Effect of Various Edible Coatings in Extending the Storage Life of Apricot Fruit

Research Article

Effect of Various Edible Coatings in Extending the Storage Life of Apricot Fruit

Muhammad Kefayatullah* and Said Wahab

Department of Food Science and Technology, Faculty of Nutrition Sciences, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan.

Abstract | The research work was carried out to determine the effect of edible coatings on the storage life of apricot fruit. The fruits were stored at 5±1°C with 85–90% relative humidity during the period of analysis. The data regarding various parameters were recorded at each 7days intervalup to 28 days of storage. The samples T1 (control), SA1 (1 % sodium alginate), SA2(2 % sodium alginate), MC1(1 % methyl cellulose), MC2(2 % methyl cellulose), P1(1 % pectin), P2(2 % pectin), BW1(1 % bees wax), BW2(2 % bees wax), CC1(1 % calcium chloride) and CC2 (2 % calcium chloride) were studied for TSS, pH, acidity, ascorbic acid, reducing sugar, non-reducing sugar, moisture content, percent weight loss, decay index, chilling injury, total phenols, sugar acid ratio and organoleptic evaluation. An increase was observed in TSS (11.05 to 13.00°Brix), pH (3.71 to 4.25), reducing sugar (1.43 to 2.76), decay index (0.0 to 35.13), weight loss (0.0 to 5.85), sugar acid ratio (14.88 to 20.96), chilling injury (0.0 to 19.41) and a decrease in percent acidity (0.76 to 0.57), ascorbic acid (9.67 to 6.13 mg/100gm), non-reducing sugar (5.66 to 4.81), moisture content (85.92 to 76.45). During sensory evaluation, the sample BW2 (2.0 % bees wax) was found the most acceptable. The statistical analysis showed that both the treatments and storage interval had a significant effect on physicochemical and sensory analysis of apricot fruit during postharvest storage.

Received | November 23, 2021; Accepted | February 20, 2023; Published | April 21, 2023

*Correspondence | Muhammad Kefayatullah, Department of Food Science and Technology, Faculty of Nutrition Sciences, The University of Agriculture, Peshawar, Khyber Pakhtunkhwa, Pakistan; Email: [email protected]

Citation | Kefayatullah, M., and S. Wahab. 2023. Effect of various edible coatings in extending the storage life of apricot fruit. Sarhad Journal of Agriculture, 39(2): 381-389.

DOI | https://dx.doi.org/10.17582/journal.sja/2023/39.2.381.389

Keywords | Apricot fruit, Edible coating, Sodium alginate, Methyl cellulose, Pectin, Bees wax and calcium chloride

Copyright: 2023 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Apricot (Prunusarmeniaca L.) belongs to family Rosaceae. It plays a vital part in preservation of public well-being as it contains lycopene and carotene pigments which protect the heart and senses as well as sickness struggling properties of roughage that avoids gastrointestinal conditions, diverculosis and have antiseptic, emetic, antipyretic and ophthalmic properties (Haydar et al., 2007). Apricot is climacteric fruit, the maturing progression synchronized by ethane and short hotness, and altered atmospheric storing is generally used to prevent fruit decline and to prolong post-harvest life. Though, some physiological disorders can be developed which contain steady and juiceless epidermis and inner searing after two to three weeks of storing at 1-4 oC (De Martino et al., 2002). In Pakistan the total area under apricot cultivation was 42000 hectares and the annual production was 32000 tons during the year 2022 (FAOSTAT 2022).

Apricot contains (Per 100 g) eatable part 94%, glucose 2.1g, sucrose 4.1g, sorbitol 0.6g, fructose 0.1g, fibre 3.0g, fat 0.1g, vitamins 16mg, sodium 3mg, potassium 320mg, protein 0.7g and water 85.6g (Wills, 1987). Apricots fruit can be used as a fresh, dried and processed commodity. It has been found beneficial for human health and enriched with various nutrients required by the human body. Mechanical injury is the one of the most important factors in postharvest losses in terms of both quantity and quality (Kader, 2002). Nowadays, farmers are trying to harvest their fruit earlier to avoid and diminish the bruising impact. In addition, the speedy processes are used for handling in order to have maximum fragrance and aroma before and during distribution (Botondi et al., 2003).

Postharvest storage can to distress phenolic contents level and antioxidants capability in produces (Holcroft and Kader, 1999). Edible layers and coverings also are used to aid the fruit and vegetable conservation as they offer a restricted hurdle to dampness, oxygen and carbon dioxide; Similarly, they may recover manual management characters, carry essences, escaping volatile damage and also add to the assembly of fragrances and odor volatiles (Olivas and Barbosa Canovas, 2005).

Fruit coat, a technique used to deferment maturing and extend the storing lifecycle of a product (Ghaouth et al., 1991). Edible coat is modest, environment responsive and reasonably cheap knowledge which can deferment the maturing of climacteric fruit, retard colour variations in non-climacteric fruit, decrease loss of water, decrease deterioration and mend appearances (Donhowe and Fennema, 1994). Edible coatings have numerous benefits in contrast with other methods, never the less simply when, the layered produces are kept at suitable temperature, that depends on the product. They act as moisture and gas barrier of the commodity and efficiently prolong the shelf lifetime of the commodity (Sehat, 2012).

Horticultural crops have offered huge potential to enhance profit-cost ratio followed by nutritional standard as well as to boost up the biological production (Khalid et al., 2022). Food safety could be kept at best if post-harvest losses have been controlled once. Post-harvest losses have been seen a big issue in poor countries where they do not have any modest technology to avoid them. It is al long-term process to boost up the supply chain of food by minimizing the natural resources dependence through enhancing the livelihood and making food security (Khalid et al., 2022). Apricot harvesting at their young age could lead us towards to preserve the fruit for long time. Currently, the techniques including edible coating have been using to preserve fruits and vegetables throughout the world (Algarni et al., 2022).

The objective of the research work was to extend the storage life of apricot fruit with minimum losses after harvesting and to evaluate the effectiveness of different edible coatings on physico-chemical and sensory quality attributes of apricot fruit during storage.

Materials and Methods

This analytical work was conducted in postgraduate food technology laboratory, Department of Food Science and Technology, The University of Agriculture, Peshawar and at Food Technology Section, Pakistan Council of Scientific and Industrial Research (PCSIR), Peshawar.

Selection of fruits

Apricot fruits of large and uniform size, good physical shape and colour, free from diseases were preferred and selected. The pre-cooled fruits were then kept under the shade and brought to the Food Technology Laboratory in card board crates lined with soft paper.

Preparation of sample

Apricot fruits were divided into different lots symbolically expressed as Control, SA1, SA2, MC1, MC2, P1, P2, BW1, BW2, CC1 and CC2. Each lot was treated separately according to the plan of the study, as shown below. The fruits were stored at 5±1°C with 85–90% relative humidity during the period of analysis. The data regarding various parameters were recorded at an interval of 7 days for a period of 28 days.

Plan of study

Effect of different edible coatings on postharvest quality of apricot fruit during storage

Control = Apricot fruit without any treatment (control)

SA1 = Apricot fruit with 1 % sodium alginate treatment

SA2 = Apricot fruit with 2 % sodium alginate treatment

MC1= Apricot fruit with 1 % methyl cellulose treatment

MC2= Apricot fruit with 2 % methyl cellulose treatment

P1 = Apricot fruit with 1 % pectin treatment

P2 = Apricot fruit with 2 % pectin treatment

BW1 = Apricot fruit with 1 % bees wax treatment

BW2 = Apricot fruit with 2 % bees wax treatment

CC1 = Apricot fruit with 1 % calcium chloride treatment

CC2 = Apricot fruit with 2 % calcium chloride treatment

Chemical analysis

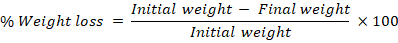

Ascorbic acid was determined by direct calorimetric method using 2, 6-dichlorophenol indophenols as decolorizing agent by ascorbic acid in sample extract and in standard ascorbic acid solution as described in (AOAC, 2019). Acidity was determined by standard method of AOAC (2019). Standard method of AOAC (2019) was used for the determination of pH. Reducing and non-reducing sugars were determined by Lane Eynon method as described. Total soluble solids were determined by using Abbe refractometer as described in (AOAC, 2019). Moisture content of apricot fruits was determined using the standard method. The percent weight loss, of three replicates of each treatment were evaluated on day 0 and at 7 days intervals till the end of the experiment by using the following formula:

Sugar acid ratio was measured by using the given equation:

TSS/Acid = Total sugar/ Titratable acidity

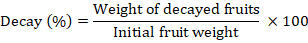

Total phenolic compounds in apricot fruits were determined with the Folin-Ciocalteu method as described by (Pattanayak et al., 2012). The chilling injury index was assessed on a 4-point hedonic scale in each fruit based on the percentage of the fruit surface affected by CI symptoms (browning and pitting, dehydration): 0 indicates no damage; 1 indicates 1 to 25% damaged area; 2 indicates 26 to 50% damaged area; 3 indicates > 51% damaged area. CI = (value of hedonic scale) x (number of fruit with corresponding scale number)/4 x total number of fruit in the sample (Sayyari et al., 2009). Fruit was considered unacceptable for the consumer if it had CI indices of 1 or higher. The loss in weight percentage was periodically calculated on an initial weight basis. The number of decayed fruit was periodically recorded and expressed as a percentage from the total fruit number. Decay (%) was measured by using the method (Tarabih et al., 2012).

Sensory evaluation

Sensory evaluation was carried out by using 9 points Hedonic Scale as described by (Larmond, 1977). A panel of 10 judges was selected that grade the colour, flavour, texture and overall acceptability of the samples by scoring the samples on a scale from 1-9, with 1 representing extremely disliked and 9 extremely liked.

Statistical analysis

All the data regarding different parameters was statistically analyzed using a completely randomized design (CRD) through Statistix 8.1 software. Means were separated by LSD test at 5% level of significance as reported by (Steel et al., 1997).

Results and Discussion

Chemical analysis

The results disclosed that total soluble solids were significantly affected by different concentrations of edible coating treatments. The calculated mean values showed that maximum of total soluble solids was recorded for Control and minimum value for total soluble solids was observed in treatment BW2. There was a gradual increase in total soluble solids from 11.05 to 13.00 (Figure 1). These results are in agreement with previous observations of (Ishaq et al., 2009; Antunes et al., 2006).

The statistical analysis indicated that both the treatments and storage interval had a significant effect on pH of all the samples. The mean pH values of all the samples increased from 3.71 to 4.25 during storage. Highest mean value for pH was observed in Control while the lowest value of pH was observed in treatment BW2 (Figure 2). Similar trends for effect of edible gum based coating on pH of peach fruit were reported by (Ali et al., 2011; Maftoonazad et al., 2006).

Acidity of the samples gradually decreased during storage period. The mean values decreased from 0.76 to 0.57. The highest mean value for percent acidity was observed in BW2followed byBW1while the lowest value for percent acidity was observed in control (Figure 3). It is also believed that edible coatings reduce the respiration rate and delay the consumptions of organic acids which might results in decrease of percent acidity during storage (El-Anany et al., 2009). Similar explanations have also been found by (Ishaq et al., 2009) that during storage times calcium chloride maintained higher acidity values in apricot.

The data showed that different treatments and storage intervals had a significant effect on ascorbic acid content of different samples. Treatment BW2 showed the highest mean value for ascorbic acid while the lowest mean value for ascorbic acid was observed in treatment Control. The results also showed that ascorbic acid content (mg/100g) was significantly affected by storage period. The maximum mean value for ascorbic acid was (9.67 mg/100g) recorded initially while the lowest mean value recorded for ascorbic acid was (6.13 mg/100g) at 28th day of storage (Figure 4). This research outcomes are in line with earlier reports that vitamin C decreased in fruits due to oxidation, respiration process (Ghasemnezad et al., 2010; Abbasi et al., 2011) during cold storage.

Results showed that reducing sugars increased from 1.43 to 2.76 during storage period. The calculated mean values showed that maximum reducing sugar was recorded for T1and minimum value for reducing sugar was observed in treatment BW2 (Figure 5). These outcomes are also confirmed by (Ali et al., 2011) who reported that reducing sugars increased with the storage period in apricot fruits up to optimum maturity. Similar trends were also reported by (Tareen et al., 2012) in peach fruit during storage.

The non-reducing sugars decreased in all the samples during storage. Highest mean value for non-reducing sugar was observed in BW2 while the lowest mean value of non-reducing sugar was observed in treatment Control. The maximum mean value of non-reducing sugar (5.66) was observed at 0 day of storage while the minimum mean value for non-reducing sugar was noted (4.81) at 28 days of storage (Figure 6). The outcomes of this research work are in agreement with the findings of (Jan et al., 2012) who observed an increase in reducing sugar and a decline in non-reducing sugar during extended storage duration.

The moisture content decreased in all the samples during storage. Highest mean value for moisture content was observed in BW2 while the lowest mean value of moisture content was observed in treatment Control. The maximum mean value of moisture content (85.92) was observed at 0 day of storage while the minimum mean value for moisture content was noted (76.45) at 28 days of storage (Figure 7). The outcomes of this research work are in agreement with the findings of (Sartaj et al., 2011) who observed a decline in moisture content during extended storage duration.

Results showed that maximum total phenols were recorded for BW2 (80.80) and minimum value for total phenols was observed in treatment Control (78.66) (Figure 8). These outcomes are also confirmed by (Gil et al., 2006) who also observed an increase in fruits and vegetables during storage.

The decay index increased in all the samples during storage. Highest mean value for decay index was observed in control while the lowest mean value of decay index was observed in treatment BW2 (Figure 9). The trends of decay index are in agreement with the results of (Hernandez et al., 2005) for the effect of edible coatings and storage on strawberry, cut pears and plum, respectively.

The results disclosed that sugar acid ratio was significantly affected by different concentrations of edible coating treatments. The calculated mean values showed that maximum sugar acid ratio was recorded for T1and minimum value for sugar acid was observed in treatment BW2. There was a gradual increase in sugar acid ratio from 14.88 to 20.96 (Figure 10). These research findings are in comparison with the previous studies of (Khalil et al., 2012) who mentioned an increase in the sugar acid ratio in the peach fruits.

The statistical analysis indicated that both the treatments and storage interval had a significant effect on weight loss of all the samples. The mean weight loss values of all the samples increased from 0.0 to 5.85 during storage. Highest mean value for weight loss was observed in control while the lowest value of weight loss was observed in treatment BW2 (Figure 11). Similar results were reported by (Zapata et al., 2008) for the effect of edible coatings and plasticizer incorporated in edible coatings on weight loss of tomatoes and strawberries, respectively.

Results showed that chilling injury increased from 0.0 to 19.41 during storage period. The calculated mean values showed that maximum chilling injury was recorded for control and minimum value for chilling injury was observed in treatment BW2 (Figure 12). Similar findings have also been reported by (Yan et al., 2012).

Sensory evaluation

The analysis of the data showed treatments and storage period had a significant effect on overall acceptability (obtained from color, flavor and texture) of apricot fruit. The mean score of judges decreased from 7.62 to 3.27. Highest mean score of judges for overall acceptability was observed in sample BW2 while the lowest score for overall acceptability was observed in treatment control (Figure 13). The results are also in line with the previous work of Ishaq et al. (2009), who reported a decrease in sensory score with ripening and storage of apricot fruits.

Table 1: Standard deviation of apricot studied parameters.

|

S. No |

Parameter |

Standard deviation |

|

1 |

Total soluble solids |

2.214 |

|

2 |

pH |

0.699 |

|

3 |

Acidity |

0.219 |

|

4 |

Ascorbic acid |

4.157 |

|

5 |

Reducing sugar |

1.626 |

|

6 |

Non reducing sugar |

1.061 |

|

7 |

Moisture content |

10.793 |

|

8 |

Total phenols |

26.692 |

|

9 |

Decay index |

39.620 |

|

10 |

Sugar acid ratio |

6.987 |

|

11 |

Weight loss |

6.498 |

|

12 |

Chilling injury |

22.411 |

|

13 |

Overall acceptability |

4.899 |

Conclusions and Recommendations

The research study confirmed the effectiveness of edible coatings sodium alginate, methyl cellulose, pectin, bees wax and calcium chloride. The treated fruits retained higher quality than untreated ones. Fruits coated with edible coatings had minimum moisture loss, slow increase in TSS, pH, sugar acid ratio, reducing sugar, and retained maximum percent acidity, ascorbic acid, and firmness and total phenols as compared to uncoated ones.

As a result of edible coatings, the fruit sampleBW2 (2% bees wax) showed lower microbial load, decay index, chilling injury and higher sensory attributes during cold storage.

- Impact of edible coatings sodium alginate, methyl cellulose, pectin, bees wax and calcium chloride in combination with different packaging materials as well as combined treatment at different storage conditions i.e., ambient, low, control and modified atmospheric storage for a better assessment.

- Impact of edible coatings sodium alginate, methyl cellulose, pectin, bees wax and calcium chloride in combination with different varieties at different level of maturity.

Novelty Statement

The current study has resulted in the extension of stor-age life of apricot fruit, ultimately minimizing the post-harvest losses, and as a result the market value of this important commodity will improve drastically.

Author’s Contribution

Muhammad Kefayatullah: Data collection, analysis and writing of the manuscript.

Said Wahab: Formulation and designing of the experiments.

Conflict of interest

The authors have declared no conflict of interest.

References

Abbasi, K.S., N. Anjum, S. Sammi, T. Masud and S. Ali. 2011. Effect of coatings and packaging material on the keeping quality of mangoes (Mangifera indica L.) stored at low temperature. Pak. J. Nutr., 10(2): 129-138. https://doi.org/10.3923/pjn.2011.129.138

Algarni., E. H. A., I. A. Elnaggar., A. El-wahed., N. A. El-wahed., I. M. Taha, H. AL-Jumayi., S. M. Elhamamsy., S. F. Mahmoud and A. Fahmy. 2022. Effect of chitosan nanoparticles as edible coating on the storability and quality of apricot fruits. Polymers (Basel), 14:2227

Ali, S., T. Masud and K.S. Abbasi. 2011. Physico-chemical characteristics of apricot (Prunus armeniaca L.) grown in northern areas of pakistan. Sci. Hortic., 130(2): 386-392. https://doi.org/10.1016/j.scienta.2011.05.040

Ali, S., T. Masud, K.S. Abbasi, T. Mahmood and I. Hussain. 2013. Influence of calcium chloride on biochemical composition, antioxidant and enzymatic 2 activity of apricot at ambient storage. Pak. J. Nutr., 12(5): 476. https://doi.org/10.3923/pjn.2013.476.483

Antunes, M., N. Neves, F. Curado, S. Rodrigues, J. Franco and T. Panagopoulos, 2006. The effect of calcium applications on kiwifruit quality preservation during storage. VI Int. Symp. Kiwifruit, 753: 727-732. https://doi.org/10.17660/ActaHortic.2007.753.95

AOAC, 2019. Official methods of analysis 17th Edition, Association of Official Agric. Chem. Washington D.C. 1970.

Botondi, R., D. Desantis, A. Bellincontro, K. Vizovitis and F. Mencarelli. 2003. Influence of ethylene inhibition by 1-methylcyclopropene on apricot quality, volatile production, and glycosidase activity of low- and high-aroma varieties of apricots. J. Agric. Food Chem., 51(5): 1189-1200. https://doi.org/10.1021/jf025893o

De Martino, G., R. Massantini, R. Botondi, and F. Mencarelli. 2002. Temperature affects impact injury on apricot fruit. Postharvest Biol. Tech., 25(2): 145–149. https://doi.org/10.1016/S0925-5214(01)00165-X

Donhowe, I.G., and O. Fennema. 1994. Edible films and coatings: Characteristics, formation, definitions, and testing methods. In edible coatings and films to improve food quality (J. Krochta, E.A. Baldwin and M.O. Nisperos, eds.), Technomic Publishing Co., Inc, Lancaster, PA. pp.1-65.

El-Anany, A.M., G.F.A. Hassan and F.M. Rehab. 2009. Effect of edible coatings on the shelf life and quality bof Anna apple during cold storage. J. Food Technol., 7: 5-11.

Eman, H., A. Algarni, I.A. Elnaggar, A. El-Wahed, N.A. El-Wahed, I.M. Taha, H.A. Al-Jumayi, S.M. Elhamamsy, S.F. Mahmoud and A. Fahmy. 2022. Effect of chitosan nanoparticles as edible coating on the storability and quality of apricot fruits. 14: 22-27. https://doi.org/10.3390/polym14112227

FAOSTAT, 2022. Food and Agriculture Organization. Statistical Yearbook. https://www.fao.org/documents/card/en/c/cc2211en

Ghaouth, A.E., J. Arul and R. Ponnampalam. 1991. Use of chitosan coating to reduce water loss and maintain quality of cucumber and bell pepper fruits. J. Food Proc. Preserv., 15(5): 359-368. https://doi.org/10.1111/j.1745-4549.1991.tb00178.x

Ghasemnezhad, M., M.A. Shiri and M. Sanavi. 2010. Effect of chitosan coatings on some quality indices of apricot (Prunusarmeniaca L.) during cold storage. Caspian J. Environ. Sci., 8(1): 25-33.

Gil, M.I., Aguayo, E. and Kader, A.A. 2006. Quality changes and nutrient retention in fresh-cut versus whole fruits during storage. J. Agric. Food Chem., 54(12):4284–4296.

Al-Jumayi, H.A., S.M. Elhamamsy, S.F. Mahmoud and A. Fahmy. 2022. Cappellini R.A. and M.J. Ceponis. 1984. Measuring postharvest losses in fresh fruits and vegetables In: H.E., Moline (Ed.), postharvest pathology of fruits and vegetables: postharvest losses in perishable crops, Univ. Calif. Bull., pp. 24–30.

Haydar, H., G. Ibrahim, O.M. Mehmet and M. Bayram. 2007. Postharvest chemical and physical-mechanical properties of some apricot varieties cultivated in Turkey. J. Food Eng., 79: 364-373. https://doi.org/10.1016/j.jfoodeng.2006.02.003

Hernandez M.P., E. Almenar, O.M. Jose and G. Rafael. 2005. Effect of calcium dips and chitosan coatings on post-harvest life of strawberries. Postharvest. Biol. Technol., 39:247-253.

Holcroft, D.M. and A.A. Kader. 1999. Carbon dioxide-induced changes in color and anthocyanins synthesis of stored strawberry fruits. Hortic. Sci., 34: 1244–1248. https://doi.org/10.21273/HORTSCI.34.7.1244

Ishaq, S., H.A. Rathore, T. Masud and S. Ali. 2009. Influence of post harvest calcium chloride application, ethylene absorbent and modified atmosphere on quality characteristics and shelf life of apricot (Prunus armeniaca L.) fruit during storage. Pak. J. Nutr., 8(6): 861-865. https://doi.org/10.3923/pjn.2009.861.865

Jan, I., A. Rab and M. Sajid. 2012. Storage performance of apple cultivars harvested at different stages of maturity. J. Anim. Plant Sci., 22(2): 438-447.

Jan, I., A. Rab and M. Sajid. 2013. Influence of calcium chloride on physical characteristics and soft rot incidence on fruit of apple cultivars. J. Anim. Plant Sci., 23: 1353-1359.

Kader, A.A., 2002. Postharvest technology of horticultural crops. 3rd edition. University of California, Agri and Natural Resources, Publ., 3311-535.

Khalid, M.A., B. Niaz, F. Saeed, M. Afzaal, F. Islam, M. Hussain, Mehwish, H.M.S. Khalid, A. Siddeeg and A. Al-Farga. 2022. Edible coatings for enhancing safety and quality attributes of fresh produce: A comprehensive review. Int. J. Food Prop., 25(1): 1817–1847. https://doi.org/10.1080/10942912.2022.2107005

Khalil, S.A., M. Ayub, R. Zamir, M. Sajid, A. Muhammad and Faiq, M. 2012. Influence of postharvest hot water dip treatment on quality of peach fruit (Prunus persica L.). J. Med. Plants Res., 6(1): 108-113.

Larmond, E., 1977. Laboratory methods for sensory evaluation of foods research branch, Canada, Department Agriculture Publication, pp. 1637.

Maftoonazad, N. and H.S. Ramaswamy. 2006. Post harvest shelf life extension of avocados using methyl cellulose-based coatings. Lebensmittel Wissensch. Technol., 38: 617-624. https://doi.org/10.1016/j.lwt.2004.08.007

Olivas, G.I. and G.V. Barbosa-Cánovas. 2005. Edible coatings for fresh-cut fruits. Crit. Rev. Food Sci. Nutr., 45: 657–670. https://doi.org/10.1080/10408690490911837

Pattanayak, S., P.M. Mazumder and P. Sunita. 2012. Total phenolic content, flavonoid content and in vitro antioxidant activities of dendrophthoe falcata (lf) ettingsh. Res. J. Med. Pl., 6: 136-148.

Sartaj. A., T. Masood and Abbasi, K.S. 2011. Physico-chemical characteristics of apricot (Prunus armeniaca L.) grown in Northern Areas of Pakistan. Sci. Hort., 130(2): 386-392.

Sayyari, M., M. Babalar, S. Kalantari, M. Serrano and Valero, D. 2009. Effect of salicylic acid treatment on reducing chilling injury in stored pomegranates. Postharvest. Biol. Technol., 53(3): 152-154.

Sehat, N.N.B.M., 2012. Effect of dipping treatments and cassava starch coating on keeping quality of fresh cut pineapple (Ananascomosus). Final year project report submitted in partial fulfillment of the requirements of the degree of Bachelor of Science (Hons). Food Sci. and Technology in the faculty of applied sciences, University Teknologi MARA, Malaysia.

Steel, R., J. Torrie and D. Dickey. 1997. Principle and procedure of statistics. A biometrical approach, mcgraw-hills book companies. Inc., New York.

Tarabih, M., E. EL-Eryan and M. Tourky. 2012. Effect of fumigation with some volatile substances on peach fruits during cold storage. Trend. Horticul. Res., 2(2): 14-27.

Tareen, M.J., N.A. Abbasi and I.A. Hafiz. 2012. Postharvest application of salicylic acid enhanced antioxidant enzyme activity and maintained quality of peach cv.‘Flordaking’fruit during storage. Sci. Hortic., 142: 221-228. https://doi.org/10.1016/j.scienta.2012.04.027

Wills, R.H. 1987. Composition of Australian fresh fruit and vegetable. Food Tech. Aust., 39(1): 523-26.

Yan, S.C., J.Y. Chen, W.M. Yu, J.F. Kuang, W.X. Chen, X.P. Li and W.J. Lu. 2012. Expression of genes associated with ethylene-signalling pathway in harvested banana fruit in response to temperature and 1-mcp treatment. J. Sci. Food Agric., 91(4): 650-657.

Zapata, P.J., F. Guillen, D. Martinez-Romero, S. Castillo, D. Valero and Serrano, M. 2008. Use of alginate or zein as edible coatings to delay post-harvest ripening process and to maintain tomato (Solanum lycopersicum Mill) quality. J. Sci. Food and Agri., 88: 1287-1293.

To share on other social networks, click on any share button. What are these?