Challenges and Opportunities in Managing Fruit and Vegetable Waste: A Comprehensive Review

Challenges and Opportunities in Managing Fruit and Vegetable Waste: A Comprehensive Review

Sana Nawaz1, Shahzor Gul Khaskheli1*, Aijaz Hussain Soomro1, Inayatullah Rajper2, Saghir Ahmed Sheikh3, Ashfaque Ahmed Khaskheli1 and Shaista Soomro1

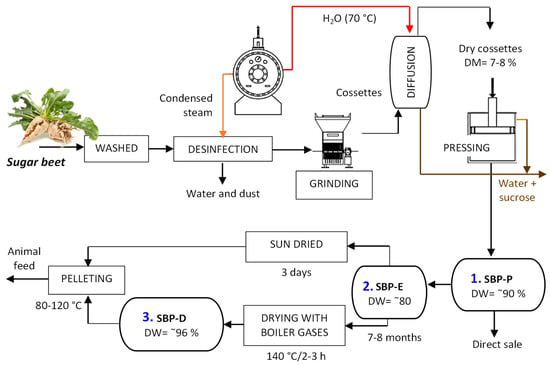

Industrial process of sugar extraction form sugar beet. By-products obtained: 1. SBP-P: sugar beet pulp pressed, 2. SBP-E: sugar beet pulp ensiled, 3. SBP-D: sugar beet pulp dried. DW: dry weight. (Pacheco et al., 2019)

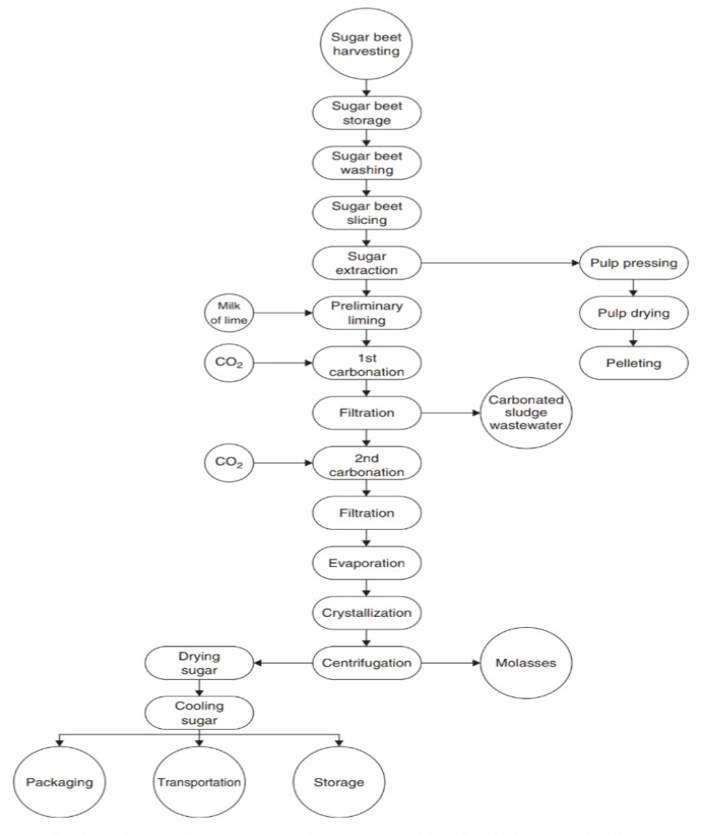

A simplified Flow diagram of the sugar industry (Kotzamanidis et al., 2000; Vaccari et al., 2005).

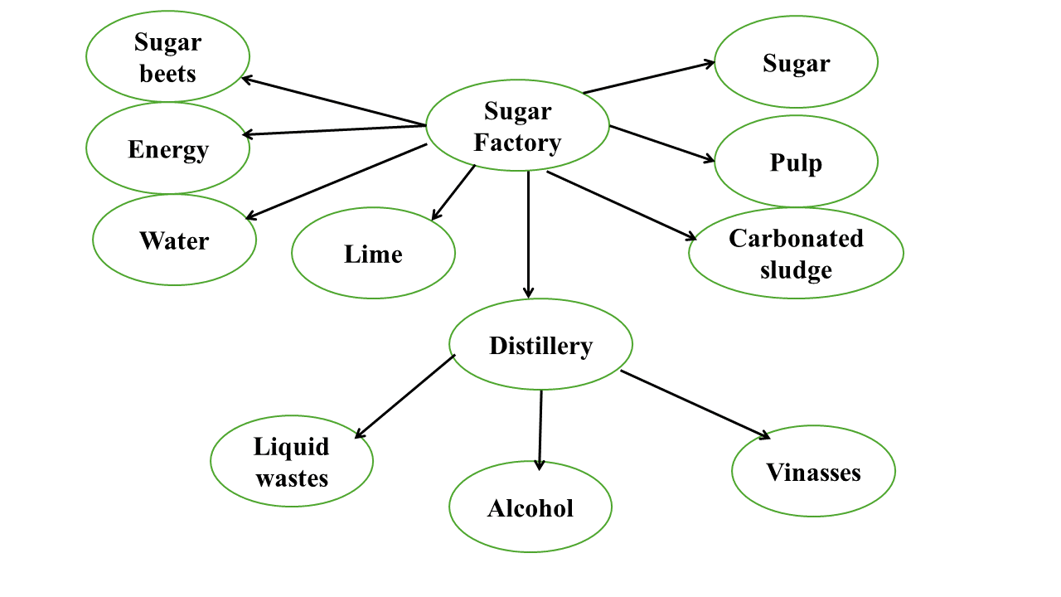

Flow in and out of the distillery/distillery (Kotzamanidis et al., 2000; Vaccari et al., 2005).