Estimation of Technical Efficiency of Broiler Farms in District Mardan, Khyber Pakhtunkhwa

Estimation of Technical Efficiency of Broiler Farms in District Mardan, Khyber Pakhtunkhwa

Nihal Ahmad Hadi, Shahid Ali* and Umer Wahid

Department of Agricultural and Applied Economics, The University of Agriculture, Peshawar-Pakistan

Abstract | This study was carried out to estimate technical efficiency of broiler farms in district Mardan of Khyber Pakhtunkhwa, Pakistan. A multi-stage sampling technique was used to collect data from 150 broiler farmers. A well-structured interview schedule was used with both close and open-ended questions. Data from broiler farmers were collected during April and May 2016. Maximum Likelihood Estimation (MLE) technique was used for estimation of stochastic frontier Cobb-Douglas type production function. Results indicated the mean technical efficiency of 0.89 with the range of 0.63 to 0.97. This implies that farmers having average technical efficiency level can increase broiler output by 8% to reach to the frontier output by using best management practices with available farm resources and technology. Results further revealed that day old checks, feed intake and labor have positive and significant effect on broiler output. Technical inefficiency results showed that estimated coefficients of age of broiler farmers, education and experience were negative and statistically significant. This means that with the increase in age of broiler farmers, education and experience, technical inefficiency decreases. It is recommended that broiler farmers needs to increase the number of day old chicks according to the capacity of shed as well as feed to the broilers to accelerate production and efficiency. Moreover, government also needs to educate broiler farmers and provide trainings specific to rearing of broilers for efficient utilization of resources for enhancing productivity and efficiency.

Received | December 14, 2016; Accepted | April 22, 2018; Published | May 23, 2018

*Correspondence | Shahid Ali, The University of Agriculture, Peshawar-Pakistan; Email: drshahid@aup.edu.pk

Citation | Hadi, N.A., S. Ali and U. Wahid. 2018. Estimation of technical efficiency of broiler farms in District Mardan, Khyber Pakhtunkhwa. Sarhad Journal of Agriculture, 34(2): 349-358.

DOI | http://dx.doi.org/10.17582/journal.sja/2018/34.2.349.358

Keywords | Broiler farms, Technical efficiency, Stochastic Frontier Analysis, Cobb-Douglas Production Function, District Mardan

Introduction

Livestock farming is important contributor to agriculture sector of Pakistan. Being rich source of protein, meat is considered one of the essential source in daily human diet, in which Poultry farming is the leading sector. Poultry contributes 66% to daily human intake of protein from livestock sector. Poultry are reared for the production of meat and eggs around the globe (FAO, 2012). As human population increases, poultry production also increases to fulfill the increasing human demand for poultry meat. Generally, poultry are reared for three main purposes i.e., broiler, layers and breeders. Broilers are raised to provide meat, layers are reared to supply eggs which are rich source of protein and vitamins while breeders are nourished for producing new offsprings (Hamra, 2010).

The economic value of poultry cannot be underestimated; they are highly contributing in GDP and fast growing industry providing large number of employment and animal food production (Adebayo and Adeola, 2005). From 1990’s Commercial poultry industry was emerged with the concentrating techniques of production and getting high popularity (Akhtar and Rashid, 2008). Major exporting countries of broiler are Brazil, US, EU, Thailand and China with the exporting stock of 3665, 3030, 1150, 570 and 430 (‘000’MT), respectively. Major importing countries of broiler are Japan, Saudi Arabia, Mexico and Iraq [United States Department of Agriculture (USDA, 2015).

In Pakistan, commercial poultry farming started in 1963 while in 1965 first modern hatchery was established with the partnership of PIA and Shaver (Canadian Firm) at Karachi (Mohsin et al., 2008). It is the second largest industry of the country after textile increasing with rapid speed (FAO, 2014). Poultry is one of the important sectors of agriculture in Pakistan which annually produce 530 million birds and serves as income source for 1.5 million people. Its contribution in agriculture and livestock growth is 5% and 10%, respectively. It provides 19% of the total meat produced in the country. This sector shows 8-10% of growth annually (Govt. of Sindh, 2013).

There are more than 25000 poultry farm in the country with the capacity of 5000 to 500000 birds per shed. Poultry contributes 35 to 40% of the total meat consumption while 1220 million kilograms of meat was produced per annum. In Pakistan, per capita consumption of meat and eggs is only 6.5 kilograms and 65-70 numbers, respectively while the recommended consumption is about 40 kilograms of meat and more than 300 eggs per year (PPA, 2014).

Poultry are reared in two farming system in Pakistan; one is open shed farm while the other is environmentally controlled shed farm. In Pakistan, open shed poultry farms are decreasing and are replaced by environmentally control shed farms. Poultry farm owners who rear poultry in open sheds are transforming their farms into controlled sheds (The Express Tribune, 2014). Broiler Parent Stock was 8.0 million birds in Pakistan with 68% share coming from Punjab, 30% from Khyber Pakhtunkhwa and 2% from Sindh, respectively while commercial broiler stock was 800 million birds with the share of 70% coming from Punjab, 23% from Sindh, 5% from KPK and 2% from Baluchistan, respectively (PPA, 2012).

As this industry was new in Khyber Pakhtunkhwa therefore in 1990’s broiler farms hit the disease named Gambaro which results a high mortality rate. After few years again a new disease caught the broiler farms in North-Sothern areas where 80% of the birds were effected from this disease and farmers and entrepreneur’s suffered great financial losses, again in 1996 the output price fell down even from cost of production and in next year ban was imposed on food in marriages resulted 40% decrease in consumption of broiler meat (PPA, 2012).

In Khyber Pakhtunkhwa province, Mardan is one of the important districts regarding the industries and other factors that influence the economy of the province. Mardan is the second largest district in growing of poultry farming after Peshawar (Govt. of Khyber Pakhtunkhwa, 2014).

A number of studies were carried on different economic aspects i.e., cost and net retunes, profitability analysis, marketing system etc. of broiler farming at home and abroad as well. No research work in the knowledge of researchers has yet been conducted on the estimation of technical efficiency of open shed broiler farms. Due to the growing demand for broiler meat, growth in broiler productivity is essential. Productivity can be increased either by innovation (introduction of new technology) or efficiency. Introduction of new technology is a long term phenomenon whereas efficiency in productivity can be easily achieved if available resources and technology is judiciously utilized. Therefore, this study was designed to estimate and examine technical efficiency of broiler farms and to identify factors that are responsible for technical inefficiency across broiler farms in district Mardan of Khyber Pakhtunkhwa province.

Hypothesis

H0: Broiler farmers are technically efficient

H1: Broiler farmers are technically inefficient

Research Methodology

Universe of the study

This study was carried out in district Mardan of Khyber Pakhtunkhwa province of Pakistan. Most of the population of this district are residing in rural areas and their professions are farming. They are engaged in agriculture either directly or indirectly.

Sampling technique and sample size

Multistage sampling procedure was used for selection of sampled broiler farms. In first stage, two tehsils namely Mardan and Katlang were randomly selected through simple random sampling. In second stage, three union councils namely Manga, Par Hoti and Sawaldher were randomly selected. In stage third, through proportional allocation sampling procedure 150 broiler farms (Table 1) were randomly selected (Cochran, 1977) as follows:

ni = n (Ni/N) …….. (1)

Where

ni = Sampled broiler farms from ith Union Council.

n = Total sample size.

Ni = Population of broiler farms in ith Union Council.

N = population of broiler farms in study area

Table 1: Sampling technique and sample size

| District | Tehsil | Union Council | Population of broiler farms | Sample size (%) |

| Mardan | Mardan | Manga | 300 | 55 (36) |

| Par Hoti | 250 | 45 (30) | ||

| Katlang | Sawaldher | 270 | 50 (34) | |

| Total | - | - | 820 |

150 (100) |

Source: Broiler dealers of Mardan poultry market, January 2016.

Data collection

Both primary and secondary data was used in this study. Primary data was collected from 150 sampled broiler farmers through a well-structured interview schedule. Data from farmers were gathered through face to face interview at their farms or guest houses (locally known as Hujras). Interview from farmers were conducted in their local language (Pashto). Farmers were informed about the purpose of interview and were taken into confidence that this data would be purely used for academic research. Secondary data for this study was collected from Agriculture Statistics of Pakistan, Pakistan Poultry Association and Food and Agriculture Organization.

Analysis

Data collected on output of broiler in kilograms, inputs used in rearing of broiler, prices of output of broiler and manure and prices of factors involved in production was utilized in analysis as follows:

Cost of production and net revenue from broiler farms

Various costs incurred on the purchase of inputs for broiler farming and revenue generated were calculated as follows (Debertin, 2012; Varian, 1992):

NRi = GRi – TCi…......... ..(2)

Where

GRi = PYi * Yi + PYi * Yi........ (3)

TCi = ∑ PXi * Xi………...... (4)

NRi = Net revenue from ith broiler farm

TCi=Total cost of production of ith broiler farm

GRi = Total revenue from ith broiler farm

PY1i = Price of broiler of ith farm in Rs per kilogram

Y1i = Output of broilers of ith farm in kilograms per shed

PY2i = Price of manure/litter of ith farm per square feet

Y2i = Manure/litter produced by ith farm in square feet per shed

Xi = Quantities of inputs used ith farm (unit)

PXi = Prices of inputs used in ith farm per unit

All the prices are are in PKR.

Purchased prices of day old chicks (DOC), feed, vaccines, hired labor, electricity, litter and transportation were considered, for land rent, the actual cash paid to the owner was taken, while for owned operated shed, imputed values of rent was calculated. Cost of family labor was calculated by using prevailing wages in market. Sale price of broiler per kilogram and sale price of manure/litter per square feet was used for estimation of gross revenue.

Theoretical framework

Technical efficiency can be measured with two approaches namely 1) Data Envelopment Analysis (DEA) approach and 2) Stochastic Frontier Analysis (SFA) approach. DEA is a nonparametric test based on liner programming and very sensitive to error term. It is deterministic in nature and measure error from maximum as inefficiency. The second approach (SFA) is a parametric and statistical approach that measures stochastic error in data set. All the deviation from frontier is measured as farm or farmers’ specific inefficiency errors as well as natural errors. A comparison of DEA and SFA is given in Figure 1.

As stochastic frontier analysis is based on econometric techniques and hypothesis can be tested therefore, SFA approach was used in estimating technical efficiency broiler farms.

To estimate technical efficiency a stochastic frontier production function is presented in equation (2). This model was introduced first time by Aigner et al. (1977), Meeusen and van den Broeck (1977) and then developed later by Schmidt and Lovell (1979) and Jondrow et al. (1982).

Figure 1: Comparison of DEA and SFA Model

Source: Adopted from Kumbhakar and Sarkar, 2004.

Yi = f (Xi; βi) + εi i = 1, 2, 3 ………(5)

Where

Yi = Output

Xi = Inputs

βi = Parameters

εi = Composed error term

Composed error term consists of two components:

εi = vi - ui………. (6)

vi is natural error term and identically and normally distributed while ui is farm or farmer specific error term and independently and half normally distributed. vi and ui are independent of each other. vi measure the difference between maximum and actual value by the effect of natural shocks while the ui capture the inefficiency effects. The difference between actual production function and frontier production function is allowed by this error term.

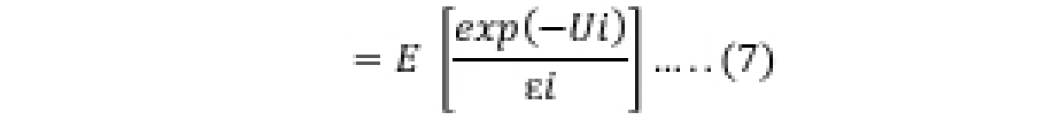

The ratio of actual production to the maximum (frontier) production keeping technology constant is known as technical efficiency.

TE = Yi/Yi*

The range of technical efficiency is from 0 to 1. 1 shows efficient farming condition and 0 depicts inefficient farming condition.

Empirical model

In order to find out the technical efficiency of broiler farming a stochastic frontier Cobb-Douglas type production model was estimated as follows:

ln Yi = β0 + β1 lnDOC + β2 lnFeed + β3 lnVaccine + β4 lnLabor + vi - ui ….(8)

Where

Yi = Output of broilers (kilograms/shed)

DOC = Day Old Chicks (Numbers/shed)

Feed = Feed (kilograms/shed)

Vaccine = Vaccination (milliliters/shed),

Labor = Labor used (Man days/shed)

β0 = Intercept

βi = Estimated parameters

ln = natural logarithm

vi = error due to natural shocks

ui = effect of inefficiency factors

Technical inefficiency determinants

To determine the factors that affect technical inefficiency, the following model was estimated using stochastic frontier model with maximum likelihood estimation technique as follows:

ui = δ0 + δ1 Age + δ2 Edu + δ3 Exp + δ4 Credit + δ5 Occ + δ6 Labr + ωi…….(9)

Where

Age = Age of broiler Farmer (Years)

Edu = Education of broiler Farmer (Years)

Exp = Experience of broiler Farmer (Years)

Credit = Credit Access (Rs.)

Occ = Occupation of farmer (farming/any other)

Labr = Labor used (Family/Haired)

δ0 = Constant

δi = Parameters to be estimated, ωi = Stochastic error term.

Table 2: Individual and Mean VIF values of the variables

| Variables | VIF | 1/VIF |

| DOC | 8.230 | 0.122 |

| Feed | 7.560 | 0.132 |

| Vaccine | 6.910 | 0.145 |

|

Labor |

2.330 | 0.429 |

| Mean VIF | 6.258 |

0.207 |

Source: Survey data estimates, 2016

Model adequacy tests

Normality of residuals, heteroscedasticity, multicollinearity and model specification tests were performed to check the robustness of estimated.

JB test for normality of residuals: Jorque Bera (JB) test results showed that the p-value was 0.156 which is greater than 5% level of significance suggesting normal distribution of residuals.

White’s test for heteroscedasticity: Estimated p-value of White’s test for heteroscedasticity was 0.111 and statistically insignificant at 5% significant level therefore we can conclude that the residuals are homoscedastic.

Multicollinearity test : Table 2 shows the individual and mean Variance Inflationary Factor (VIF) value and also the tolerance (1/VIF) values. Mean value of VIF and tolerance are 6.258 and 0.207, respectively, which confirms the absence of multicollinearity problem.

Ramsey’s (RESET) test for model specification: Ramsey’s test follows F distribution. Our estimated Fcalculated (2.01) was less than Ftabulated (8.55) so we accepted the null hypothesis that the model was correctly specified.

Results and Discussion

Cost of production and net revenue from broiler farms

Cost

Table 3 presents average cost of production of broiler farms. On average 4,163.33 number of DOC were reared having per chick cost of Rs. 23.93 with the total cost on DOC was Rs. 99,628.49 (13.71% of the total cost). Similarly the total feed cost was Rs. 516,833.31. Feed was the major contributor to the total cost which was about 71.14% of the total production cost. Cost on vaccines was Rs. 32,186.31 accounted 4.43% to the total cost. Cost incurred on labor was Rs. 21,393.38 constituted 2.94% of total cost. Electricity, litter and transportation cost were estimated Rs. 13,523.00, Rs. 9,808.06 and Rs. 8,771.00 respectively with the percentage in total cost of 1.86, 1.35 and 1.21%, respectively. Total variable cost was Rs. 702,143.55 (96.64%) while total fixed cost was 24,386.00 (3.36%). Fixed cost includes building rent and depreciation of equipments used in farming operations. Building rent was Rs. 15,993.67 (2.20%) and depreciation of equipments was Rs. 8,393.17 (1.16%). Total cost of broiler production was estimated Rs. 726,530.39.

Table 3: Cost of production of broiler farms

| Variables | Units | Quantity | Cost/Unit | Total cost (Rs) | % in total cost |

| DOC | No. | 4,163.33 | 23.93 | 99,628.49 | 13.71 |

| Feed intake | Kg | 11,019.90 | 46.90 | 5,16,833.31 | 71.14 |

| Vaccines | Ml | 13,523.66 | 2.38 | 32,186.31 | 4.43 |

| Labor | Days | 73.00 | 293.06 | 21,393.38 | 2.94 |

| Electricity | Month | 2.00 | 6,761.50 | 13,523.00 | 1.86 |

| Litter | Trolley | 1.50 | 6,538.71 | 9,808.06 | 1.35 |

| Transportation | Rs | - | - | 8,771.00 | 1.21 |

| TVC | Rs | - | - | 7,02,143.55 | 96.64 |

| Rent | Rs | - | - | 15,993.67 | 2.20 |

| Equipments | Rs | - | - | 8,393.17 | 1.16 |

| TFC | Rs | - | - | 24,386.84 | 3.36 |

| TC | Rs | - | - | 7,26,530.39 |

100.00 |

Source: Survey data estimates, 2016.

Gross and net revenues

Table 4 presents the gross and net revenue from broiler farms. On average 6,913.74 kg broiler meat was produce and sold @ of 110.38 Rs/kg having the value of 7, 63,138.62 rupees. The by-product was sold at the rate of 3.49 Rs/Sqft with the value of Rs. 13764. The gross revenue comes from the broiler farms was Rs. 776902.62 with the net revenue of 50372.30 rupees.

Table 4: Gross and net revenue from broiler farms

| Particulars | Units | Quantity | Price/unit (Rs) | Total Value (Rs) |

| Broiler | kilograms | 6,913.74 | 110.38 | 7,63,138.62 |

| Manure/litter | Square feet | 3,947.95 | 3.49 | 13,764.00 |

| Gross revenue | Rs | - | - | 7,76,902.62 |

| Total cost | Rs | - | - | 72,6530.39 |

| Net revenue | Rs | - | - |

50,372.30 |

Source: Survey data estimates, 2016.

Descriptive statistics of the variables used in model

Table 5 presents descriptive statistics of the variables used in the stochastic frontier Cobb-Douglas type production function. Mean output of broilers per shed was 6,908.87 kg with the std. deviation of 2,423.35 ranging from 3,020 kg to 10,780 kg. Average feed intake per shed was 11,019.9 kg with std. deviation of 3962.95 ranging from 6,500 kg to 20,000 kg. On average, 4,163 Day Old Chicks were reared with the std. deviation of 1372.82 ranging from 2,500 to 7,000 per shed.

In order to maintain good health and resistance against diseases in broiler, on average, 13,523.7 ml vaccine were used with the range of 6,500 to 29,600 ml per shed.

Average age of farmers was 44 year ranging from 27 to 62 years. Similarly, average education level was 7 schooling years ranging from 0 to 16 years. On average, experience of the farmer in broiler rearing was 6 years ranging from 1 to 15 years. 48% farmers was credit holders, 58% farmers were rearing broilers as a main business while 45% farmers employed family labor for operating their sheds.

MLE estimates of parameter of stochastic production Frontier

Table 6 presents parameters estimated from the stochastic frontier Cobb-Douglas type production function. Results showed that DOC, feed and labor have positive and significant effect on broiler output while vaccines have insignificant effect on broiler output. Estimated coefficient of DOC was 0.70; implies that broiler output increases by 0.70% if day old chicks are increased by 1%. These results are in accordance with the findings of Ali et al. (2014) and Ohajianya et al. (2013). Output increases by 0.17% if feed intake is increased by 1%. This finding is in line with the results of Omar (2014), Ali et al. (2014) and Udoh and Etim (2009). Production increases by 0.07% if number of labor days are increased by 1%. These results are in agreement with the findings of Ali et al. (2014) and Ohajianya et al. (2013). Coefficient of vaccine was 0.02 but statistically insignificant and in accordance with the findings of Akhtar and Rashid (2008).

The lower part of table 6 shows the factors that affect technical inefficiency of broiler farms. Results

Table 5: Descriptive statistics of the variables used in model

| Variables | Units | Minimum | Maximum | Mean | Std. Dev. |

| Output | Kg | 3,020 | 10,780 | 6,908.87 | 2,423.35 |

| Feed | Kg | 6,500 | 20,000 | 11,019.90 | 3,962.95 |

| DOC | No. | 2,500 | 7,000 | 4,163.33 | 1,372.82 |

| Vaccine | ML | 6,500 | 29,600 | 13,523.70 | 5,880.17 |

| Labor | Days | 48 | 129 | 73.39 | 19.76 |

| Age | Years | 27 | 62 | 44.17 | 7.68 |

| Education | Years | 0 | 16 | 7.12 | 4.64 |

| Experience | Years | 1 | 15 | 6.21 | 2.77 |

| Loan/Credit | Dummy | 0 | 1 | 0.48 | 0.501 |

| Occupation | Dummy | 0 | 1 | 0.587 | 0.494 |

| Labor used | Dummy | 0 | 1 | 0.453 |

0.499 |

Source: Survey data estimates, 2016

indicated that age has negative and statistically significant effect on technical inefficiency at 1% level of significance implies that technical inefficiency decreases as age of farmers increases. These findings are in accordance with the results of Ali et al. (2014). Education has negatively and significantly affected technical inefficiency of farmers.

Table 6: MLE estimates of parameter of stochastic production Frontier

| Variable | Parameters | Coefficients | t-ratios |

| Constant |

β0 |

1.05 |

3.35* |

| ln DOC |

β1 |

0.70 |

8.72* |

| ln Feed |

β2 |

0.17 |

2.54* |

| ln Vaccine |

β3 |

0.02 | 0.981 |

| ln Labor |

β4 |

0.08 |

1.80** |

| Technical inefficiency effects model | |||

| Intercept |

α0 |

1.26 |

2.89* |

| Age |

α1 |

-0.007 |

-1.70** |

| Education |

α2 |

-0.017 |

-1.82** |

| Experience |

α3 |

-0.106 |

-2.42* |

| Credit |

α4 |

-0.163 | -1.53 |

| Occupation |

α5 |

-0.137 | -1.52 |

| Labor used |

α6 |

-0.023 | -0.36 |

| Variance Parameters |

ẟs2 |

0.034 |

2.23* |

| ϒ | 0.90 |

17.34* |

|

Source: Survey data estimates, 2016

* and ** indicates significance at 1% and 5%, respectively.

These results were also found by Ali et al. (2014). Similarly experience in broiler farming also negatively affected technical inefficiency of farmers and turned out to be significant at 5%. These results matched with the findings of Akhtar and Rashid (2008). Credit, occupation and labor (family labor) have insignificant effect on technical inefficiency of broiler farmers.

Frequency distribution of broiler farms on the basis of technical efficiency

Table 7 presents frequency distribution of broiler farms on the basis of technical efficiency level. 29 broiler farms were having less than 80% technical efficiency. These farms were 19% of total sampled farms. 47 broiler farms were found to have technical efficiency between 80 and 90%. These farms constitute 32% of total number of farms. 74 broiler farms have technical efficiency above 90%. These farms constitute 49% of total number of farms. Mean technical efficiency was 89% ranging from 63 to 97%. This implies that farmers have mean technical efficiency can increase broiler output by 8% to reach to the frontier output by using best management practices with available farm resources and technology. Efficiency gap was 34% between technical inefficient farm and the farm operating at frontier (technically efficient). This means that farmers have minimum technical efficiency can increase broiler output by 34% to reach to the frontier output by using best management practices with available farm resources and technology.

Table 7: Distribution of broiler farms on the basis of technical efficiency

| Technical Efficiency | Frequency | Percentage |

| <0.80 | 29 | 19 |

|

0.81-0.90 |

47 | 32 |

| 0.90> | 74 | 49 |

| Max TE |

0.97 (97%) |

|

| Min TE |

0.63 (63%) |

|

| Mean TE |

0.89 (89%) |

|

| Technical efficiency gap |

0.34 (34%) |

|

Source: Survey data estimates, 2016.

TE = Technical efficiency.

Table 8: Comparison of mean technical efficiency with previous study

| Author | Year | Country | Farm Type | Mean TE |

| Alrwis and Francis | 2003 | Saudi Arabia | Broiler farms | 0.89 |

| Akhter and Rashid | 2008 | Bangladesh | Broiler farming | 0.94 |

|

Adepoju |

2008 | Nigeria | Egg production | 0.76 |

| Heidari et al | 2011 | Iran | Poultry farms | 0.92 |

| Etim et al. | 2011 | Nigeria | Family farms | 0.76 |

| Ezeh et al. | 2012 | Nigeria | Poultry broiler production | 0.75 |

| Ali et al. | 2014 | Pakistan | Open Shed broiler farms | 0.88 |

| Valdes et al. | 2015 | USA | Climate control farms | 0.94 |

| Conventional farms | 0.92 | |||

| Manual farms | 0.90 | |||

| This study | 2016 | Pakistan | Broiler farms |

0.89 |

Comparison of mean technical efficiency of this study with previous studis

Table 8 shows the comparison of mean technical efficiency of this study with the previous studies in different years and countries.

Conclusions and Recommendations

This study estimated technical efficiency of broiler farms in district Mardan of Khyber Pakhtunkhwa. Multistage sampling procedure was used to collect data from 150 broiler farms. Stochastic frontier Cobb-Douglas type production function was employed to estimate technical efficiency of sampled farms. Day old chicks, feed intake, vaccines and labor were found to be major determinants of broiler production. Results indicated that DOC, feed, and labor have positive and significant effect on broiler output and vaccines have insignificant effect on broiler output. Increase in number of DOC, feed and labor would increase broilers output and technical efficiency of broiler farmers.

In technical inefficiency effects model, age, education, experience, credit, broiler farming as main occupation of farmer and employment of family labor were taken as explanatory variables. Results showed that age, education and experience negatively and significantly affected technical inefficiency of broiler farmers. Credit, occupation and labor have insignificant effect on technical inefficiency of broiler farmers.

Mean technical efficiency was 89% ranging from 63 to 97%. This implies that farmers having mean technical efficiency level can increase broiler output by 8% to reach to the frontier output by using best management practices with available farm resources and technology. Efficiency gap was 34% between technical inefficient farm and the farm operating at frontier (technically efficient). This means that farmers having minimum technical efficiency can increase broiler output by 34% to reach to the frontier output by using best management practices with available farm resources and technology.

As the estimated coefficient of number of day old chicks was 0.70 therefore broiler farmers of the study area needs to increase the number of day old chicks according to the capacity of shed to enhance productivity and ultimately efficiency. The estimated coefficient of feed was 0.17. feed intake needs to be increased to accelerate production and efficiency of broiler farms. In technically inefficiency effects model age, experience and education were found to be statistically significant and negatively related with the technical inefficiency so the government needs to educate the farmers and provide trainings specific to rearing of broiler in open shed farms for the efficient utilization of resources and enhancing productivity and efficiency. A general recommendation is that government needs to establish a regulatory body to suggest policies for price stability of broiler inputs and output.

Limitations of the Study

This study was limited to only one district of Khyber Pakhtunkhwa. Therefore findings of this study need to be carefully generalized for whole province. Moreover, it estimated only technical efficiency of broiler farms. Allocative and economic efficiency also needs to be estimated for broiler farms in future.

Author’s Contribution

Nihal Ahmad Hadi: Carried out the research, collected data and wrote the first draft.

Shahid Ali: Supervised the study, developed the main theme of the study along with other authors and helping in writing up the manuscript.

Umer Wahid: Organized and analysed the data, interpreted the results, wrote and corrected the references section of the manuscript.

References

Abedullah, M.A., and K. Bukhsh. 2007. Issues and economics of poultry production: A case study of Faisalabad Pakistan. Pakistan Vet. J. 27(1): 25-28.

Adebayo, O.O., and R.G. Adeola. 2005. Socio-economic factors affecting poultry farmers in Ejigbo local government area of Osun State. J. Human Ecol. 18(1): 39-41. https://doi.org/10.1080/09709274.2005.11905804

Aigner, D., C.K. Lovell and P. Schmidt. 1977. Formulation and estimation of stochastic frontier production function models. J. Econ. 6(1): 21-37. https://doi.org/10.1016/0304-4076(77)90052-5

Al-Fawwaz, T.M. and A. AL-Sharafat. 2013. Estimation of resource use efficiency in broiler farms: A marginal analysis approach. Global J. Finance Banking Issues. 7(7): 1-8. https://doi.org/10.1016/0304-4076(82)90004-5

Alrwis, K. N. 2010. Technical efficiency of broiler farms in the central region of Saudi Arabia: Stochastic frontier approach. Global Vet. 12(5): 588-593.

Areerat, T.K., Hiroshi, N.A. Kamori and Y. Kohen. 2012. Economic efficiency of broiler farms in Thailand: Data Envelopment Analysis Approach. Br. J. Econ. Finan. Manag. Sci. 5(1): 33-43.

Bandara, R.M.A.S. and D.M.W.K. Dassanayake. 2006. A quantitative analysis on factors affecting profitability of small scale broiler production. J. Agric. Sci. 2(3): 45-50.

Broiler dealer of Mardan Poultry (Madina) market, January 2016.

Cochran, W.G. 1977. Sampling Techniques, 3rd Edition. John Wiley and Sons, New York.

Coelli, T.J. 1996. A guide to FRONTIER version 4.1: A computer program for stochastic frontier production and cost function estimation (Vol. 7, p. 96). CEPA Working papers.

Debertin, D.L. 2012. Agricultural Production Economics, 2nd Edition. Macmillan Publishing Company, a division of Macmillan Inc., New York.

Etim, N.A., Effiong, E.O. and D.P. Okon. 2011. Measuring technical efficiency of family farms in the Rainforest Zone. J. Agric. Social Sci. 7(3): 77-82.

Etuah, S. 2014. Cost efficiency and economies of scale in broiler production in Ghana: A case study of the Ashanti Region. Master of Philosophy thesis submitted to the Department of Agricultural Economics, Agribusiness and Extension, Faculty of Agriculture, Kwame Nkrumah University of Science and Technology, Ghana.

Eze, C.C., J.C. Okere, A.I. Maduike and G.N. Ben-Chendo. 2012. Technical efficiency in poultry broiler production in Umuahia capital territory of Abia state, Nigeria. Green. J. Agric. Sci. 2(1): 01-007.

FAO. 2012. Food and Agriculture Organization of the United Nations. www.fao.org.

FAO. 2014. Food and Agriculture Organization, 2031-14.

Farooq, A., M. Ishaq, N.A. Shah, A. Hassan and K. Nabi. 2013. Economies of scale in broiler farming in Khyber Pakhtunkhwa. Sarhad J. Agric. 29: 119-126.

Govt. of Khyber Pakhtunkhwa. 2014. Development Statistics of Khyber Pakhtunkhwa, 2014. Bureau of Statistics, Planning and Development Department.

Govt. of Sindh. 2013. Sindh Board of Investment Report on Livestock. Govt. of Sindh Pakistan.

Hamra, C.F. 2010. An Assessment of the potential profitability of poultry farms: A broiler farm feasibility case study. Doctoral dissertation submitted to the University of Tennessee at Martin, USA.

Jondrow, J., C.A.K. Lovell, I. Materov and P. Schmidt. 1982. On estimation of technical inefficiency in the stochastic frontier production model. J. Econ. 19(1): 233 -238.

Kumbhakar, S.C. and S. Sarkar. 2004. Deregulation, ownership, and efficiency change in Indian Banking: An application of stochastic frontier analysis. www.igidr.ac.in/conf/finwrk/workshop.pdf

Mohsin, A.Q., R. Riaz., S. Asad and A. Mushtaq. 2008. Profitability analysis of broiler production in Rawalpindi district. Pakistan J. Agric. Sci. 45(4): 514-519.

Omar, M.A.E. 2014. Technical and economic efficiency for broiler farms in Egypt. Application of Data Envelopment Analysis (DEA). Global Vet. 12(5): 588-593.

Ohajianya, D.O., J.U. Mgbada, P.N. Onu, C.O. Enyia, A. Henri-Ukoha, N.G. Ben-Chendo and C.C. Godson-Ibeji. 2013. Technical and economic efficiencies in poultry production in Imo State, Nigeria. Am. J. Exp. Agric. 3(4): 927-938. https://doi.org/10.9734/AJEA/2013/4089

PPA, 2012. Pakistan Poultry Association. https://pakistanpoultrycentral.pk/

PPA, 2014. Pakistan Poultry Association. https://pakistanpoultrycentral.pk/

Schmidt, P. and C. Lovell. 1979. Estimating technical and allocative inefficiency relative to stochastic production and cost frontiers. J. Econ. 9(3): 343-366.

Taha, F.A. 2003. The poultry sector in middle-income countries and its feed requirements: The case of Egypt. Outlook Report No. WRS03-02. Economic Research Service, USDA. Http://www.ers.usda.gov/publications/WRS03/dec03/ wrs0302.

The Express Tribune. 2014. The daily newspaper published from Karachi, Lahore and Islamabad, Pakistan, September 5th, 2014.

Areerat, T., K. Hiroshi, N. Kamol and Y. Kohen. 2012. Production efficiency of broiler farming in Thailand: A Stochastic frontier approach. J. Agric. Sci. 4(12): 221-231.

Udoh, E.J. and N.A. Etim. 2009. Measurement of farm level efficiency of broiler production in Uyo, Akwa Ibom State, Nigeria. World J. Agric. Sci. 5(S): 832-836.

USDA. 2015. Department of Agriculture United States.

Valdes C., C. Hallahan and D. Harvey. 2015. Brazil’s broiler industry: Increasing efficiency and trade. Int. Food Agribus. Manag. Rev. 18(Special Issue A): 263-275.

Varian, H.R. 1992. Microeconomic Analysis, 3rd Edition. W.W. Norton and Company, Inc., 500 Fifth Avenue, New York, N.Y. 10110.