Dry Matter, Lint Mass and Fiber Properties of Cotton in Response to Nitrogen Application and Planting Densities

Dry Matter, Lint Mass and Fiber Properties of Cotton in Response to Nitrogen Application and Planting Densities

Muhammad Naveed Afzal1, Muhammad Tariq1*, Muhammad Ahmad1, Khuram Mubeen2, Muhammad Ayaz Khan3, Muhamamd Umer Afzal4 and Shakeel Ahmad5

1Agronomy Section, Central Cotton Research Institute, Multan-59200, Pakistan; 2Departmnet of Agronomy, Muhammad Nawaz Sharif University of Agriculture, Multan, Pakistan; 3Department of Agriculture Extension and Adoptive Research, Punjab, Pakistan; 4CIMMYT-Pakistan Office, NARC, Islamabad, Pakistan; 5Bahauddin Zakariya University, Multan, 60800, Pakistan.

Abstract | Evaluation of optimum nitrogen rate in conjunction with plant density is an important concern of cotton production. The two years’ field trials were conducted at Central Cotton Research Institute, Multan to test the hypothesis whether nitrogen (N) requirement varies with planting density (PD) for dry matter production, partitioning, nutrient use efficiency (NUE), lint yield and associated fiber properties. In this RCBD split plot experiment, two planting densities (8.88 and 4.44 plants m-2) were assigned to main plot and four nitrogen rates (0, 50,100 and 150 kg N ha-1) were kept in sub plots with three replications. The PD was maintained by altering the within plant spaces keeping the row spaces (75 cm) constant. The results indicated that significant PD X N interaction was observed for plant biomass components i.e. the high PD (8.88 plants m-2) with 0-N produced 16.80%, 25.07%, 21.54% and 33.34% and it produced 21.41%, 31.51%, 27.40% and 31.95% higher vegetative, reproductive, total biomass and total fruiting points, respectively with 150-N than its counterpart’s low PD (4.44 plants m-2). The high density planting requires relatively less nitrogen in comparison with low density to produce statistical similar values for total dry matter. However, the high density planting did not improve fiber traits. The PD X N interaction was non-significant for lint mass and fiber quality. The agronomic and economic nutrient use efficiency and partial factor productivity (PFP) was maximum with low doses of nitrogen. Whereas, the percent relative yield (PRY) at 50 kg N was very low in relevance to 150 kg.

Received | September 14, 2018; Accepted | December 19, 2018; Published | February 26, 2019

*Correspondence | Muhammad Tariq, Agronomy Section, Central Cotton Research Institute, Multan-59200, Pakistan; Email: mtariq131@gmail.com

Citation | Afzal, M.N., M. Tariq, M. Ahmad, K. Mubeen, M.A. Khan, M.U. Afzal and S. Ahmad. 2018. Dry matter, lint mass and fiber properties of cotton in response to nitrogen application and planting densities. Pakistan Journal of Agricultural Research, 32(2): 229-240.

DOI | http://dx.doi.org/10.17582/journal.pjar/2019/32.2.229.240

Keywords | Planting density, Nitrogen, Dry matter partitioning, Lint mass, Quality

Introduction

The cotton (Gossypium hirsutum L.) is the most important industrial fiber crop being produced over 76 countries, covering an area of 32 million hectares across the globe (Saranga et al., 2001). The Pakistan ranks 4th largest in production, 3rd largest exporter and consumer of raw cotton in world. The cotton crop significantly contributes to national export earnings (10 billion US$) annually, provide raw materials for local textile related industries. Consequent upon the need of cotton fiber products, cotton is surviving as most widely cultivated crop and its fiber is facing severe competition in international market with synthetic fiber and production challenges such as competition for area with maize and sugarcane and economic concerns.

Being an indeterminate growth habit, the cotton is extremely responsive to management factors. The fertilizer management and plant population are the most important facet for target production (Tariq et al., 2018; Bednarz et al., 2006). The cotton production is heavily reliant on an adequate nitrogen supply (Ali et al., 2003; Hernandez-Cruz et al., 2015). Nitrogen contributes to yield through improved canopy development and photosynthesis. Both the lower and higher supply of nitrogen determines the cotton growth and development (Staut and Kurihara, 2001; Jaynes et al., 2001) and its mismanagement causes environmental contamination along with economic losses. Therefore, nitrogen management is gaining importance (Snyder et al., 2007). The poor nitrogen supply reduces fruiting rates, leaf yellowing and stunted growth. While, overdose application may result in excessive vegetative growth. Therefore, application rate is considered an important fertilizer management strategy. The current nitrogen use is higher than cotton requirement. For example, South Wale, it was noticed that additional 40 kg N ha-1 is being used in cotton which can be reduced without yield losses (Rochester et al., 2007). On average basis, the cotton is being fertilized with 200-250 kg N ha-1 in various cotton growing areas. A significant work for nitrogen dose optimization for cotton has been carried out in the past (Jost and Cothren, 2000; Saleem et al., 2010; Ayissa and Kebedeb, 2011) for standard population but information regarding nitrogen application for varying population are few to best of our knowledge.

The planting density is another important production factor and determined by soil and environmental conditions, cultivar and growers (Silvertooth et al., 1999). Lint yield is based on lint %age, boll weight and boll density (McCarty et al., 2008) but boll density is considered the most important component which is controlled by plant density. The most important factors which alters the plant architecture in planting density studies are quality of intercepted radiations, competition for resources and microenvironment. The light quality changes with penetration from upper canopy toward lower and middle plant portion with penumbral effects. The appropriate plant density is essential for canopy micro-environment for potential yield. It has been proposed that cotton canopy should be modified for maximum light harvesting to middle and upper plant portion (Reta-Sánchez et al., 2002). Improving plant densities have been manipulated as effective mean of reducing cultivation cost (Stephenson et al., 2011). Increasing plant density produced lower number of bolls per plant and average boll weight without affecting fiber length and lint %age (Ali et al., 2009). The significant variations seed cotton yield across planting densities have been reported in literature (Saleem et al., 2009; Aslam et al., 2013; Nawaz et al., 2016).

Therefore, the objective of the study was to determine whether high plant population require less nitrogen fertilizer over normal population with respect to growth, lint yield and quality.

Materials and Methods

The two years’ field study was carried out at agronomic field area of Central Cotton Research Institute, Multan during summer season 2005-06 under irrigated conditions in arid climate with an average summer maximum temperature 45 ± 2 °C (Figure 1). The experimental site was situated at latitude 30o12’N, longitude 71o28’E and altitude 123 m a.s.l. (Makhdum et al., 2001). The composite soil samples were collected from 0-30 cm depth and analyzed for textural class using standard procedure. The soil was silt loam with alkaline in reaction having pH (8.09), sand (29.5 %), silt (55%) and clay (15.5%). The soil analysis report indicated that the soil was deficient in nitrogen with 5.57 mg kg-1 (NO3-N). The treatments were four nitrogen levels (0, 50, 100 and 150 kg ha-1) and two plant densities i.e. 8.88 and 4.44 plants (m-2). The plant density was maintained by adjusting within plant spaces 15 and 30 cm. The 8.88 plants (m-2) was designated as high and 4.44 plants (m-2) was low density. The treatments were arranged in RCBD split plot with three replications keeping the nitrogen in main plot and plant spacing in sub-plots. The land was prepared after wheat harvesting in the form of bed-furrows at 75 cm apart and Pendimethalin at the rate of 82.5 a.i g ha-1 was sprayed with a device fitted on bed-furrow shaper at the time of bed furrows shaping to control weeds in the field. The seed of genotype CIM-473 was manually dibbled on 10th May both the years at bed edges under dry conditions @ 10 kg ha-1 followed by irrigation.

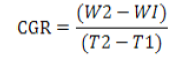

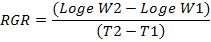

The crop received furrow irrigation after 72 hours to fill the gap and subsequent uniform irrigations were scheduled for treatments under study at 10±2days interval till maturity up to mid-October. The crop was thinned to single vigorous plant at 25 days after sowing to maintain the per treatment plant population. The full dose of phosphorus (60 Kg ha-1) was incorporated in soil with seed bed preparation through triple supper phosphate (46% P2O5) and nitrogen was applied in three splits in form of urea (46% N) at bud formation, flowering and boll formation. All the cultural and plant protection measures were kept uniform for all plots during the season. The phonological development of crop was assessed in term of days taken for bud initiation, flowering and boll splitting. The growth indices include crop growth rate (CGR) and relative growth rate (RGR) were also measured for three times at 50, 100 and 150 DAS by formulas suggested by (Hunt, 1978).

Where;

W2 and W1 represents the total biomass at T2 and T1, respectively.

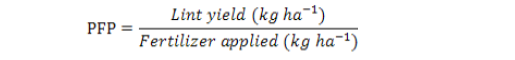

The four plants from central rows were harvested from ground level and separated into vegetative (stem and leaves) and reproductive (bud, flower, green and opened bolls) biomass. The dry matter partitioning was worked out as ratio of dry weight of fruiting forms (DWFF) to plant biomass (PB) (Dai et al., 2015). The plant samples were dried at 700C till no further weight reduction. The agronomic nitrogen use efficiency (ANUE) and partial factor productivity (PFP) was calculated by given equations.

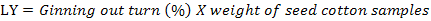

The lint yield (LY) was calculated from following equation.

The sample containing 100 opened bolls was subjected to ginning with micro saw gin. The lint was stored under room temperature for fiber quality analysis. The lint was submitted to fiber testing laboratory of institute and the fiber traits were determined by High Volume Instrument (HVI-900-A, USTER) using procedure set by ASTM- D-5867(1997). The raw data was subjected to computer-based analysis software Statistix 8.1 for statistical interpretation by using Fischer’s method of variance techniques and treatment means were compared at 5% probability level using LSD test (Steel et al., 1997).

Results and Discussion

Growth, dry matter partitioning and lint yield

The dry matter accumulation increased towards plant maturity regardless of planting density (Figure 4). The CGR was greater in dense planting than low density planting (Figure 5). In high density, it was increased from 2.39 to 2.83 gm-2day-1 during first 50 days, 5.89 to 13.02 gm-2day-1 between 50-100 days and decreased from 3.84 to 2.01 gm-2day-1 between 100-150 days with nitrogen increase from 0 to 150 kg. While, in low density, it was increased from 1.8 to 2.37 gm-2day-1 at first 50 days, 3.60 to 10.78 gm-2day-1 between 50 to 100 days and decreased from 4.66 to 1.89 gm-2day-1. Highly significant differences in CGR in both densities with nitrogen treatment were observed at 100 days over rest of observation dates. It is clear from Figure 2 that decline in growth rate from 100-150 days is high for plots received the highest nitrogen. The decline in dry matter production beyond 100 days is associated with leaf senescence and aging process. However, the linear decrease in relative growth rate was observed with the advancement of crop growth across all nitrogen levels. The results regarding CGR reported by Cawley et al. (1998), Anjum et al. (2007) and Awais et al. (2013) in relation to planting densities are similar to our results.

Within the planting density, total dry matter production was 19.32% lower in low density than high density. The similar trend was also observed for vegetative and reproductive dry mass (Table 1). The lowest reproductive matter with no fertilizer is due to poor plant development resulted by reduced fruiting. It is from fact that weeds remained suppress at high density due to early stand establishment. The total dry matter was improved significantly with nitrogen fertilization up to 100 kg and further increase produced a relatively smaller differences regardless planting density. Besides, nitrogen contribution in photosynthesis (Bondada and Oosterhuis, 2000), it also increased the root surface area for better nutrient and water absorption (Xie et al., 2009). The dry matter partitioning to reproductive parts (RVR) is key factor to boost up cotton yield other than yield components. It was measured with reproductive vegetative ratio and presented in Figure 3. The reproductive biomass at maturity accounted 58.33% of the total at control which was improved up to 58.96%, 60.58% and 61.35% with N50, N100 and N150 kg, respectively. The plants grown in combination with dense population and well fertilized allocated more dry matter to fruiting forms in comparison with low density. The difference in reproductive allocation due to planting densities became broader from control to well fertilized plots i.e. 150kg N. Higher lint yield due to higher plant density could be owing to elevated biological yield in field with less fertility (Dong et al., 2010). Higher number of plants per unit area ensure better soil coverage. Higher planting density would have increased lint yield by making efficient use of soil water with likely reduced evaporative losses compared with lower planting density. As RVR is considered a direct indicator of dry matter distribution, the highest lint yield was also recorded from treatment which produced the highest values for RVR. The ratio at 150 DAS was increased from 1.44 to 1.64 in high density and 1.32 to 1.48 in low density with N application from 0 to 150 kg. Therefore, it can be concluded that higher nitrogen supply is mandatory to allocate more assimilates to fruiting sites to harvest more economic benefits. It has already been suggested that biomass production and dry matter allocation to

reproductive tissues is major yield factor of cotton grown in extensive management (Bange and Milroy, 2004; Saleem et al., 2010). However, our results are against the findings of Sadras et al., 1997 where it was observed that dense plants in combination with low nitrogen supply produced stressful conditions.

Table 1: Effect of plant spacing and nitrogen on vegetative and reproductive dry matter of cotton at 150 days after planting (DAP).

|

Vegetative dry matter (VDM) at (gm-2) |

Reproductive dry matter (RDM) (gm-2) |

|||||

| Treatments |

Planting density (m-2) |

Planting density (m-2) |

||||

|

Nitrogen (kg ha-1) |

8.88 plants | 4.44 plants | mean | 8.88 plants | 4.44 plants | Mean |

| 0 | 247.90 d LSD=7.8076 | 212.25 e | 230.08 d LSD=10.058 | 357.90 f LSD=6.9778 | 286.20 g | 322.05 LSD=17.604 |

| 50 | 280.80 c | 249.85 d | 265.33 c | 445.65 c | 349.00 f | 397.33 c |

| 100 | 318.60 b | 274.25 c | 296.43 b | 514.95 b | 396.05 e | 455.50 b |

| 150 | 337.65 a | 278.10c | 307.88 a | 555.30 a | 422.25 d | 488.77 a |

| Mean | 296.24 a LSD=3.9038 | 253.61 b | 468.45 a LSD=3.4889 | 363.37 b | ||

|

Total dry matter (TDM) (g m-2) |

Total fruiting points (TFP) (m-2) |

|||||

|

Nitrogen (kg ha-1) |

8.88 plants | 4.44 plants | mean | 8.88 plants | 4.44 plants | mean |

| 0 | 605.80 e LSD=10.504 | 498.45 f | 552.13d LSD=25.875 | 385.35 b LSD=27.137 | 289.00 d | 337.17 b LSD=32.186 |

| 50 | 726.45 c | 598.85 e | 662.65 c | 464.50 a | 335.67 c | 400.08 a |

| 100 | 833.55 b | 670.30 d | 751.92 b | 478.50 a | 350.00 bc | 414.25 a |

| 150 | 892.95 a | 700.35 c | 796.65 a | 491.50 a | 372.50 bc | 432.00 a |

| Mean | 764.69a LSD=5.2521 | 616.99 b | 454.96 a LSD=13.568 | 336.79 b | ||

|

Bolls plant-1 (BPP) |

Lint yield (LY) (kg ha-1) |

|||||

|

Nitrogen (kg ha-1) |

8.88 plants | 4.44 plants | mean | 8.88 plants | 4.44 plants | mean |

| 0 | 9.92 g LSD=1.0368 | 17.68 d | 13.80 d LSD=1.0372 | 707.7 ns | 618.6 | 663.1 c LSD=202.49 |

| 50 | 14.00 f | 24.04 c | 19.02 c | 1052.4 | 982.9 | 1017.7 b |

| 100 | 15.20 ef | 27.00 b | 21.10 b | 1235.7 | 1116.7 | 1176.2ab |

| 150 | 16.22 e | 28.88 a | 22.55 a | 1348.0 | 1218.0 | 1283.0 a |

| Mean | 13.84 b LSD=0.5184 | 24.40 a | 1086.0 a LSD=60.883 | 984.1 b | ||

Figures in rows and columns not sharing the same letter are significantly different from each other at 0.05% probability level as determined with LSD test.

Table 2: Effect of plant spacing and nitrogen on crop phenology and seed index.

| Days taken to bud initiation (DTBI) | Days taken to flower initiation (DTFI) | |||||

| Treatments | Plant spacing | Plant spacing | ||||

|

Nitrogen (kg ha-1) |

8.88 plants | 4.44 plants | mean | 8.88 plants | 4.44 plants | Mean |

| 0 | 24.50 ns | 25.00 | 24.75 ns | 44.00 ns | 44.50 | 44.25 ns |

| 50 | 24.65 | 25.35 | 25.00 | 45.15 | 45.65 | 45.40 |

| 100 | 25.65 | 26.25 | 25.95 | 45.50 | 46.00 | 45.75 |

| 150 | 25.65 | 26.50 | 26.08 | 46.15 | 47.15 | 46.65 |

| Mean | 25.11 ns | 25.78 | 45.20 ns | 45.83 | ||

| Days taken to boll split initiation (DTBSI) | Seed index (SI) | |||||

|

Nitrogen(kg ha-1) |

8.88 plants | 4.44 plants | mean | 8.88 plants | 4.44 plants | Mean |

| 0 | 80.50 ns | 81.00 | 80.75 ns | 8.43 ns | 8.57 | 8.50 b Lsd=0.2485 |

| 50 | 81.00 | 82.15 | 81.58 | 8.82 | 8.78 | 8.80 a |

| 100 | 82.15 | 82.65 | 82.40 | 8.48 | 8.47 | 8.48 b |

| 150 | 82.15 | 83.00 | 82.58 | 8.53 | 8.52 | 8.53 b |

| Mean | 81.45 ns | 82.20 | 8.57 ns | 8.58 | ||

Figures in rows and columns not sharing the same letter are significantly different from each other at 0.05% probability level as determined with LSD test.

In such conditions, it will allocate more dry matter to fruiting structures. A strong PD X N interaction was observed for plant biomass, fruiting point and bolls per plant. The total dry matter produced with 50kg N in high density planting required 100 kg less N to produce statistically similar figure in low density. It appeared that high density requires relatively less nitrogen than low density with respect to plant biomass. For example, 8.88 plants × 0 kg nitrogen produced statistically similar reproductive dry matter as produced with 4.44 plants × 50 kg nitrogen.

Table 3: Effect of nitrogen and planting densities on fiber properties.

| Staple length (SL) (mm) | Micronaire (MIC) (µg/inch) | |||||

| Treatments |

Planting density (m-2) |

Planting density (m-2) |

||||

|

Nitrogen(kg ha-1) |

8.88 plants | 4.44 plants | mean | 8.88 plants | 4.44 plants | mean |

| 0 | 27.65 ns | 27.65 | 27.65 ns | 4.45 | 4.45 | 4.45 ns |

| 50 | 27.75 | 27.80 | 27.78 | 4.55 | 4.45 | 4.50 |

| 100 | 27.70 | 27.75 | 27.73 | 4.40 | 4.60 | 4.50 |

| 150 | 27.65 | 28.00 | 27.83 | 4.60 | 4.55 | 4.58 |

| Mean | 27.69 ns | 27.80 | 4.50 ns | 4.51 | ||

| Fiber strength (FS) (tppsi) | Uniformity index (UI) (%) | |||||

|

Nitrogen(kg ha-1) |

8.88 plants | 4.44 plants | mean | 8.88 plants | 4.44 plants | mean |

| 0 | 93.90 ns | 94.08 | 93.99 ns | 81.40 | 81.25 | 81.33ns |

| 50 | 92.90 | 94.65 | 93.78 | 81.95 | 81.70 | 81.83 |

| 100 | 94.35 | 94.50 | 94.43 | 81.35 | 81.80 | 81.58 |

| 150 | 94.90 | 95.05 | 94.98 | 82.15 | 81.50 | 81.83 |

| Mean | 94.01 ns | 94.57 | 81.71 ns | 81.56 | ||

| Fiber elongation (FE) (%) | Yellowness (+ b) | |||||

|

Nitrogen(kg ha-1) |

8.88 plants | 4.44 plants | mean | 8.88 plants | 4.44 plants | mean |

| 0 | 5.50 ns | 5.85 | 5.68 ns | 7.75 | 7.95 | 7.85 ns |

| 50 | 5.75 | 5.75 | 5.75 | 7.95 | 8.10 | 8.03 |

| 100 | 5.85 | 5.80 | 5.83 | 8.05 | 7.95 | 8.00 |

| 150 | 5.80 | 6.10 | 5.95 | 7.85 | 8.15 | 8.00 |

| Mean | 5.73 ns LSD=0.130 | 5.88 | 7.90 | 8.04 | ||

| Reflectance (Rd) | Maturity Index (MI) (%) | |||||

|

Nitrogen(kg ha-1) |

8.88 plants | 4.44 plants | mean | 8.88 plants | 4.44 plants | mean |

| 0 | 72.85 ns | 73.75 | 73.30 ns | 1.04 ns | 1.04 | 1.04 ns |

| 50 | 74.30 | 73.50 | 73.90 | 1.06 | 1.05 | 1.06 |

| 100 | 74.35 | 75.58 | 74.97 | 1.05 | 1.04 | 1.04 |

| 150 | 74.70 | 74.60 | 74.65 | 1.06 | 1.06 | 1.06 |

| Mean | 74.05 ns | 74.36 | 1.05 ns | 1.05 | ||

CVSL: 2.21%; CVMIC: 8.07%; CVFS: 5.33%; CVUI: 1.97%; CVFE: 4.52%; CV+b: 7.58%; vrd: 4.02; CVMI: 3.43%.

The data pertaining to crop phenology indicated that neither main factor nor their interactions had significant effects on the days taken to bud, flower and boll split initiation (Table 2). However, Saleem et al. (2009) and Munir et al. (2015) observed a little delay in appearance of first square and flower with increased plant spaces. These contradictions might be result of variations in genetic and environmental interactions.The application of 50 kg N was sufficient for fruiting points. Number of bolls per plant was low in high density because cotton crop coordinates the individual plant parts to maintain a growth balance according to available resource. Although, single plant bears significantly low bolls but lint yield was higher due to high boll density. Therefore, yield formation in low density population depends upon individual plant performance, while boll density remains the major yield formation factor in high density. In contrast to dry matter variables, the statistical differences in boll numbers for nitrogen was not prominent with high density planting.

The main factors (nitrogen and plant density) significantly affected the lint yield but interaction was not significant. The highest lint mass was recorded from dense population and it was increased with addition of nitrogen. The highest lint yield in high density is attributed to high boll density. The cotton grown at higher plant densities accumulates more dry matter resulting higher yield (Hensh et al., 2011). The highest lint yield with high density in our study is confirmation of results of Gerik et al. (1998). However, significant PD X N is documented in literature but trend is different. The optimal yield was obtained in

combination with high density and low nitrogen (McConnell et al., 2001) and inverse trend was reported by Rinehardt et al. (2003) for nitrogen X planting density experiment.

Fiber traits

The lint quality parameters were expected to be modified by planting density and nitrogen ranges but this could not come true. The very minute changes were observed for fiber quality assessment which ranged 92.90 to 95.05, 81.25 to 82.15, 5.50 to 6.10, 7.75 to 8.10, 72.85 to 75.58 and 1.04 to 1.06 for fiber strength, uniformity index, fiber strength, brightness, reflectance degree and maturity index, respectively across the treatments (Table 3). These results have very close association with non-significant phonological traits. The non-significant effects of plant spacing on lint quality have also been supported by the results of Wrather et al. (2008), Pettigrew and Johnson (2005) and Siebert et al. (2006). Therefore, non-significant differences in fiber traits are quite logical and supported from the results. It has already been concluded that fiber quality is mainly determined by genetic constituent (Richard et al., 2006) and the surrounding environment of the crop and management factors are secondary to alter the fiber parameters (Subhan et al., 2001). However, Bednarz et al. (2005) reported that micronaire value were significantly decreased by planting density. It is clear from results of previous studies that fiber quality measurement did not respond to nitrogen application rate (Khan and Dar, 2006; Saleem et al., 2010; Rashidi et al. (2011)). However, previous results indicated that nitrogen changes the length, strength (Gil et al., 2003) and fiber fineness and micronaire (Fritschi et al., 2003). However, the variations in fiber quality response to nitrogen application may be the result of cultivars developmental rate and prevailing surrounding environment during boll development (Estrada et al., 2008). The continuous boll setting makes the environmental conditions very convenient to influence the fiber properties because some bolls may be at elongation and others may be drying and maturation stage. In the light of present and previous results, it is advised not to put extra expenses on nitrogen application with the objective to improve the fiber traits, however, the lint yield can be successfully improved by selecting the right nitrogen application.

Nitrogen use efficiency (NUE) and partial productivity factor (PFP)

The nutrient use efficiency was highly influenced by planting densities being maximum with high density (Figure 6). The highest ANUE, ENUE and PFP was from 50 kg N which decreased linearly with further increase in nitrogen supply. In real word, this trend would show that loss of nitrogen increased at higher dose which must be managed with approaching nitrogen management strategies. In contrast to this trend, the PRY was significantly increased with successive nitrogen application rate. The percent relative yield (PRY) over the maximum (150 kg nitrogen) was 52.50, 78.07, 91.67% and 50.79, 80.70, 91.68% at 0, 50 and 100 kg nitrogen for high and low density, respectively (Figure 6). The high NUE means that high density planting reduced the losses to environment. PFP is simple expression of production efficiency with applied nutrient. The results are in line with Ahmad et al. (2015) where economic and agronomic nitrogen returns were decreased at higher application rates of nitrogen in cotton.

Conclusions and Recommendations

Maintaining the optimum plant population and fertilizer rate is important production goal. The results revealed that strong coupling between PD and N was observed for CGR, RGR, dry matter production, partitioning, total fruiting points and bolls per plant. The high density produced superior figures for dry matter production, partitioning and lint yield but fiber traits were unaffected by main and interactive factors. The effect of main factors and their combination was inconsistent for phonological and fiber traits. It was concluded that higher plant density requires less nitrogen for plant biomass. While, the concept was not true for lint yield. The impact of nitrogen on CGR and RGR was more prominent at 100 days over rest of observations dates. The maximum lint was obtained from high density and fertilization with 150 kg N. The changes in lint yield is from changes in basic yield components across planting density and nitrogen. The non-significant variations in fiber traits with current nitrogen rates suggested that some additional nitrogen supply may be required to produce significant differences.

Author’s Contribution

Shakeel Ahmad conceived the idea, Muhammad Naveed Afzal conducted the experiment, Muhammad Ayaz khan analyzed the data, Muhammad Tariq prepared the initial draft, Muhammad Ahmad provided the technical inputs, Muhammad Umer Afzal crossed checked the references and worked out nitrogen use efficiency and Khuram Mubeen improved the language of the manuscript.

References

Ahmad, S., I. Raza, D. Muhammad, H. Ali, S. Hussain, H. Doğan and M.Z.U. Haq. 2015. Radiation, water and nitrogen use efficiencies of Gossypium hirsutum L. Turk. J. Agric. Forest. 39: 1-13. https://doi.org/10.3906/tar-1410-73

Ali, A., M. Tahir, M. Ayub, I. Ali, A. Wasaya and F. Khalid. 2009. Studies on the effect of plant spacing on the yield of recently approved varieties of cotton. Pak. J. Life Soc. Sci. 7(1): 25-30.

Ali, L., M. Ali and Q.M.U. Din. 2003. Assessment of optimum nitrogen requirement and economics of cotton (Gossypium hirsutum L.) crop for seed yield. Int. J. Agric. Biol. 5(4): 493-495.

Anjum, F.H., A. Tanveer, M. Tahir, M.A. Nadeem and A. Ali. 2007. Growth and yield response of Gossypium hirsutum to plant spacing and Trianthema portulacastrum density. Int. J. Agric. Biol. 4: 559–563.

Aslam, M., A.H. Sangh, L. Khalid and S. Javed. 2013. Effect of different levels of nitrogen and plant population on growth and yield of cotton (Gossypium hirsutum L.). J. Cott. Sci. 15: 243–250.

ASTM Committee, 1997. Standard test methods for measurement of cotton fiber properties by high volume instrument (HVI). ASTM designation: D-5867. ASTM Standard on Text. Mater. Am. Soc. Test. Mater. Phila. USA.

Awais, M., A. Wajid, A. Ahmad and A. Bakhsh. 2013. Narrow plant spacing and nitrogen application enhances sunflower (Helianthus annuus L.) productivity. Pak. J. Agric. Sci. 50: 689-697.

Ayissaa, T. and F. Kebedeb. 2011. Effect of nitrogenous fertilizer on the growth and yield of cotton (Gossypium hirsutum L.) varieties in Middle Awash, Ethiopia. J. Drylands, 4(1): 248-258.

Bange, M.P. and S.P. Milroy. 2004. Growth and dry matter partitioning of diverse cotton genotypes. Field Crops Res. 87: 73–87. https://doi.org/10.1016/j.fcr.2003.09.007

Bednarz, C.W., W.D. Shurley, W.S. Anthony and R.L. Nichols. 2005. Yield, quality, and profitability of cotton produced at varying plant densities. Agron. J. 97(1): 235-240.

Bednarz, C.W., R.L. Nichols and S.M. Brown. 2006. Plant density modifies within-canopycotton fiber quality. Crop Sci. 46: 950–956. https://doi.org/10.2135/cropsci2005.08-0276

Bondada, B.R. and D.M. Oosterhuis. 2000. Yield response of cotton to foliar nitrogen as influenced by sink strength, petiole and soil nitrogen. p. 672-675. In: Proc. Beltwide Cotton Conf., San Antonio, TX. 4-8 Jan. 2000. Nat. Cotton Counc. Am. Memphis, TN

Estrada, T.O., A. Palomo-Gil, A. Espinoza-Banda, S.A. Rodriguez-Herrera and N.A. Ruiz-Torres. 2008. Rendimiento y calidad de fibra de algodon cultivado en surcos ultra-estrechos. Rev. Fitotec. Mex. 31: 79-83.

Fritschi, F.B., B.A. Roberts, R.L. Travis and R.B. Hutmacher. 2003. Response of irrigated acala and pima cotton to nitrogen fertilization: growth, dry matter partitioning, and yield. Agron. J. 95(1): 133-146. https://doi.org/10.2134/agronj2003.0133

Cawley, N., K.L. Edmisten, A.M. Stewart and R. Wells. 1998. Evaluation of ultra-narrow row cotton in North Carolina. In Proc. Beltwide Cotton Conf., San Diego, CA, January 5–9, 1998; Dugger, P., Richter, D., Eds; Natl. Cotton Council: Memphis, TN, 1998; 1402.

Dai, J., W. Li, W. Tang, D. Zhang, Z. Li, H. Lu, A.E. Eneji and H. Dong. 2015. Manipulation of dry matter accumulation and partitioning with plant density in relation to yield stability of cotton under intensive management. Field Crops Res. 180: 207–215. https://doi.org/10.1016/j.fcr.2015.06.008

Dong, H., X. Kong, W. Li and D. Zhang. 2010. Effects of plant density and nitrogen and potassium fertilization on cotton yield and uptake of major nutrients in two with varying fertility. Field Crops Res. 119(1): 106-113. https://doi.org/10.1016/j.fcr.2010.06.019

Gerik, T.J., R.G. Lemon, K.L. Faver, T.A. Hoelewyn and M. Jung-man. 1998. Performance of ultra-narrow row cotton in central Texas. p. 1406–1408. In P. Dugger and D. Richter (ed.) Proc. Beltwide Cotton Conf., New Orleans, LA. 6–10 Jan. 1998. Nat. Cotton Counc. Memphis, TN.

Gil, A.P., A.G. Mascorro and S.G. Ávila. 2003. Cotton yield, yield components and fiber quality in relation to nitrogen dosage and plant density. Rev. Fitotec. Mex. 26 (3): 167 – 171.

Hernandez-Cruz, A.E., E. Sanchez, P. Preciado-Rangel, M.L. Garcia-Banuelos, A. Palomo-Gil and A. Espinoza-Banda. 2015. Nitrate reductase activity, biomass, yield and quality in cotton in response to nitrogen fertilization. FYTON. 84: 454-460.

Hensh, S., G.C. Malik, M. Banerjee and S. Mandal. 2011. Effect of fertilizer management and spacing on growth and yield of kharif cotton (Gossypium hirsutum L.) under lateritic belt of West Bengal. J. Crop Weed. 7(2): 238-240.

Hunt, R. 1978. The fitted curve in plant growth studies,” in Plant Physiology, D. A. Rose and D. A. C. Edwards, Eds., pp. 283–298, Acad. Press, London, UK, 1978.

Jaynes, D.B., T.S. Colvin, D.L. Karlen, C.A. Cambardella and D.W. Meek. 2001. Nitrate loss in subsurface drainage as affected by nitrogen fertilizer rate. J. Environ. Qual. 30: 1305-1314. https://doi.org/10.2134/jeq2001.3041305x

Jost, P.H. and J.T. Cothren. 2000. Growth and yield comparisons of cotton planted in conventional and ultra-narrow row spacing. Crop Sci. 40: 430-435. https://doi.org/10.2135/cropsci2000.402430x

Khan, M.B. and J.S. Dar. 2006. Response of cotton (Gossypium hirsutum L.) cultivars to different levels of nitrogen. J. Res. Sci. 17: 257-261.

Makhdum, M.I., M.N. Malik, F. Ahmad, F.I. Chaudhry and Shabab-ud-Din. 2001. Investigation on the physical parameters of environment and their impact on cotton crop production in the southern Punjab, Pakistan. J. Res. Sci. 12(2): 147-154.

McCarty, J.C, J. Wu and J.N. Jenkins. 2008. Genetic association of cotton yield with its component traits in derived primitive accessions crossed by elite upland cultivars using the conditional ADAA genetic model. Euphytica. 161: 337-352. https://doi.org/10.1007/s10681-007-9562-8

McConnell, J.S., R.C. Kirst, R.E. Jr., Glover and R. Benson. 2001. Nitrogen fertilization of ultra-narrow-row cotton. p. 63–66. Ark. Agric. Exp. Stn. Res. Ser. 480.

Munir, M.K., M. Tahir, M.F. Saleem and M. Yaseen. 2015. Growth, yield and earliness response of cotton to row spacing and nitrogen management. J. Anim. Pl. Sci. 25(3): 729-738.

Nawaz, H., N. Hussain, M.I.A. Rehmani, A. Yasmeen and M. Arif. 2016. Comparative performance of cotton cultivars under conventional and ultra-narrow row (UNR) spacing. Pure Appl. Biol. 5(1): 15-25.

Pettigrew, W.T. and J.T. Johnson. 2005. Effects of different seeding rates and plant growth regulators on early-planted cotton. J. Cotton Sci. 9: 189–198.

Rashidi, M., M. Seilsepour, M. Gholami. 2011. Response of yield, yield components and fiber properties of cotton to different application rates of nitrogen and boron. American-Eurasian J. Agric Environ. Sci. 10 (4): 525-531.

Reta-Sánchez, D.G. and J.L. Flowler. 2002. Canopy light environment and yield of narrow-row cottons as affected by canopy architecture. Agron. J. 94: 1317-1323. https://doi.org/10.2134/agronj2002.1317

Richard, G.P., G.C. Roy and Z. Jinfa. 2006. Genetic variation for agronomic and fiber properties in an introgressed recombinant inbred population of cotton. Crop Sci. 46: 1311–1317. https://doi.org/10.2135/cropsci2005.08-0284

Rinehardt, J.M., K.L. Edmisten, R. Wells and J.C. Faircloth. 2003. Response of ultra-narrow and conventional spaced cotton to variable nitrogen rates. J. Plant Nutr. 27: 741- 753.

Rochester, I. and M. Filmer. 2007. Benchmarks identified for nitrogen efficiencies, Farming Ahead No. 190: 52 - 55.

Saleem, M.F., S.A. Anjum, A. Shakeel, M.Y. Ashraf and H.Z. Khan. 2009. Effect of row spacing on earliness and yield in cotton. Pak. J. B. 41(5): 2179-2188.

Saleem, M.F., M.F. Bilal, M. Awais, M.Q. Shahid, S.A. Anjum. 2010. Effect of nitrogen on seed cotton yield and fiber qualities of cotton (Gossypium hirsutumL.) cultivars. J. Anim. Plant Sci. 20: 23-27.

Saranga, Y., M. Menz, C.X. Jiang, J.W. Robert, D. Yakir and H.P. Andrew. 2001. Genomic dissection of genotype x environment interactions conferring adaptation of cotton to arid conditions. Genome Res. 11, 1988-1995. https://doi.org/10.1101/gr.157201

Sadras, V.O., M.P. Bange and S.P. Milroy. 1997. Reproductive allocation of cotton in response to plant and environmental factors. Ann. Bot. 80: 75-81. https://doi.org/10.1006/anbo.1997.0402

Siebert, J.D., A.M. Stewart and B.R. Leonard. 2006. Comparative growth and yield of cotton planted at various densities and configurations. Agron. J. 98: 562-568. https://doi.org/10.2134/agronj2005.0181

Silvertooth, J.C., K.L. Edmisten and W.H. McCarty. 1999. Production practices. In C.W. Smith ed. Cotton: Origin, history, technology, and production. pp. 463-465. John Wiley and Sons, Inc. New York, NY.

Staut, L.A., C.H. Kurihara and Calagem e adubação. 2001. In: Embrapa agropecuária oeste. algodão: tecnologia de produção. dourados, embrapa agropecuária oeste/embrapa algodão.

Steel, R.G.D., J.H. Torrie and D.A. Dickey. 1997. Principles and procedures of statistics: abiometrical approach. 3rd ed. mcgraw hill, inc. book Co. New York (U.S.A.). pp: 352-358.

Stephenson, D.O., L.T. Barber and F.M. Bourland. 2011. Effect of twin-row planting pattern and plant density on cotton growth, yield, and fiber quality. J. Cotton Sci. 15: 243–250.

Subhan, M., H.U. Khan and R.O. Ahmed. 2001. Population analysis of some agronomic and technological characteristics of upland cotton (Gossypium hirsutum L.). J. Biol. Sci. 1: 120-123. https://doi.org/10.3923/jbs.2001.120.123

Snyder, C.S., T.W. Bruulsema and T.L. Jensen. 2007. Greenhouse gas emissions from cropping systems and the influence of fertilizer management – a literature review. Int. Plant Nutr. Inst. Norcross, Georgia, USA.

Tariq, M., M.N. Afzal, D. Muhammad, S. Ahmad, A.N. Shahzad, A. Kiran and A. Wakeel. 2018. Relationship of tissue potassium content with yield and fiber quality components of Bt cotton as influenced by potassium application methods. Field Crops Res. 229: 37–43. https://doi.org/10.1016/j.fcr.2018.09.012

Wrather, J.A., B.J. Phipps, W.E. Stevens, A.S. Phillips and E.D. Vories. 2008. Cotton planting date and plant population effects on yield and fiber quality in the Mississippi Delta. J. Cott. Sci: 12:1–7.

Xie, Z.L., C.Y. Tian and W.G. Bian. 2009. Effects of water and nitrogen on cotton root architecture under film drip irrigation. Cotton Sci. 21: 508-514.

To share on other social networks, click on any share button. What are these?