Grain Losses and Head Rice Yield of Paddy Under Different Harvesting Methods

Research Article

Grain Losses and Head Rice Yield of Paddy Under Different Harvesting Methods

Muddassir Ali, Fraz Ahmad Khan*, Mohsin Ali Raza, Muhammad Shahid Munir and Muhammad Usman Saleem

Rice Research Institute, Kala Shah Kaku, Sheikhupura, 39018, Pakistan.

Abstract | Rice harvesting is generally done by hand or with a combine harvester. The major challenges include loss of yield and quality during the harvesting process. Rice yield and quality losses may be minimized with the use of a suitable harvesting method. This study aims to evaluate the different paddy harvesting methods in terms of grain losses and head rice yield. This research evaluated the three harvesting methods: a Head-feed harvester (model PRO-588I-G, Kubota, Japan), a Whole-stalk harvester (model 8060, NH, Italy), and manual harvesting. The experiments were carried out on an area of 12,060 m2 with a complete randomized design (CRD) and three replications during the year 2021. The yield-related crop parameters were measured before harvesting. All crop parameters were non-significant except for the productive tiller, filled and unfilled grain, and 1000-grain weight which were significant at p < 0.05. The grain moisture content during harvesting was 21% which was within the recommended range. The effect of harvesting methods on grain losses and head rice yield was highly significant at p < 0.01. Higher grain losses (10.73%) and lower head rice yield (15.40%) were found in the Whole-stalk harvester. Lower grain losses (4.78% and 2.96%) and greater head rice yields (31.73% and 29.73%) were obtained using Head-feed harvesters and manual harvesting, respectively. In conclusion, the Head-feed combine harvesters are found to be a more practical choice for paddy harvesting.

Received | March 21, 2024; Accepted | May 20, 2024; Published | June 05, 2024

*Correspondence | Fraz Ahmad Khan, Rice Research Institute, Kala Shah Kaku, Sheikhupura, 39018, Pakistan; Email: fraz465@gmail.com

Citation | Ali, M., F.A. Khan, M.A. Raza, M.S. Munir and M.U. Saleem. 2024. Grain losses and head rice yield of paddy under different harvesting methods. Pakistan Journal of Agricultural Research, 37(2): 127-133.

DOI | https://dx.doi.org/10.17582/journal.pjar/2024/37.2.127.133

Keywords | Paddy, Grain losses, Head rice yield, Head-feed harvester, Whole-stalk harvester, Manual harvesting

Copyright: 2024 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Rice (Oryza sativa L.) is one of the most significant crops and the staple food of almost half of the world’s population. The demand for rice is increasing; therefore, it is imperative to adopt the right technologies to preserve biodiversity and the environment while increasing productivity on the same amount of land. Given limited land resources, reducing paddy losses is essential at each stage of the rice production process to ensure its safety. In rice cultivation, time is critical since late or early harvests reduce the amount and quality of rice that can be recovered. Rice yield will certainly decrease if harvesting is delayed or hastened, affecting resource consumption and environmental sustainability. Although timely rice harvesting ensures improved yields and good quality, farmers usually harvest transplanted rice before or after it reaches full maturity, consequently reducing their earnings (Wang et al., 2021).

Mechanized harvesting is required due to rice’s enormous planting area and timely harvesting of the crop. As a result, reviewing harvesting methods is critical for enhancing yield and quality, boosting farmer revenue, and encouraging sustainable agricultural growth. Reducing losses in combined harvesters requires careful management of mechanical losses. During the harvesting process, these losses are inevitable; however, they can be reduced with suitable measures (Wang et al., 2021). Some investigations have analyzed mechanical loss during rice harvesting. Khir et al. (2017) evaluated harvesting losses caused by several harvesters and headers in different weather situations. Adisa et al. (2016) found that the important operational parameters of rice harvesting greatly impacted its performance. The optimal values for rotor height, stripper rotor speed, and forward speed were determined to be 270 mm, 17.55 m/s, and 3 km/h, respectively. Additionally, the differences in harvesting losses between manual and combined harvesting have been covered in certain research. Allameh and Alizadeh (2020) evaluated the performance of five harvesting practices. They found that the effective field capacity was highest for whole-crop combine (0.361 ha/h) and lowest for hand harvesting (0.009 ha/h). The average losses during grain and panicle shattering were 2.33% and 2.58% for combined harvesters (head-feed and whole-crop) and manual harvesting (manual cutting + threshing, reaper + thresher, reaper + universal harvester), respectively. The quality losses, such as broken, husked, and cracked grains, were 0.61% for combined harvesters and 2.30% for manual harvesting. Total harvesting losses were 5.07% for the reaper + universal harvester and 2.74% for the head-feed combine harvester.

Producing rice of superior quality is key to the rising selling of rice, especially rice with a high head rice yield. Several variables influence head rice yield before, during, and after harvesting. When the moisture content of the rice harvest exceeds the optimal range, the rice grains yield, milled rice %, and the head rice yield all decrease while drying costs increase. Head rice yield increases when grains are filled and the immature grain proportion decreases (Thompson and Mutters, 2006). Bunna et al. (2018) found that, compared to crops harvested 35 and 45 days after harvesting, head rice yield was greater when the crop was harvested 25 days after flowering. Grain moisture content frequently decreased and fissured grain increased with the postponement of harvest. However, because there was significant fluctuation in head rice yield for a given grain moisture content, it was determined that grain moisture content was not a reliable prediction of the best harvest time. Xangsayasane et al. (2019) observed that the head rice yield dropped when harvesting time was extended from 25 to 30 and then to 35 days. Thus, harvesting had a great impact on grain yield and quality. It is; therefore, the objective of the study was to evaluate the different harvesting practices in terms of grain losses and head rice yield.

Materials and Methods

Experimental site

The trial was carried out at Rice Research Institute, Kala Shah Kaku, Sheikhupura, Punjab, Pakistan (31.7214o N, 74.2702o E) in the rice seasons of 2021-2022 (Figure 1). The average yearly rainfall is around 585 mm, and the climate is subtropical and subhumid (Zahid et al., 2020). The highest temperature recorded each year ranged from 36 to 42 °C, with summer maxima reaching 48 °C and winter lows reaching 4-6 °C. The annual light duration from January to May ranged from 5.1 to 10.4 hours, while the relative humidity levels from May to September fluctuated from 35-70%. The region’s soil type is Bahalike series loam (Zahid et al., 2020).

Crop sowing and husbandry

The Kisan Basmati variety was used with a 25 kg/ha seed rate, to develop the nursery. The crop was transplanted after 25 days using an eight-row transplanter (model 2ZG-8S2, Wishope, China) with plant-to-plant space of 15 cm and 30 cm row-to-row space. The crop was given 133:82:62 kg/ha doses of Nitrogen (N), Phosphorus (P2O5), and Potassium (K2O), respectively. The P2O5, K2O, and N were used as a base at a rate of 82 kg/ha, 62 kg/ha, and 66.5 kg/ha, respectively while the rest (N) was applied during the booting stage. Regarding weeds, proper flooding was used to control biotypes.

Experimental procedure

The three harvesting practices such as Head-feed combine harvester, Whole-stalk combine harvester, and manual (Sickle + manual shattering) harvesting were used as experimental treatments. An area of 180 m × 67 m was used in the experiment. The area was divided into 3 plots, one for each treatment. Each plot area was 60 m × 67 m. The CRD experimental design with three replications was used. The rice crop was harvested 25-30 days after flowering as suggested by researchers (Bunna et al., 2019).

Manual harvesting

Using the quadrat, three samples were chosen at random. Each sample area measured 3m2. The rice crop was harvested using a sickle. It was then spread out on stubble to dry for a day or two before being bundled and manually threshed in the field (Figure 2).

Following threshing, the grain was cleaned, its weight and moisture content was calculated, and its yield was stated at 14% moisture content. Grain losses (shattering and threshing) were estimated using the approach described by Gummert et al. (2020).

Machine harvesting

The Head-feed combine harvester (PRO-588I-G, Kubota, Japan) and Whole-stalk combine harvester (model 8060, New Holland, Italy) were used in the experiment (Figure 3). Depending on the state of the rice crop, the combine operators were instructed to work at the proper speed. The forward speed and threshing drum speeds were 2 to 3.5 km/h and 500-600 rpm, respectively (Feliz et al., 2005). After harvesting the paddy rice crop samples, the weight and moisture content of the grain were determined. Grain losses (shattering and threshing) by combine harvesters were estimated using the approach described by Gummert et al. (2020), although the sampled area was 22 m2 for both combine harvesters (Figure 4). Three samples were collected.

Crop parameters

The yield-related parameters such as plant height (cm), panicle length (cm), grain yield (t/ha), productive and unproductive tillers (no. per m2), 1000-grain weight (g), filled and unfilled grains (no. per panicle), and biomass yield were determined at the harvesting stage. The productive and unproductive tillers (no. per m2) were determined using a 1.0 m2 quadrant randomly put in each plot at three different places. Simultaneously, ten plants from each plot were chosen randomly to determine phenological data such as plant height, panicle length, and filled and unfilled grain (no. per panicle). In the middle of each plot, a 9 m2 area was used to determine grain yield. Using a moisture meter (Riceter f506, Kett, Japan), the moisture content of the grains was determined for each plot. At 14% moisture content, the grain yield (ka/ha) was computed. The weight of 1000-grain was determined by counting and weighing each sample using an analytical balance (Italiana Macchi TB Series, Gallarate VA, Italy). The straw’s moisture content was evaluated by oven-drying a 500 g sample at 70 oC for 72 hours. At 0% moisture content, the straw yield (ka/ha) was computed.

Head rice yield

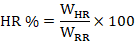

The head rice yield was determined in this study. The sample size was 2 kg for each treatment. Head rice yield: The percentage of unbroken white rice recovered following milling is called head rice yield (Sultana et al., 2022). The procedure typically comprises five crucial steps. Firstly, samples were dried to 12% using a testing dryer (Satake Engineering Co., LTD, Ueno Taito-Ku, Tokyo, Japan). After that, cleaning was done using a cleaner (ALMCO, 99.M Ave Nevada, IOWA, 50201, USA). Secondly, husking and polishing were carried out using the husking machine (THU 35 A Satake Engineering Co., LTD, Ueno Taito-Ku, Tokyo, Japan) and polisher (model: 65-220-50-3, Grain Machinery Mfg. Corp. 1130 NW 163 Drive, Miami, FL, 33169, USA), respectively. Thirdly, grading was done to separate the unbroken kernels from the grains (Nawaz Engineering (Pvt.) Ltd, Sheikhupura, Pakistan) (Sultana et al., 2022) (Figure 5). For calculating head rice % the following formula was used (Sultana et al., 2022).

Where HR is the head rice in %, WHR is the weight of head rice in g, and WRR is the weight of rough rice in g.

Statistical analysis

The SPSS v27.0. ((IBM, SPSS Inc. NY, USA) software was used to perform the ANOVA test. Following that, the Shapiro-Wilk tests (p > 0.05) and Leven’s tests (p > 0.05) were used to validate the error assumptions (homogeneity and normality). Duncan’s test (p ≤ 0.05) was used to differentiate the means for effects that were significant.

Results and Discussion

Crop parameters and their effect on harvesting

Crop parameters were assessed before harvesting operations in terms of plant height (cm), panicle length (cm), productive tiller (no. per m2), unproductive tillers (no. per m2), filled grain (no. per panicle), unfilled grain (no. per panicle), 1000-grain weight (g), biomass yield (t/ha), grain yield (t/ha), plants per m2, and grain moisture content (%) (Table 1). Table 1 shows that the unfilled grain (no. per panicle) was highly significant at p < 0.01, productive tiller (no. per m2), filled grain (no. per panicle), and 1000-grain weight (g) were significant at p < 0.05, and the rest crop parameters were non-significant for all harvesting methods. The healthy crop was selected for trials because the crop health and standing significantly affect the harvesting method performance. Healthy crops and standing provided a higher head rice yield for manual and combined harvesters. Salassi et al. (2013) observed that the head rice yield of all harvesting methods was lower for semi-lodge crops. Some researchers found that crop health affected the head rice yield by harvesting methods and time (Khan and Salim, 2005; Hossain et al., 2009; Roy et al., 2011).

Grain moisture content also affects the performance of the harvesting method and grain quality. According to Siebenmorgen et al. (2006), the ideal moisture level for long-grain paddy ranges from 19 to 22%, whereas medium-grain paddy ranges from 22 to 24%. In our case, the grain moisture content during harvesting was 21% for all harvesting methods.

Table 1: Crop parameters with their significance level.

|

Crop parameters |

Units |

Head-feed harvester |

Whole-stalk harvester |

Manual harvesting |

Harvesting method |

|

PH ± SD |

(cm) |

128±4.04a |

124±4.00a |

122±4.50a |

ns |

|

PL ± SD |

(cm) |

22±0.57a |

22±1.00a |

22±1.52a |

ns |

|

PT ± SD |

(no. per m2) |

229±3.60a |

234±4.00a |

242±5.03b |

* |

|

UPT ± SD |

(no. per m2) |

10±1.52a |

11±2.51a |

12±1.52a |

ns |

|

FG ± SD |

(no. per panicle) |

40±2.00a |

39±2.00a |

45±2.08b |

* |

|

UFG ± SD |

(no. per panicle) |

14±1.00a |

3±1.00b |

9±1.00c |

** |

|

TGW ± SD |

(g) |

27±2.00a |

33±1.00a |

29±1.52b |

* |

|

BY ± SD |

(t/ha) |

9±1.00a |

10±1.52a |

9±1.52a |

ns |

|

GY ± SD |

(t/ha) |

3.99±0.11a |

4±0.14a |

4±0.10a |

ns |

|

P ± SD |

(m-2) |

14±1.52a |

14±2.51a |

14±1.52a |

ns |

|

GMC ± SD |

(%) |

21.2±0.26a |

21.3±0.20a |

21.3±0.20a |

ns |

According to Duncan’s test (0.05), different letters signify that means are significantly different from one another. PH stands for plant height. PL stands for panicle length. PT stands for productive tiller. UPT stands for unproductive tiller. FG stands for filled grain. UFG stands for unfilled grain. TGW stands for 1000-grain weight. BY stands for biomass yield. GY stands for grain yield. P stands for Plants/m2. GMC stands for grain moisture content. SD stands for standard deviation. ns stands for non-significant. Significant values are shown by ** and * at 0.01 and 0.05, respectively.

Table 2: Grain and head rice yield losses with their significance level.

|

Harvesting method |

Grain losses (%) ± SD |

Head rice yield (%) ± SD |

|

Head-feed harvester |

4.78±0.99b |

31.73±2.01b |

|

Whole-stalk harvester |

10.73±0.79c |

15.40±3.13a |

|

Manual harvesting |

2.96±0.15a |

29.73±1.97b |

|

Harvesting method |

** |

** |

According to Duncan’s test (0.05), different letters signify that means are significantly different from one another. SD stands for standard deviation. Significant values are shown by ** at 0.01.

Grain and head rice yield losses

Grain losses (shattering + threshing) during harvesting and head rice yield were measured in this study. Table 2 shows that the effect of harvesting methods on grain losses and head rice yield was highly significant at p < 0.01. The results revealed that the manual harvesting grain losses were less compared to other harvesting methods. On the other hand, the head-feed combine harvester grain losses were 55% less compared to the whole-stalk combine harvester. The head rice yield of the Head-feed harvester was 51.5% and 6.3% higher than the Whole-stalk and manual harvesting methods. The higher grain losses in Whole-stalk harvesters may be due to improper rice kits installed on the harvester or reel shaking effect and its impact force. Khan and Salim (2005) reported that shattering losses increase by up to 12% due to reel shaking and its impact force. The low head rice yield in whole-stalk harvester might be due to threshing grain in repeated quick and severe blows. This causes the rice grains to break during the milling process. Mohtasebi et al. (2006) found that the head rice yield was affected by increased threshing cylinder impact force, moisture content, and feed rate. The lower grain losses and higher head rice yield in head-feed harvesters may be due to being specifically designed for rice crops.

Conclusions and Recommendations

Three paddy harvesting methods such as head-feed harvester, whole-stalk harvester, and manual harvesting were assessed in terms of grain losses and head rice yield. All crop parameters were non-significant except for the productive tiller, filled and unfilled grain, and 1000-grain weight which were significant at p < 0.05. The grain moisture content during harvesting was 21% which was within the recommended range. The effect of harvesting methods on grain losses and head rice yield was highly significant at p < 0.01. Higher grain losses (10.73%) and lower head rice yield (15.40%) were found in the Whole-stalk harvester. Lower grain losses (4.78% and 2.96%) and greater head rice yields (31.73% and 29.73%) were obtained using head-feed harvesters and manual harvesting, respectively. Based on the findings, Head-feed combine harvesters are recommended as a more practical choice for paddy harvesting.

Acknowledgments

Asian Development Bank Knowledge and Support Technical Assistance 2021-22, MESKAY and FEMTEE company, and Mr. Adnan Aslam (Foreman RRI, KSK) are acknowledged for providing support to conduct this study.

Novelty Statement

Evaluating the paddy harvesting methods could guide the rice framer regarding which harvesting method would be beneficial for farm income. The present study suggested that a Head-feed combine harvester is a more suitable method for paddy harvesting because its grain and quality losses are minimal, and it is a time-saving technique.

Author’s Contribution

Muddassir Ali: Conceived idea, execute the experiment, collect the data, and review the article.

Fraz Ahmad Khan: Analyze the data, write up of article, and review the article.

Mohsin Ali Raza: Quality analysis and review of the article.

Muhammad Shahid Munir: Quality analysis and review of the article.

Muhammad Usman Saleem: Field data collection and review of the article.

Conflict of interest

The authors have declared no conflict of interest.

References

Adisa, A.F., V.I.O. Ndirika, Y.D. Yiljep and U.S. Mohammed. 2016. Others Determination of optimum critical operating parameters of stripping rice harvester in a rural area. In Proceedings of the CIGR-AgEng Conference, Aarhus, Denmark, 26–29: 1–10.

Allameh, A. and M.R. Alizadeh. 2020. Rice losses characteristics in various harvesting methods. Agrofor. Int. J., 5(1): 94-103. https://doi.org/10.7251/AGRENG2001094A

Bunna, S., H. Sereyvuth, Y. Somaly, N. Ngoy, L. Mengsry, C. Sareth and S. Fukai. 2018. Head rice yield of crops harvested by combine and hand at different ripening times in Cambodia. Exp. Agric., pp. 1–11. https://doi.org/10.1017/S0014479717000606

Bunna, S., P. Sinath, I.H. Sereyvuth, Y. Somaly, S. Chea, M. Ouk, C. Sinh, N. Lina, H. Sreypov, Y. Rumduol, J. Mitchell and S. Fukai. 2019. Fissured grain and head rice yield of crops harvested manually or by combine at different ripening stages in Cambodia. Plant Prod. Sci., 22(1): 88-97. https://doi.org/10.1080/1343943X.2018.1538700

Feliz, D.J., A. Proctor, M.A. Monsoor and R.L. Eason. 2005. The effects of kernel damage caused by combine harvester settings on milled-rice free fatty acid levels. J. Food Sci., 70: 376-379. https://doi.org/10.1111/j.1365-2621.2005.tb11432.x

Gummert, M., N.V. Hung, C. Cabardo, R. Quilloy, Y.L. Aung, A.M. Thant, M.A. Kyaw, R. Labios, N.M. Htwa and G.R. Singleton. 2020. Assessment of post-harvest losses and carbon footprint in intensive lowland rice production in Myanmar. Sci. Rep., 10: 19797. https://doi.org/10.1038/s41598-020-76639-5

Hossain, M.F., M.S.U. Bhuiya, M. Ahmed and M.H. Mian. 2009. Effect of harvesting time on the milling and physiochemical properties of aromatic rice. Thai J. Agric. Sci., 42: 91-96.

Khan, A.S. and M. Salim, 2005. Rice harvesting and threshing. Pak. J. Food Sci., 15: 45-52.

Khir, R., G. Atungulu, P.M.D. Chao and Z. Pan. 2017. Influence of harvester and weather conditions on field loss and milling quality of rough rice. Int. J. Agric. Biol. Eng., 10(4): 216–223.

Mohtasebi, S.S., M. Behroozi-Lar, J. Alidadi and K. Besharti. 2006. A new design for grain combine thresher. Int. J. Agric. Biol., 8: 680-683.

Roy, P., T. Orikasa, H. Okadome, N. Nakamura and T. Shiina. 2011. Processing conditions, rice properties, health, and environment. Int. J. Environ. Res. Publ. Health, 8: 1957-1976. https://doi.org/10.3390/ijerph8061957

Salassi, M.E., M.A. Deliberto, S.D. Linscombe, C.E. Wilson, T.W. Walker, G.N. McCauley and D.C. Blouin. 2013. Impact of harvest lodging on rough rice milling yield and market price. Agron. J., 105: 1860-1867. https://doi.org/10.2134/agronj2013.0238

Siebenmorgen, T.J., R.C. Bautista and P.A. Counce. 2006. Optimal harvest moisture contents for maximizing rice milling quality. Rice quality and processing, B.R. Wells Res. Stud., pp. 390-401.

Sultana, S., M. Faruque and M.R. Islam. 2022. Rice grain quality parameters and determination tools: A review on the current developments and prospects. Int. J. Food Propt., 25(1): 1063-1078. https://doi.org/10.1080/10942912.2022.2071295

Thompson, J.F. and R.G. Mutters. 2006. Effect of weather and rice moisture at harvest on milling quality of California medium-grain rice. Trans. ASABE, 49(2): 435–440. https://doi.org/10.13031/2013.20392

Wang, J., X. Sun, Y. Xu, W. Zhou, H. Tang and Q. Wang. 2021. Timeliness harvesting loss of rice in cold region under different mechanical harvesting methods. Sustainability, 13: 6345. https://doi.org/10.3390/su13116345

Xangsayasane, P., K. Vongsaiya, S. Phongchanmisai, J.H. Mitchell and S. Fukai. 2019. Rice milling quality as affected by drying method and harvesting time during ripening in wet and dry seasons. Plant Prod. Sci., 22(1): 98-106. https://doi.org/10.1080/1343943X.2018.1544463

Zahid, A., S. Ali, M. Ahmed and N. Iqbal. 2020. Improvement of soil health through residue management and conservation tillage in rice-wheat cropping system of Punjab, Pakistan. Agronomy, 10(12): 1844. https://doi.org/10.3390/agronomy10121844

To share on other social networks, click on any share button. What are these?