Advances in Animal and Veterinary Sciences

Short Communication

Improving Sakura Block Quality as Feed Supplement to Optimize Rumen Fermentation Products and Nutrients Digestibility In Vitro

Jarmuji Jarmuji1,3, Lili Warly2*, Mardiati Zain2, Khasrad Khasrad2

1Department of Animal Nutrition, Faculty of Animal Science Andalas University, KampusLimau Manis, Padang, West Sumatera, Indonesia; 2Department of Animal Nutrition, Faculty of Animal Science Andalas University, Kampus Limau Manis, Padang, West Sumatera, Indonesia; 3Departement of animal science, University of Bengkulu, Bengkulu, 38371, Indonesia.

Abstract | The purpose of this research was to formulize the best sakura block enriched with earthworm flour by utilizing palm kernel cake as a substitute for corn in optimizing rumen fermentation products and nutrient digestibility in vitro. This research used a completely randomized design with 6 treatments and 3 replications namely the commercial sakura block as control (P0), and sakura block with palm kernel cake and earthworm flour of 0% (P1), 2% (P2), 4% (P3), 6% (P4) and 8% (P5). Result: The findings of the study showed that the higher the earthworm flour in the sakura block, the higher the crude protein content and the total digestible nutrient of the sakura block. However, optimal NH3, VFA, acetate, propionate, and butyrate were obtained in the treatment of sakura block with palm kernel cake and 6% earthworm flour. Although the average digestibility of dry matter, organic matter, and protein in vitro in the research was quite high, there was no difference between treatments. It was concluded that sakura block with palm kernel cake and 6% earthworm flour resulted in the best to optimize rumen fermentation products.

Keywords | Sakura block, Earthworm flour, Palm kernel cake, Rumen fermentation products, Nutrient digestibility

Received | February 22, 2021; Accepted | July 07, 2021; Published | August 15, 2021

*Correspondence | Lili Warly, 2Department of Animal Nutrition, Faculty of Animal Science Andalas University, Kampus Limau Manis, Padang, West Sumatera, Indonesia; Email: liliwarly_uapdg@yahoo.co.id

Citation | Jarmuji J, Warly L, Zain M, Khasrad K (2021). Improving sakura block quality as feed supplement to optimize rumenfermentation products and nutrients digestibility in vitro. Adv. Anim. Vet. Sci. 9(10): 1594-1600.

DOI | http://dx.doi.org/10.17582/journal.aavs/2021/9.10.1594.1600

ISSN (Online) | 2307-8316; ISSN (Print) | 2309-3331

Copyright © 2021 Lukkananukool et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

INTRODUCTION

Sakura block (Sago arenga block) is a feed supplement as a modification of Urea Molasses Multinutrient Block (UMMB) with a mixed formulation of local raw materials to support the energy, nitrogen, and other nutrient needs of ruminants to get quality feed. Sakura block provides a balance of energy, soluble nitrogen, and other nutrients for the growth and development of rumen microbes for livestock (Yanuartono et al., 2016). The contribution of rumen microbial protein in supplying amino acid needs for livestock is 70-100% (AFRC, 1992). Cattle with forage-based feed or agricultural waste for livestock protein needs are sourced from microbes up to 100% (Given et al., 2000). Apart from being a source of protein, rumen microbes also contribute 70-85% of energy requirements in the form of volatile fatty acids (Dewhurst et al., 1986).

The use of sakura block as a feed supplement has been tested on ruminants and has been produced by the Nutrition Laboratory, Department of Animal Husbandry, Bengkulu University. Sakura block consists of 72.59% Total digestible nutrient (TDN). 89.19% dry matter, 17.39% crude protein, 3.73% crude fiber, 3.36% crude fat, 7.55% ash and 65.1% Nitrogen Free Extract (NFE). 10% of the total need for dry matter supplementation can increase body weight gain of 0.6 kg per day on Kaur cattle Jarmuji et al., 2017) and 0.50 kg per day on Bali cattle (Santoso et al., 2017). Sakura block supplementation in dairy goats has received good quality forage and the concentrate does not affect milk production and quality (Soetrisno et al., 2018). Sakura block supplementation of 600 grams per day can increase the income over feed cost of dairy cows (Jarmuji et al., 2018). Sakura block nutritional enrichment as a feed supplement needs to be done, especially in the development of cattle in oil palm plantation areas. In Indonesia, there are 14.32 million hectares of oil palm plantations spread across 24 provinces producing 50.7 tons of crude oil (Directorate General of Plantation, 2019). This high production has the potential to produce huge by-products. Palm kernel cake is a byproduct of oil palm processing with the highest proportion or an average of 12% (Suparjo, 2000). Palm kernel cake has 15-20% crude protein, 2-10.6% crude fat, 13-21.3% crude fiber, 46.7-66.4% Neutral Detergent Fiber (NDF), 39.6-44% Acid Detergent Fiber (ADF) and 3- 12% ash (Alimon, 2006). Palm kernel cake is easily degraded protein sources in the rumen into NH3 and α keto acid (Baktiar et al., 2013). Another protein source that has the potential to enrich the sakura block in developing an integration between cattle and oil palm is the earthworm. The earthworm can be developed by integrating cow-oil palm because most of its food source is the decomposed cow manure (Jarmuji et al., 2015, 2016; Dani et al., 2017). The earthworm can break down cow manure into 3–5 times vermicompost faster than other decomposers with better quality to support oil palm growth (Brata, 2003). Earthworm contains 63.08% crude protein, 18.51% crude fat, 1.08% crude fiber, ash, and 12.41% Nitrogen free extract (Damayanti et al., 2008). Earthworm flour contains branched amino acids 2.75% valine, 2.96% leucine, and 3.14% isoleucine (Hayati et al., 2011). This study aims to obtain the optimal level of earthworms flour in sakura block as a supplementary feed by increasing rumen fermentation products and nutrient digestibility.

MATERIALS AND METHODS

Ethical approval

This research did not use any live animals so, ethical approval is not needed.

Treatment

This research used a completely randomized design with 6 treatments and 3 replications namely the commercial sakura block as control (P0) and sakura block with palm kernel cake and earthworm flour of 0% (P1), 2% (P2), 4 % (P3), 6% (P4) and 8% (P5). The composition of the control and treatment sakura blocks materials can be seen in Table 1.

Procedure

Sampling: Sakura blocks were made from a mixture of ingredients, which included brown sugar, rice bran, corn, sago, urea, salt, crushed Triple Super Phosphate, mineral mix, and topmix, respectively. The ingredients in the form of flour were mixed until they were homogeneous. Water-soluble materials such as brown sugar, urea, and salt were dissolved in water as much as 7% of the total material, then heated over low heat until dissolved. Furthermore, the dry ingredients were mixed with the liquid ingredients until evenly and molded. The molded sakura blocks were dried for 2-3 days.

Table 1: The composition of the control and treatment sakura block materials.

| Material | Treatment | |||||

| P0 | P1 | P2 | P3 | P4 | P5 | |

| Rejected brown sugar | 32.0 | 32.0 | 32.0 | 32.0 | 32.0 | 32.0 |

| Rice barn | 28.0 | 28.0 | 26.0 | 24.0 | 22.0 | 20.0 |

| Corn | 15.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Palm kernel cake | 0.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 |

| Earthworm flour | 0.0 | 0.0 | 2.0 | 4.0 | 6.0 | 8.0 |

| Sagoo | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 |

| Urea | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 |

| Salt | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Triple superphospate | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Mineral mix | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Topmix | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Total | 100 | 100 | 100 | 100 | 100 | 100 |

Chemical analysis of sampling

The chemical composition of the sakura block was analyzed using the proximate analysis to determine the dry matter, organic matter, crude protein, crude fiber, crude fat, ash, and Nitrogen Free Extract (AOAC, 2005). Total Digestible Nutrients (TDN) was calculated using an equation developed by Hartadi et al. (2017).

| Total Digestible Nutrien (TDN) | : |

92.464-3.338(CF)-6.945(EE)-0.762(NFE)+1.115(CP)+0.031(CF2)-0.133(EE2)+0.036(CF)(NFE)+0.100(EE)(CP)-0.022(EE2)(CP) |

Description: CF: crude fiber ,EE: ether extract, NFE: Nitrogen free extract, CP: Crude protein.

In vitro analysis

In vitro analysis was carried out to determine the pH, NH3, total VFA, partial VFA, acetic acid, propionic acid, and butyric acid of each feed component using the (Tilley and Terry, 1969) for 48 hrs for forage and 24 hrs for concentrate. Rumen liquor was obtained from a slaughterhouse from the local goat fed with native grass and concentrate. Incubation was stopped by immersing the Erlenmeyer flask into ice water to stop the microbial activity, after pH measurement was carried out using a pH meter. Next, the supernatant was separated from the residue. Thus, the mixture obtained from in vitro analysis was put into a centrifuge tube and then centrifuged for 30 min, 3000 rpm, at 4°C. The supernatant was stored in bottles and then frozen until subsequent NH3, total VFA, and partial VFA analyses. The Conway method was used to determine NH3 concentration, steam distillation was used to obtain total VFA concentration, and gas chromatography was used to estimate partial VFA concentration. The residue was filetered and dried in a 60°C oven using Whatman No. 41 filter paper. Subsequently, it was examined using the proximate analysis method for nutrient digestibility.

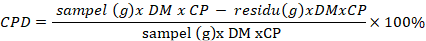

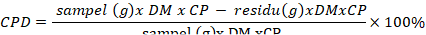

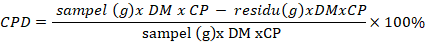

Digestibility of dry matter, organic matter and crude protein

Measurement of dry matter, organic matter and crude protein was carried out by analyzing the sakura block samples and the sakura blok residue as a result of in vitro analysis with proximate analysis. The calculation of digestibility is carried out with the equation.

Description= DMD: dry matter digestibility; OMD: organic matter digestibility; CPD: crude protein digestibility.

Data analysis

The obtained data were analyzed using an analysis of variance. If there were differences, they were then tested by Duncan’s multiple range test. Data obtained from this research were statistically analyzed using SPSS software version 21.0 (SPSS, 2012).

RESULTS AND DISCUSSION

Effect of earthworm flour level in sakura block on the chemical composition

The chemical composition of the sakura block can be seen in Table 2. Experimental results showed that significantly in the components of crude protein, crude fiber, and Total Digestible Nutrient (TDN) between treatments (P <0.05).

Sakura block with palm kernel cake and earthworm flour produced greater protein and Total Digestible Nutrient than control sakura block. The crude protein content of the sakura block with palm kernel cake and earthworm flour ranged from 21.95 to 25.28%, while the control sakura block was only 17.83%. The increase in crude protein content was derived from palm kernel cake and earthworm flour in the sakura block. Palm kernel cake was used as a sakura block substitute for corn, while earthworm was substituted for bran (Table 1). The crude protein content of palm kernel cake was higher than that of corn, 14-20% crude protein depending on the type of oil palm, soil type, and processing (Putri et al., 2019). A high protein source was also obtained from the earthworm of 67-76% (Palungkung, 1999). The higher the earthworm level, the higher the TDN content. The average TDN at 2, 4, 6 and 8% earthworm were 84.35%, 86.96%, 87.76% and 88.28%, respectively (Table 2). TDN is used to describe how much energy in the feed can be absorbed in the body. Sakura block with palm kernel cake (P1) had higher crude fiber content than control sakura block (P0). Meanwhile, the higher the earthworm flour, the lower the crude fiber. The difference in crude fiber is due to differences in the nutrient content of its constituents, where the crude fiber content of palm kernel cake was higher than that of corn (Hartadi et al., 2017) and the crude fiber content of earthworm flour was lower than bran (Palungkung, 1999; Damayanti et al., 2008; Hayatiet al., 2011).

Effect of earthworm flour level in sakura block on rumen fermented products

Characteristics of rumen fluid can be seen in Table 3. The results of the study showed that there was increased ammonia (NH3), total Volatile Fatty Acid (VFA), accetate, propionate, and butyrate between treatments (P<0.05). while there was no difference in the pH of the rumen (P> 0.05).

Rumen pH is important to see the ability of microbes to synthesize protein, where the pH of the rumen was below 6.2, the degradation of rumen microorganisms would be inhibited (Ismartoyo, 2011). Rumen microorganisms can thrive at pH 6.8 with a temperature of 38-41oC (Arora, 1989). The rumen pH in this study was in the normal range of 6.64-7.06. The ammonia (NH3) concentration of the rumen fluid from this study was ranging from 16.60 - 22.62 mM. Sakura block with palm kernel cake and 6% earthworm flour (P4) produced higher concentrations of NH3 compared to other treatments namely 22.62 mM, while the ammonia concentration of control sakura block (P0) was 16.60 mM, sakura block with palm kernel cake (P1) was 19.37 mM. Sakura block with palm kernel cake and 2, 4 and 8 % earthworm flour (P2, P3, P5) were 20.12 mM, 22.49 mM, and 17.80 mM, respectively. The highest concentration of NH3 in rumen fluid was found in 6% earthworm (P4), then higher earthworm showed a decrease in NH3 concentration. The NH3 concentration of this study was above the normal NH3 concentration namely 6-17.65 mM (McDonald et al., 2002). The high concentration of NH3 was due to protein and non-protein nitrogen (NPN) derived from the ingredients of the sakura block, especially palm kernel cake and urea, which are easily dissolved and degraded in the rumen. Palm kernel cake is a source of easily degraded protein in the rumen (Baktiar et al., 2013). Urea is one of the ingredients for sakura block which has a very high degradation rate in the ground. In the rumen, urea will be broken down rapidly by the microbial urease enzyme into NH3 and CO2 (Arora, 1989; Ginting, 2005). The difference in NH3 concentrations is due to differences in constituent materials and crude protein content (Tables 1 and 2). Ammonia in the rumen fluid is a degradation of protein and nitrogen. Ammonia is the main source of nitrogen needed by microbes for protein synthesis (Arora, 1995). The decrease in NH3 concentration at 8% earthworm flour treatment was suspected to be the influence of the branched amino acid content of earthworm flour. This is in line with a study by Zhang et al. (2013) that the maximum concentration of addition of branched amino acids such as valine, leucine, and isoleucine in the ration to increase the NH3 concentration and the concentration of volatile fatty acids in the rumen fluid of 2 mMol. The use of earthworm flour in ration of up to 6% did not affect on consumption and digestibility of dry matter and organic matter but was able to maintain the quality of feed for local male rams (Sihombing et al., 2010).

The concentration of Volatile Fatty Acid (VFA) produced was 132.98 - 154.56 mM and differed between treatments (P <0.05). The highest VFA concentration was produced in the sakura block with 6% earthworm flour namely 154.56 mM followed by 8%, 4%, 2%, 0%, and control. Sakura block as a feed supplement produces a total VFA concentration above the normal concentration produced by rumen bacteria of 80-160 mM (Sutardi, 1980). The difference in VFA concentrations in this treatment was due to differences

Table 2: Proximate analysis of sakura block (%).

| Parameter | Treatment | |||||

| P0 | P1 | P2 | P3 | P4 | P5 | |

| Dry Matter | 89.06±0.51 | 89.81±2.69 | 89.80±0.42 | 90.07±0.71 | 90.78±0.61 | 89.19±0.66 |

| Organic Matter (%) | 93.55±0.44 | 93.65±0.53 | 93.60±0.35 | 93.61±0.48 | 93.85±0.17 | 93.61±0.56 |

| Crude Protein (%) |

17.83±0.55a |

20.37±0.90b |

21.95±0.54c |

23.50±0.56d |

25.28±0.49e |

25.72±0.29e |

| Crude Fiber (%) |

3.67±0.51a |

5.25±0.39b |

4.97±0.33b |

4.53±0.60ab |

4.62±0.79ab |

4.58±0.70ab |

| Crude Fat (%) | 3.00±0.75 | 3.27±0.59 | 2.91±0.68 | 3.92±0.42 | 3.05±0.25 | 3.21±0.14 |

| Total Digestible Nutrient (TDN) (%) |

78.87±2.31a |

81.90±2.90b |

84.35±0.49bc |

86.96±0.74cd |

87,76±0.85d |

88.27±0.71d |

Mean±Standard Deviation. Source: Ruminant Animal Nutrition Laboratory, Faculty of Animal Husbandry, Andalas University (2021).

Table 3: pH, NH3, total VFA, and partial VFA concentration of sakura block.

| Parameter | Treatment | |||||

| P0 | P1 | P2 | P3 | P4 | P5 | |

| pH | 7.06±0.78 | 6.78±0.57 | 6.90±0.83 | 6.65±0.23 | 6.65±0.33 | 6.64±0.42 |

|

NH3( mM) |

16.60±0.79a |

19.37±0.10c |

20.12±0.25c |

22.49±0.23d |

22.62±0.67d |

17.80±0.67b |

| VFA (mM) |

132.98±7.05a |

136.35±4.21a |

137.96±13.37ab |

138.13±12.21ab |

154.56±4.70b |

140.24±4.23ab |

|

Acetate (C2) (mM) |

71.71±3.74 a |

73.41±2.60a |

73.97±4.06ab |

76.50±4.22ab |

81.04±1.90b |

74.95±4.70ab |

|

Propionate (C3) (mM) |

34.97±2.60a |

34.11±2.20a |

35.43±1.80a |

36.47±3.86a |

41.38±1.69b |

36.75±0.66a |

| Butyrate (mM) |

13.64±0.28a |

14.82±0.31ab |

15.05±2.06ab |

15.21±2.9ab |

17.12±1.27b |

15.39±0.81ab |

|

C2/C3 |

2.12±0.05b |

1.87±0.09a |

2.28±0.03c |

2.25±0.05c |

2.19±0.09bc |

2.24±0.09c |

Mean±Standard Deviation. Source: Ruminant Animal Nutrition Laboratory, Faculty of Animal Husbandry, Andalas University (2021).

Table 4: Dry matter digestibility, organic matter digestibility, and crude protein digestibility of sakura block (%).

| Parameter | Treatment | |||||

| P0 | P1 | P2 | P3 | P4 | P5 | |

| Dry matter digestibility (%) | 84.91±3.45 | 86.71±3.55 | 88.25±2.81 | 86.64±1.78 | 88.14±1.21 | 86.18±1.86 |

| Organic matter digestibility (%) | 85.74±3.16 | 87.74±3.46 | 89.01±2.86 | 87.53±1.84 | 89.31±1.30 | 87.28±2.02 |

| Crude protein digestibility (%) | 68.24±1.19 | 68.33±1.47 | 69.80±3.04 | 69.05±0.95 | 71.35±1.66 | 67.87±2.27 |

Mean±Standard Deviation. Source: Ruminant Animal Nutrition Laboratory, Faculty of Animal Husbandry, Andalas University (2021).

in the concentration of NH3 in the rumen fluid, where the rumen microbial synthesis activity was highly dependent on the NH3 concentration, if the NH3 concentration was low it would be inhibited and cause feed degradation to decrease (Widyobroto et al., 2007). Furthermore, the process of feed degradation by rumen microbes will be converted into main products namely VFA and CH4 and CO2 gases (Parakkasi, 1999; McDonald et al., 2002). The role of VFA is very important as a source of energy and a source of carbon atoms to form the framework for the protein structure of the rumen microbes (Asplund, 1994). VFA is also a source of energy for ruminants, VFA is absorbed into the circulatory system through the process of gluconeogenesis, then converted into blood sugar in the liver, this blood sugar is used as an energy source (Lehningger, 1992). Volatile fatty acid contributed to energy requirements of 70-85% for livestock (Dewhurst et al., 1986).

The concentrations of partial VFAs such as acetate (C2), propionate (C3), and butyrate (C4) differed between treatments. The highest concentrations of C2, C3, and C4 were found at 6% earthworm treatment (P4), namely 81.04 mM, 41.38 mM, and 17.12 mM. The difference in high concentration is a representation of the high total VFA at 6% earthworm treatment (P4). Acetate and propionate are the main components of VFA in large amounts followed by butyrate and other smaller components such as formic acid, isobutyric, valerate, isovaleric, and is caproate (Czerkawski, 1986). Acetate, propionate, and butyrate are produced from the substrate fermentation process resulting from the degradation of hexose (carbohydrates) in feed by microbes in the rumen (Ismartoyo, 2011). The proportions of C2 and C3 for each treatment showed a significant difference (P <0.05). 0% earthworm treatment (P1) showed the lowest proportion C2: C3 compared to other treatments namely 1.87%, then controls (P0), 6% (P4), 8% (P5), 4% (P3), and 2% (P1). However, further test results showed no difference between the 2%, 4%, 6%, and 8% treatments. The difference in the proportion of C2: C3 is due to differences in the ingredients and composition of the Sakura block constituents (Table 1). According to Russsel et al. (1992), the end product of rumen fermentation is influenced by the rate of degradation of proteins and carbohydrates in the feed. According to Sniffen et al. (1992), based on the rate of degradation, carbohydrates are grouped into non-structural carbohydrates (sugar, starch, and pectin) and structural carbohydrates (NDF, ADF, and lignin).

Effect of earthworm flour level in sakura block on nutrient digestibility

Dry matter digestibility, organic matter digestibility, and crude protein digestibility of sakura block can be seen in Table 4. There were no significant differences in dry matter digestibility, organic matter digestibility, and protein digestibility of sakura block between treatments (P> 0.05).

Dry matter digestibility, organic matter digestibility, and crude protein digestibility were 84.91-86.71%, 85.74-89.31%, and 68.24-71.35%, respectively. Although not different, sakura block with palm kernel cake as a substitute for corn and earthworm tended to be higher than the control (Table 4). This is because there is a good and synchronous nutritional content of the ingredients that make up sakura block as a source of protein, carbohydrates, and minerals for rumen microbial synthesis. Coconut sugar and sago are non-structural carbohydrates that have a fast degradation rate in the rumen, as well as N non-nitrogen such as ammonia, nitrates, amines, amino acids, and nucleic acids with fast solubility and are readily available to rumen microbes (Sniffen et al., 1992). Other ingredients such as salt, Triple Super Phosphate (TSP), mineral mix, and topmix are mineral sources as cofactors for rumen microbial cell formation (Ginting, 2005). Feed digestibility is determined by the rate of degradation and the rate at which feed substances leave the rumen, where feed degradation is determined by the characteristics of feed degradation and the rumen environment (Ismartoyo, 2011). It is estimated that microbial protein can contribute 75-100% of the total protein available to livestock (AFRC, 1992).

CONCLUSIONS AND RECOMMENDATIONS

The utilization of earthworm flour in sakura block contributes greatly to improving the quality of sakura block and rumen fermentation product invitro. The maximum limit for the use of earthworm flour in sakura block as a supplementary feed is 6% level, where sakura block with a level of 6% earthworm flour produces the best concentrations of NH3, VFA, acetate, propionate, and butyrate. Although there was no significant difference between treatments, there was a tendency to increase nutrient digestibility in sakura block with a level of 6% earthworm flour. Futhermore, earthworms are a protein source feed ingredient that has the potential to be developed in supporting the development of of the cattle-oil integration system.

ACKNOWLEDGEMENTS

The authors are grateful to theDirectorate of Research and Community Service, The Ministry of Research and Technology for Funding this Research under the scheme of Doctoral research of Dissertation (Penelitian Disertasi Doktor) with contract number:104/SP2H/LT/DRPM/2021.

AUTHOR’S CONTRIDBUTION

JJ, LW, MZ and KK formulated experimental designs and experimental work in the laboratory. JJ compiled the manuscript and performed data analysis under the supervision of LW, MZ, and KK. All authors read and agreed to the final version of the manuscript.

Conflict of interest

The authors have declared no conflict of interest.

REFERENCES