Evaluating the Nutritional Value of the Newly Developed Quality Protein Maize in Pakistan: Impact on Broiler Performance and Profitability

Evaluating the Nutritional Value of the Newly Developed Quality Protein Maize in Pakistan: Impact on Broiler Performance and Profitability

Nazir Ahmad Khan1,*, Mudassir Alam1, Rafiullah khan1, Kamran Khan2 and Sadeeq ur Rahman3

1Faculty of Animal Husbandry and Veterinary Sciences, The University of Agriculture, Peshawar 25130, Khyber Pakhtunkhwa

2Department of Animal Sciences, Shaheed Benazir Bhutto University, Sheringal, Khyber Pakhtunkhwa

3College of Veterinary Sciences and Animal Husbandry, Section Microbiology, Abdul Wali Khan University, Mardan

ABSTRACT

Quality protein maize (QPM) with high protein and essential amino acids contents can be potentially used in broiler feeds to reduce the inclusion level and cost of expensive protein ingredients. This study quantified the chemical composition and amino acid profile of grains from newly developed QPM hybrids and evaluated the effect of replacing conventional maize (CM) with QPM in broiler feed on bird’s performance, diet digestibility, nitrogen retention, meat amino acids profile and farm profitability. Grains of QPM200 and QPM300 hybrids, approved by Pakistan maize variety evaluation committee in January 2017, were provided by International Maize and Wheat Improvement Centre (CIMMYT), Pakistan. The content of CP was higher in QPM300 (10.8% dry matter (DM)) and QPM200 (9.12% DM) than the CM (7.78% DM). Moreover, QPM200 and QPM300 had higher contents (% of DM) of methionine (0.20-0.24 vs. 0.12), threonine (0.43-0.69 vs. 0.17), and tryptophan (0.07 each vs. 0.05) as compared to CM. For testing the QPM in broiler feeds, four iso-nitrogenous and iso-caloric feeds were prepared: commercial feed (control) containing only CM; (ii) diet containing only QPM200; (iii) diet containing only QPM300; (iv) diet containing 50% each of the QPM. Birds fed on QPM300-based diet had higher (P < 0.05; 2438.5 g) final body weight and better (P < 0.05; 1.743) feed to weight gain efficiency throughout the experimental period. Eight days in vivo digestibility assay showed that QPM300 had higher (P < 0.05; 81.7%) dry matter digestibility, followed by diets containing QPM200 (78.3%) and QPM-mix (78.2%), while lowest (P < 0.05) digestibility was recorded for the control diet (74.1%). The three QPM based diets did not differ in N retention; however, they retained higher (P < 0.05) percentages of nitrogen (51.4-53.9%) than the control diet (43.9%), suggesting higher amino acids availability from the QPM-based diets. The QPM300 diet had the highest (P < 0.05) net profit (70.2 PKR/bird) and the CM-based diet had the lowest (61.5 PKR/bird). The newly released QPM hybrids with higher protein and essential amino acids contents enhanced diet digestibility and broiler production efficiency and can be potentially exploited to reduce the dependency on imported protein ingredients and improve farm profitability.

Article Information

Received 16 March 2018

Revised 30 March 2019

Accepted 17 August 2019

Available online 20 January 2020

Authors’ Contribution

NAK wrote the manuscript and supervised the research. MA and KK executed the experiments and collected and refined the data. RK conducted the laboratory work. SR analysed the data.

Key words

Conventional maize, Quality protein maize, Performance trait, Amino acid profile, Broiler.

DOI: https://dx.doi.org/10.17582/journal.pjz/20180316190348

* Corresponding author: nazir.khan@aup.edu.pk

0030-9923/2020/0002-0585 $ 9.00/0

Copyright 2020 Zoological Society of Pakistan

Introduction

Maize (Zea mays L.) is an important cereal crop and ranks third in terms of production among the cereal crops produced in Pakistan (ESP, 2017). More than 60% of the maize grains produced in Pakistan are used in feed industry, as a principal energy ingredient in poultry feed, owing to its higher energy, lower fiber and essential fatty acids contents, and higher palatability and digestibility (Panda et al., 2014). Although, the conventional maize (CM) has lower content of crude protein (CP; 7-8%), it still contributes about 20% of the metabolizable protein requirements of the birds (Cowieson, 2005), due to higher levels (50-70%) of inclusion in poultry feed. It is evident that a small improvement in maize protein and essential amino acids contents can have a larger impact on the overall supply of these nutrients to the birds.

The biological value of CM protein is low, particularly for monogastric animals such as poultry, because it contains high zein protein fraction, which is inherently devoid of lysine and low in tryptophan (NRC, 1994; Prasanna et al., 2001). Therefore, CM protein requires lysine and tryptophan supplementation to optimize broiler performance (Jia et al., 2013). Many traditional maize varieties (yellow and white) with a wide range of nutrient concentration are available (Snow et al., 2004); however, the newly developed quality protein maize (QPM) cultivars offer promising nutritional benefits over the CM (Vasal, 2000; Prandini et al., 2011).

The first mutant QPM, recognised as Opaque 2 was developed in 1963 containing higher concentration of lysine and tryptophan (Mertz et al., 1964). However, its production was ceased due to soft endosperm that made it susceptible to pests and crop storage problems. Over the time, using conventional breeding methods (such as selection and hybridization) and biotechnological advancements (such as genetic engineering), the International Maize and Wheat Improvement Centre (CIMMYT), produced QPM cultivars with improved agronomic and nutritional characteristics such as with a hard endosperm, enriched with lysine and tryptophan (Nuss and Tanumihardjo, 2011; Jia et al., 2013).

Recently, Pakistan maize variety evaluation committee approved QPM200 and QPM300 hybrids, for large-scale cultivation in Pakistan. These hybrids were developed by CIMMYT in Colombia and evaluated and selected in Pakistan by the National Agricultural Research Centre (NARC) with reported 3 times more yield than the national average. It is envisioned that the use of QPM hybrids, with high grain yield, and high protein content and better amino acids composition can be used by the feed manufacturers to produce balanced poultry feeds with lower proportion of expensive imported protein ingredients and synthetic amino acids (lysine and tryptophan) to reduce feed cost.

The cost of imported soybean has significantly increased over the past few decades due the rapid growth of poultry industry on global basis, as well as by the rising demand of soybean in human food industry (Hansen and Gale, 2014; Ullah et al., 2017). Moreover, the local plant and animal origin protein sources are also becoming scarce and expensive due to rapid growth poultry and livestock industries (Habib et al., 2013) and this background provides impetus to evaluate nutritional value of the newly developed QPM for poultry. This study was therefore designed to quantify the chemical composition and amino acid profile of the newly released QPM hybrids, and evaluate the effect of replacing CM with QPM in broiler feed on broilers growth performance, nitrogen retention, nutrients digestibility, meat amino acids profile, and farm profitability.

Materials and methods

Quality protein maize hybrids description, grain sampling and chemical analysis

The QPM hybrids used in this study were developed by CIMMYT in Colombia and evaluated and selected for commercial scale production in Pakistan in 2017 by the National Agricultural Research Centre (NARC) based on the reported 3 times more yield than the national average. The nutrient profile and amino acids (essential and non-essential) compositions of QPM hybrids, QPM200 and QPM300, were evaluated in comparison with CM. Grain samples (n = 4) were collected from four replicate fields of each grain type, kept in pre-labelled polythene zip-bags, and transported to the laboratory of animal nutrition the University of Agriculture Peshawar for further processing and analysis. The samples were pooled by the replicate of each hybrid, mixed, and a representative sub-sample of ~2 kg was taken for further processing and chemical analysis. All samples were freeze dried, ground through a 1 mm mesh sieve and analysed for the contents of dry matter (DM), ash, ether extract (EE) and CP according to the standard methods of AOAC (1990). The DM content was determined by oven drying at 103°C (method 930.15), the Soxhlet extraction method with diethyl ether was used for EE (method 920.39), the CP (N × 6.25) content was determined by the Kjeldahl method (method 984.13; using a KjeltecTM 2400 autoanalyzer; Foss Analytical A/S, Hillerod, Denmark), and ash content by incineration at 550°C till constant weight (method 942.05) as reported earlier by Khan et al. (2017). All laboratory measurements were taken in duplicate and cross-validated using control samples.

The amino acid profile of the maize grain and meat samples was determined by ion exchange column chromatography using amino acid analyser (Biochrom 30 plus, Biochrom Ltd. Cambridge, UK) as reported earlier (Ullah et al., 2016). Briefly, samples were ground (500 micron), and oxidized with hydrogen peroxide-formic acid-phenol solution to protect cysteine and methionine. The oxidized samples were hydrolysed using 6 M HCL/phenol for 24 h. The pH of hydrolysate was adjusted at 2.20, using 7.5 M NaOH. Following hydrolysis, the samples were diluted, filtered and then poured into sample vials. The separation of the different amino acids was performed by amino acid analyser (Biochrom 30 plus, Biochrom Ltd., Cambridge, UK), and their amount was calculated on the basis of elution and standard solution volumes as reported earlier (Ullah et al., 2016).

Feeding trials with broilers

For testing the QPM in broiler feeds, four iso-nitrogenous and iso-caloric feeds were prepared: (i) balanced commercial feed (control) containing only CM; (ii) diet containing only QPM200; (iii) diet containing only QPM300; (iv) diet containing 50% each of the QPM. The four diets were fed to broilers from 0-42-days, including one-week adaptation period. A total of 128 broiler chicks (day-old; average body weight, 41.41 g) were procured from commercial hatchery. The chicks were further sub-divided into 16 replicate groups (8 chicks/ replicate), and each experimental diet was assigned to 4 replicate groups. Each replicate group was kept in separate cage (10’ L × 8’ W × 4’ H) in the same shed, with a floor space of 1 square feet, and wood shavings were used as litter.

The experimental birds were fed starter (1 to 18 days), grower (19 to 36 days) and finisher (37 to 42 days) diets, formulated according to the recommended nutrient requirements of commercial broiler according to NRC (1994). Energy and protein requirements were met by adjusting the proportion of non-maize ingredients. All diets were formulated to the same protein, amino acid and metabolizable energy levels. The ingredients and nutrient profile of the broiler starter, grower and finisher diets are presented in Table I. The diets were offered ad-libitum either in mash (0-10 days) or pellet (10-41 days) form. All birds had free access to clean drinking water all the time. The experimental birds were vaccinated against ND (on day 6 and 24), IB (day 6) and IBD (day 18).

Table I.- Ingredients and chemical composition of the broiler starter, grower and finisher diets containing conventional maize (CM) and newly developed commercial hybrids of quality-protein maize (QPM).

|

Ingred-ients (%) |

Starter (D1-18) |

Grower (D19-36) |

Finisher (37-42) |

|||||||||

|

CM |

QPM 200 |

QPM 300 |

QPM- mix |

CM |

QPM 200 |

QPM300 |

QPM- mix |

CM |

QPM 200 |

QPM 300 |

QPM- mix |

|

|

Ingredients |

||||||||||||

|

Corn |

54.0 |

0.00 |

0.00 |

0.00 |

64.0 |

0.00 |

0.00 |

0.00 |

64.0 |

0.00 |

0.00 |

0.00 |

|

QPM-200 |

0.00 |

54.0 |

0.00 |

27.0 |

0.00 |

64.0 |

0.00 |

32.0 |

0.00 |

54.0 |

0.00 |

27.0 |

|

QPM-300 |

0.00 |

0.00 |

54.0 |

27.0 |

0.00 |

0.00 |

64.0 |

32.0 |

0.00 |

0.00 |

54.0 |

27.0 |

|

Broken Rice |

2.40 |

2.40 |

2.40 |

2.40 |

1.10 |

1.10 |

1.10 |

1.10 |

1.10 |

2.40 |

2.40 |

2.40 |

|

Cotton meal |

5.00 |

5.00 |

5.00 |

5.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

5.00 |

5.00 |

5.00 |

|

Guar meal |

4.00 |

4.00 |

4.00 |

4.00 |

4.00 |

4.00 |

4.00 |

4.00 |

4.00 |

4.00 |

4.00 |

4.00 |

|

Sunflower meal |

3.40 |

3.40 |

3.40 |

3.40 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

3.40 |

3.40 |

3.40 |

|

Soya bean meal |

10.0 |

8.53 |

6.53 |

7.53 |

10.0 |

8.00 |

5.50 |

6.50 |

10.0 |

8.53 |

6.53 |

7.53 |

|

Maize gluton meal (30%) |

7.50 |

7.50 |

7.50 |

7.50 |

7.20 |

7.20 |

7.20 |

7.20 |

7.20 |

7.50 |

7.50 |

7.50 |

|

Fishmeal (50%) |

5.00 |

5.00 |

5.00 |

5.00 |

3.00 |

3.00 |

3.00 |

3.00 |

3.00 |

5.00 |

5.00 |

5.00 |

|

Rice polish |

6.00 |

7.50 |

9.53 |

8.51 |

4.00 |

6.00 |

8.50 |

7.50 |

4.00 |

7.50 |

9.53 |

8.51 |

|

Molasses |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

|

Lime stone |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

|

Rock phosphate |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

|

Lysine |

0.10 |

0.09 |

0.09 |

0.09 |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

0.09 |

0.09 |

0.09 |

|

Methio-nine |

0.10 |

0.08 |

0.05 |

0.07 |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

0.08 |

0.05 |

0.07 |

|

Vit and Min. premix |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

0.10 |

|

Calculated chemical composition† |

||||||||||||

|

Crude protein |

20.3 |

20.6 |

20.6 |

20.5 |

17.4 |

18.4 |

18.7 |

18.5 |

17.4 |

20.6 |

20.7 |

20.5 |

|

Ether extract |

4.20 |

4.20 |

4.20 |

4.20 |

4.20 |

4.20 |

4.20 |

4.20 |

4.20 |

4.20 |

4.20 |

4.20 |

|

Fiber |

3.95 |

3.95 |

3.95 |

3.95 |

3.95 |

3.95 |

3.95 |

3.95 |

3.95 |

3.95 |

3.95 |

3.95 |

|

Ash |

5.48 |

5.48 |

5.48 |

5.48 |

5.48 |

5.48 |

5.48 |

5.48 |

5.48 |

5.48 |

5.48 |

5.48 |

|

Calcium |

0.77 |

0.77 |

0.77 |

0.77 |

0.77 |

0.77 |

0.77 |

0.77 |

0.77 |

0.77 |

0.77 |

0.77 |

|

Phosph-orous |

0.31 |

0.31 |

0.31 |

0.31 |

0.31 |

0.31 |

0.31 |

0.31 |

0.31 |

0.31 |

0.31 |

0.31 |

|

Amino acid (% of total amino acids) |

||||||||||||

|

Lysine |

1.36 |

1.36 |

1.36 |

1.36 |

1.36 |

1.36 |

1.36 |

1.36 |

1.36 |

1.36 |

1.36 |

1.36 |

|

Methionine |

0.46 |

0.46 |

0.46 |

0.46 |

0.46 |

0.46 |

0.46 |

0.46 |

0.46 |

0.46 |

0.46 |

0.46 |

|

Cysteine |

0.34 |

0.34 |

0.34 |

0.34 |

0.34 |

0.34 |

0.34 |

0.34 |

0.34 |

0.34 |

0.34 |

0.34 |

|

Metabo-lizable energy (kcal/kg) |

2997 |

2963 |

2957 |

2967 |

3120 |

3100 |

3099 |

3110 |

3120 |

2963 |

2957 |

2967 |

†g/100 g DM until otherwise stated.

Performance traits, meat amino acid analysis and farm profitability

Known quantity of feed was offered to each bird twice daily and the refusal was weighted next morning (8:00 am). Feed intake was determined on daily basis. All birds were weighed individually at the start of the trial and then every week for calculation of feed conversion ratio (FCR). Average daily feed intake (g/d), daily weight gain (g/d) and feed to gain (F/G) ratio was calculated for the starter, grower, finisher and total growing periods. Mortality was recorded on daily basis for each experimental group. For the meat amino acids analysis, samples were collected from 2 randomly selected birds of each replicate group on day 42 of the trial; and sacrificed after a fasting period of 5 h (only access to water). Samples were collected from breast region, cut into small pieces, mixed and a representative subsample of ~20 g was collected and kept at 4°C until the time of analysis. Total cost, gross return and net profit of diets used in the trial was determined. The value of gross return was calculated on per kg live weight according to the market rate.

Digestibility trial

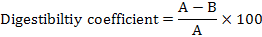

The measurement of total tract apparent nutrient digestibility co-efficient for DM and EE, and nitrogen-retention of broilers diets was performed in the period of D35-42 of the trial including 4 days acclimatization period. For the digestibility assay 32 birds from the four-dietary groups (8 birds/diet) were used. The birds were kept in individual metabolic cages containing facilities for feed and water provision, and feces collection. During the end of each 4 days period (D39-42), data was recorded on feed intake, and fresh feces were collected during 24 h, weighed, pooled and stored in labelled plastic bags in freezer (-20 °C) until analysis. The nitrogen retention was determined by the ingesta-excreta balance method. The apparent digestibility coefficient of dry matter (DMD) and ether extract (EED) of the experimental diets were calculated by the difference between the nutrients consumed and voided by the broiler birds in feces using the following equation.

Where, A is the quantity of nutrients consumed by birds and B is the quantity of nutrients voided in feces.

Statistical analysis

The effect of diets composition on bird’s performance, feed digestibility, nitrogen retention, meat amino acids profile and farm profitability was determined using PROC GLM Procedure of the SAS (SAS, 2009). The model used for data analysis was:

Where, Yij is the dependent variable, µ is the overall mean; Dxi, is the effect of diet, ϵij is the random error. Post-hoc analysis was carried out for mean comparison using Tukey-Kramer test in case of significant (P < 0.05) effect.

Table II.- Chemical composition and amino acid profile of grain from conventional maize (CM) and newly developed hybrids of quality protein maize (QPM).

|

CM |

QPM hybrids |

||

|

QPM200 |

QPM300 |

||

|

Chemical composition (%) |

|||

|

Dry matter |

86.7 |

88.9 |

87.4 |

|

Crude protein |

7.78 |

9.12 |

10.8 |

|

Ether extract |

3.32 |

3.69 |

3.92 |

|

Ash |

1.32 |

1.19 |

1.28 |

|

Metabolizable energy (MJ/Kg) |

13.7 |

13.9 |

13.6 |

|

Essential amino acids (%) |

|||

|

Valine |

0.32 |

0.06 |

0.04 |

|

Lysine |

0.21 |

0.24 |

0.23 |

|

Histidine |

0.22 |

0.24 |

0.61 |

|

Arginine |

0.38 |

0.63 |

0.52 |

|

Threonine |

0.17 |

0.43 |

0.69 |

|

Methionine |

0.12 |

0.20 |

0.24 |

|

Iso-leucine |

0.81 |

1.10 |

0.92 |

|

Phenylalanine |

0.31 |

0.43 |

0.36 |

|

Tryptophan |

0.05 |

0.07 |

0.07 |

|

Leucine |

0.31 |

0.13 |

0.14 |

|

Non-essential amino acids |

|||

|

Glutamic acid |

1.23 |

1.71 |

0.50 |

|

Glycine |

0.22 |

0.12 |

0.03 |

|

Serine |

0.26 |

0.03 |

0.05 |

|

Proline |

0.55 |

1.02 |

0.16 |

|

Tyrosine |

0.23 |

0.26 |

0.06 |

|

Alanine |

0.51 |

0.66 |

0.11 |

Results

Data on the chemical composition and amino acids profile of grains from CM and newly released commercial hybrids of quality protein maize, QPM200 and QPM300, are summarized in Table II. The content of CP was higher in QPM300 (10.8 % DM basis) and QPM200 (9.12% DM) than the CM (7.78% DM). Similarly, the content of EE was higher in QPM300 (3.92% DM) as compared to QPM200 (3.69% DM) and CM (3.32% DM). Except valine and leucine, the QPM hybrids had higher contents of all essential amino acids compared to CM. Notably, the QPM200 and QPM300 had higher concentration of methionine (0.20, 0.24, vs. 0.12% DM), threonine (0.43, 0.69 vs. 0.17% DM), lysine (0.24, 0.23 vs. 0.21% DM) and tryptophan (0.07 each vs. 0.05% DM) compared to the CM. Among the non-essential amino acids glycine and serine were higher in CM, whereas the rest of non-essential amino acids were higher in QPM200.

Data on the effect of CM and QPM based diets on feed intake, growth performance and feed conversion efficiency are summarized in Table III. The inclusion of QPM in the feed altered (P < 0.01) body weight gain of broilers during the growing (D19-36) and finisher (D37-42) phase. The highest (P < 0.05) weight gain during growing and finisher phase was recorded for QPM300, and the lowest (P < 0.05) weight gain was recorded for CM based control diet. Similarly, the average daily gain for the periods of D19-36, D37-42 and D0-42 was highest (P < 0.05) for QPM300 based diet and lowest (P < 0.05) for CM based control diet. Feed intake of broiler did not differ (P > 0.05) due to inclusion of QPM in the broiler feed. The QPM300-based diet supported best (P < 0.05) FCR in the period of D19-36, D37-42 and D0-42. Mortality throughout the experimental trial was 1.85% in the groups receiving CM and QPM200 diets, and 0% in those receiving QPM300 and QPM-mix diets. Inclusion of QPM in the diet did not alter (P > 0.05) the amino acid composition of meat (Table IV).

Results of the nitrogen retention, and apparent DMD and EED coefficients during finisher phase (D35-42) are shown in Figure 1A and B. Replacement of CM with QPM improved (P < 0.05) nitrogen retention in broilers. However, nitrogen retention of birds fed on QPM200, QPM300 and QPM-mix based diets was not different (P > 0.05). Birds fed with QPM300-based diet had highest (P < 0.05) feed DMD than birds fed on all the other diets (Fig. IB). The QPM200 and QPM-mix based feed had higher DMD than the CM based diet. On the other hand, diets composition did not alter (P > 0.05) EED. Data on total cost, gross return and net-profit are summarized in Figure 2. Birds raised on QPM300 diet had highest (P < 0.05) profit, followed by those raised on QPM200 and QPM-mix diets, while birds raised on the CM-based diet had the lowest (P < 0.05) profit. Overall, the QPM300 diet had 14.2% more profit than the CM-based diet.

Table III.- Growth performance of broilers fed diets containing grains from conventional maize (CM) and newly developed commercial hybrids of quality-protein maize (QPM).

|

Diets† |

SEM†† |

Significance††† |

||||

|

Control |

QPM200 |

QPM300 |

QPM-mix |

|||

|

Average weight (g) |

||||||

|

Initial, D0 |

41.36 |

41.54 |

41.54 |

41.21 |

0.183 |

ns |

|

Starter, D0-18 |

674.80 |

681.30 |

692.10 |

677.56 |

0.453 |

ns |

|

Grower, D19-36 |

1933.2c |

1958.7b |

1998.5a |

1950.4b |

1.684 |

** |

|

Finisher, D37-42 |

2356.7c |

2389.6b |

2438.5a |

2378.6b |

3.251 |

** |

|

Average daily gain (g/d) |

||||||

|

Day 0-18 |

35.19 |

35.54 |

36.14 |

35.35 |

1.667 |

ns |

|

Day 19-36 |

69.91c |

70.97b |

72.58a |

70.71b |

1.189 |

** |

|

Day 37-42 |

70.58c |

71.82b |

73.34a |

71.36bc |

2.196 |

** |

|

Day 0-42 |

55.13c |

55.91b |

57.07a |

55.65b |

1.345 |

** |

|

Feed intake (g/d) |

||||||

|

Day 0-18 |

44.5 |

44.3 |

44.1 |

45.3 |

1.189 |

ns |

|

Day 19-36 |

135.7 |

135.49 |

135.59 |

136.37 |

3.445 |

ns |

|

Day 37-42 |

188.67 |

189.87 |

188.98 |

187.98 |

2.834 |

ns |

|

Day 0-42 |

99.67 |

99.91 |

99.45 |

100.47 |

0.021 |

ns |

|

F/G efficiency |

||||||

|

Day 0-18 |

1.265 |

1.246 |

1.220 |

1.281 |

0.113 |

ns |

|

Day 19-36 |

1.941a |

1.909a |

1.868b |

1.929a |

0.121 |

** |

|

Day 37-42 |

2.673a |

2.644a |

2.577b |

2.634a |

0.032 |

** |

|

Day 0-42 |

1.808a |

1.787ab |

1.743b |

1.805a |

0.136 |

** |

|

Mortality (%) |

1.850 |

1.850 |

0 |

0 |

3.452 |

ns |

Mean with different superscript letters (a, b and c) in the same row differ at P < 0.05. †CM, control diet containing conventional maize grains, whereas in other diets the conventional maize was replaced with QPM200, QPM300 or their mixture (50% of each hybrid). ††, standard error of the mean. †††, ns = non-significant; **, P < 0.01.

Table IV.- Meat amino acid profile (%) of broiler fed with diets fed diets containing grains from conventional maize (CM) and newly developed commercial hybrids of quality-protein maize (QPM).

|

Amino acids (%) |

Diets† |

SEM†† |

Significance††† |

|||

|

Control |

QPM200 |

QPM300 |

QPM-mix |

|||

|

Alanine |

4.27 |

4.22 |

4.63 |

4.47 |

1.27 |

ns |

|

Arginine |

4.97 |

5.09 |

5.29 |

5.24 |

0.68 |

ns |

|

Aspartic Acid |

6.96 |

6.86 |

7.46 |

7.33 |

1.26 |

ns |

|

Cystine |

0.71 |

0.69 |

0.72 |

0.70 |

1.36 |

ns |

|

Glutamic Acid |

11.94 |

11.71 |

12.55 |

12.4 |

1.27 |

ns |

|

Glycine |

3.19 |

3.08 |

3.42 |

3.28 |

1.09 |

ns |

|

Histidine |

2.23 |

2.27 |

2.25 |

2.37 |

1.35 |

ns |

|

Isoleucine |

3.58 |

3.54 |

3.88 |

3.86 |

1.35 |

ns |

|

Leucine |

5.97 |

5.84 |

6.51 |

6.33 |

1.24 |

ns |

|

Lysine |

6.38 |

6.23 |

6.81 |

6.58 |

1.36 |

ns |

|

Methionine |

2.05 |

2.04 |

2.17 |

2.05 |

1.42 |

ns |

|

Phenylalanine |

2.92 |

2.89 |

3.18 |

3.15 |

1.36 |

ns |

|

Serine |

2.85 |

2.75 |

2.98 |

2.93 |

1.58 |

ns |

|

Threonine |

3.26 |

3.21 |

3.45 |

3.41 |

2.11 |

ns |

|

Tyrosine |

2.70 |

2.43 |

2.84 |

2.71 |

1.79 |

ns |

|

Valine |

3.66 |

3.65 |

4.13 |

3.93 |

1.47 |

ns |

Values are shown as mean, in the same row no superscript letters shows no significant difference (P > 0.05). † CM, control diet containing conventional maize grains, whereas in other diets the conventional maize was replaced with QPM200, QPM300 or their mixture (50% of each hybrid). †† standard error of the mean. †††, ns = non-significant. †††, ns = non-significant.

Discussion

The importance of maize grain in poultry feed has been well established. The QPM hybrids with high protein and essential amino acids contents are a very promising alternative to the CM grains in poultry feed. The inclusion of QPM in broiler feed reduces the inclusion level of expensive protein ingredients and synthetic amino acids, and can potentially reduce the dependence on the expensive imported soybean meal and improve farm profitability (Prandini et al., 2011). The results of the present study report the first comprehensive database on the chemical composition and amino acids profile of grains from two newly released QPM hybrids in Pakistan, and compare the growth performance, feed digestibility, meat amino acids profile and profitability of broilers raised under uniform conditions on CM and the QPM based feeds.

The results show that grains from QPM200 and QPM300 hybrids have greater feeding value for broilers as compared to CM, because of their high protein and essential amino acids content, in particular, the essential amino acids viz. lysine and tryptophan. Prandini et al. (2011) argued that the high protein content of QPM is related to the higher germ to endosperm proportion of their grains. Maize kernel comprises largely on endosperm (storage tissue; 82%), followed by germ (embryo; 12%) and pericarp (outer layer; 6%) (Prasanna et al., 2001). Though, both the germ and endosperm contain protein, the germ protein are quantitatively and qualitatively superior (Prasanna et al., 2001; Sofi et al., 2009). Moreover, the greater proportion of germ to endosperm in QPM is also connected with an improved quality (essential amino acid content) of protein. Compared to CM, the levels of other amino acids such threonine and methionine was higher, while that of leucine was lower in QPM. Lower concentration of leucine is desirable, because it balances the ratio of leucine to iso-leucine, which in turns contributes to the release of more tryptophan for niacin biosynthesis. In agreement with our findings higher content of protein and essential amino acid in QPM than CM was reported earlier (Harrelson et al., 2008; Idikut et al., 2009).

In our study QPM300 and QPM200 based diets supported high weight gain. The high weight gain was due to a higher feed conversion efficiency of the QPM based diets. Literature shows that diets incorporated with QPM have better FCR than CM-based diets in monogastric animals such as chicken (Lucas et al., 2007; Onimisi et al., 2009). The improvement observed in body weight gain and FCR could be, in part, related to the high nutritional quality of QPM such as high protein and essential amino acids contents, particularly lysine and tryptophan. It is an established fact that lysine is crucial for protein synthesis, while tryptophan is the biological precursor for niacin and vitamin-B synthesis. The superior protein quality and amino acids availability in QPM improves the efficiency of feed utilization (Onimisi et al., 2009). It is further reported that only 37% of the CM protein intake is utilized in monogastric animals as compared to 74% of the QPM protein (Zhai and Zhang, 2007; Prandini et al., 2011). Moreover, the CM-based diet did not support optimum performance due to lack of an adequate content of the essential amino acids, thus reducing the overall biological value of its protein (Prandini et al., 2011).

It is evident from the results of present study that the digestibility coefficient of DM was higher in QPM300 based diet. Moreover, the nitrogen in the QPM based diets was better retained by the broilers as compared to the CM-based diet. Our results are supported by findings of Douglas et al. (2000) and Zhai and Zhang (2007), and the higher percentage of nitrogen retention in QPM-based diets could be partly due to the efficient CP utilization and higher amino acid availability. Due to high CP and essential amino acids contents, lower amount of soybean meal was included in the QPM300-based diet that leaded to lower feed cost. The lower feed cost coupled with higher performance of broilers in terms of weight gain and feed conversions efficiency on the QPM300 based diet resulted in highest net-profit.

Conclusions

The newly released QPM hybrids in Pakistan have higher protein and essential amino acids contents than CM, highlighting the scope for exploiting these potential nutritional advantages in food and feed industries. Replacement of CM with QPM in broiler diets, reduced feed cost and resulted in better growth performance, improved feed conversion efficiency and profitability. The PQM300 had the highest portion and essential amino acids contents, and the QPM300 based feed supported highest weight gain, feed conversion efficiency and profitability in broilers.

Acknowledgements

The author’s thanks International Livestock Research institute and the USAID funded Agriculture Innovation Program (AIP) for Pakistan for financially supporting this study.

Statement of conflict of interest

We certify that there is no conflict of interest with any funding organization.

References

AOAC, 1990. Official methods of analysis, 15th edition. Association of Official Analytical Chemists, Arlington, VA, USA.

Cowieson, A.J., 2005. Factors that affect the nutritional value of maize for broilers. Anim. Feed Sci. Technol., 119: 293-305. https://doi.org/10.1016/j.anifeedsci.2004.12.017

Douglas, M.W., Peter, C.M., Boling, S.D., Parsons, C.M. and Baker, D.H., 2000. Nutritional evaluation of low phytate and high protein corns. Poult. Sci., 79: 1586-1591. https://doi.org/10.1093/ps/79.11.1586

ESP, 2016-17. Economic survey of Pakistan. Government of Pakistan, Economic Advisor’s Wing, Finance Division, Islamabad, Pakistan.

Habib, G., Khan, N.A., Ali, M. and Bezabih, M., 2013. In situ ruminal crude protein degradability of cereal grains, oilseeds and animal byproduct-based protein feedstuffs. Livest. Sci., 153: 81-87. https://doi.org/10.1016/j.livsci.2013.01.017

Hansen, J. and Gale, F., 2014. China in the next decade: Rising meat demand and growing imports of feed. Amber Waves Mag., 2014: 1-10. https://www.ers.usda.gov/amber-waves/2014/april/china-in-the-next-decade-rising-meat-demand-and-growing-imports-of-feed/

Harrelson, F.W., Erickson, G.E., Klopfenstein, T.J., Jackson, D.S. and Fithian, W.A., 2008. Influence of corn hybrid, kernel traits and growing location on digestibility. Nebraska Beef Cattle Report, Animal Science Department, University of Nebraska, Lincoln.

Idikut, L., Atalay, A.I., Kara, S.N. and Kamalak, A., 2009. Effect of hybrid on starch, protein and yields of maize grain. J. Anim. Vet. Adv., 8: 1945-1947.

Jia, M., Wu, H., Clay, K., Jung, R., Larkins, B. and Gibbon, B., 2013. Identification and characterization of lysine-rich proteins and starch biosynthesis genes in the opaque2 mutant by transcriptional and proteomic analysis. BMC Pl. Biol., 13: 60. https://doi.org/10.1186/1471-2229-13-60

Khan, K., Khan, S., Ullah, S., Khan, N.A, Khan, I. and Ahmad, N., 2017. Nutritive value, fiber digestibility and methane production potential of tropical forages in rabbits: effect of species and harvest maturity. J. Anim. Pl. Sci., 27: 1094-1100.

Lucas, D.M., Taylor, M.L., Hartnell, G.F., Nemeth, M.A., Glenn, K.C. and Davis, S.W., 2007. Broiler performance and carcass characteristics when fed diets containing Lysine maize (LY038 or LY038 x MON 810), control, or conventional reference maize. Poult. Sci., 86: 2152-2161. https://doi.org/10.1093/ps/86.10.2152

Mertz, E.T., Bates, L.S. and Nelson, O.E., 1964. Mutant gene that changes protein composition and increases lysine content of maize endosperm. Science, 145: 279-280. https://doi.org/10.1126/science.145.3629.279

NRC, 1994. Nutrient requirements of poultry, 9th revised edition. National Research Council, National Academy Press, Washington, DC, USA.

Nuss, E.T. and Tanumihardjo, S.A., 2011. Quality protein maize for Africa: Closing the protein inadequacy gap in vulnerable populations. Adv. Nutr., 2: 217-224. https://doi.org/10.3945/an.110.000182

Onimisi, P.A., Omage, J.J., Dafwang, I.I. and Bawa, G.S., 2009. Replacement value of normal maize with quality protein maize (Obatampa) in broiler diets. Pak. J. Nutr., 8: 112-115. https://doi.org/10.3923/pjn.2009.112.115

Panda, A.K., Zaidi, P.H., Rama-Rao, S.V. and Raju, M.V.L.N., 2014. Efficacy of quality protein maize in meeting energy and essential amino acid requirements in broiler chicken production. J. appl. Anim. Res., 42: 133-139. https://doi.org/10.1080/09712119.2013.822812

Prandini, A., Sigolo, S., Morlacchini, M., Marocoo, A. and Pinto, M.L., 2011. High-protein maize in the diets of broilers. Italian J. Anim. Sci., 55: 244-249. https://doi.org/10.4081/ijas.2011.e55

Prasanna, B.M., Vasal, S.K., Kassahun, B. and Singh, N.N., 2001. Quality protein maize. Curr. Sci., 10: 1308-1319.

Snow, J.L., Stein, H.H., Ku, P.K. and Trottier, N.L., 2004. Amino acid digestibility and nitrogen utilization of high oil, high lysine, and waxy maize fed to growing pigs. Anim. Feed Sci. Technol., 113: 113-126. https://doi.org/10.1016/j.anifeedsci.2003.09.006

Sofi, P.A., Wani, A.S., Rather, A.G. and Wani, S.H., 2009. Quality protein maize (QPM): Genetic manipulation for the nutritional fortification of maize. J. Pl. Breed. Crop Sci., 1: 244-253.

Ullah, R., Khan, S., Hafeez, A., Sultan, A., Khan, N.A., Chand N. and Ahmad N., 2017. Silkworm (Bombyx mori) meal as alternate protein ingredient in broiler finisher ration. Pakistan J. Zool., 49: 1463-1470. https://doi.org/10.17582/journal.pjz/2017.49.4.1463.1470

Ullah, Z., Ahmed, G., Nisa, M.U. and Sarwar, M., 2016. Standardized Ileal amino acid digestibility of commonly used feed ingredients in growing broilers. Asian-Australas. J. Anim. Sci., 29: 1322-1330. https://doi.org/10.5713/ajas.15.0703

Vasal, S.K., 2000. Quality protein maize: Overcoming the hurdles. J. Crop Prod., 6: 193-227. https://doi.org/10.1300/J144v06n01_11

Zhai, S.W. and Zhang, M.L., 2007. Comparison of true metabolisable energy and true amino acid availability between normal maize and quality protein maize (Shandan 17). Italian J. Anim. Sci., 6: 289-294. https://doi.org/10.4081/ijas.2007.289

To share on other social networks, click on any share button. What are these?