Comparative Study of Fine and Whole Wheat Flour of Selected Varieties Grown in Khyber Pakhtunkhwa

Comparative Study of Fine and Whole Wheat Flour of Selected Varieties Grown in Khyber Pakhtunkhwa

Saifullah* and Ihsan Mabood Qazi

Department of Food Science and Technology, The University of Agriculture Peshawar, Khyber Pakhtunkhwa, Pakistan.

Abstract | Due to lake of information regarding the wheat varieties grown in Khyber Pakhtunkhwa, this study was design to investigate the chemical composition, functional properties and microstructure of fine wheat flour (FWF) and whole wheat flour (WWF) of the selected varieties. These varieties were collected from different research stations located in the province. The grains were milled using laboratory scale flour mill. Part of the flour of each variety was passed from mesh to remove the bran and get fine flour. Both whole and fine flour of the selected wheat varieties were subjected to qualitative study. The data disclosed that L* value was more in FWF than WWF. FWF had high Water absorption index (WAI) 9.19-9.25g/g, Swelling Index (SI) 6.6-8.7g/g, Water Solubility Index (WSI) 5.7-9.77% and gluten (20.76-34.45%) content while WWF was high in moisture (6.08-8.03%) and ash (0.95-0.98%). It is cleared from the data that FWF of all the selected varieties especially Shahkar-13 could be used in the production of various bakery products especially noodles.

Received | June 18, 2019; Accepted | October 19, 2019; Published | November 26, 2019

*Correspondence | Saifullah, Department of Food Science and Technology, The University of Agriculture Peshawar, Khyber Pakhtunkhwa, Pakistan; Email: saifkhalilfood@gmail.com

Citation | Saifullah and I.M. Qazi. 2019. Comparative study of fine and whole wheat flour of selected varieties grown in Khyber Pakhtunkhwa. Sarhad Journal of Agriculture, 35(4): 1272-1283.

DOI | http://dx.doi.org/10.17582/journal.sja/2019/35.4.1272.1283

Keywords | Wheat varieties, Fine and whole wheat flour, Functional properties, Chemical composition, Color, Microstructure

Introduction

Both cultivated and wild wheat belongs to grass family. There are many species in the world, but the most important are common or bread wheat (Triticum aestivum) and durum or pasta wheat (Triticum durum). Compare to common wheat, durum wheat has hard and elongated kernel containing more protein and large starch granules (Heneen and Brismar, 2003; Wiseman, 2001). Common wheat is hexaploid and cultivated about 90-95% all over the world.

Wheat grain is composed of endosperm enriched with protein and starch, germ containing protein and lipids and bran composed of dietary fiber and minerals (Marquart et al., 2007). During milling, these fractions are separated in the refining process for the production of white flour and the germ and bran are removed and discarded. The discarded fractions contain vitamins, natural antioxidants and dietary fiber which are crucial for health (Rosa et al., 2014; Seibel, 1996; Onyeneho and Hettiarachchy, 1992). Utilization of whole grain products has been accossiated to reduce the risk of cancer, diabetes and cardiovascular disease (Liu, 2007).

The major component of wheat grain is starch (70-75%) present in endosperm. Starch is composed of two component amylose and amylopectin. Amylose is straight chain consisting of α-(1, 4)-linked d-glucopyranosyl units. Amylopectin has highly branched chain consisting α - (1, 6)-linkages (Hung et al., 2006; Tester et al., 2004). In normal wheat starch the ratio of amylose to amylopectin is 22-35% and 65- 78% depending on botanical source (Cai and Shi, 2010). The difference in the ratio of amylose and amylopectin influences the processing, physicochemical and edible properties of the products (Kozlov et al., 2007; Kozlov et al., 2006). Protein is the second important constituent of the wheat flour. Various types of protein are present in wheat but the most important structural protein is gluten which is formed by the hydration of gladin and glutenin. This protein is responsible for elasticity, viscosity and cohesiveness of the dough (Misra et al., 2015; MacRitchie, 1984).

The use of whole grain flour containing bran in food products has linked with several technological, nutritional and sensorial challenges (Liu et al., 2017; Le et al., 2015). Mostly the insoluble fraction of bran creates technological problems by disturbing the gluten network formation resulting low elastic dough, poor loaf volume and baking quality (Aktas-Akyildiz et al., 2017; Pruckler et al., 2014).

In the world Pakistan is the leading country in wheat production contributing 2% of the total production (Anjum and Walker, 2000). Wheat contributes about 10% to agriculture in the country and shares 2.1% in GDP (GOP, 2014-15). In Khyber Pakhtunkhwa the area under cultivation is 680.31 hectare with annual production of 1251.48 tons (Kpbos, 2013-14). Pakistani varieties have high protein content ranging 11 to 13%. These varieties can be used in the production of numerous products including noodles, bread, pasta and Naan (Alam et al., 2009). Previous data in literature conform that there is a continuous development in these varieties in term of production and disease resistance such as Pirsabak-2008, Pakhtunkhwa-2015, Hashim-8, Zam-04, Fareed-06, pirsabak-2013, Shahkar-2013 (Shah et al., 2017; Khan et al., 2011; Hussain et al., 2010; Shah et al., 2010; Uddin et al., 2005).

The aim of this study is to characterize the local varieties for the production of various products especially noodles. This will help both the farmers to sell their produce as well as manufacturer to get the cheap raw material.

Materials and Methods

Collection of wheat varieties

Selected wheat varieties namely; Pirsabak-2013, Pirsabak-2008, Shahkar-2013, Pakhtoonkhwa-2015 and Durum-97 were collected from cereal crop research institute, Pirsabak nowshera, NIFA insaf-2015 from nuclear institute for food and Agriculture turnab, KT-2014 from Barani research station kohat, Shahid-2017 from Agriculture research station D.I. Khan and Janbaz and Ghanemat-2015 from the plant breeding and genetics department The University of Agricultural Peshawar.

Milling of wheat grain

The grain of all selected varieties was brought to the laboratory of Food science and Technology, The University of Agricultural Peshawar. Straws and other foreign materials were removed from grains and then grains were milled using a laboratory scale flour mill (Thomas-Wiley, Model 4. USA). The flour was divided in to two lots, whole wheat flour and fine flour received after passing it from 100 mesh. The flour was packed in airtight polyethylene bags and stored in a refrigerator for further analysis.

Color

Color of the fine and whole wheat flour of the selected varieties were studied by using Color Tec in three replicates. Three parameters of color were recorded as L* (index of lightness/darkness), a* (index of hue, red/green) and b* (index of yellowness).

Micro structure analysis of wheat flour

The scanning of samples was carried out by a focused electron beam of 10kV and the magnification power of the SEM images ranged between 100 x to 5000 x using a scanning electron microscope (Niu et al., 2014). The samples were dehydrated and then mounted on an aluminum stub with the help of double sided tape. The samples were coated with 50 nm gold and observed at 10 kV.

Proximate composition of wheat flour

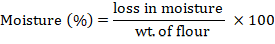

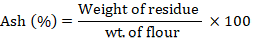

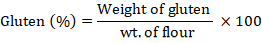

The fine and whole wheat flour of selected varieties was characterized for moisture, ash, wet and dry gluten according to the method of (AACC, 2013).

Iodine method was used for the determination of amylose content of the flour of selected wheat verities according to the method of (Juliano, 1971).

Functional properties

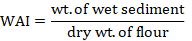

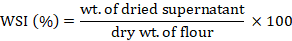

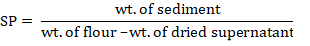

Functional properties namely swelling power (SP), water absorption index (WAI) and water solubility index (WSI) of the flour of selected wheat varieties were analyzed by the method of (Schoch, 1964; Qazi et al., 2014) with little modification. Flour sample (0.2 g) of each wheat varieties were taken in a pre cleaned and pre weighed test tubes in triplicate and to each test tube 10 ml of distilled water was added. Each test tube was subjected to 30 minutes heating on water bath and shake with 10 minutes interval to avoid grit formation. After 30 minutes test tubes were removed from water bath and cooled to room temperature. The test tubes were then placed in a centrifuge machine and centrifuged to 3000 rpm for 15 minutes. After 15 minutes the supernatants were collected in a pre cleaned and weighed Petri dishes and the sediments were weight. The petri dishes along with supernatants are heated in an oven at 1050C for 24 hours and weighed. After complete dehydration the swelling power and solubility of the wheat flour were calculated according to the following formula.

Results and Discussion

Color

Results of color measurements are shown in Table 1, Figures 2, 3, 4. It is clear from the data that there was significant difference (p<0.05) between FWF and WWF. The L* value of the FWF is more than WWF. The L* values of FWF were in range of 75.28 to 78.94 while the L* value of WWF were in range of 73.05 to 76.52. The results were consistent with the early findings of Chen et al. (2011) and Chillo et al. (2008) who reported an increased trend in L* value with the addition of coarse bran in refined flour. The a* showed reversed tendency. The a*value was lesser for FWF as compared to WWF. This phenomenon was in agreement with the study of Chen et al. (2011) and Reungmaneepaitoon et al. (2006). No significant difference (p < 0.05) was occurred in the b* value of the FWF and WWF. A slight fluctuation was recorded in the b* value. Our results were consistent with the findings of Cao et al. (2017) who reported that yellowness is slightly affected by addition of WWF. Similarly, Pedreschi et al. (2006) reported that several factors like inherent pigments, reducing sugar, protein and poly-phenol oxidase activity would contribute to yellow color during oxidation and Maillard reaction.

SEM

The microstructure of selected wheat varieties was examined under scanning electron microscope (Figure 1). The microphotograph of the wheat flour indicated circular and lentil shaped starch granules with different sizes. Adhesive protein areas attached to starch granules and the protein matrix can be observed in all SEM images which were also observed by Gutierrez et al. (2002). These microphotographs also showed that wheat starch contains round, oval and irregular shaped of starch granules. In some scanning electron micrograph (Figure 1F) disk shape and elongated starch granules were also present. Additionally, these starch granules were embedded by the protein matrix

Table 1: Color (L*, a*, b*) of fine and whole wheat flour of selected varieties.

| Variety | L* | a* | b* | |||

| FWF | WWF | FWF | WWF | FWF | WWF | |

| Shahid-17 | 77.61±0.02b | 75.05±0.04ef | 3.22 ± 0.03 ij | 3.36 ± 0.02 f | 13.33 ± 0.05b | 13.97 ± 0.01 b |

| Shahkar-13 | 78.60 ±0.02a | 76.43±0.04cd | 2.70 ± 0.02 n | 3.28 ± 0.03 gh | 14.11 ± 0.02 b | 13.52 ± 0.03 b |

| Ghanemat-15 | 76.39±0.05cd | 75.05±0.06ef | 3.17 ± 0.07kl | 3.45 ± 0.03 e | 12.84 ± 0.05 b | 13.24 ± 0.05 b |

| Janbaz | 76.82 ± 0.03c | 74.69 ± 0.06f | 2.58 ± 0.02o | 3.07 ± 0.02 m | 14.20 ± 0.01 b | 12.86 ± 0.04 b |

| Pirsabak- 08 | 78.94 ± 0.03a | 75.48 ± 0.03e | 3.82 ± 0.03 c | 3.19 ± 0.03jk | 12.56 ± 0.05 b | 12.95 ± 0.01 b |

| Pirsabak- 13 | 77.65 ±0.05b | 76.25 ±0.04d | 3.12 ± 0.02 l | 3.37 ± 0.02 f | 11.84 ± 0.05 b | 11.85 ± 0.05 b |

| Pakhtunkhwa-15 | 76.23 ±0.05d | 75.46 ± 0.02e | 2.16 ± 0.03 p | 3.26 ± 0.02hi | 12.85 ± 0.05 b | 12.50 ± 0.02 b |

| KT-14 | 78.89 ± 0.03a | 72.87 ±0.02g | 3.64 ± 0.04 d | 4.27 ± 0.02 a | 11.94 ± 0.04 b | 14.15 ± 0.03 b |

| NIFA insaf-15 | 77.96 ±1.17b | 76.52±0.03cd | 3.90 ± 0.02 b | 3.45 ± 0.03 e | 13.44 ± 0.04 b | 13.46 ± 0.02 b |

| Durum- 97 | 75.28 ± 0.03e | 73.05 ±0.03g | 2.59 ± 0.02 o | 3.31 ± 0.01 g | 22.71 ± 0.02 a | 14.06 ± 0.02 b |

as shown in all SEM images. The present study results were similar to that of Parda and Aguilera (2011), Peressini et al. (2008), Autio et al. (2005), Bellido and Hatcher (2011) who found that gluten matrix surrounded the wheat starch granules. The damaged starch granules can also be seen in Figure 1H. Similarly, Figure 1A showed double disk structural starch granules and simple granules covered by protein matrix as reported by Le et al. (2015) who reported double disk starch granules in wheat starch.

Composition of fine and whole wheat flour starch

Amylose: Amylose is an important parameter for the quality of noodles (Qazi et al., 2011; Fu, 2008). Statistical analysis showed significant (p < 0.05) difference in Amylose content of the selected wheat varieties (Figure 5). Maximum amylose was found in Pakhtunkhwa-15 (31.22 %) while minimum amylose was found in KT-14 (20.47 %). The data from the table disclosed that the amylose content of the selected varieties was in the acceptable range for the production of noodles as described by Saeid et al. (2015), Konik-Rose et al. (2007) who reported the normal range of the amylose of wheat starch between 20 – 30 % and amylopectin 70–80 %. Similarly, it was reported that the range of amylose of different starches is in between 15.5 % -35 %. This variation may be explained by botanical source, growing conditions, fertilizer, growing area, genetic makeup of the kernel, as well as the extraction methods and amylose determination (Saeid et al., 2015). Amylose content is responsible for the pasting properties of the starch (Singh et al., 2006) and hardness of the noodles is due to the strong matrix bounded to each other (Sandhu et al., 2010). Wheat starch has round lenticular shape with 25 % amylose, having gelatinization temperature 58 to 64 oC, pasting temperature 77 oC and produce opaque gel (Murphy, 2000). The strength of the gel is associated with the degree of amylose content of the starch, higher the amylose content high will be the gel strength (Ishiguro et al., 2000). Texture of the noodle is also affected by the amylose content of the flour (Park and Baik, 2004). Amylose has less water retention capacity than amylopectin because the solubility power of amylopectin is more than amylose (Vandeputte et al., 2003). Similarly, solubility and swelling power of the starch was influenced by the amylose content of the starch and subsequent quality of noodles (Liu and Shen, 2007). They further reported that high amylose starches are preferred for good quality noodles.

Moisture: Moisture is an important quality parameter for the quality of flour. The data from the Table 2 and Figure 6 disclosed that there was minimal significant (p < 0.05) difference in the moisture content of fine and whole wheat flour. Whole wheat flour contained more (6.08-8.18 %) moisture than fine flour (5.40-7.40%). This is due to the high fiber content in whole wheat flour as reported by Maneju et al. (2011) who concluded that flour having high fiber content will have more moisture. Our results were in agreement with the findings of Yadav et al. (2014) and Akanbi et al. (2011), who concluded that the moisture content of wheat flour was in the range of 4.65-8.50 %. Flour having 10% or below moisture content has long shelf life (Omeire, 2014; SON, 2007; Nnam, 2002). Similarly, Ajani et al. (2012) reported that flour having low moisture content has good storage potential while high moisture content flour has short storage life as they encourage the microbial growth (Ngozi, 2014; Ezeama, 2007). Likewise, storage condition and variety of wheat also influenced the moisture content of wheat flour (Oppong et al., 2015).

Ash: Ash is the amount of minerals present in flour which reflects the milling efficiency (Saeid et al., 2015). The results of ash for fine and whole wheat flour are tabulated in Table 2 and Figure 7. Significant difference (p < 0.05) was present in the values of fine and whole wheat flour. Data showed that WWF had high ash content ranged between 0.95-0.98% while the FWF contain 0.54-0.69 %. WWF contained bran layer which is reach in minerals and have high ash content, as described by Liu et al. (2015). Likewise, Banu et al. (2012) observed the same result that addition of 3-39 % bran to FWF raised the ash content. Various factors, such as climate, soil, variety, origin, agronomic practices and milling process influenced the ash content of the flour (Kassegn, 2018; Saeid et al., 2015; Bilgicli, 2013; Han et al., 2011). The results were in the agreement with the findings of Ngozi (2014) and Han et al. (2013) who observed that the range of the ash content of the wheat flour was in between 0.08 to 2.29 %. High ash content had negative effect on the color of the products as described by Aravind et al. (2012a) who concluded that addition of high level of pollard in semolina produce undesirable color in spaghetti.

Gluten: Gluten is formed by the hydration of glaidin and glutenin during the mixing step of the dough preparation and is an important parameter for dough quality. Gluten gives strength and elasticity to dough and is responsible for the structure of different products. Statistical analysis showed significant difference (p < 0.05) in gluten content of both FWF and WWF of selected varieties (Table 2 and Figures 8, 9). The range of wet and dry gluten in fine wheat flour was 13.96g (Janbaz) -34.45g (Shahkar-13) and 6.84g (Ghanemat-15) – 16.61g (Shahkar-13) respectively. Furthermore, the wet and dry gluten of the whole wheat flour were in the range of 8.77 g (Janbaz) to 30.07g (Shahkar-13) and 4.18 g (Ghanemat-15) to 11.80g (Shahkar-13) respectively. The results were similar to the findings of Samaan et al. (2006) who concluded wet and dry gluten in the range of (24.41g-29.37g) and (8.96g- 10.6g) respectively. Similarly, Pasha (2006) concluded that the ranges of the dry gluten in Pakistani varieties were 7g-17g. The reason for the low gluten in WWF may due to the dilution effect of bran on WWF. Similarly, the bran particles also negatively affect the hydration of gluten (Sobota et al., 2015).

Functional properties of fine and whole wheat flour Water absorption index: The water absorption index of the FWF and WWF is represented in Table 3 and Figure 10. The data disclosed (p < 0.05) that FWF has high WAI as compared to WWF. The low WAI value for WWF may be due to high quantity of bran and germ. High value of WAI for FWF represented small particle size which promotes the development of protein starch matrix that absorbed more water. The results were similar to the findings of Vignola et al. (2018) and Aravind et al. (2012). Likewise, Brennan et al. (2008) concluded that water absorption index of starch decreased in food system that containing bran, because bran content competes starch for water. In addition, WAI decreased by the addition of pollard in salmonella (Ramy et al., 2002). Among the tested varieties FWF of Janbaz and NIFA insaf-15 showed high WAI values (9.25 g/g and 9.19 g/g) while in case of WWF Shahid-17 and NIFA insaf-15 varieties showed high WAI index (7.09 g/g and 8.29 g/g) respectively. The variation in the WAI of the tested varieties may be due to fiber, protein and amylose (Chandra et al., 2013; Thumrongchote et al., 2012; Nura et al., 2011). Similarly, another study conducted by Olukeim et al. (2013) showed that high protein molecule exhibited high hydrogen bonding between water and protein and thus absorbed more water. Carbohydrates also weaken the WAI of the flour (Kinsella, 1979).

Swelling power (SP): Swelling power is the ability of starch granules to hold water, which is due to the amylopectin fraction of the starch and the difference in SP indicates the extent of the action of water to the internal of the starch granules (Ruales et al., 1993). The SI values for FWF were in the range of 6.60 g/g to 8.790g/g while the range of SP for WWF were in the range of 4.58g/g to 5.99g/g. Statistical analysis showed significant difference (p < 0.05) between the varieties and also between the FWF and WWF (Table 3 and Figure 11). Fine flour showed high SI value as compared to whole wheat flour. The variation between the FWF and WWF is due to presence of bran and germ in whole wheat flour as reported by Kaur et al. (2012) who concluded that the bran and germ decrease the SP of the flour. The granule swelling and water holding ability of swollen granules is mostly dependent on the intact structure of the amylopectin molecule in starch granules (Wang and Copeland, 2012a, 2012c).

Table 2: Chemical characterization of Fine and whole wheat flour of selected varieties.

| Variety | Moisture (%) | Ash (%) | Wet Gluten (%) | Dry Gluten (%) | ||||

| FWF | WWF | FWF | WWF | FWF | WWF | FWF | WWF | |

| Shahid-17 | 6.99 ±0.11ce |

8.03 ±0.09a |

0.56 ± 0.02c | 0.97 ±0.01a |

31.55 ±0.29 b | 25.51 ±1.32f |

14.65 ±0.11c |

9.59 ±0.50f |

| Shahkar-13 | 7.40 ±0.16bc |

8.18 ±0.19a |

0.56 ±0.03 c | 0.95 ±0.04a |

34.45 ±0.29 a | 30.07 ±0.89c |

16.61 ±0.30a |

11.80 ±0.86d |

| Ghanemat-15 | 5.40 ± 0.16 j |

6.47 ±0.37fh |

0.54 ±0.04 c | 0.96 ±0.01a |

14.64 ±0.36kl | 9.52 ±0.65n |

6.84 ±0.25 k |

4.18 ±0.23n |

| Janbaz | 6.69 ±0.39eg |

7.43 \±0.43bc |

0.56 ±0.03 c | 0.97 ±0.03a |

13.96 ±0.09 l | 8.77 ±0.44n |

6.94 ±0.14 k |

4.33 ±0.11mn |

| Pirsabak-08 | 5.79 ±0.16 ij |

6.34 ±0.52gh |

0.54 ±0.04 c | 0.95 ±0.04a |

16.69 ± 0.13 i | 11.32 ±1.0m |

8.64 ±0.29 g |

4.28 ±0.17mn |

| Pirsabak- 13 | 6.37 ±0.07gh |

7.47 ±0.11b |

0.55 ± 0.03c | 0.96 ±0.02a |

27.67 ±0.33e | 20.49 ±0.93g |

7.62 ± 0.38ij | 4.26 ±0.51n |

| Pakhtunkhwa-15 | 6.88 ±0.11ef |

7.49 ±0.35 b |

0.69 ±0.02b | 0.98 ±0.01a |

20.76 ±0.21 g | 15.08 ±1.04k |

7.97 ±0.09hi |

4.90 ±0.16lm |

| KT-14 | 6.68 ±0.29efg |

7.38 ±0.19bd |

0.55 ±0.03 c | 0.96 ±0.02a |

21.52 ±0.27 g | 15.87 ±0.97ij |

8.58 ±0.17gh |

5.12 ±0.47e |

| NIFA insaf-15 | 6.94 ± 0.24de | 7.93 ±0.09a |

0.55 ±0.04 c | 0.98 ±0.01a |

25.65 ± 0.10 f | 17.86 ±0.45h |

12.35 ±0.26d |

6.99 ±0.85jk |

| Durum 97 | 5.75 ±0.13 ij |

6.08 ±0.44 hi |

0.54 ±0.02 c | 0.96 ±0.01a |

33.60 ±0.14 a | 28.97 ±0.43d |

15.95 ±0.07b |

10.87 ±0.36e |

Table 3: Functional properties of fine and whole flour of selected wheat.

| Variety | WSI (%) | WAI (g/g) | SP (g/g) | |||

| FWF | WWF | FWF | WWF | FWF | WWF | |

| Shahid-17 | 7.24 ± 0.08 de | 7.22 ± 0.81de | 8.53 ± 0.03 bcd | 7.09 ± 0.27 f | 8.27 ± 0.18 b | 5.99 ± 0.12 g |

| Shahkar-13 | 9.77 ± 0.19 a | 7.82 ± 0.52 bc | 9.25 ± 0.03 a | 8.29 ± 0.34 cde | 8.23 ± 0.28 b | 5.21 ± 0.04 h |

| Ghanemat-15 | 8.16 ± 0.08 b | 5.67 ± 0.39 fg | 7.37 ± 0.02 f | 4.94 ± 0.10 ij | 7.63 ± 0.19 d | 4.91 ± 0.15 hi |

| Janbaz | 8.25 ± 0.23 b | 5.35 ± 0.12 g | 9.19 ± 0.03 a | 5.24 ± 0.06 i | 7.52 ± 0.32 d | 4.58 ± 0.34 i |

| Pirsabak- 08 | 5.78 ± 0.12 fg | 6.09 ± 0.47 f | 8.94 ± 0.02 ab | 5.91 ± 0.27 h | 8.79 ± 0.16 a | 5.88 ± 0.83 g |

| Pirsabak- 13 | 7.51 ± 0.24 cde | 4.26 ± 0.37 h | 8.37 ± 0.02 cd | 5.10 ± 0.32 i | 8.14 ± 0.18 bc | 5.07 ± 0.29 h |

| Pakhtunkhwa-15 | 7.72 ± 0.10 bcd | 5.76 ± 0.48 fg | 7.89 ± 0.03 e | 5.04 ± 0.29 ij | 7.72 ± 0.26 cd | 5.01 ± 0.06 hi |

| KT-14 | 9.41 ± 0.06 a | 7.03 ± 0.61 e | 8.70 ± 0.03 bc | 4.89 ± 0.83 ij | 6.93 ± 0.07 e | 4.86 ± 0.09 hi |

| Nifa insaf-15 | 7.77 ± 0.28 bcd | 5.62 ± 0.31 fg | 8.21 ± 0.04 de | 4.61 ± 0.15 j | 7.54 ± 0.20 d | 6.30 ± 0.01fg |

| Durum- 97 | 9.48 ± 0.29 a | 5.73 ± 0.21 fg | 6.62 ± 0.03 g | 6.03 ± 0.04 h | 6.60 ± 0.09 ef | 6.00 ± 0.27g |

Water solubility index (WSI): The WSI values are tabulated in Table 3 and Figure 12. The data disclosed that the FWF has high WSI values as compared to WWF. The range of WSI for FWF was 5.78%-9.77% and for WWF the range was 4.26%- 7.82%. The results were in the close proximity to that of (Saeid et al., 2015; Heo et al., 2013; Thumrongchote et al., 2012; Wadchararat et al., 2006) who observed the WSI in the range of 0.06% - 8.99%. The difference in the range may be due to the difference in temperature (Wadchararat et al., 2006) and milling procedure (Heo et al., 2013). Flodin (1997) concluded that high water absorption leads to increase the swelling power which results in improved solubility. Flour having high solubility is more digestible (David et al., 2015). WSI is dependent on the disruption of starch granules, semi crystalline structure of starch granule and bonding of water molecule to amylose and amylopectin (Eliasson and Gudmundsson, 1996).

Conclusions and Recommendations

This research has characterized the functional and chemical properties of the fine and whole wheat flour. It is concluded that the functional properties of fine flour of all varieties showed that the fine flour has high potential to use as ingredients in various food products as functional ingredient. Whole wheat flour might be creating problems in food system due to high ash and low functional properties.

Novelty Statement

The study investigates the chemical composition, functional properties and microstructure of fine wheat flour (FWF) and whole wheat flour (WWF) of selected wheat varieties grown in Khyber Pakthunkhwa was. Thus, it will be helpful for production of various bakery products especially noodles.

Author’s Contribution

Saifullah, Collect the wheat varieties, performed the experiments, analyzed the data. Ihsan Mabood Qazi, Design the research and edited the article.

References

Ajani, A.O., O.F. Oshundahunsi, R. Akinoso, K.A. Arowora, A.A. Abiodun and P.O. Pessu. 2012. Proximate composition and sensory qualities of snacks produced from breadfruit flour. Glob. J. Sci. Front. Res. Biol. Sci. 12(7): 1-9.

Akanbi, T.O., S. Nazamid, A.A. Adebowale, A. Farooq and A.O. Olaoye. 2011. Breadfruit starch-wheat flour noodles: preparation, proximate composition and culinary properties. Int. Food Res. J. 18(4): 1283-1287.

Aktas-Akyildiz, E., O. Mattila, N. Sozer, K. Poutanen, H. Koksel and E. Nordlund. 2017. Effect of steam explosion on enzymatic hydrolysis and baking quality of wheat bran. J. Cereal Sci. 78: 25-32. https://doi.org/10.1016/j.jcs.2017.06.011

American Association of Cereal Chemists (AACC) International. 2013. Approved methods of analysis. Method 08-01.01. St. Paul, MN: AACC International.and health. Ames, IA, USA: Blackwell Publishers.

Anjum, F.M and C.E. Walker. 2000. Grain, flour and bread-making properties of eight Pakistani hard white spring wheat cultivars grown at three different locations for 2 years. Inter. J. Food Sci. Technol. 35: 407-416. https://doi.org/10.1046/j.1365-2621.2000.00400.x

Aravind, N., M. Sissons, N. Egan and C. Fellows. 2012. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 132: 993-1002. https://doi.org/10.1016/j.foodchem.2011.11.085

Autio, K., K. Kruus, A. Knaapila, N. Gerber, L. Flander and J. Buchert. 2005. Kinetics of ransglutaminase-induced cross-linking of wheat proteins in dough. J. Agric. Food Chem. 53: 1039-1045. https://doi.org/10.1021/jf0485032

Bellido, G.G. and D.W. Hatcher. 2011. Effects of a cross-linking enzyme on the protein composition, mechanical properties, and microstructure of Chinese-style noodles. Food Chem. 125: 813-822. https://doi.org/10.1016/j.foodchem.2010.08.008

Brennan, M.A., I. Merts, J. Monro, J. Woolnough and C.S. Brennan. 2008. Impact of guar gum and wheat bran on the physical and nutritional quality of extruded breakfast cereals. Starch/Staerke, 60: 248-256. https://doi.org/10.1002/star.200700698

Cao. X., S. Zhou, C. Yi, L. Wang, H. Qian, H. Zhang and X. Qi. 2017. Effect of whole wheat flour on the quality, texture profile, and oxidation stability of instant fried noodles. J. Texture Stud.1-9. https://doi.org/10.1111/jtxs.12274

Chen, J.S., M.J. Fei, C.L. Shi, J.C. Tian, C.L. Sun, H. Zhang and H.X. Dong. 2011. Effect of particle size and addition level of wheat bran on quality of dry white Chinese noodles. J. Cereal Sci. 53: 217-224. https://doi.org/10.1016/j.jcs.2010.12.005

Chillo, S., J. Laversea, P.M. Falconea, A. Protopapab and M.A. Del Nobile. 2008. Influence of the addition of buckwheat flour and durum wheat bran on spaghetti quality. J. Cereal Sci. 47: 144-152. https://doi.org/10.1016/j.jcs.2007.03.004

Cai, L.M., and Y.C. Shi. 2010. Structure and digestibility of crystalline short-chain amylose from de branched waxy wheat, waxy maize, and waxy potato starches. J. Carbo. Polym. 79 (4): 1117-1123. https://doi.org/10.1016/j.carbpol.2009.10.057

Eliasson, A.C. and M. Gudmundsson. 1996. Starch: Physicochemical and functional aspect. in: Carbohydrates in Food. A.C. Eliasson, ed. Marcel Dekker: New Yark. pp. 431-503.

Ezeama, C.F. 2007. Food Microbiology: Fundamentals and applications. Natural prints, lagos. Food Sci. Technol. 1-17.

Flodin, N.W. 1997. The metabolic roles, pharmacology, and toxicology of lysine. J. Am. Coll. Nutr. 16(1): 7-21. https://doi.org/10.1080/07315724.1997.10718644

Fu, B.X. 2008. Asian noodles: History, classification, raw materials, and processing. Food Res. Int. 41(9): 888-902. https://doi.org/10.1016/j.foodres.2007.11.007

Gutierrez, A.D.R., S. Guilbert and B. Cuq. 2002. Description of microstructural changes in wheat flour and flour components during hydration by using environmental scanning electron microscopy. Lebensm. Wiss. Technol. 35: 730-740. https://doi.org/10.1006/fstl.2002.0932

Han, L., Y. Zhou, E. Tatsumi, Q. Shen, Y. Cheng and L. Li. 2013. Thermo mechanical properties of dough and quality of noodles made from wheat flour supplemented with different grades of tartary buckwheat (Fagopyrum tataricum Gaertn.) flour. Food Bioprocess Technol. 6(8): 1953-1962. https://doi.org/10.1007/s11947-012-0831-8

Han, H.M., J.H. Cho and B.K. Koh. 2011. Processing properties of Korean rice varieties in relation to rice noodle quality. J. Food Sci. Biotech. 20: 1277-1282. https://doi.org/10.1007/s10068-011-0176-5

Heneen, W. and K. Brismar. 2003. Structure of cooked spaghetti of durum and bread wheat. Starch - Stärke. 55 (12): 546–557. https://doi.org/10.1002/star.200300187

Heo, S., S.M. Lee, J.H. Shim, S.H. Yoo and S. Lee. 2013. Effect of dry and wet milled rice flours on the quality attributes of gluten-free dough and noodles. J. Food Eng. 116: 213-217. https://doi.org/10.1016/j.jfoodeng.2012.11.017

Hung, P.V., T. Maeda and N. Morita. 2006. Waxy and high-amylose wheat starches and flours - characteristics, functionality and application. Trends Food Sci. Technol. 17(8): 448-456. https://doi.org/10.1016/j.tifs.2005.12.006

Ishiguro, K., T. Noda, K. Kitahara and O. Yamakawa. 2000. Retrogradation of Sweet potato Starch. Starch/Stärke. 52: 13-17.

Juliano, B.O. 1971. A simplified assay for milled rice amylose. J. Cereal Sci. Today. 6: 334-338.

Kassegn, H.H. 2018. Determination of proximate composition and bioactive compounds of the Abyssinian purple wheat. Cogent Food Agric. 4: 1421415. https://doi.org/10.1080/23311932.2017.1421415

Kaur, G., S. Sharma, H.P.S. Nagi and B.N. Dar. 2012. Functional properties of pasta enriched with variable cereal bran. J. Food Sci. Tech. 49: 467-474. https://doi.org/10.1007/s13197-011-0294-3

Kinsella, J.E. 1979. Functional properties of soy proteins. J. Am. Oil Chem. Soc. 56: 242–259. https://doi.org/10.1007/BF02671468

Kpbos. 2013-14. Planning and development department. Govt of Khyber Pakhtunkhwa, Peshawar. pp. 17.

Konik-Rose, C., J. Thistleton, H. Chanvrier, I. Tan, P. Hally, M. Gidley, B. Kosar-Hashemi, H. Wang, O. Larroque, J. Ikea, S. McMaugh, A. Regina, S. Rahman, M. Morell and Z. Li. 2007. Effect of starch synthase IIa gene dosage on grain, protein and starch in endosperm of wheat. Theor. Appl. Genet. 115:1053-1065.

Kozlov, S.S., T. Noda, E. Bertoft and V.P. Yuryev. 2006. Structure of starch extracted from near isogenic wheat line. J. Therm. Anal. Calorim. 86: 291-301. https://doi.org/10.1007/s10973-005-7319-y

Kozlov, S.S., A.V. Krivandin, O.V. Shatalova, T. Noda, E. Bertoft, J. Fornal and V.P. Yuryev. 2007. Structure of starch extracted from near isogenic wheat line: Part 2. Molecular organization of amylopectin clusters. J. Therm. Anal. Calorim. 87: 575-584. https://doi.org/10.1007/s10973-006-7880-z

Le Bleis, F., L. Chaunier, H. Chiron, G. Della Valle and L. Saulnier. 2015. Rheological properties of wheat flour dough and French bread enriched with wheat bran. J. Cereal Sci. 65: 167-174. https://doi.org/10.1016/j.jcs.2015.06.014

Liu, W., M.A Brennan, L. Serventi and C.S. Brennan. 2017. Effect of cellulase, xylanase and α-amylase combinations on the rheological properties of Chinese steamed bread dough enriched in wheat bran. Food Chem. 234: 93-102. https://doi.org/10.1016/j.foodchem.2017.04.160

Liu, C., L. Liu, L. Li, C. Hao, X. Zheng, K. Bian and X. Wang. 2015. Effects of different milling processes on whole wheat flour quality and performance in steamed bread making. LWT-Food Sci. Technol. 62(1): 310- 318.

Liu, W. and Q. Shen. 2007. Studies on the physicochemical properties of mung bean starch from sour liquid processing and centrifugation. J. Food Eng. 79 (1): 358-363.

Liu, R.H. 2007. Whole grain phytochemicals and health. J. Cereal Sci. 46: 207- 219. https://doi.org/10.1016/j.jcs.2007.06.010

MacRitchie, F. 1984. Baking quality of wheat flours. Adv. Food Nutr. Res. 29: 201-277. https://doi.org/10.1016/S0065-2628(08)60058-0

Maneju, H., C.E. Udobi and J. Ndife. 2011. Effect of added brewers dry grain on the physicochemical, microbial and sensory quality of wheat bread. Am. J. Food Nutr. 1(1): 39-43. https://doi.org/10.5251/ajfn.2011.1.1.39.43

Marquart, L., D. Jacobs, G. McIntosh, M. Reicks and K. Poutanen. 2007.Whole grains and health. Ames, IA, USA: Blackwell publishers. https://doi.org/10.1002/9780470277607

Misra, N.N., K. Seeratpreet, Brijesh, K. Tiwari, A. Kaur, N. Singh and P.J. Cullen. 2015. Atmospheric pressure cold plasma (ACP) treatment of wheat flour. Food Hydrocolloids. 44: 115-121. https://doi.org/10.1016/j.foodhyd.2014.08.019

Moorthy, S.N. and T. Ramanujam. 1986. Variation in properties of starch in cassava varieties in relation to age of the crop. Starch-Starke. 38: 58-61. https://doi.org/10.1002/star.19860380206

Ngozi, A.A. 2014. Effect of whole wheat flour on the quality of wheat baked bread. Glob. J. Food Sci. Technol. 2(3): 127-133.

Niu, M., G.G. Hou, B. Lee and Z. Chen. 2014. Effects of fine grinding of mill feeds on the quality attributes of reconstituted whole-wheat flour and its raw noodle products. LWT Food Sci. Technol. 57: 58-64. https://doi.org/10.1016/j.lwt.2014.01.021

Olukemi, A.R., O.A. Olayiwola and S.S. Abdulsalam. 2013. Functional properties and antinutritional factors of some selected Nigerian cereals. J. Agric. Sci. 1: 001-005.

Omeire, G.C., O.F. Umeji and N.E. Obasi. 2014. Acceptability of noodles produced from blends of wheat, acha and soybean composite flours. Nig. Food J. 32(1): 31-37. https://doi.org/10.1016/S0189-7241(15)30093-X

Onyeneho, S.N. and N.S. Hettiarachchy. 1992. Antioxidant activity of durum wheat bran. J. Agric. Food Chem. 40: 1496–1500. https://doi.org/10.1021/jf00021a005

Pasha, I. 2006. Biochemical characterization of Pakistani wheat in relation to grain hardness. M.Sc. thesis, Dept. Food Technol. Univ. Agric. Faisalabad, Pakistan.

Pedreschi, F., K. Kaack and K. Granby. 2006. Acrylamide content and color development in fried potato strips. Food Res. Int. 39(1): 40-46. https://doi.org/10.1016/j.foodres.2005.06.001

Parda, J. and J.M. Aguilera. 2011. Microstructure, mechanical properties, and starch digestibility of cooked dough made with potato starch and wheat gluten. LWT-Food Sci. Technol. 44: 1739-1744. https://doi.org/10.1016/j.lwt.2011.03.012

Peterson, C., V. Johnson and P. Mattern. 1986. Influence of cultivar and environment on mineral and protein concentrations of wheat flour, bran, and grain. Cereal Chem. 63: 183–186.

Peressini, D., S.H. Peighambardoust, R.J. Hamer, A. Sensidoni and A.J. Van Der Goot. 2008. Effect of shear rate on microstructure and rheological properties of sheared wheat dough. J. Cereal Sci. 48: 426-438. https://doi.org/10.1016/j.jcs.2007.10.008

Pruckler, M., S. Siebenhandl-Ehn, S. Apprich, S. Holtinger, C. Haas and E. Schmid. 2014. Wheat bran-based biorefinery 1: Composition of wheat bran and strategies of functionalization. LWT-Food Sci. Technol. 56(2): 211-221. https://doi.org/10.1016/j.lwt.2013.12.004

Qazi, I.M., S.K. Rakshit and T. Tran. 2011. Effect of physico-chemical properties of tropical starches and hydrocolloids on rice gels texture and noodles water retention ability. Starch/Starke. 63: 558–569.

Ramy, A., M.F. Salama and A.A. Shouk. 2002. Pollard as potential source of dietary fibre for pasta manufacture. Egypt. J. Food Sci. 30(2): 313-330.

Reungmaneepaitoon, S., C. Sikkhamondhol and C. Tiangpook. 2006. Nutritive improvement of instant fried noodles with oat bran. Songklanakarin J. Sci. Technol. 28: 89-97.

Rosa-Sibakov, N., K. Poutanen and V. Micard. 2014. How does wheat grain, bran and aleurone structure impact their nutritional and technological properties. Trends Food Sci. Technol. 1-17.

Ruales, J., S. Valencia and B. Nair. 1993. Effect of processing on the physiochemical characteristics of guinea flour (Chenopodium guinea Wild). Starch-Starke. 46: 13-19. https://doi.org/10.1002/star.19930450105

Saeid, A., S. Hoque, U. Kumar, M. Das, N. Muhammad, M.M. Rahman and M. Ahmed. 2015. Comparative studies on nutritional quality of commercial wheat flour in Bangladesh. Bangladesh J. Sci. Ind. Res. 50(3): 181-188. https://doi.org/10.3329/bjsir.v50i3.25581

Samaan, J., H.G. El- Hayat, F.A. Manthey, M.P. Fuller and S.C. Brennan. 2006. Durum wheat quality: II. The relationship of kernel physicochemical composition to semolina quality and end product utilization. Inter. J. Food Sci. Techno. 41(2): 47–55. https://doi.org/10.1111/j.1365-2621.2006.01313.x

Schoch, T.J. 1964. Swelling power and solubility of granular starches. In: Whistler, R.I., Smith, R.J. and BeMiller, J.N., Editors, 1964. Methods in carbohydrate chemistry. New York: Academies press. pp. 106-108.

Seibel, W. 1996. Future trends in pasta products. In J.E. Kruger, R.B. Matsuo and J.W. Dick (Eds.). Pasta and noodle technology. St. Paul, MN: Am. Soc. Cereal Chem. pp. 331–349.

Shah, R.U., K. Naveed., I. Hussain., S.M. Khan and N. Ali. 2017. physio-morphological and grain protein content of different wheat genotypes under agro-ecological conditions of Haripur. Sci. Int. (Lahore), 29(1): 225-228.

Shah, N.H., Inamullah, M. Siddiq, I. Ahmad and S. Rehman. 2010. Pirsabak-2008, a new high yielding wheat variety for cultivation in irrigated tracts of NWFP, Pakistan. Sarhad J. Agric. 26(2): 213-220.

Singh, N., L. Kaur, K.S. Sandhu, J. Kaur and K. Nishinari. 2006. Relationships between physicochemical, morphological, thermal, rheological properties of rice starches. Food Hydro. 20: 532-42.

Sobota, A., Z. Rzedzocki, P. Zarzycki and E. Kuzawinska. 2015. Application of common wheat bran for the industrial production of high-fiber pasta. Int. J. Food Sci. Technol. 50: 111-119. https://doi.org/10.1111/ijfs.12641

Tester, R.F., J. Karkalas and X. Qi. 2004. Starch composition, fine structure and architecture. J. Cereal Sci. 39(2): 151–165. https://doi.org/10.1016/j.jcs.2003.12.001

Uddin, N., M.H. Khan, A.A. Khakwani, M. Zubair, M.S. Baloch, S. Khan and A.W. Khan. 2005. Rainfed area improvement in perspective: Development of Zam-04, improved wheat variety for rainfed areas of NWFP. Indus J. Plant Sci. 4 (1): 119-123.

Vandeputte, G.E., V. Derycke, J. Geeroms and J.A. Delcour. 2003. Rice starch. II. Structure aspect provide insight in to swelling and pasting properties. J. Cereal Sci. 38: 53-59.

Vignola, M.B., M.C. Buston and G.T. Perez. 2018. Comparison of quality attributes of refined and whole wheat extruded pasta. LWT - Food Sci. Technol. 89: 329-335. https://doi.org/10.1016/j.lwt.2017.10.062

Wang, S.J. and L. Copeland. 2012a. New insight into loss of swelling power and pasting profiles of acid-hydrolysed starch granules. Starch-Starke, 64: 538–544. https://doi.org/10.1002/star.201100186

Wang, S.J. and L. Copeland. 2012c. Nature of thermal transitions of native and acid hydrolysed pea starch: Does gelatinization really happen? Carbo. Polymers. 7: 1507-1514. https://doi.org/10.1016/j.carbpol.2011.09.047

Wiseman, G. 2001. Durum Wheat. In: R. C. Kill and K. Turnbull (Eds.). Pasta and Semolina. Tech. Oxford, UK, Blackwell Science Ltd. pp. 11-42. https://doi.org/10.1002/9780470999370.ch2

Yadav, D.N., M. Sharma, N. Chikara, T. Anand and S. Bansal. 2014. Quality characteristics of vegetable blended wheat pearl millat composit pasta. Agric. Res. 3(3): 263–270. https://doi.org/10.1007/s40003-014-0117-7

To share on other social networks, click on any share button. What are these?