Hydroponics Production Function, Returns to Scale and Domestic Resource Cost in Pakistan

Hydroponics Production Function, Returns to Scale and Domestic Resource Cost in Pakistan

Arshad Mahmood Malik1*, Khalid Mahmood Mughal2 and Abdul Saboor3

1Assistant Professor, Department of Economics, PMAS-Arid Agriculture University Rawalpindi, Pakistan; 2Associate Professor, Department of Economics, Preston University Kohat, Islamabad Campus, Pakistan; 3Dean and Professor, Faculty of Social Sciences, PMAS-Arid Agriculture University Rawalpindi, Pakistan.

Abstract | Hydroponics production function provides technically efficient production system in the globe. Technological development is changing the shape of production systems all over the world. A Cobb Douglas type hydroponics production system was developed for estimation of production elasticity of hydroponics in Pakistan. Return to scale was calculated by adding all betas, which indicate the stage of production function of hydroponics system. Domestic resource cost indicates relative efficiency of hydroponics products in domestic resource use. Results indicated that labor used in production of hydroponics products and supply chain management of hydroponics products both in the domestic market and in regional markets has significantly affecting total value product of the hydroponics. Return to scale value of 1.77 indicated that the product function is positive and increasing return to scale in TVP in relation to increase in input cost. The value of (DRC<1) indicated that Pakistan has comparative advantage in the efficiently utilizing domestic resources in the production of hydroponics products.

Received | May 13, 2019; Accepted | May 22, 2019; Published | June 29, 2019

*Correspondence | Arshad Mahmood Malik, Assistant Professor, Department of Economics, PMAS-Arid Agriculture University Rawalpindi, Pakistan; Email: [email protected]

Citation | Malik, A.M., K.M. Mughal and A. Saboor. 2019. Hydroponics production function, returns to scale and domestic resource cost in Pakistan. Pakistan Journal of Agricultural Research, 32(3): 449-455.

DOI | http://dx.doi.org/10.17582/journal.pjar/2019/32.3.449.455

Keywords | Hydroponics, Production function, Return to scale, DRC, Pakistan

Introduction

Hydroponics production system has the potential to revolutionize agricultural production and ensure food security in the era of accelerating urbanization. Hydroponics is a dynamic system of multifarious symmetric interactions (Lindsay, 1979; Tan, 1993; Peverill et al., 1999; Essington, 2004; J.B. Jones, 2016). Hydroponics technology was tested in many countries and found successful in terms of productivity enhancement and food safety. Developed countries are promoting the technology for food security and safety. Future food insecurity is a critical issue among masses. Developing countries were facing serious issue of food insecurity and solution of this issue lies in the adoption of modern technology like hydroponics for improving productivity and production without compromising food safety. Pakistan tested this technology at commercial scale and found it successful (Malik et al., 2018, 2014). Development of hydroponics Production function will support in improving productivity and efficiency of the system. Return to scale helped in estimating the production stage of the technology. Domestic resource cost helped in estimating export earnings of the one rupee spent on hydroponics technology.

Developed countries producing commercial hydroponics products and capturing the market of developing countries. To combat this situation, hydroponic vegetable production system was introduced at research scale and was successful. Commercial hydroponics is yet a dream in developing countries. In 2006, a private company introduced commercial hydroponics and, on its failure, donated the green houses to PMAS-Arid Agriculture University Rawalpindi. Hydroponics is an extension of a traditional agriculture production system which limits efficient use of scarce resources. Farm productivity assessment and resource use efficiency provide a path to change conventional agriculture production system. Production always meant to improve productivity through improving factor transformation. Many studies focused on input output space and technological improvement. Identified cause of low productivity was poor marginal productivity. Hydroponics is a high tech. system which stimulate employment (Van Roy, Vértesy and Vivarelli, 2018).

The population is still rising and needs more increase in productivity to overcome rising population demand in the country. Improvement in resource efficiency and factor productivity can increased output. Pakistan is facing the challenge of relatively poor productivity (Arifullah et al., 2009).

Materials and Methods

Primary data was collected from hydroponics firm on monthly basis from last nine years was collected using well-structured questionnaire. Target variables were input and output variables.

Estimation of hydroponics production function

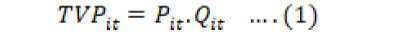

Monthly revenue generation of hydroponic firm was the lifeline of functioning of hydroponics system. Revenue generation was defined as the product of price of the product and quantity of the product sold. It was also called total value product (TVP) (Debertin, 2012) as given in Equation 1.

Where;

TVP was total value product, P was market price of the product, Q was the quantity sold, i was the type of product and t was the time of selling of the product.

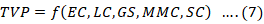

Many factors were identified for better performance of hydroponics production system to improve efficiency which directly affects TVP. In aquaponics production system factors identified as 1) primary source of business, 2) location, 3) gross sale revenue, 4) knowledge of the system, 5) sale of non-food products (Love et al., 2015). In present study, various factors affect TVP of hydroponics firm were energy, labour, growing supplies (inputs), marketing mix costs and supply chain management cost.

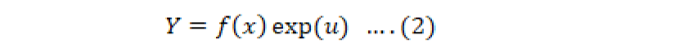

Cobb Douglas type production function of the hydroponics firm yielded better results in different previous studies in terms of statistical significance and expected signs of parameters (Banaeian et al., 2011; Hatirli, Ozkan and Fert, 2006; Singh, Singh and Singh, 2004). The Cobb Douglas type production function can be expressed as in Equation 2.

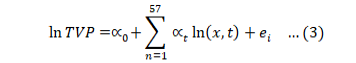

Many authors use this production function to estimate the relationship between input cost and output (Hatirli et al., 2006; Mohammadi and Omid, 2010). Monthly output of hydroponics firm was estimated as the function of cost incurred on electricity, labour cost, growing supply cost, marketing mix cost and supply chain management cost. The mathematical form of the model can be linearized as in Equation 3.

Where;

TVP is the total value product of the hydroponics firm in Rs.; X is the vector of inputs used in hydroponics production function; α0 = constant term; and ei is the error term.

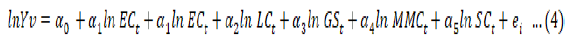

The Equation 3 can be expanded with respect to different cost involved in hydroponics production function in Equation 4.

Where;

Yv= value of output of hydroponics; EC=energy cost; LC= labour cost; GS= growing supplies; MMC=marketing mix cost; SC= supply chain management cost.

In Equation 4, impact of various cost inputs on total value product (TVP) was studied. Estimation method used was ordinary least square (OLS). The data was entered in Excel spread sheet and then transported to IBM SPSS and Eviews 9 for further analysis.

A positive value of coefficients of the Cobb Douglas production function indicates that the hydroponics production was increasing with an increase in input. This also indicates that the increasing use of respective input should not be stopped, until the fixed resource was fully utilized. A negative value of any factor input represents that additional use of this input was adversely affecting the production process (Singh et al., 2004).

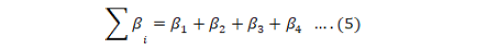

Returns to scale

Returns to scale represents the proportionate change in hydroponics output due to an equi-proportionate change in all factors of production (Singh et al., 2004). In Cobb Douglas Production function, sum of the elasticities (Ʃβi) calculated from the regression coefficients represent the return to scale (Eq-5). In case of decreasing return to scale, the sum of elasticities would be less than one. Sum of elasticities if equal to one represent constant return to scale and greater than one indicates increasing return to scale.

Domestic resource cost of hydroponics and foreign market competitiveness

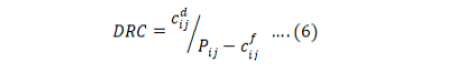

Domestic resource cost concept as presented by (Bruno, 1965), measures relative efficiency of hydroponics products in domestic resource utilization and was used to represent Pakistan’s comparative advantage in the production of hydroponics products.

In hydroponics production system different kinds of factor costs were involved. Some of the inputs were available in the country and others were imported from different regions. DRC help in determining the shadow prices of hydroponics. Following equation was used to determine the DRC of hydroponics (Equation 6).

Where;

Cijd and Cijf = cost of domestic and foreign resources and non-traded inputs for hydroponics tomato production. Pij = Border Price of hydroponics products.

If domestic resource cost of hydroponics was less than one (DRC<1), it represents its value as positive and welfare effects on economy, the country should produce the hydroponics crop locally and should save the precious foreign exchange from import of inputs. A negative value of domestic resource cost will be when DRC was greater than one (DRC>1), benefits are negative; the country should be careful in the production of the crop locally and should import (Anjum and Barmon, 2017).

Results and Discussions

Hydroponics production function

Total value product (TVP) of hydroponics was the function of costs incurred on hydroniums. Cobb Douglas type production function was used to describe hydroponics production process. TVP was the dependent variable of the model and labour and capital costs were independent variables of the model. Capital cost of hydroponics production system was disaggregated to identify most important variable in the production process. Capital cost was divided into two major components of input cost and marketing cost. Input cost was subdivided into growing supplies cost and energy costs. Marketing cost was also further subdivided into supply chain management cost and marketing mix costs (Figure 1).

The daily data collected from hydroponics firm was aggregated into monthly observations with a total number of 57 months. Due to limitation of observations, partial regression was carried out to highlight the contribution of variable cost items on total value (Debertin, 2012) product in hydroponics production system. Total value product of hydroponics firm in Rs. is the function of labour cost, energy cost incurred on hydroponics, growing supplies cost, marketing mix cost and supply chain management cost. Functional form of the model was given in Equation 7.

Where;

TVP= total value product; EC=energy cost; LC= labour cost; GS= growing supplies; MC=marketing cost.

Coefficient of determination of the OLS regression analysis was found to be 55 percent indicating that the factors under study explain 55 percent of variation in dependent variable. In a similar study on vegetables, 54.55 percent R square was noticed (Umar and Abdulkadir, 2015).

Table 1: Summary of Results of Hydroponics Production Function.

| Variable | Coefficient | Std. Error | t-Statistic | Prob. |

| C | -9.627882 | 7.891954 | -1.219962 | 0.2309 |

| Log(Mmix) | 0.044068 | 0.123069 | 0.358073 | 0.7225 |

| Log(Supplychain) | 0.805977 | 0.120417 | 6.693236 | 0.0000 |

| Log(Laborsm) | 1.160774 | 0.519399 | 2.234841 | 0.0321 |

| Log(Inputs) | -0.014772 | 0.106705 | -0.138442 | 0.8907 |

| Log(Energy) | -0.224075 | 0.241138 | -0.929241 | 0.3593 |

Source: Authors own calculations.

Results revealed that supply chain and labour are major determinants of value of the hydroponics products. Both labour and supply chain management cost has positive relationship with dependent variable (Table 1).

Supply chain management is a newly developed area of economics whose importance is increasing day by day. It is a multidisciplinary approach comprising of field of marketing, economics, logistics and organizational behavior which include transaction cost analysis (Hobbs, 1996). Logistic performance is integrated with financial performance (Germain and Iyer, 2006). A one percent increase in supply chain management cost increased value of hydroponics products by 0.81 percent. It has highly significant relationship with dependent variable having probability value of (P<0.01). Results of the present study were consistent with (Germain, 2006). Supply chain management in hydroponics system include carriage inward, carriage outward, vehicle POL expense for supply of FMP products to the local market and to the airport. It also includes freight charges in case of CNF prices offered to the customer. Mostly FMP offered CNF prices to the customers.

Average export freight expense calculated was US $ 1.1 per kg. The dominant expanse in hydroponics products was freight charges spent on export of hydroponics products (83 percent) because on an average, 73 percent of hydroponics products are exported due to high export intensity of the products (Malik, Mughal, Mian et al., 2018). The results are consistent with (Banaeian et al., 2011) while discussing cost and production function of hydroponics identified transportation cost as the most important and only highly significant cost in hydroponics production in Iran.

Other important cost in supply chain management includes both backward and forward supply chain management cost. Input supply chain management cost was found to be nine percent of the total supply chain management cost. Inland output supply chain cost was comprised of eight percent of the total supply chain management cost (Figure 2).

Labour is an important factor of production in economics. The reward of labor is wages. In Pakistan two types of wage structure exist. First one is permanent labour and hired labour and contractual labour. In FMP hydroponics contractual and casual hired labour was used. Contractual staff includes management, technical and administration staff. Results revealed that one percent increase in labor cost would increase value of hydroponics products by 1.16 percent. It has significant effect on hydroponics productivity. Positive relationship indicated that when labour in hydroponics increased productivity and revenue in hydroponics increased (Table 1) significantly. In a similar study on tomato in Nigeria, labour was found to be significantly affecting production (Umar and Abdulkadir, 2015). Semiskilled labour including greenhouse squad constitutes 52 percent and unskilled labour 28 percent are the major labour force of hydroponics production system (Figure 3).

Input use and energy has negative relationship with the value of hydroponics products produced at FMP. Hydroponics sustainability need abundance of energy (Barbosa et al., 2015). In FMP hydroponics, negative relationship of hydroponics revenue with energy use cost indicates that when energy use increased, Total value product of hydroponics decreased.

Input use is also important in hydroponics production system. Inputs include, minerals and chemicals used in hydroponics, growing supplies, water, and other related input bundle. Increased use of inputs adversely affects the total value product of hydroponics. Both energy and input use have non-significant relationship with value of hydroponics products.

Return to scale in hydroponics

The summation of all the beta coefficient of the cost component was found to be 1.77. This indicated that production function is positive and increasing return to scale in TVP relative to increase in input cost (Table 2).

Table 2: Total revenue of hydroponic firm.

| Year | Total Revenue PKR | Exchange rate Rs./US$ | TR US$ |

| 2009-10 | 32,807,252 | 85.06 | 385,695 |

| 010-11 | 38,554,111 | 85.28 | 452,089 |

| 2011-12 | 39,073,375 | 93.8 | 416,561 |

| 2012-13 | 38,378,709 | 97.85 | 392,220 |

Source: Authors own calculations.

Domestic resource cost of hydroponics products

Domestic Resource Cost (DRC) is generally represents firm’s comparative advantage in the production of hydroponics products in Pakistan. DRC value lower than one indicated that the country has comparative advantage in the utilization of local resource in the crop production and country is efficiently utilizing its domestic resources in the production of the commodity (Cai, Leung and Hishamunda, N., 2009). The DRC of hydroponics remained much lower than one during four years of regular production. This implied that Pakistan has comparative advantage in the production of hydroponics products. The DRC value remained minimum during 2011-12, the year of maximum profit (Table 3).

Table 3: Domestic resource cost of hydroponics products in Pakistan.

| Year | Domestic cost | Foreign cost | TPP | Cd/kg | Cf/kg | DRC |

| 2009-10 | 64,390 | 35,818 | 328,432 | 0.196053 | 0.10906 | 0.2837 |

| 2010-11 | 55,892 | 18,128 | 299,844 | 0.186404 | 0.06046 | 0.2520 |

| 2011-12 | 63,370 | 28,001 | 408,822 | 0.155006 | 0.06849 | 0.2119 |

| 2012-13 | 94,400 | 27,881 | 338,099 | 0.279208 | 0.08246 | 0.3891 |

Source: Author own calculation.

Where; cd was domestic share of cost of production and cf was foreign share in cost of production in hydroponics production. Many countries have comparative advantage in the production of different commodities. Bangladesh has comparative advantage in the production of lentil and mustard on the basis of DRC lower than one (Tithi and Barmon, 2018). Similarly, Bangladesh has comparative advantage in the production of onion as calculated on the basis of DRC (Anjum and Barmon, 2017).

Conclusion and Recommendation

Commercial hydroponic production system was assessed in Pakistan for its resource use efficiency and factor mobility. Key variables of the study included production function analysis, resource efficiency, return to scale and domestic resource cost. Labour use efficiency significantly affects hydroponics productivity. Efficient supply chain management is significantly important in improving output value. Hydroponics production is still in first stage of production function and return to scale is increasing which leads to more input use. Lower DRC value represents domestic resource use efficiency of hydroponics.

On the basis of production function, return to scale and domestic resource cost, hydroponics is only hope of improving productivity in Pakistan.

Authors Contribution

Arshad Mahmood Malik: Conceived the idea, Wrote the abstract, Methodology, Did SPSS analysis, Conclusion, Data collection, Data entry in SPSS and analysis, Result and Discussion, Introduction and References.

Khalid Mahmood Mughal: Conceived the idea of DRC, Technical input at every step, Overall management of the article.

Abdul Saboor: Technical input at every step, Overall management of the article.

References

Anjum, A. and B.K. Barmon. 2017. Profitability and comparative advantage of onion (Allium cepa) production in Bangladesh: An economic study in some selected areas. Agric. 15(2): 66-78. https://doi.org/10.3329/agric.v15i2.35466

Arifullah, S., A. Chishti, M. Zulfiqar, G. Yasmeen, N. Farid and I. Ahmad. 2009. Estimating yield potential of the major crops and its implications for Pakistan’s crops sector. Sarhad J. Agric. 25(4): 611-615.

Banaeian, N., M. Omid and H. Ahmadi. 2011. Energy and economic analysis of greenhouse strawberry production in Tehran province of Iran. Energy Convers. Manage. 52(2): 1020-1025. https://doi.org/10.1016/j.enconman.2010.08.030

Barbosa, G. L., Gadelha, F. D. A., Kublik, N., Proctor, A., Reichelm, L., Weissinger, E., . . . & Halden, R. U. (2015). Comparison of land, water, and energy requirements of lettuce grown using hydroponic vs. conventional agricultural methods. Int. J. Environ. Res. Pub. Health. 12(6): 6879-6891.

Bruno, M. 1965. The optimal selection of export-promoting and import-substituting projects. Project Quant. Res. Econ. Dev. Center Int. Aff. Harv. Univ.

Cai, J., P. Leung and N. Hishamunda. 2009. Assessment of comparative advantage in aquaculture: framework and application on selected species in developing countries. FAO Fish. Aquacult. Tech. Paper. (528).

Debertin, D.L. 2012. Agricultural production economics.

Essington, M.E. 2004. Soil and chemistry. An integrated approach, CRC Press, Boca Raton, FL.

Germain, R. and K.N. Iyer. 2006. The interaction of internal and downstream integration and its association with performance. J. Bus. Log. 27(2): 29-52. https://doi.org/10.1002/j.2158-1592.2006.tb00216.x

Hatirli, S.A., B. Ozkan and C. Fert. 2006. Energy inputs and crop yield relationship in greenhouse tomato production. Renewable Energy. 31(4): 427-438. https://doi.org/10.1016/j.renene.2005.04.007

Hobbs, J. E. (1996). A transaction cost approach to supply chain management. Supply Chain Manag. An Int. J. 1(2): 15-27.

Jones Jr, J.B. 2016. Hydroponics: a practical guide for the soilless grower. CRC press.

Lindsay, W.L. 1979. Chemical equilibria in soils. John Willey and Sons. New York.

Love, D.C., J.P. Fry, X. Li, E.S. Hill, L. Genello, K. Semmens and R.E. Thompson. 2015. Commercial aquaponics production and profitability: Findings from an international survey. Aquacult. 435. 67-74. https://doi.org/10.1016/j.aquaculture.2014.09.023

Malik, A.M., K.M. Mughal, S.A. Mian and M.A.U. Khan. 2018. Hydroponic tomato production and productivity improvement in Pakistan. Pak. J. Agric. Res. 31(2): 133-144. https://doi.org/10.17582/journal.pjar/2018/31.2.133.144

Mohammadi, A. and M. Omid. 2010. Economical analysis and relation between energy inputs and yield of greenhouse cucumber production in Iran. Appl. Energy. 87(1): 191-196. https://doi.org/10.1016/j.apenergy.2009.07.021

Peverill, K.I., L.A. Sparrow and D.J. Reuter (Eds.). 1999. Soil analysis: An interpretation manual, CSIRO Publ. Collingwood, Australia. https://doi.org/10.1071/9780643101357

Singh, G., S. Singh and J. Singh. 2004. Optimization of energy inputs for wheat crop in Punjab. Energy Convers. Manage. 45(3): 453-465. https://doi.org/10.1016/S0196-8904(03)00155-9

Tan, K.H. 1993. Principles of soil chemistry, 2nd ed., Marcel Dekker, New York.

Tithi, S.M. and B.K. Barmon. 2018. Comparative advantages of lentil (Lens culinaris) and mustard (Brassica nigra L.) production and their profitability in a selected district of Bangladesh. Agric. 16(1): 21-33. https://doi.org/10.3329/agric.v16i1.37531

Umar, A. and M. Abdulkadir. 2015. Analysis of resource-use efficiency and productivity of residual soil moisture tomato production in Kaduna State, Nigeria. Int. Lett. Soc. Human. Sci. 51: 152-157. https://doi.org/10.18052/www.scipress.com/ILSHS.51.152

Van Roy, V., D. Vértesy and M. Vivarelli. 2018. Technology and employment: Mass unemployment or job creation? Empirical evidence from European patenting firms. Res. Policy. 47(9): 1762-1776. https://doi.org/10.1016/j.respol.2018.06.008

To share on other social networks, click on any share button. What are these?