The Effect of Natural Pellet Binders and Dosage to Produce Pellet made of Miana Plant (Plectranthus scutellarioides, (L.) R. Br.) as Poultry Feedstuffs

Research Article

The Effect of Natural Pellet Binders and Dosage to Produce Pellet made of Miana Plant (Plectranthus scutellarioides, (L.) R. Br.) as Poultry Feedstuffs

Maria Endo Mahata1*, Hamdan Sukri Lubis1, Takayuki Ohnuma2, Yose Rizal1

1Nutrition and Feed Technology Department, Faculty of Animal Science, Universitas Andalas, Padang, Indonesia; 2Department of Advanced Biosciences, Kindai University, 3327-204 Nakamachi, Nara 631 8505, Japan.

Abstract | An experiment was conducted to determine the interaction between natural pellet binders and dosage in producing pellet made of Miana plant as poultry feedstuffs. This experiment was administered in a completely randomized design with two factors. The first factor was natural pellet binders composed of brown seaweed Sargassum binderi, taro tubers (Colocasia esculenta (L.) Schott), and tapioca flour (Manihot utilissima), and the second factor was dosage (1.5; 3; and 4.5%) of natural pellet binders. Each treatment was repeated three times. The measurements were moisture content, stack density, stack compaction density, stack angle, and pellet durability. The results showed no interaction (P>0.05) between the natural pellet binders and dosage on moisture content, stack density, stack compaction density, stack angle, and pellet durability of the Miana plant. Both the first factor (natural pellet binders) and the second factor (dosage) affected moisture content, stack density, stack compaction density, stack angle, and pellet durability highly significantly (P<0.01). In conclusion, the best natural pellet binder to produce pellet made of Miana plant as poultry feedstuffs was tapioca flour with a dosage of 4.5%.

Keywords | Poultry, Miana plant, Natural pellet binder, Physical quality, Pellet

Received | April 27, 2022; Accepted | July 17, 2022; Published | August 16, 2022

*Correspondence | Maria Endo Mahata, Nutrition and Feed Technology Department, Faculty of Animal Science, Universitas Andalas, Padang, Indonesia; Email: maria@ansci.unand.ac.id

Citation | Mahata ME, Lubis HS, Ohnuma T, Rizal Y (2022). The effect of natural pellet binders and dosage to produce pellet made of miana plant (Plectranthus scutellarioides, (l.) R. Br.) As poultry feedstuffs. Adv. Anim. Vet. Sci. 10(9): 1945-1952.

DOI | http://dx.doi.org/10.17582/journal.aavs/2022/10.9.1945.1952

ISSN (Online) | 2307-8316

Copyright: 2022 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

INTRODUCTION

The quality and the form of feed greatly affect the productivity of poultry. Pellet diets were reported positively affect growth performance, feed intake, and feed conversion of broiler (Abdollahi et al., 2013; Abdollahi et al., 2018) and improve the performance and albumen quality of laying hens (Wan et al., 2021). On the other hand, making pelleted feed also has detrimental effects on production through chemical and physical changes that occur during the pelleting (Svihus, 2011; Shivus and Zimonja, 2011). The physical form of the pellet is strongly influenced by the type of diet material used, the size of the pellet, the amount of water, pressure, and pellet binder material to produce a pellet with a strong, compact, and sturdy structure so that the pellets are not easily broken (Rahmana et al., 2016). Miana plant is an ornamental plant widely spread in Indonesia. This plant contains some phytochemicals substance like alkaloids, flavonoids, saponins, tannins, and anthocyanin (Auliawan and Cahyono, 2014; Puspita et al., 2018), which are very beneficial for health and improve the performance of poultry. Beside that Miana plants contain water 84.5%, dry matter 15.5%, crude protein 14.96%, crude fiber 21.09%, crude fat 10.18%, ash 13.6%, metabolic energy 1,357.39 kcal/kg, and 206.40 ppm anthocyanins (Mahata et al., 2021). This plant is known by local names in Indonesia, such as Miana, Jawer Kotok, and Iler. Salim and Munadi. (2017) stated Miana plant is included in 66 biopharmaceutical plant commodities according to the Decree of the Indonesian Minister of Agriculture, Number 511/Kpts/PD.310/9/2006. Previous research reported that Miana plant flour in broiler diets could be used as much as 12.5% in the diet without affecting broiler performance (Mahata et al., 2021). Based on our previous experience in a feeding trial of Miana plant flour in broiler diet, diet out from the feeder so that the phytochemicals substances contained in Miana flour in the diet were not consumed and utilized optimally by broilers. Therefore, the feeding of the Miana plant for the broiler should be modified into pellet form as an effort to the phytochemical substances from the Miana plant can be consumed optimally by the broiler.

To produce feed in pellet form requires a pellet binder to combine the feedstuff to form a pellet. The pellet binder commonly used by animal feed factories is synthetic binder such as bentonite lignosulphonate (Retnani et al., 2010). Furthermore, Carboxyl Methyl Cellulose (CMC) is expensive, increasing production costs and pellet prices. For this reason, it is necessary to look for alternative binders that are inexpensive, have a high binder, are easy to obtain, non-toxic, and do not interfere with the nutritional content of the diet.

Brown seaweed Sargassum binderi is a type of seaweed that is widely distributed in almost all Indonesian waters. Brown seaweed can be used as a pellet binder because it contains an alginate compound of as much as 40.51%, and it has properties as a gelling, stabilizer, emulsifier, suspending agent, and binder (Kadi, 2005; Tayag et al., 2010). The use of brown seaweed as a pellet binder for fish feed can be used up to 3.7% with pellet diet quality equivalent to commercial pellet diets (factory pellet diet) (Sutrisno, 2016). The other report showed that the range of brown seaweeds as pellet binder was 5-10% (Wulansari et al., 2016). Taro tubers contain relatively high starch, as much as 75.19%, with amylose of 7.51% and amylopectin of 67.68%, so it has the potential as a binder in making pellets (Kaushal et al., 2011). The taro tuber could be used as pellet binder as much as 2-8% (Sandro et al., 2020). Tapioca is a starch derived from the extraction of cassava tubers. Hartanti et al. (2017) reported that Tapioca flour contains 89.11% starch. This flour has a high viscosity and fast gelatinization time compared to the rice flour and wheat flour (Imanningsih, 2012), so it can be used as a binder for producing diets in pellet form. The use of 4% tapioca flour as a feed pellet binder for the broiler diet was reported to have an excellent physical property (Syamsu, 2007).

The type and dosage of pellet binder will affect the moisture content, stack density, stack compaction density, stack angle, and pellet durability due to the starch content of each different binder type. The information about the type and dosage of pellet binder is also needed to produce pelleted diets that have good physical quality for packing, transporting, and storing feed. Based on the variation of pellet binders dosage in previous research, we decided to use the dosage of pellet binder in this experiment were 1.5%, 3%, and 4.5%.

So far, rarely a report of Miana plant in the form of pellets as broiler feedstuff, and it is also unknown what type of pellet binders and the proper dosage to produce this feedstuff in the form of pellets that can meet the quality standards of pellet. Therefore, research was conducted to determine the type and dosage of the pellet binders for the Miana plant in pellet form and their quality as broiler feedstuff.

MATERIALS AND METHODS

Research material

The raw materials used in this research were Miana plant flour and pellet binders. The materials of pellet binders used in this experiment were brown seaweed, taro tubers, and tapioca flour.

The Miana plant flour sample preparation

The Miana plant flour was prepared by chopping the Miana leaves into a size of 2-3 cm. Then, the sliced leaves were dried in the sun for 3-5 days, and were milled by a Hummer mill HMR-50 grinder machine.

Pellet binder preparation

The pellet binders used in this experiment were brown seaweed flour, taro tuber flour, and tapioca flour. The brown seaweed Sargassum binderi flour was first cleaned from the sea salt by soaking in water flow for 15 hours. Secondly, the brown seaweed was dried and ground into flour. The taro tubers (Colocasia esculenta (L.) Schott) were peeled, cleaned with water, and cut into small pieces. Then the sliced tubers were dried in the sun and ground into flour with moisture content of 14%. Furthermore, tapioca (Manihot utilissima) flour was purchased from local minimarkets.

Each type of pellet binder was weighed with dosage according to the treatment (1.5, 3, and 4.5%) of 500 g of Miana plant flour as pellet diets, namely 7.5, 15, and 22.5 g. Furthermore, each type of pellet binder was mixed with 500 ml water and heated at 100°C while stirring until it formed a gel and allowed to stand until the temperature reached 70°C. Furthermore, each type of pellet binder formed a gel is mixed with 500 g of Miana plant flour until well mixed. Then the pellet manufacturing process is carried out.

Pellet preparation from Miana plant flour

Miana plant flour mixed with each type of pellet binder was printed using a Thcheng PZ30 brand pellet machine. The pellet eyes used were 0.5 cm with a diameter and length of 1 cm. The resulting pellets were dried in the sun for 3 hours and continued in the oven at 60°C for 24 hours. Then the resulting pellet will be tested for physical quality.

The measurements

Water content: The moisture content of the pellets was measured using an oven at 105°C for 6-8 hours (AOAC, 1999).

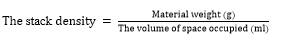

Stack density: The stack density can be calculated by weighing the measuring cup by normalizing the scales first. The measuring cup on top of the scales was added slowly by the bulk method using white paper up to a measuring limit of 250 ml, and the result was the weight of the material (Jaelani et al., 2016). The stack density was expressed in g/ml and was calculated by the formula:

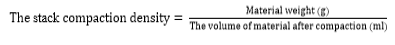

Stack compaction density: The measurement of the compaction density of the pellet stack could be calculated in the same way as the determination of the stack density, but the volume of the material was read after the compaction process was carried out by shaking the measuring cup until the volume did not change anymore (Jaelani et al., 2016). Compaction was carried out in no more than 10 minutes. The formula that calculates the stack compaction density is:

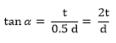

Stack angle: The measure of the pellet stack angle by dropping 0.5 kg of the sample onto a flat plane through a plastic funnel. The height of the stack of material must be below the funnel. The sample was poured slowly and as close as possible to the wall of the plastic funnel to avoid clogging the feed at the end of the plastic funnel and reduce the weight of the feed. Diameter measurements were made on the same side for all observations using a ruler. Height measurements were carried out on the feed height from the flat to the top in all observations using a ruler (Khalil, 1999b). The formula that calculates the stack angle is:

Description: α= The angle of the stack of feed ingredients is expressed in degrees (°) ; d = stack diameter; and t = Tall

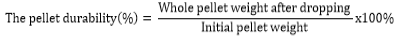

Pellet durability: Pellet durability to impact was measured by dropping the pellet from a height of 2 meters on a 2 mm thick iron plate. The pellets were dropped simultaneously by measuring the weight of the pellets first, then filtering with a vibrator ball mill german using the sieve analysis and weighing (Balagopalan et al., 1988). The formula that calculates the pellet durability is:

Statistical analysis

All data were analyzed by analysis of variance (ANOVA), differences among treatments would be further analyzed using an analysis of Duncan’s multiple range test (Steel and Torrie, 1991).

RESULTS AND DISCUSSION

The highest water content found in the pellet binder brown seaweed was 11.87%, while the water content in the pellet binders made from taro tuber and tapioca was lower than the pellet brown seaweed (10.7% and 9.06%, respectively). The starch content in each of the different binders affects the water content of the Miana plant in pellet form. In this experiment, each type of pellet binders (brown seaweed, taro tubers, and tapioca flour) was mixed with hot water at 70 oC before being used. Mixing each pellet binders with hot water causes the granules in the binder starch to break, making it difficult for water to penetrate and causing the water content to be low. According to Retnani (2010), the volume of starch granules would increase due to heating and cause starch granules to expand, resulting in gelatinization. This experiment found the highest starch content in the tapioca binder was 89.11% (Hartanti et al., 2017), 75.19% in the taro tubers (Rahmawati et al., 2012), and 56.80% in the brown seaweed (Diharmi et al., 2011). The amylopectin content in the taro tuber and tapioca binders did not differ much, i.e., 67.65% and 72.61%, respectively. Therefore, the taro tuber and tapioca binders had a lower water content effect than did the brown seaweed binders. The high water content in brown seaweed pellet binder was caused by low amylopectin of 50.52%, and brown seaweed had hydrocolloid properties, which absorbed water easily. According to Herawati (2018), hydrocolloids have the characteristics of absorbing water easily. The hydrocolloid properties found in the brown seaweed were caused by the presence of alginate. Furthermore, Dewi (2018) reported that brown seaweed Sargassum binderi contains 20.89% alginate.

Table 1: The average moisture content of Miana plant pellet

| Variables | Pellet binders type | Pellet binder dosage (%) | Mean | ||

| B1 | B2 | B3 | |||

|

Moisture content (%) |

A1 | 12.94 | 11.40 | 11.26 |

11.87a |

| A2 | 10.84 | 9.93 | 9.33 |

10.04b |

|

| A3 | 10.49 | 9.57 | 8.61 |

9.56b |

|

| Mean |

11.42a |

10.30b |

9.74b |

10.49 | |

A1 = Pellet binder of brown seaweed Sargassum binderi; A2 = Pellet binder of taro tuber (Colocasia esculenta (L.) Schott); and A3 = Pellet binder of tapioca flour (Manihot utilissima). Pellet binder dosage (B1 = 1.5%; B2 = 3%; and B3 = 4.5%).

Different lowercase superscripts in columns and rows showed a highly significant effect (P < 0.01).

Table 2: The average stack density of Miana plant pellet

| Variables | Pellet binders type | Pellet binder dosage (%) | Mean | ||

| B1 | B2 | B3 | |||

|

Stack density (kg/m3) |

A1 | 413.95 | 444.85 | 464.05 |

440.95a |

| A2 | 431.37 | 455.43 | 473.41 |

453.40b |

|

| A3 | 433.11 | 464.47 | 485.15 |

460.91c |

|

| Mean |

426.14a |

454.92b |

474.20c |

451.75 | |

A1 = Pellet binder of brown seaweed Sargassum binderi; A2 = Pellet binder of taro tuber (Colocasia esculenta (L.) Schott); and A3 = Pellet binder of tapioca flour (Manihot utilissima). Pellet binder dosage (B1 = 1.5%; B2 = 3%; and B3 = 4.5%).

Different lowercase superscripts in columns and rows showed a highly significant effect (P < 0.01).

Table 3: The average stack compaction density of Miana plant pellet

| Variables | Pellet binders type | Pellet binder dosage (%) | Mean | ||

| B1 | B2 | B3 | |||

|

Stack compaction density (kg/m3) |

A1 | 446.19 | 484.32 | 513.03 |

481.85a |

| A2 | 481.39 | 514.58 | 547.34 |

514.44b |

|

| A3 | 510.64 | 546.50 | 583.41 |

546.85c |

|

| Mean |

479.41a |

515.13b |

548.59c |

514.38 | |

A1 = Pellet binder of brown seaweed Sargassum binderi; A2 = Pellet binder of taro tuber (Colocasia esculenta (L.) Schott); and A3 = Pellet binder of tapioca flour (Manihot utilissima). Pellet binder dosage (B1 = 1.5%; B2 = 3%; and B3 = 4.5%).

Different lowercase superscripts in columns and rows showed a highly significant effect (P < 0.01).

Table 4: The average stack angle of Miana plant pellet

| Variables | Pellet binders type |

Pellet binder dosage (%) |

Mean | ||

| B1 | B2 | B3 | |||

|

Stack angle ( 0) |

A1 | 46.45 | 45.42 | 44.14 |

45.33a |

| A2 | 45.60 | 44.35 | 41.63 |

43.86b |

|

| A3 | 44.42 | 42.10 | 40.42 |

42.31c |

|

| Mean |

45.49a |

43.95b |

42.06c |

43.84 | |

A1 = Pellet binder of brown seaweed Sargassum binderi; A2 = Pellet binder of taro tuber (Colocasia esculenta (L.) Schott); and A3 = Pellet binder of tapioca flour (Manihot utilissima). Pellet binder dosage (B1 = 1.5%; B2 = 3%; and B3 = 4.5%).

Different lowercase superscripts in columns and rows showed a highly significant effect (P < 0.01).

Table 5: The average pellet durability of Miana plant pellet

| Variables | Pellet binders type | Pellet binder dosage (%) | Mean | ||

| B1 | B2 | B3 | |||

|

Pellet durability (%) |

A1 | 92.77 | 93.94 | 94.77 |

94.82a |

| A2 | 95.47 | 96.40 | 97.28 |

96.39b |

|

| A3 | 97.75 | 98.55 | 99.29 |

98.53c |

|

| Mean |

95.33a |

96.30b |

97.11c |

96.25 | |

A1 = Pellet binder of brown seaweed Sargassum binderi; A2 = Pellet binder of taro tuber (Colocasia esculenta (L.) Schott); and A3 = Pellet binder of tapioca flour (Manihot utilissima). Pellet binder dosage (B1 = 1.5%; B2 = 3%; and B3 = 4.5%).

Different lowercase superscripts in columns and rows showed a highly significant effect (P < 0.01).

The lower dosage of each pellet binder in this experiment reduced the water content in the Miana plant pellet (Table 1). This is due to the lower starch content in the binder, thus creating more pellet cavities. These cavities become a way for water to enter the pellets, which causes the pellet water content to increase. Besides that, the pellet binder’s composition strengthens the intermolecular bonds, thereby reducing porosity, and more pores will provide more space for water to enter (Jahiding et al., 2014). Furthermore, Sadee (2009) argues that a higher pellet binder dosage increases the physical quality of pellets.

The tapioca pellet binder in this experiment affected the highest stack density at 460.91 kg/m3, while the taro tuber and brown seaweed pellet binders were lower at 453.40 kg/m3 and 440.95 kg/m3, respectively (Table 2). High stack density is associated with high starch content, causing starch granules to fill unfilled pores, and when compacted, the stack density value was also high. According to Supriadi et al. (2020), starch content causes a gelatinization process, which binds each feed component so that the volume of pellets produced gets smaller, and the volume of space occupied gets bigger. This experiment found that the increasing pellet binders dosage caused more production of starch and low water content, so the value of the stacking density was higher. According to Sholihah (2011), the stack density value was influenced by water content, so the higher moisture content of pellets reduces the value of stack density, the high water content causes the material to expand. Therefore, the volume of space was required significantly.

The highest stack compaction density was found in the tapioca pellet binder, while the taro tuber and brown seaweed pellet binders were lower (Table 3). The high stack compaction density in tapioca pellet binder was related to the stack density and starch content in tapioca, causing the pellets to become solid and compact, in addition to increasing the value of the stack compaction density. Stack density and stack compaction density of pellet show a positive correlation; the higher the stack density, the higher the stack compaction density, and vice versa (Luciana, 2012). Besides that, the pellet binder dosage affects the compaction density of the Miana plant pellet. The pellet binders in the dosage of 4.5% caused the high compaction density, compared to those in the dosages of 3% and 1.5%. The high pellet binder dosage produces more starch and causes low water content so that the value of the compaction density will be higher. Sholihah (2011) argues that the higher the moisture content, the lower the compaction density, and vice versa (Sholihah, 2011).

Table 4 showed the highest stack angle was found in the brown seaweed pellet binder, while it was lower in the taro tuber and tapioca pellet binders. The high stack angle in brown seaweed pellet binders was associated with the high moisture content and low stack density. According to Khalil (1999b), the size of the stack angle was strongly influenced by the water content, density, size, shape, particle characteristics, and specific gravity. Furthermore, the stack angle of the taro tuber pellet binder was higher than the tapioca pellet binder. It was caused by the high water content in the taro tuber pellet binder. Wigati (2009) stated the high water content increases the stack angle of the pellet. This experiment also found the decreasing pellet binders dosage increased the stack angle; this was due to the less starch produced by low pellet binder dosage. The low stack angle at a dosage of 4.5% was caused by the higher starch content. According to Khalil (1999b), a high binder dosage will produce high starch that reduces the number of the pellet cavities. Therefore, it flows easily, and the stack angle value is low. In this experiment, the highest starch content found in tapioca pellet binder at 89.11% (Hartanti et al., 2017). Furthermore, taro tubers contain 75.19% starch (Rahmawati et al., 2012), and brown seaweed contains 56.86% starch (Diharmi et al., 2011). Therefore, this experiment obtained the highest stack angle for the brown seaweed pellet binder was 45.330000, and the lowest one was 42.31000, found in the tapioca pellet binder. In addition, the moisture content affects the stack angle. In this experiment, the increased pellet binder dosage decreased the water content of the pellet, resulting in lower stack angle values. Moisture content also significantly affects the value of the stack angle (Khalil, 1999b).

Pellet durability is crucial, reflecting resistance to pellet damage during handling, transport, and storage. Furthermore, the pellet durability can be influenced by the materials’ characteristics used as a pellet binder and temperature during the pellet-making process (Siyal et al., 2021). The highest pellet durability found in tapioca pellet binder was 98.53%, while it was lower in taro tuber and brown seaweed pellet binders (96.39% and 94.82%, respectively) (Table 5). The high pellet durability in tapioca pellet binder was related to the stack density and high starch content. According to Jaelani et al. (2016), pellet durability was related to the stack density level of the feed; the denser the feed stack, the smaller the cavity between the particles, so that the feed will have more pellet durability. The starch in pellet binders could be gelatinized to make the pellets compact and have pellet durability (Retnani et al., 2011). According to Usmiati (2018), tapioca flour contains high carbohydrates at 86.55%, and is suitable for pellet binders. Furthermore, Setiyatwan et al. (2008) stated the carbohydrates in feed function as binders strengthen the bonds of the particles that make up the feed. The pellet durability of the taro tuber pellet binder was higher than the brown seaweed pellet binder used for higher stack density and starch content. Pellet binder dosage affects pellet durability. The pellet binder dosage at 4.5% was the highest pellet durability (97.11%), while the pellet durability of pellet binder dosage at 3% and 1.5% was lower than 4.5%, i.e., 96.30% and 95.33%, respectively. The increase of pellet binder dosage decreased the water content of pellets because the increase of starch content as a binder strengthens the bond of the material particles. As a result, the pellets dropped from a height of 2 meters are less damaged. According to Retnani et al. (2010), the high moisture content in pellets decreased the pellet durability.

CONCLUSION

In conclusion, there is no interaction between the type and dosage of pellet binder, the best type of pellet binder in this experiment was tapioca flour, with the best dosage of 4.5%.

ACKNOWLEDGMENTS

This research was funded by BASIC RESEARCH SKIMMED (SKIM PENELITIAN DASAR) in the 2021 budget. Contract number project from Ministry of Education, Culture, Research, and Technology: 104/E4.1/AK.04.PT/2021 and Contract number project from Research Institution and community service of Universitas Andalas: T/33/UN.16.17/PT.01.03/PD-Pangan/2021. We appreciated the Indonesian Education, Culture, Research, and Technology who provided us the opportunity and financial support to perform this research. We also thank the Research Institution and community service of Universitas Andalas, who have facilitated this research.

CONFLICTS OF INTEREST

All authors declare that they have no conflicts of interest concerning the work presented in this manuscript.

AUTHORS’ CONTRIBUTIONS

Maria Endo Mahata participated in all stages of the research, namely the research design, the conduct of the experiment, sample analysis, data analysis, writing, and editing of articles. Hamdan Sukri Lubis participated in conducting the investigation and was responsible for data analysis. Takayuki Ohnuma and Yose Rizal participated in the research and editing of the article. All authors participated in writing the article and checking the statistical analysis, and finally approved the last version of the article for publishing.

REFERENCES

Abdollahi MR, Ravindran V, Svihus, B (2013). Pelleting of broiler diets: An overview with emphasis on pellet quality and nutritional value. Animal Feed Science and Technology, 179 (1-4): 1-23. https://dx.doi.org/10.1016/j.anifeedsci.2012.10.011

Abdollahi MR, Zaefarian F, Ravindran V (2018). Feed intake response of broilers: Impact of feed processing. Animal Feed Science and Technology, 237 (2018): 154–165. https://doi.org/10.1016/j.anifeedsci.2018.01.013

AOAC (1990). Official methods of analysis, 15th Edition. Association of official analytical chemists, Arlington VA, USA. https://law.resource.org/pub/us/cfr/ibr/002/aoac.methods.1.1990.pdf

Auliawan R, Cahyono B (2014). Efek hidrolisis ekstrak daun Iler (Coleus scutellarioides) terhadap aktivitas inhibisi enzim α-glukosidase. J. Sains dan Matematika, 22(1): 15-19. https://ejournal.undip.ac.id/index.php/sm/article/view/8052

Balagopalan C, Padmaja G, Nanda SK and Moorthy SN (1988). Cassava in Food, Feed and Industry. CRC Press, Florida.

Dewi YL, Yuniza A, Nuraini, Sayuti K and Mahata ME (2018). Immersion of Sargassum Binderi Seaweed in River Water Flow to Lower Salt Content before Use as Feed for Laying Hens. Int. J. Poult. Sci., 17(1): 22-27. https://doi.org/10.3923/ijps.2018.22.27

Diharmi A, Fardiaz D, Andarwulan N dan Heruwati ES (2011). Karakteristik keragenan hasil isolasi Euchema Spinosum (Alga Merah) dari perairan semenep madura. J. Perikanan dan Kelautan. 16 (1) : 117-124. https://jpk.ejournal.unri.ac.id/index.php/JPK/article/view/53

Hartanti L, Syamsunihar A dan Anom WK (2017). Experiment of agronomypotential and flour quality of local types cassava. J. Ilmu dan Teknol. Pangan., 3(2): 247-255. https://doi.org/10.29303/profood.v3i2.57

Herawati H (2018). The hydrocolloids potential as additive materials to the qualified food and non-food products. J. Litbang Pertanian., 37 (1): 17-25. https://doi.org/10.21082/jp3.v37n1.2018.p17-25

Imanningsih N (2012). Gelatinisation profile of several flour formulations for estimating cooking behaviour. Penel Gizi Makan, 35(1): 13-22. http://ejournal.litbang.kemkes.go.id/index.php/pgm/article/view/3079

Jaelani A, Dharmawati S dan Wacahyono (2016). Effect of stack and time storage of pellet feed to physical quality. Ziraa’ah, 41(2): 261-268. https://ojs.uniska-bjm.ac.id/index.php/ziraah/article/view/429

Jahiding M, Mashuni, Hasan ES dan Gangganora AS (2014). Pengaruh jenis dan komposisi perekat terhadap briket batu bara muda. J. Aplikasi Fisika., 10 (10): 67-76. http://ojs.uho.ac.id/index.php/JAF/article/view/1498/1053

Kadi A (2005). Makro Algae di Perairan Kepulauan Bangka, Beliung dan Karimatan. Jurusan Ilmu Kelautan., 10 (2) : 98-105. https://doi.org/10.14710/ik.ijms.10.2.98-105

Kaushal P, Kumar V, Sharma HK (2011). Comprative experiment of physicochemical, function, antinutritional adn pasting properties of Taro (Coocasiaesculenta), Rice (Oryzasativa) flour, Piogenpa (Cajanuscajan) flour and their blends. Food Sci. Technol. 48 (1) : 59-68. https://doi.org/10.1016/j.lwt.2012.02.028

Khalil (1999b). Pengaruh Kandungan Air dan Ukuran Partikel Terhadap Sifat Fisik Pakan Loka: Sudut Tumpukan, Data Ambang dan Faktor Hidroskopis. Media Peternakan. 22 (1) : 1-11.

Laboratorium Nutrisi Non Ruminansia (2019). Hasil Analisis Kandungan Gizi dan Energi Termetabolisme Tanaman Miana. Fakultas Peternakan Universitas Andalas, Padang.

Luciana YD (2012). Quality test of physical and storage capacity of pellet contains corn husk and sweet potato by-product as a substitute for the leaves Pennisetum purpureum. Thesis. Bogor Agricultural University. https://repository.ipb.ac.id/handle/123456789/61582

Mahata ME, Putri DO, Arif, Ohnuma, Rizal Y (2021). The Performance of Broiler Chickens Fed on Miana Plant Flour (Plectranthus scutellarioides, L.) R. Br. J. World’s Poult. Res., 11 (3): 332-337. https://dx.doi.org/10.36380/jwpr.2021.39

Puspita D, Tjahyono YD, Samalukang Y, Anthon B, Toy BAI, Totod NW (2018). Anthocyanin production from miana leaves (Plectranthus scutellarioides) as natural pigment. J. Ilmu dan Teknol. Pangan, 4 (1): 298-303. https://www.doi.org/10.29303/profood.v4i1.78

Rahmana I, Mucra DA dan Febrina D (2016). Kualitas fisik pelet ayam broiler periode akhir dengan penambahan feses ternak dan bahan perekat yang berbeda. J. Peternakan, 13 (1): 33-40. http://dx.doi.org/10.24014/jupet.v13i1.2387

Rahmawati W, Kusumastuti YA dan Aryanti N (2012). Karakteristik pati Talas (Colocasia Esculenta (L.) Schoot) sebagai alternatif sumber pati industri di Indonesia. J. Teknol. Kimia dan Industri., 1 (1): 347-351. https://ejournal3.undip.ac.id/index.php/jtki/article/view/947

Retnani Y, Hasanah N, Rahmayeni, Herawati L (2010). The physical characteristic test of broiler ration pelleted that added of onggok as binder with water spraying process. Agripet., 10 (1): 13-18. https://doi.org/10.17969/agripet.v10i1.632

Retnani Y, Herawati L dan Khusniati S (2011). Physical characteristics on crumble ration of broiler starter using tapioca, bentonite and onggok binders. J. Inovasi Teknol. Pendidikan, 1 (2): 88-97. https://media.neliti.com/media/publications/100186-ID-none.pdf

Ridwan Y, Satrija F, Darusman LK, Handharyani E (2010). Effectivity of anticestode of painted nettle extract (Coleus blumei Bent) againts Hymenolepis microstoma in Mice. Media Peternakan, 33 (1): 6-11. https://journal.ipb.ac.id/index.php/mediapeternakan/article/view/1226

Sadee, E. Dan Aslamsyah S. (2009). The Physical and chemical a nalysis of tiger prawn’s feed using seaweed s as b inder. J. Ilmu Kelautan dan Perikanan., 19 (2): 107-115. https://pdfcoffee.com/uji-fisik-dan-kimiawi-bahan-pakan-pdf-free.html

Salim Z, Munadi E (2017). Information on medicinal plant commodities. Agency for the experiment and development of trade, ministry of trade of the republic of Indonesia. pp. 11-12. http://bppp.kemendag.go.id/media_content/2017/12/Isi_BRIK_Tanaman_Obat.pdf

Sandro A. L., Tri A. Y. F, dan Theresia N. I. K. (2020). Evaluasi penggunaan tepung keladi terhadap kualitas fisik dan kandungan nutrien pelet pakan ayam. J. Ilmu dan Teknol. Peternakan Tropis., 7 (2): 158-165. http://dx.doi.org/10.33772/jitro.v7i2.10940

Setiyatwan H, Saefulhajar D and Hidayat TU (2008). Effect of binder subtances and long time storage on performance pellets feed form. Jurnal Ilmu Ternak, 8 (2): 105-108. http://pustaka.unpad.ac.id/archives/124684

Sholihah UI (2011). The effect of pellet diameter and storage time on physical pellet quality of indigofera sp leaves. Thesis. Bogor Agricultural University. https://repository.ipb.ac.id/handle/123456789/48194

Steel RGD, Torrie JH (1991). Statistical principles and procedures of a biometric approach. 2nd edition, translated by Bambang Sumatri. PT. Gramedia Pustaka Utama, Jakarta, Indonesia. 168-205. https://opac.perpusnas.go.id/DetailOpac.aspx?id=249306

Supriadi WJ, Jamila dan Syamsu JA (2020). Kualitas fisik pakan pelet ayam pedaging fase finisher dengan penambahan berbagai bahan perekat. Agrovital: J. Ilmu Peternakan, 5 (2): 51-54. https://journal.lppm-unasman.ac.id/index.php/agrovital/article/view/1737

Sutrisno (2016). Pemanfaatan rumput laut coklat sebagai bahan tambahan pembuaatan pelet pakan ikan. J. Optimasi Sistem Industri, 9 (2): 127-131. https://media.neliti.com/media/publications/289337-pemanfaatan-rumput-laut-coklat-sebagai-b-5d89e8a0.pdf

Svihus B (2011). The gizzard: Function, influence of diet structure and effects on nutrient availability. World’s Poult. Sci. J., 67 (2): 207-224. https://doi.org/10.1017/S0043933911000249

Svihus B, Zimonja O (2011). Chemical alterations with nutritional consequences due to pelleting animal feeds: A review. Anim. Prod. Sci., 51(7) 590-596. https://doi.org/10.1071/AN11004

Syamsu JA (2007). Phyical characterisics of duck ration in pellet form that added various different agglutinants and different storage times. J. Ilmu Ternak, 7 (2): 128 – 134. https://doi.org/10.24198/jit.v7i2.2246

Siyal AA, Liu Y, Mao X, Ali B, Husaain S, Dai j, Zhang T, Fu J, Liu G (2021). Characterization and quality analysis of wood pellets: effect of pelletization and torrefaction process variables on quality of pellets. Biomass Conversion Biorefine., 11:2201–2217. https://doi.org/10.1007/s13399-020-01235-6

Tayag CM, Lin YC, Li CC, Liou CH, Chen JC (2010). Administration of the hot-water extract of Spirulina Platensis enhanced the immune response of white shrimp Litopenaeus vannamei and its resistence against Vibrio alginolyticus. Fish Shellfish Immunol. 28 (5-6): 764-773. https://doi.org/10.1016/j.fsi.2010.01.023

Usmiati S (2009). Bakso sehat. Warta Penelitian dan Pengembangan., 31 (6): 13-14. http://203.190.37.42/publikasi-summary.php?contentID=wr316098

Wan Y, Ma R, Khalid A, Chai L, Qi R, Liu W, Li J, Li Y, Zhan K (2021). Effect of the pellet and mash feed forms on the productive performance, egg quality, nutrient metabolism, and intestinal morphology of two laying hen breeds. Animals., 11 (3): 1-10. https://doi.org/10.3390/ani11030701

Wigati D (2009). Effect of packaging type and storage time on insects and physical properties of crumbled starter broiler ration. Thesis. Bogor Agricultural University. : https://repository.ipb.ac.id/handle/123456789/11361

Wulansari R, Andriani Y, Hatami K (2016). The use of this type of binder on quality of physical of shrimp. J. Perikanan Kelautan., 7 (2): 140-149. http://jurnal.unpad.ac.id/jpk/article/view/11374

To share on other social networks, click on any share button. What are these?