Modification and Performance Evaluation of Fertilizer Band Placement Drill Machine for Wheat Crop in Rain-Fed Areas

Modification and Performance Evaluation of Fertilizer Band Placement Drill Machine for Wheat Crop in Rain-Fed Areas

Muhammad Adnan Islam1*, Zia-Ul-Haq2, Rana Shahzad Noor2, Matiullah Khan4, Muhammad Mohsin Ali1, Zulfiqar Ali3, Asif Ali Mirani3, Hafiz Sultan Mahmood1, Muzammil Husain1 and Badar Munir Khan Niazi1

Already developed fertilizer band placement drill.

Drive wheel mounted at rear fertilizer band placement drill.

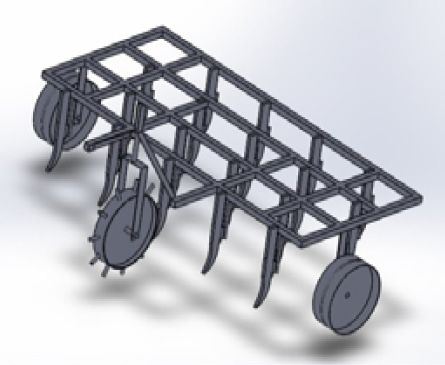

Top view of the drill.

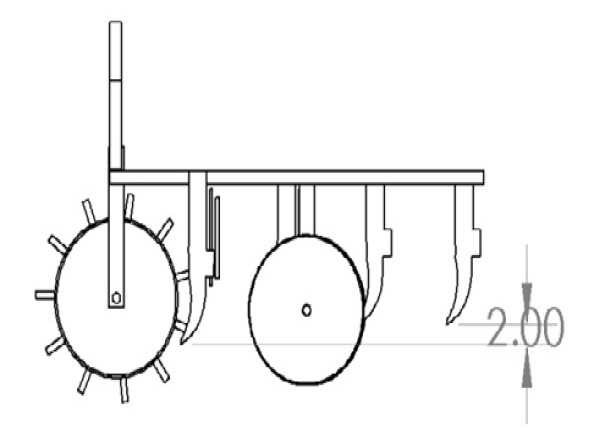

Front view of the drill.

Side view of the drill.

Isometric view of the drill.

Modified Fertilizer band placement drill.

Drive wheel mounted at front.

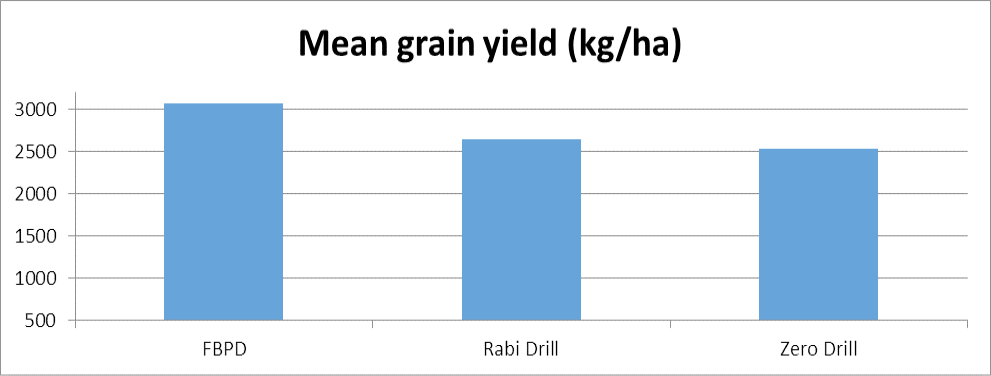

Shows mean grain yield (kg/ha) under Fertilizer band placement drill, Rabi drill and zero drill.

Cost comparison between Conventional drill, Fertilizer band placement drill and modified fertilizer band placement drill (Rs/h) and (Rs/ha).