Advances in Animal and Veterinary Sciences

Research Article

Physiochemical, Sensory Characteristics and Acceptability of a New Set Yogurt Developed From Camel and Goat Milk Mixed with Buffalo Milk

Marwa I. Khalifa*, Asem M. Zakaria

Department of Food Hygiene, Faculty of Veterinary Medicine, Aswan University, 81528 Sahary City, Egypt.

Abstract | To the best of our knowledge, this study is the first trial for production of plain set yogurt from camel milk without addition of non-dairy additives. Camel milk is the top healthy functional milk since it contains hypocholesterolaemic, anti-diabetic factors as well as prolonged shelf life. Camel milk, however, has a salty taste that makes it unpalatable to the consumers, besides its poor yield of yogurt that makes it almost economically inadequate. Goat milk, in another hand, can yield a standard yogurt although is not so palatable to Egyptian populations. This experiment was designed to improve camel and goat yogurt by addition of different concentrations from buffalo milk. The physiochemical and sensory properties were investigated and revealed great advances in total solids, firmness, taste, and overall acceptability of the new yogurt products. The acidity degree of pure buffalo yogurt was 75.3, while that for both pure camel and goat yogurt was 90. Such acidity was reduced with the increase of buffalo milk added. In order to obtain a set yogurt from camel milk without use of non-dairy additives and overcome its sharp taste it is strongly recommended being fortified with buffalo milk.

Keywords | Camel milk, Buffalo milk, Goat yogurt. Set yogurt

Editor | Kuldeep Dhama, Indian Veterinary Research Institute, Uttar Pradesh, India.

Received | October 25, 2018; Accepted | December 02, 2018; Published | December 29, 2018

*Correspondence | Marwa L Khalifa, Department of Food Hygiene, Faculty of Veterinary Medicine, Aswan University, 81528 Sahary City, Egypt; Email: [email protected]

Citation | Khalifa MI, Zakaria AM (2019). Physiochemical, sensory characteristics and acceptability of a new set yogurt developed from camel and goat milk mixed with buffalo milk Adv. Anim. Vet. Sci. 7(3): 172-177.

DOI | http://dx.doi.org/10.17582/journal.aavs/2019/7.3.172.177

ISSN (Online) | 2307-8316; ISSN (Print) | 2309-3331

Copyright © 2019 Khalifa and Zakaria. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Introduction

Yogurt is not only a fermented dairy product, but also therapeutic functional food as well. It can duplicate the milk benefits and minimize its mischief like milk allergy and/or lactose intolerance. The conversion of liquid milk into yogurt is considered public and commercial demand. Yogurt inherits the feature of the plain milk from which it is made. Therefore, the composition of the plain milk (from which the yogurt is made) is potentially affected the quality and character of the yogurt produced.

Buffalo, camel and goat are widely distributed in the Arab countries and North Africa. Milk from such animals has its own characteristics and distinct components, even if they are generally similar.

Buffalo milk is the formal milk in Egypt. It has a great white color and characterized by its high fat-lactose percent, total solids, and its excellent opportunity to manufacture products. Buffalo’s milk is very palatable and considered as the most available and popular milk in Egypt.

Casein in buffalo milk is present in a form of large size micelles. The fat content in buffalo milk may reach 7.06: 8%, which is the highest among all ruminant milks. Additionally it has a high total solids of about 14.5: 18% that makes buffalo milk produce yogurt in a high yield with a low synersis without any need to add milk powder or hydrocolloids (Ahmad et al., 2009).

Camel’s milk, on the contrary, is rare in Egyptian urban market and non-palatable to Egyptian consumers in spite of the fact that camel milk is the top healthy milk due to its bioactive peptides released when protein of camel milk is digested. Such bioactive peptides promote consumer health by acting as hypocholestrimic, hypoglycemic, hypoallergic, immune stimulants, antimicrobial factors and anti-carcinogenic (Mudgil et al., 2018a). Camel milk is also rich in vitamin C (3-5 times more than that in bovine milk), unsaturated fatty acids and B vitamins as well as minerals. (Al Shamsi, et al., 2018).

Casein in camel milk is chiefly in a form of B- casein, while whey proteins are composed mainly of lactoalbumin, similar to that in human milk, which may explain why camel milk is non-allergic to human (El-Agamy, 2000; Al-Shamsi et al., 2018).

The chloride percentage in camel milk is very high comparing to other ruminants’ milk. This may be due to nature of camel life and nutrition on dry plants and long physiological periods of thirsty. Unlike conventional cow’s milk, camel milk is characterized by noticeably high iron and copper levels (Khaskheli et al., 2005). This chloride and iron may be the responsible elements of salty taste of camel milk. Camel milk has a long- shelf life of 3 days for raw camel milk in room temperature vs few hours for bovine milk, and 10 days of pasteurized camel milk vs 3 days of pasteurized bovine milk (Wernery, 2008). The longer shelf life of camel milk is referred to its dynamic antimicrobial system, which consists of lysozyme, lactoferrin, hydrogen peroxide, and low molecular antibodies (Algboory and Muhialdin, 2018).

Despite the unique health benefits and nutritional values of camel milk, it is very difficult to convert it into economically fermented dairy products; it consumed long coagulation time and produce weak fragile curd and therefore its use remains by far distance restricted as liquid milk. The poor ability of camel milk to yield fermented dairy products is mainly due to its content of the strong antimicrobial agents that interferes with the starter action. Other causes may be related to its protein nature which shows low content of K-casein with high content of large casein micelles and low total solids (El-Agamy, 2000; Al haj and Al Kanhal, 2010).

Goat milk is not very favored by consumer, although its high nutritive value and high digestibility, which referred to less lactose and smaller fat globules (Domagala, 2009) that make the caprine milk (naturally homogenized) providing a greater surface area of fat for enhanced digestive action by lipases enzyme (Chandan et al., 1992). In addition, the higher levels of short- and medium-chain- fatty acids capric, caprylic and caproic acids are responsible for the characteristic flavor associated with goat’s milk. (Bruhn and Davis, 2000). Goat milk is also recommended to those whom suffer from cow milk allergy especially infants due to its different composition of protein with lower casein and lactose content (Clark et al., 2017). Due to the small size of fat globules and protein in goat milk, as well as its high total solids, the yogurt yield from goat milk is standard with soft smooth firm gel and good water holding capacity. (Haenlein, 2004).

In Egypt goat milk is not an available product in all markets, and its characteristic fatty acids flavor may be the reason that makes it unaccepted by most of the Egyptian consumers although it may be accepted in another countries.

According to the plain composition of goat and camel milk, the yogurt produced from them will have dissimilar characters, the camel yogurt are liquid and with long shelf life due to naturally occurring antimicrobial lactoferrins that retard the microbial starter activities and microbial spoilage. Goat yogurt, on the other hand, is more viscous than camel and less firm than buffalo yogurt and have higher digestibility and lower allergenic properties (Ranadheera et al., 2012).

Therefore, this experiment was designed to manufacture new yogurt by mixing buffalo milk with camel and goat milk to improve their quality, acceptability and palatability; and at the same time to reserve the buffalo milk, which is valuable and rare in arid areas.

Materials and Methods

Milk Samples

Fresh raw buffalo’s, camel’s and goat’s milks were used in this experiment. Seven litters from buffalo’s milk were purchased from local markets in Egypt. Two litters from goat’s milk were obtained by direct milking of lactating goats from local farm in Aswan. Two litters from camel’s milk were purchased from Aswan markets, Egypt.

Lyophilized starter culture (YoFlex® Express 2.0 Chr Hansen, Hørsholm, Denmark) containing Streptococcus thermophilus and Lactobacillus was used for yoghurt preparation.

Examination of Sampled Milk

All fresh milk types were submitted to alcohol precipitation test (APT) and growth inhibitors to guarantee its suitability for yogurt formation then scanned by Lactoscan MCCW in the Laboratory of Food Safety Program, Mansoura University, Egypt for compositional analysis of raw milk.

Yoghurt Preparation

Raw samples of the three types of milk were pasteurized separately at 85 °C for 5 min in a stainless-steel double jacket container before being cooled to the inoculation temperature (40: 42 °C). Three samples of 100% buffalo milk, 100% camel milk and 100% goat milk were used as control samples. Six different formulations were prepared, by mixing buffalo’s milk in different proportions with other two types (Table 1). After cooling, the starter was inoculated at a concentration of 1:1000 and the mixtures were transferred to sterile plastic containers which were kept at 42 °C in an incubator until a pH reached 4.6 then kept at the refrigerator at 4 °C. This experiment was repeated five times.

Table 1: Different formulations for experimental yogurt preparation

| Sample | Code | Composition | N.B |

| 1 | BFM | 100% buffalo milk | control |

| 2 | CMM | 100% camel milk | control |

| 3 | GTM | 100% goat milk | control |

| 4 | BC50 | 50% buffalo milk: 50% camel milk | |

| 5 | BC60 | 60% buffalo: 40% camel | |

| 6 | BC90 | 90% buffalo: 10% camel | |

| 7 | BG50 | 50% buffalo: 50% goat milk | |

| 8 | BG60 | 60% buffalo: 40% goat | |

| 9 | BG90 | 90% buffalo: 10% goat |

Physical Properties

Titratable acidity: Titratable acidity, expressed as percentage of lactic acid, was determined by mixing 10 g of yogurt with 20 mL of distilled water, 0.5 mL phenolphthalein at 5% indicator, and then titrated against NaOH N/10 solution until appearance of end point (stable faint pink color).

pH determination: The pH value of yogurt samples was determined by using a pH-meter (HANNA-pH 210, Germany). The measurements were done in triplicate for each sample.

Sensory Evaluation

Rheological properties: Coagulation time of each formula was calculated till pH dropped to 4.6. The consistency of curd produced was measured. Syneresis (the quantity of whey which has drained from a known weight of the sample) was determined according to Hassan et al. (1996). Thirty grams of the gel was cut in a single action by clean ladle and drained for 2 h at 5°C on a funnel lined with filter paper introduced in a graduated cylinder to collect the whey,. Syneresis degree was expressed by the amount of the drained whey in ml.

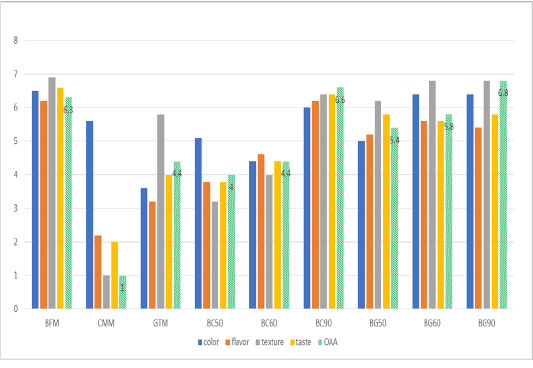

Consumer acceptance testing: Consumer acceptance testing was designed in a form of seven grade score card (1 = very bad and 7 = very good) expressing five properties of yogurt including: color (degree of whiteness), flavor, texture, taste and overall acceptability. Eleven experienced panelists were asked to score the quality of coded yoghurt samples on this score card.

Shelf Life

Shelf life of each product was calculated in days, from manufacturing till spoilage. Total mold count (TMC) was the indicator of spoilage. Dichloran-Glycerol (DG18) agar with chloramphenicol was used in TMC by inoculating 0.1 ml of yogurt sample on surface and incubation at 25 °C for 72hrs in upright position.

Statistical Analysis

Data were analyzed using SPSS (Statistical Package for Social Science) program version 20 (SPSS Inc, Chicago, Illinose, USA). Data were entered as numerical or categorical, as appropriate. Quantitative data were presented as mean and standard deviation (SD).

Results and discussion

Camel milk is an exceptional milk, rich in different therapeutic agents against infection, allergy, diabetes, hypercholesterolaemia, hypertension and cancer. (Al haj et al., 2010; Algboory and Muhialdin, 2018). Nonetheless it has a salty taste and difficult to be converted into palatable products. The sharp taste defect of camel milk minimize its use as a liquid milk by the consumers, and hence deprivation of consumers from getting most of its benefits. If buffalo milk is mixed with camel milk to compensate its low total solids and sharp taste, the camel milk will be fully gainful.

Chemical Composition

Chemical composition of fresh milk of buffalo, camel and goat was shown in Table 2 which declared that buffalo’s milk exhibited the highest protein (3.69), fat (7.52) and lactose (5.07) ratios in comparison with both of camel milk, which revealed 3.01, 3.22, 4.53, and goat milk, which contained 2.91, 3.7, 4.99 for protein, fat and lactose, respectively. Similar percentages were recorded by Hussain et al. (2011), Salih and Hamid (2013) and Ibrahem and El Zubeir (2016). Surprisingly, the total solids in goat milk is a little bit than expected this may be due to several factors including breed difference, stage of lactation, feeding system and individual variations (Haenlein, 2004; Pirisi et al., 2007; Gaddour et al., 2013).

Acidity and pH

The plain goat milk has the highest pH of 7. It is almost certainly a result of goat milk protein buffering capacity and casein content versus whey proteins as reported by Puvanenthiran, et al. (2002). This high pH did not affect the produced yogurt pH which was ranged for all formulas

Table 2: Physiochemical composition of plain fresh milk.

| Sample | Fat % | SNF % | Lactose % | Salts % | Protein % | Total solids % | pH | Density | Conductivity |

|

BFM

|

7.52± 0.03* |

9.23± 0.04 |

5.07± 0.02 |

0.75± 0.02 |

3.69 ± 0.03 |

16.75 ± 0.06 |

6.4 ± 0.03 |

31.5 ± 1.3 |

4.03 ± 0.03 |

|

CMM

|

3.22 ± 0.05 |

8.24 ± 0.05 |

4.53± 0.01 |

0.68 ± 0.02 | 3.01 ± 0.02 |

11.46 ± 0.1 |

6.75± 0.03 |

30.6 ± 0.8 |

5.38 ± 0.02 |

|

GTM

|

3.7 ± 0.18 |

8.56 ± 0.1 |

4.99± 0.04 |

0.66± 0.01 |

2.91 ± 0.1 |

12.26 ± 0.12 |

7 ± 0.08 |

28.6 ± 1.2 |

± 0.14 |

*±= SD

Table 3: Acidity and rheological properties of yoghurt formula

| Formula | Acidity ±SD | pH | Coagulation time (minuets) | Consistency | Syneresis Ml/2hrs | Shelf-life (Days) |

| BFM | 75.3 ±2.51 | 4.6 | 180±10 |

Firma |

6.13 ± 0.95c |

7 |

| CMM | 90 ±1.73 | 5 | 960 | liquid | 24.33 ± 1.53 | 18 |

| GTM | 90 ±0 | 4.7 | 235±10 | Moderately firm | 9.07 ± 1.001 | 6 |

| BC50 | 87 ±1 | 4.8 | 420±10 | Slightly firm | 17.97 ± 1.95 | 9 |

| BC60 | 81.3 ±1.53 | 4.6 | 380±10 | Moderately firm | 14.23 ± 1.96 | 9 |

| BC90 | 77 ±1 | 4.6 | 250±10 |

Firmb |

8.7 ± 0.72 | 8 |

| BG50 | 75.5 ±0.5 | 4.6 | 230±10 | Slightly firm | 8.2 ± 1 | 7 |

| BG60 | 76 | 4.6 | 210±10 |

Firmb |

6 ± 0.5 | 7 |

| BG90 | 74.83 ±0.76 | 4.6 | 210±10 |

Firma |

1.97 ± 0.25 |

7 |

a= standard curd, b= good curd, c= SD

between 4.6 and 4.8 except CMM yogurt which have a pH 5 (Table 3). Similar results for pH in camel and goat milk were obtained by Salih and Hamid (2013); Eissa et al. (2011). Conversely, the titratable acidity was significantly different; camel and goat yogurt showed the highest acidity degree (90), while buffalo yogurt showed the lowest (75.3).

The present study indicated that the degree of acidity decreased with the increase of buffalo milk percentage in the formulations. These findings are in accordance with those of Eissa et al. (2011) and Nahar et al. (2007) who recorded acidity degree of 0.93 and 0.74 in goat and buffalo yogurt, respectively. Similarly Boycheva et al. (2011) and Damunupola et al. (2014) recorded acidity degree of 98.7 and 91in goat yogurt, respectively.

Sensory Evaluations

Rheological properties: Rheological properties scheduled in Table 3 showed that BFM formula had the shortest coagulation time (180 min) comparing with CMM formulation which showed the highest coagulation time of 960 min. This finding for camel formula is in agree with the results of Ibrahem and El Zubeir (2016), who recorded 15 to 17 h as a coagulation time for camel yogurt formation. On the other hand, GTM required only 235 min to form coagulum. Shorter coagulation times are of course referred to the high total solids contents of buffalo and goat milk, while the long time consumed by CMM (˃ 960 min) is as a result of the antimicrobial system of camel milk like lactoferrin and lactoperoxydase, which hampered the growth of lactic acid bacteria (El Sayed et al., 1992; El Agamy, 1994; El-Agamy, 2000). On the other hand, the nature and size of casein missiles which characterized by a low proportion of kappa casein is a serious cause of non-coagulation of camel milk (Farah, 1993; Raznikiewicz, 1994; Shuiep et al., 2013). For other yogurt formulations, the intensification of buffalo and goat milk leads to reduction of the coagulation time.

The obtained results revealed that the consistency of coagulum was covenant with the coagulation time. BFM and BG90 formulations showed the ideal firmness due to ideal total solids and fat %, along with the subsequent good gel formation yields, low syneresis amounts and little whey separation (Table 3). While, CMM formula persist as a liquid. Similarly, a liquid yogurt has been yielded previously in camel milk (Mustafa et al., 2015; Ibrahem and El Zubeir, 2016).

Firmness and consistency of yogurt are very essential elements in judging its quality. Therefore, the liquid consistency of the yogurt produced from camel’s milk is considered a major defect in the product. Restricted studies had been carried out to produce camel set yogurt by addition of hydrocolloids and stabilizers like gelatin, alginate (Mudgil et al., 2018 b), carboxymethyl cellulose CMC, pectin, gum acacia (Al-Zoreky et al., 2015) or skim milk powder (Salih et al., 2013). However they did not produce a typical curd and still non-natural yogurt.

The present study indicated that the shelf- life of yogurt is extended, by the presence of camel milk, to 18 days for CMM versus 6 to7 days for buffalo and goat milk mixers. Ibrahem and El Zubeir (2016) recorded longer shelf-life of camel yogurt up to 28 days. The richness of camel milk with lysozymes, lactoferrin, Igs and antioxidants -or what are known as anti-microbial system is the responsible agents for this long shelf- life.

Standard TMC is 10/g in yogurt according to NACMCF (2015). In this study the TMC in day 7 was exceeding 10x 103 in all formulae. While, in camel milk formula TMC still lower than 1x 102 up to day 19.

Consumer Acceptance Testing

Sensory attributes of color, flavor, texture, taste and overall acceptability for all yogurt formulations were displayed in Figure 1. The figure revealed that CMM formula achieved the highest score for color but it was the lowest accepted by majority of panelists due to the weak taste and liquid texture. GTM formula also produced good firm texture but it has non-typical yogurt taste and flavor. While, BFM, BCMs and BGMs formulations achieved the highest scores. Among all formulations tested, BG90 and BC90 have the highest overall acceptability (6.8 and 6.6, respectively). This could be attributed to its lower water content and higher fat content in buffalo milk. Comparable results were described by Vargas et al. (2008).

Conclusions

Addition of buffalo milk to camel milk will produce a classic set yogurt acceptable to the consumers with a long shelf-life. Additionally, the palatability of buffalo milk will cover goat milk poor palatability hence a great new set yogurt is yield carrying benefits of each animal plain milk without need to add non-dairy additives.

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Conflict of interest

The authors declared that they have no conflict of interests.

authors contribution

Marwa I. Khalifa, designed, performed the experiment and wrote the manuscript. Asem M. Zakaria collected milk samples and starter culture, analyzed the data, revised the paper. All authors have delegated to Marwa I. Khalifa to assume responsibility for publication and correspondence to the journal. All authors approved the final version of the manuscript for publication.

References