Advances in Animal and Veterinary Sciences

Research Article

Zootechnical and Economic Efficiency of Premix use in Poultry Feeding

SI Nikolayev1*, AK Karapetyan1, VN Rudnikov1, LV Andreyenko1, VG Frizen2, SO Shapovalov3

1Volgograd State Agrarian University; 2MegaMix LLC; 3SRC “Cherkizovo”

Abstract | The paper presents the results of the use of a premix, in which a mustard protein-containing feed concentrate “Gorlinka” was used as a filler, in the rations of broiler chickens and laying hens. The use of premix based on the derivative products of the oil extraction industry made it possible to increase the average daily weight gain in broiler chickens by 3.5%, the live weight at the end of the experiment – by 3.42%, and the total gain – by 3.51%. The authors also observed a tendency to feed cost reduction per 1 kg of live weight gain in poultry of the experimental group. Thus, the feed costs were lower in the experimental group by 3.68% and the cost efficiency of the new premix was 6,730 rubles per 1,000 animals. Positive results were also obtained for the second experiment on laying hens. The use of the premix based on the “Gorlinka” feed concentrate in rations contributed to an increase in egg-laying capacity of the poultry by 0.81%, an increase in the average egg weight by 1.26%. The cost of compound feed for the production of ten eggs was reduced by 2.27%. The cost efficiency of the new premix was 3,782.24 rubles per 1,000 animals. Based on the obtained results, the recommend the inclusion of premix with “Gorlinka” concentrate in rations of agricultural poultry in order to increase its productivity and the cost efficiency of the poultry industry.

Keywords | Broiler chickens, Laying hens, Compound feed, Premix, Live weight, Egg-laying capacity

Received | June 12, 2019; Accepted | August 30, 2019; Published | October 15, 2019

*Correspondence | SI Nikolayev, Volgograd State Agrarian University; Email: [email protected]

Citation | Nikolayev SI, Karapetyan AK, Rudnikov VN, Andreyenko LV, Frizen VG, Shapovalov SO (2019). Zootechnical and economic efficiency of premix use in poultry feeding. Adv. Anim. Vet. Sci. 7(s1): 106-111.

DOI | http://dx.doi.org/10.17582/journal.aavs/2019/7.s1.106.111

ISSN (Online) | 2307-8316; ISSN (Print) | 2309-3331

Copyright © 2019 Nikolayev et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

INTRODUCTION

Poultry farming is the most rapidly developing branch of the agro-industrial complex, which demands better quality of feed and feeding technology for poultry (Nikolaev et al., 2013; Patterson and Burkholder, 2003).

A lack of feed and an increase in their cost stimulates the need to search for opportunities to further increase the biological value of basic feeds and to determine the texture of compound feeds, in which the addition of biologically active substances and feed additives would be the most effective (Volkolupov et al., 2016; Nikolaev et al., 2014).

Premixes, which contain minerals, amino acids, vitamins, and other biologically active substances, play an important role in the diets (Karapetyan et al., 2014; Sherstyugina et al., 2014).

In recent years, the oil processing industry has been rapidly developing in the Lower Volga region and cake and meal resulting from it are secondary concentrate products (Lipova et al., 2014; Sherstyugina et al., 2015).

Therefore, our studies aimed at a comprehensive study of the effectiveness of the use of the latest premixes (in which mustard protein-containing feed concentrate “Gorlinka” is used as filler) in poultry rations are relevant.

The aim of our study was to increase the production of poultry meat and chicken eggs using premixes based on mustard protein-containing feed concentrate “Gorlinka” in compound feeds for broiler chickens and laying hens.

MATERIALS AND METHODS

Before carrying out a series of scientific experiments on poultry, we studied the chemical and amino acid composition of sunflower meal and protein-containing feed concentrate “Gorlinka”.

After that, a series of experiments was conducted to identify the effectiveness of the use of the premix based on the “Gorlinka” concentrate in the rations of broiler chickens and laying hens. Studies were conducted during the period from 2015 to 2017 at the leading poultry enterprises of the Volgograd region.

For the experiments, the birds were divided into groups using the analog method: age, physiological condition, productivity, health, live weight, and other indicators were taken into account.

For the experiment on broilers of the “Ross 308” cross, two groups (control and experimental) with 100 animals in each were formed at the age of one day. The period of the experiment was 37 days.

For the experiment on laying hens of the “Hisex Brown” cross, two groups (control and experimental) with 60 animals in each were formed. The experiment began when the birds were 120 days old, and its duration was 52 weeks.

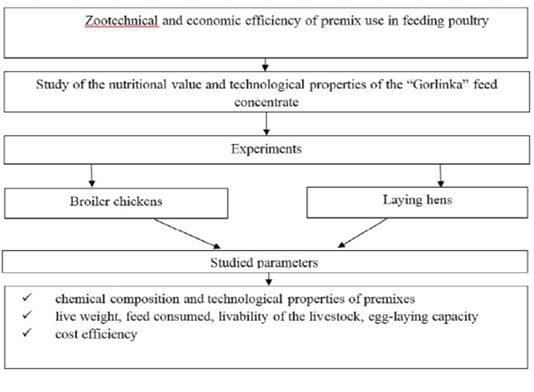

The general scheme of research is presented in Figure 1.

Figure 1: General research scheme.

RESULTS AND DISCUSSION

The chemical composition of sunflower oil meal and “Gorlinka” feed concentrate is presented in Table 1.

Table 1: Comparative analysis of the chemical composition of sunflower meal and mustard protein-containing feed concentrate “Gorlinka”.

| Parameter | Sunflower meal | Mustard protein-containing feed concentrate “Gorlinka” |

| Water, % | 9.3 | 8.9 |

|

Dry matter, % |

90.7 | 91.1 |

|

Crude fat, % |

8.4 | 9.3 |

|

Crude fiber, % |

13.8 | 10.1 |

|

Crude ash, % |

6.0 | 6.8 |

|

Crude protein, % |

36.9 | 38.5 |

|

Nitrogen-free extractive substances, % |

25.6 | 26.4 |

|

Metabolic energy, kcal/100 g |

296.29 | 312.43 |

Results of the chemical composition study suggest that the content of crude protein in “Gorlinka” feed concentrate was 38.5%, which was 1.6% higher than in sunflower meal. The content of dry matter, crude ash and nitrogen-free extractive substances in concentrate was also higher than in oil meal by 0.4%, 0.8% and 0.8%, respectively.

The amount of crude fiber was 3.7% lower in “Gorlinka” concentrate than in sunflower meal, which had a positive effect on the quality of the resulting product. The amount of amino acids in concentrate was 25.57%, which was 2.93% higher than in sunflower meal.

The technological properties of the filler for premixes were also studied. “Gorlinka” concentrate met the basic requirements for the filler: the pH level was close to neutral (5.5-7.5), water content was 8.9%, fat and fiber contents were 9.3% and 10.1%, respectively. The studied concentrate was not prone to dust generation, met the friability and caking requirements and facilitated the formation of a homogeneous mixture.

Therefore, the mustard protein-containing feed concentrate “Gorlinka” met the basic requirements for premix fillers.

The first experiment was carried out on laying hens of the “Hisex Brown” cross. For the experiment, two groups of laying hens with 120 animals in each were formed. The duration of the experiment was 52 weeks.

During the experiment, the birds from the control group received the standard ration used at the poultry farm, in which sunflower meal was used as a filler for the premix, and the birds from the experimental group were fed with compound feed with premix based on the “Gorlinka” feed concentrate.

In poultry egg production, production is determined based on the number of eggs laid and their weight. Egg production is inextricably linked with the development and physiological state of the reproductive organs of the hens and depends on the intensity of metabolic processes in the chicken body (Nikolaev et al., 2013).

In the studies conducted on laying hens, it was found that the use of the premix under study contributed to an increase in gross egg production (Table 2).

Table 2: Egg-laying capacity of the laying hens.

| Parameter | Group | |

| Control | Experimental | |

| Total number of chickens | 120 | 120 |

| Total number of eggs produced |

39,864 |

40,188 |

| by one hen on average | 332.2 | 334.9 |

|

Average egg weight, g |

61.97 | 62.75 |

| Total weight of eggs produced, kg |

2,470.37 |

2,521.80 |

As can be seen from the data in Table 2, 332.2 eggs per one hen were obtained in the control group and 334.9 eggs per one hen were produced in the experimental group, which received premixes based on the mustard protein-containing feed concentrate “Gorlinka”. This parameter in the experimental group exceeded the control by 0.81%. The average weight of eggs was 1.26% higher in poultry from the experimental group. The total weight of the eggs produced during the experiment in the control group was 2,470.37 kg. This parameter of egg productivity was 2.10% higher in the experimental group (by 51.43 kg) compared to the control group.

An important indicator in assessing egg productivity of hens is the feed consumption per 10 eggs (Table 3).

Table 3: Feed consumption for the duration of the experiment.

| Parameter | Group | |

| Control | Experimental | |

|

Feed consumption, kg: total |

5,222.18 |

5,184.25 |

| per 1 kg of egg weight | 2.11 | 2.06 |

| per 10 eggs | 1.31 | 1.29 |

It was established that, with the use of the premix based on mustard protein-containing feed concentrate “Gorlinka” in the feed for laying hens of the experimental group, the total feed consumption during the entire experiment was 37.93 kg lower. At the same time, the calculation of the feed consumption per 1 kg of egg mass showed that in the control group this parameter was 2.11 kg, which is 0.05 kg higher than in the experimental group. The feed consumption per 10 eggs in the experimental group was 1.29 kg, which is 0.02 kg lower than in the control group.

Thus, the introduction of premix based on mustard protein-containing feed concentrate “Gorlinka” into the compound feed for laying hens contributed to an increase in egg production and egg weight, as well as a reduction in feed consumption per 10 eggs.

Currently, there is a deficiency of protein in the forage resources, which calls for the use of new, more modern protein sources (Nikolaev et al., 2018b). One of the accessible and inexpensive feeds is the mustard protein-containing feed concentrate “Gorlinka”, which is equal in nutrition value to many feeds and even exceeds the sunflower meal in amino acids content. The cost efficiency of the premix based on the mustard protein-containing feed concentrate “Gorlinka” as part of the feed is shown in Table 4.

Table 4: Cost efficiency of the premix based on mustard protein-containing feed concentrate “Gorlinka”.

| Parameter | Group | |

| Control | Experimental | |

| Number of animals: | ||

| at the beginning of the experiment | 120 | 120 |

| at the end of the experiment | 120 | 120 |

|

Viability, % |

100 | 100 |

|

Gross egg production |

39,864 |

40,188 |

| Average egg-laying capacity of one laying hen | 332.2 | 334.9 |

|

Feed consumption, kg |

5,222.18 |

5,184.25 |

| Cost of feed consumed, rubles |

47,887.39 |

47,021.15 |

| Additional net profit due to cost savings on feeds, rubles | 866.24 | |

| Gross egg sale revenues, rubles |

358,776 |

361,692 |

| Additional net profit from egg sales, rubles |

2,916 |

|

| Cost advantage of using the premix, rubles |

3,782.24 |

|

According to the experimental results presented in Table 4, it can be concluded that the use of the premix based on the mustard protein-containing feed concentrate “Gorlinka” contributed to an increase in the gross production of eggs by 324, or 0.81%, compared with the control group.

Following the described above results, the average egg-laying capacity per one laying hen was 334.9, which was 2.7 more than in the control group. Due to the lower price of compound feed used in the experimental group, the cost of the feed used during the entire period of the experiment was 1.81% lower than in the control group. Thus, additional net

Table 5: Changes in live weight of experimental broiler chickens, g. (М ± m).

| Group | Age, days | Total gain | Average daily gain | ||||||

| 1 | 7 | 14 | 21 | 28 | 35 | 37 | |||

| Control | 57 |

188±1.02 |

482±2.39 |

930±5.2 |

1,503±13.03 |

2,145±14.47 |

2,339±15.50 |

2,282 |

61.68 |

| Experimental | 57 |

190±0.99 |

489±2.62 |

948±2.63* |

1,538±11.18* |

2,209±12.50** |

2,419±17.63*** |

2,362 |

63.84 |

profit due to cost savings on feed was 866.24 rubles. The average sales value of 1,000 hatching eggs is 9,000 rubles, and the gross profit for the experimental group was 0.81% higher compared to the control group, which made it possible to obtain an additional net profit of 2,916 rubles from the sale of eggs. As a result, the cost advantage of the use of premix was 3,782.24 rubles.

Additionally, at the “Krasnodonskaya Poultry Farm” JSC located in the Ilovlinsky District of the Volgograd Region, a second experiment was carried out using one-day-old broiler chicks of the “Ross 308” cross. For the experiment, two groups of birds (control and experimental, 100 animals in each) were formed. Birds for the experiment were selected using the analog method. All zoohygienic parameters for the poultry of the experimental and control groups corresponded to the recommendations for the cross.

During the experiment, the broiler chicks from the control group received the basic ration with premix based on sunflower meal, and the birds from the experimental group were fed with basic ration with premix based on the “Gorlinka” feed concentrate.

One of the criteria for the sufficiency of poultry feeding and one of the factors that determine its further productive and reproductive properties is the live weight both in the early stages of the productive period and in the future (Buryakov et al., 2015; Kornilova and Senko, 2012). Data on the dynamics of the live weight of broiler chickens are presented in Table 5.

Feeding of the experimental broiler chickens with feed with the premix based on the mustard protein-containing feed concentrate “Gorlinka” returned positive results.

The live weight of the chickens from the experimental group during the entire growing period was higher compared to the control group.

For example, at the end of the growing period at the age of 37 days, live weight of broilers of the experimental group was 2,419 g, which was 3.42% higher (by 80 g) than in the control group. Live weight of the birds of the control group at the end of the experiment was 2,339 g. The total live weight gain in chickens of the experimental group was 2,362 g, which is 3.51% higher than in the control group.

The average daily live weight gain in chickens of the experimental group was 3.5% higher than that of the control group birds.

One of the most important indicators in the assessment of the effectiveness of feeding broiler chickens is the reduction of the feed cost per animal per day (Nikolaev et al., 2018c).

Balanced ration contributes to the reduction of feed consumption per unit of production (Nikolaev et al., 2018a). Feed consumption in poultry of both groups was the same (Table 6). However, the feed consumption per 1 kg of live weight gain in broiler chickens of the experimental group was 3.68% lower compared to the control group.

Table 6: Feed consumption per one animal and 1 kg of weight gain in experimental broiler chickens, kg.

| Parameter | Group | |

| Control | Experimental | |

| Feed consumption: | ||

| total for group | 371 | 371 |

| per one animal | 3.71 | 3.71 |

| per 1 kg of weight gain | 1.63 | 1.57 |

Table 7: Cost efficiency of the premix based on mustard protein-containing feed concentrate “Gorlinka” in broiler chicken feeding.

| Parameter | Group | |

| Control | Experimental | |

| Number of animals | 100 | 100 |

| Live weight gain per one animal, kg | 2.282 | 2.362 |

| Weight of eviscerated carcass, g |

1,726 |

1,787 |

| Total feed consumption per one animal, kg | 3.71 | 3.71 |

|

Feed cost, rubles |

7,791 |

7,642.6 |

| Gross yield of meat, kg | 172.6 | 178.7 |

| Price of 1 kg of carcass, rubles | 86 | 86 |

| Total revenue from selling, rubles |

14,843.6 |

15,368.2 |

|

Additional production obtained, rubles |

7,052.6 |

7,725.6 |

|

Additional profit, rubles |

- | 673 |

| Attributable profit per 1,000 animals, rubles | - | 6,730 |

The key to the successful development of the poultry industry in modern conditions is the proper organization of fully functional feeding of poultry using complete feeds, which leads to lower production costs (Nikolaev and Karapetyan, 2012; Xu et al., 2012). Cost efficiency of the premix based on the mustard protein-containing feed concentrate “Gorlinka” in the composition of the feed is shown in Table 7.

The gross yield of meat was 6.1 kg higher in the experimental group than in the control. Analysis of the cost efficiency of the new premixes in poultry feeding showed that 14,843.6 rubles were earned from the sale of meat from the control group, and 15,368.2 rubles were earned from the sale of meat from the experimental group.

Additional profit was 673 rubles per 100 animals. Estimated additional profit was 6,730 rubles per 1,000 animals.

CONCLUSION

The use of the premix that we developed contributed to an increase in live weight of broiler chickens by 80 g (3.42%), and an increase in average daily gain by 2.66 g (3.50%). Feed consumption per 1 kg of gain was lower by 0.06 kg (3.68%) in the group of broilers that received “Gorlinka” premix in their compound feed. According to the cost efficiency analysis, the birds from the experimental group demonstrated better results. For example, the additional profit was 673 rubles, which translates into 6,730 rubles per 1,000 broiler chickens.

Analysis of the egg productivity of laying hens showed that the birds from the experimental group, in which premix based on “Gorlinka” concentrate was used, had a higher egg-laying capacity. For example, the use of the new premix with feed concentrate “Gorlinka” increased the egg production per laying hen by 2.7 (0.81%), the average egg weight – by 0.78 g (1.26%), while lowering the feed costs per 10 eggs by 0.02 kg. The cost efficiency analysis showed that the best economic effect (3,782.24 rubles per 1,000 animals) was achieved in the group of birds that were fed with premix based on “Gorlinka” concentrate.

Therefore, the inclusion of premix based on mustard protein-containing feed concentrate “Gorlinka” in the compound feed contributed to the improvement of the productivity of poultry, and the efficiency of feed utilization, which positively affected the cost efficiency of poultry enterprises.

Authors Contribution

All authors contributed equally.

conflict of interest

The authors state that there are no conflicts of interest.

Ethical Clerance

Ethical permission to conduct research was obtained from the methodological commission of the Faculty of Biotechnology and Veterinary Medicine of the Volgograd State Agrarian University.

REFERENCES