing the tool.

The operation of pulverization requires the ideal depth spent on farms. Therefore, the depth of mulching is important in order to determine the blade lifting angle and geometry that could be used in pulverizing oil palm fronds for the tractor mounted mulcher. The depth required for mulcher implementing is influenced by the soil conditions and mulcher blade geometry (Taniguchi et al., 1999; Olatunji and Davies, 2009). The pulverizing depths of the mulcher can easily be adjusted. The rotating blades cut the oil palm fronds and mix them homogeneously throughout the depth of mulching of the unit, performing in terms of mulching in addition to other tractor-mounted tools (Mandal et al., 2013).

A mulching tool, particularly the lifting angles of the blade, must mulch the soil and mix it properly to the required degree with the oil palm fronds and work the soil properly. Mulching blades must allow the effective use of the energy applied to the soil by integrating the oil palm fronds into the soil with high capacity as mentioned by Jones et al. (1990). The soil parameters used to determine the performance of mulching blade are disturbed soil volume, blade penetration depth and soil condition.

Soil intensity variations decrease or increase the mulcher implement’s penetration rate. When the soil is very hard or thick, the tool’s penetration capacity decreases significantly, causing the entire frame of the implement to be raised. Nalavade et al. (2011) stated that the disks can cut, rolls over the roots and other obstructions through crop residues. They can operate in non-scoring soil using scrapers but do not provide the complete waste coverage. This research study evaluates the performance of the tractor operated mulcher with four different blade lifting angles for mulching the oil palm fronds on the basis of mulching depth. The specific objective of the study is to compare the performance of the four tractor-mounted mulcher blades for mulching oil palm fronds based on depth of mulching.

Materials and Methods

Experiments were conducted to study the effects of depth of mulching on the performance of four mulcher blades at Universiti Putra Malaysia oil palm plantation. Soil profiles are classified as textures of sandy clay loam. For this analysis, three determining factors were chosen: the lifting angles of the blade at four scales (0o, 60o, 120o and 150o) as shown in Figure 1, tractor’s forward speed, V0 at 3 levels (1, 3 and 5 km/h) and tractor’s PTO speed at two levels (540 and 1000 RPM, or 56.55 and 104.7 rad/sec), giving a total of 24 treatments. This was considered as a factorial concept fitted into a completely randomized block design (CRBD). Each test was conducted in three replications, which gave a total of 72 experimental plots. In the experiment, a tractor working width of 1.4 m for Howard Mulcher HM 50 was used, a running length of 5 m and an appropriate plot size of 7 m2. A 0.5 m wide swath was left on each plot’s sides for wheeling. After the mulching operations, a specialized graduated steel ruler was used to measure each plot depth of mulching. ANOVA was used to analyze the treatment effects and the method of Tukey’s means separation (α ≤ 0.05) was used to identify significant differences among treatment means through SAS v9.2 software. A mulcher implement (1.4 m) and a New Holland tractor (G240) were used, as shown in Figure 2.

Results and Discussion

Effect of treatments using analysis of variance

A variance analysis (ANOVA) was performed to determine if there were significant effects of blade lifting angles, tractor’s forward speed, and tractor’s PTO speed on the depth of oil palm fronds on a plantation, as shown in Table 1. The results of the ANOVA indicated that the geometry difference in blade lifting angles has a significant influence on the depth of mulching at F=44.02 and P=0.0001 (P-value≤0.05). During the mulching operation, tractor’s forward speed levels also showed a significant effect on the depth of mulching at F=28.03 and P=0.0001 (P-value≤0.05). Similarly, mean depth of mulching varies with the PTO speed of the tractor at F=7.33 and P=0.0095 (P-value≤0.05). A significant impact of blocks (test areas) at F=0.02 and P=0.044 (P-value≤0.05) was observed on mulching depth. This could be attributed to the undulating nature of the plantation of oil palms.

Table 1: ANOVA for effects of treatments on the depth of mulching.

| Source | DF | Mean square | F value |

| Model | 25 | 26.68 | 16.84** |

| Blade lifting angles | 3 | 69.73 | 44.02** |

| Tractor’s forward speed | 2 | 44.41 | 28.03** |

| Tractor’s PTO speed | 1 | 11.61 | 7.33* |

| Block | 2 | 0.02 | 0.02* |

| Blade lifting angles*tractor forward’s speed | 6 | 14.47 | 9.13** |

| Blade lifting angles*tractor’s PTO speed | 3 | 8.29 | 5.24* |

| Tractor’s forward speed*tractor’s PTO speed | 2 | 45.12 | 28.48** |

| Blade lifting angles*tractor’s forward*speed*tractor’s PTO speed | 6 | 25.91 | 16.35** |

| Error | 46 | 1.58 | |

| Corrected total | 71 |

**highly significant at P≤0.01; *Significant at P≤0.05

The interactions between blade lifting angles with tractor’s forward speed; blade lifting angles with tractor’s PTO speed; the combination of tractor’s forward speed with mulching tractor’s PTO speed, all contributed significantly to the depth of mulching. Three-way treatment interaction among blade lifting angles, tractor’s forward speed, and tractor’s PTO speed also had a highly significant impact on depth of mulching at F=28.48 and P=0.0001 (P-value≤0.05). Further, pairwise comparison of treatments indicated the level and variation of significant effect on depth of mulching.

Effect of blade lifting angles on the depth of mulching

The influence of blade lifting angles on the mulching depth using Tukey’s means comparison is illustrated in Figure 3. Depths of mulching are not significantly different for blades with 60o and 120o lifting angles, with a depth of 17.8 and 17.5 cm deep. Likewise, for blades with 0o and 150o lifting angles, the depth of the 21.2 and 20.9 cm mulching means are not significantly different. There was a significant difference between 0o and 60o lifting angles of the blades. Similarly, the lifting angles of the blade were significantly different from 120o to 150o. Depth of mulching with 0o blade lifting angle generally yielded the highest depth of mulching, while the 120o blade lifting angle yielded the lowest depth of mulching. It is concluded that for mulching operations, the blade with a lifting angle depth of 120o is suitable. The findings are consistent with the research of Naderloo et al. (2009).

Effect of tractor’s forward speed on the depth of mulching

The findings of ANOVA, as shown in Table 1, indicate that tractor’s forward speeds during mulching have a significant effect on the depth of mulching. Figure 4 provides a comparison of the Tukey’s means for the impact of tractor’s forward speeds (1, 3 and 5 km/h) on the depth of mulching. It shows that the depth of mulching with tractor’s forward speeds of 1 and 3 km/h by means of 18.7 and 18.4 cm is not significantly different, whereas the depth of mulching at tractor’s forward speeds of 5 km/h is significantly different from the means of mulching at tractor’s forward speeds of 1 and 3 km/h. Conclusively, the oil palm fronds are mulched deeper in soil, when tractor’s forward speed is higher. The same trend in soil disturbance effect of depth of mulching has been reported by Makange and Tiwari (2015).

Effect of tractor’s PTO speed on the depth of mulching

The tractor’s PTO speed provided the power required for mulching and had a significant effect on the depth of mulching. Figure 5 shows a significant difference in depth of mulching between tractor’s PTO speeds of 540 and 1000 RPM, showing that the mulching depth varies with tractor’s PTO speeds. Figure 5 shows; higher the tractor’s PTO speed, deeper the depth of mulching is.

Effect of tractor’s forward speed and blade lifting angles on the depth of mulching

Figure 6 shows that for all three speeds of the tractor, the blade with 0o lifting angle has almost same significant effect on mulching depth with mean values of 21.5, 20.6 and 21.5 cm. Similar effect is observed for blade with 60o and 120o lifting angles at all three speeds of tractor except for blade lifting angle of 120o at 5 km/h which penetrated deeper at 19.1 cm. The blade with 150o lifting angle showed a significant effect on mulching depth for all three speeds and penetrated deeper i.e. 24.92 cm for 5 km/h. This confirmed the results of Perdok and Kouwenhoven (1994) i.e. quicker the tractor is moving forward, the more powerful the blade movement is.

Effect of tractor’s PTO speed and blade lifting angles on the depth of mulching

Blade lifting angles with a combination of tractor’s PTO speed showed a significant difference in the depth of mulching as shown in Figure 7. With PTO speeds of 540 and 1000 RPM, the blade for 0o lifting angle showed no significant difference in average depth of mulching but this angle has different effect as compared to the other mentioned angles. Blade with 60o and 120o lifting angles at both 540 and 1000 RPM of PTO has no significantly different effect on mulching depth. At 540 and 1000 RPM of PTO, the blade with 150o lifting angle showed a clear significant difference in mean depth of mulching (i.e. 19.9 and 21.9 cm). As stated by Naderloo et al. (2009); the increased PTO speed of tractor contributes towards higher depth of mulching which is in line with the results of this study.

Effect of tractor’s forward and PTO speeds on the depth of mulching

Figure 8 shows that 540 and 1000 RPM of PTO speeds at 1 and 3 km/h speed of tractor have no significantly different effect on mulching depth. PTO speed of 1000 RPM and forward speed of 5 km/h acted differently from all other speed combinations and mulched oil palm fronds at the greater depth of 22.93 cm. Generally, combination of the tractor’s forward and PTO speeds have little significance in evaluating the depth of mulching oil palm fronds in field operation.

Effect of blade lifting angles, tractor’s forward and PTO speeds on mulching depth

Variance analysis showed that there is a significant interaction effect (P≤0.05) of blade lifting angles, tractor’s forward speeds and tractor’s PTO speed on mulching depth (Table 1). At 540 PTO RPM and 1 km/h, blade lifting angle of 120o has significantly different effect on mulching depth (i.e. 15.1 cm) as compared to the blade lifting angles of 0o, 60o and 150o (Table 2). Similarly, at 540 PTO RPM and 3 km/h, blade lifting angle of 150o is significantly different at 17.3 cm mulching depth from other blade lifting angles except 60o which resulted mulching at 18.9 cm. At 540 PTO RPM and 5 km/h, blade lifting angles of 60o and 120o have significantly different effects on mulching depth as compared to the blade lifting angles of 0o and 150o but mutually blade lifting angles of 60o and 120o are not significantly different resulting 15.09 and 16.25 cm mulching depths.

For 1000 PTO RPM and 1 km/h forward speed, blade lifting angle of 60o mulched the oil palm fronds at significantly shallow depth of 14.8 cm as compared to all other blade lifting angles. On the other hand, for same PTO RPM at 3 km/h, blade lifting angle of 60o and 120o acted differently from blade lifting angles of 0o and 150o at 15.9 cm and 14.2 cm mulching depths. Further, for 1000 PTO RPM and 5 km/h, blades at lifting angle of 150o significantly penetrated deep in the soil up to 26.4 cm (Table 2).

Multiple linear regression model for estimation of mulching depth

Multiple linear regression was performed to predict the mulching depth considering tractor’s forward speed, tractor’s PTO speed and blade lifting angles. The results of multiple linear regression model were significant at p= 0.0435 and R2= 0.792 as shown in Table 3.

Table 2: Effect of blade lifting angles, tractor’s forward speed and tractor’s PTO speed on the depth of mulching.

| Tractor’s PTO speed | 540 RPM | 1000 RPM | Mean±SEM | |||||

| Tractor’s forward speed | 1 km/h | 3 km/h | 5 km/h | 1 km/h | 3 km/h | 5 km/h | ||

| Blade lifting angles | 0° |

20.25efgh |

20.85efgh |

21.18efgh |

22.86ghi |

20.52efgh |

21.95fgh |

21.27B±0.4 |

| 60° |

21.35fgh |

18.93defgh |

15.09abc |

14.83ab |

15.91abcd |

21.22efgh |

17.89A±1.23 |

|

| 120° |

15.17abcd |

19.10defg |

16.25abcd |

18.22bcdef |

14.20a |

22.13fgh |

17.51A±1.19 |

|

| 150° |

19.02cdefg |

17.30abcde |

23.42hi |

18.27bcdef |

21.04efgh |

26.41i |

20.91B±1.42 |

|

| Mean±SEM |

18.95A±1.35 |

19.05A±0.73 |

18.99 A ±1.98 |

18.55A±1.65 |

17.92A±1.69 |

22.93B±1.18 |

||

Means having the same letters are not significantly different within the column at P≤0.05 level using Tukey’s test.

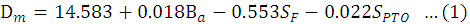

Linear prediction equation with its coefficient in Equation 1 showed that approximately 79% of the mulching depth variance can be explained by blade lifting angles, tractor’s forward speed and tractor’s PTO speed. Table 4 shows that blade lifting angles were not significant predictors of mulching depth at t= 0.193, p= 0.847 while tractor’s forward and PTO speeds are significant predictors of mulching depth.

Where;

Dm= depth of mulching; Ba= blade lifting angles; SF= tractor’s forward speed; SPTO= tractor’s PTO speed.

Table 3: Linear regression model summary.

| Model | Sig. F | R2 | Adj. R2 |

| Linear | 0.0235 | 0.794 | 0.7103 |

Table 4: Linear regression coefficients.

| Variables | Coefficients | t-Stat | P-value |

| Intercept | 14.583 | 3.298 | 0.002 |

|

Ba |

0.018 | 0.193 | 0.847 |

|

SF |

0.553 | 2.471 | 0.016 |

|

SPTO |

0.022 | 2.099 | 0.044 |

Conclusions and Recommendations

It has been found that tractor mounted mulcher blades are ideal for mulching oil palm fronds at various mulching depths. Based on the above results, the blade lifting angles, tractor’s forward speed and tractor’s PTO speed combinations have significant influence on the blade depth with a lifting angle of 120o, resulting in a minimum mulching depth at a tractor’s forward speed of 5 km/h. In conclusion, the prescribed blade lifting angle and tractor’s forward speed must be adjusted for the achievement of proper shallow mulching depth. This will help to minimize the damage to the roots of oil palm while mulching oil palm fronds. The generated multiple linear regression model can be used for the adjustment of blade lift angles and tractor’s speed to achieve the required mulching depth during field maintenance, replanting and access operation for similar design and mulching mode of oil palm fronds.

Acknowledgments

The Howard Alatpertanian Sdn Bhd, Malaysia and the Department of Biological and Agricultural Engineering, Universiti Putra Malaysia, jointly supported this work for the data acquisition instruments purchased using Research Grant No. GP-PPI/2013/9415000.

Novelty Statement

The oil palm roots exist at a shallow depth and are easily damaged during the mulching of the oil palm fronds. This study addresses the problem by developing a multiple linear regression model to predict appropriate blade lift angles and tractor speed for the achievement of optimal and secure mulching depth during the field maintenance, replanting and access operation.

Author’s Contributions

Bala Gambo Jahun, Desa bin Ahmad and Muhammad Razif Mahdi mainly planned the study and Bala Gambo Jahun collected the data. Bala Gambo Jahun and Muhammad Yamin have written the manuscript in coordination with Shamsuddin Suleiman and Salihu Ahmad Abdulkadir.

Conflict of interest

Authors claim no conflict of interest.

References

Abdullah, N., F. Sulaiman and Z. Aliasak. 2013. A case study of pyrolysis of oil palm wastes in Malaysia. AIP Conf. Proc. Am. Inst. Phys. pp. 331-336. https://doi.org/10.1063/1.4803619

Aljuboori, A.H.R., 2013. Oil palm biomass residue in Malaysia: Availability and sustainability. Int. J. Biomass Renewables. 2: 13-18.

Andrejs, V., 2006. Possibilities to reduce energy intensity of mulching in dependence on quality of work. Czech Univ. Life Sci. Prague, Prague, Czech Republic.

Bayala, J., G. Sileshi, R. Coe, A. Kalinganire, Z. Tchoundjeu, F. Sinclair and D. Garrity. 2012. Cereal yield response to conservation agriculture practices in drylands of West Africa: a quantitative synthesis. J. Arid Environ. 78: 13-25. https://doi.org/10.1016/j.jaridenv.2011.10.011

Haafiz, M.M., A. Hassan, Z. Zakaria and I. Inuwa. 2014. Isolation and characterization of cellulose nanowhiskers from oil palm biomass microcrystalline cellulose. Carbohydr. Polym. 103: 119-125. https://doi.org/10.1016/j.carbpol.2013.11.055

Jones, O., R. Allen and P. Unger. 1990. Tillage systems and equipment for dryland farming. Adv. Soil Sci. Springer. https://doi.org/10.1007/978-1-4613-8982-8_5

Makange, N. and V. Tiwari. 2015. Effect of horizontal and vertical axis rotavators on soil physical properties and energy requirement. Trends Biosci. 8: 3225-3234.

Mandal, S.K., B. Bhattacharya and S. Mukherjee. 2013. Optimization of design parameters for rotary tiller’s blade. Power. 4: 5.

Naderloo, L., R. Alimadani, A. Akram, P. Javadikia and H.Z. Khanghah. 2009. 1805101. Tillage depth and forward speed effects on draft of three primary tillage implements in clay loam soil. J. Food, Agric. Environ. 7: 382-385.

Nalavade, P.P., P. Soni, V.M. Salokhe and T. Niyamapa. 2011. Application of powered disc implements for efficient on-farm residue management: a review. Int. Agric. Eng. J. 20: 1-7.

Olatunji, O. and R. Davies. 2009. Effect of weight and draught on the performance of disc plough on sandy-loam soil. Res. J. Appl. Sci. Eng. Technol. 1: 22-26.

Perdok, U. and J. Kouwenhoven. 1994. Soil-tool interactions and field performance of implements. Soil Tillage Res. 30: 283-326. https://doi.org/10.1016/0167-1987(94)90008-6

Raper, R., 2002. The influence of implement type, tillage depth, and tillage timing on residue burial. Trans. ASAE. 45: 1281. https://doi.org/10.13031/2013.11056

Shamshiri, R.R., I.A. Hameed, S.K. Balasundram, D. Ahmad, C. Weltzien and M. Yamin. 2018. Fundamental research on unmanned aerial vehicles to support precision agriculture in oil palm plantations. Agric. Robots-Fundam. Appl.

Syrový, O., M. Světlík, R. Pražan, Z. Pastorek, K. Kubín and I. Gerndtová. 2013. Mobilní energetické prostředky a orientační hodnoty jednotkových spotřeb paliv a energií (Mobile energy devices and the approximate values of unit fuel and energy consumption). Res. Inst. Agric. Eng. Pri, Prague.

Taniguchi, T., J. Makanga, K. Ohtomo and T. Kishimoto. 1999. Draft and soil manipulation by amoldboard plow under different forward speed and body attachments. Trans. ASAE. 42: 1517. https://doi.org/10.13031/2013.13315

To share on other social networks, click on any share button. What are these?