Straw Bending and Lodging in Landrace Barley: Finite Element Modelling

Straw Bending and Lodging in Landrace Barley: Finite Element Modelling

Dara Jaff1,2* and Michael C. Jarvis2

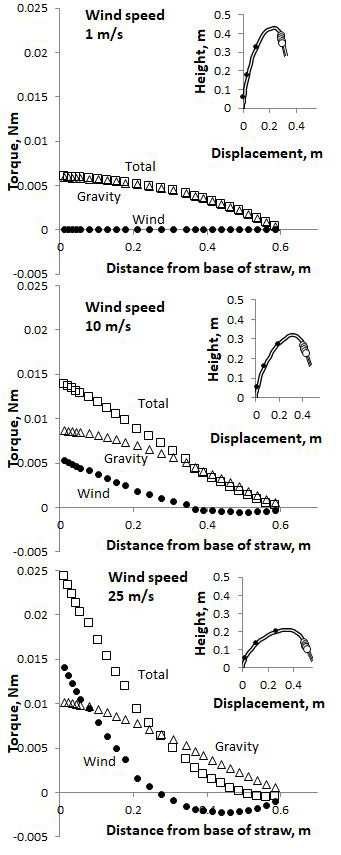

Modelled effect of wind strength on lodging and the relative contributions of wind (horizontal) and gravity (vertical) to the torque bending the stem at each point on its length measured along the curve from base to tip. Inset: plant geometry at each wind strength.

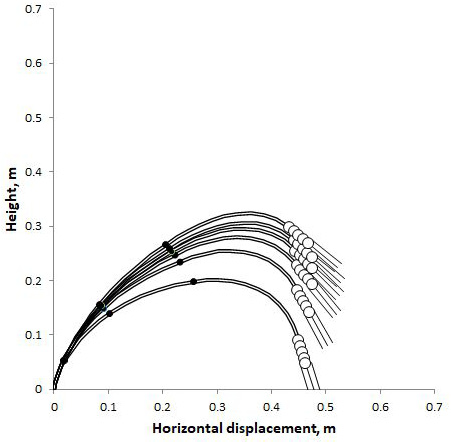

Modelled effect of straw diameter on lodging at 15 m s-1 wind speed. Maximum diameter (internode 2), top to bottom (m): .00309, 0.00275, 0.00240, 0.00206, 0.00172, 0.00137. Diameters and wall thicknesses of other internodes were held in constant ratio to internode 2.

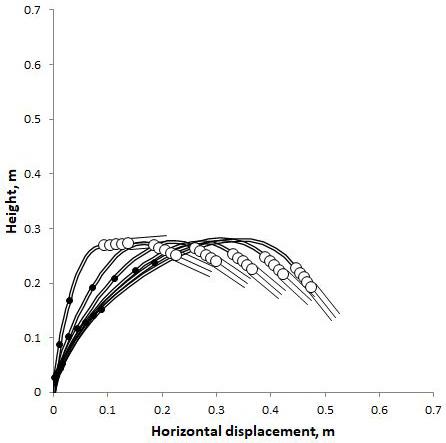

Modelled effect of mean longitudinal modulus of the culm wall material on lodging at 15 m m s-1 wind speed. Modulus for the three lower internodes, top to bottom (GPa): 16, 14, 12, 10, 8, 6. The top internode had half the modulus of the three lower internodes.

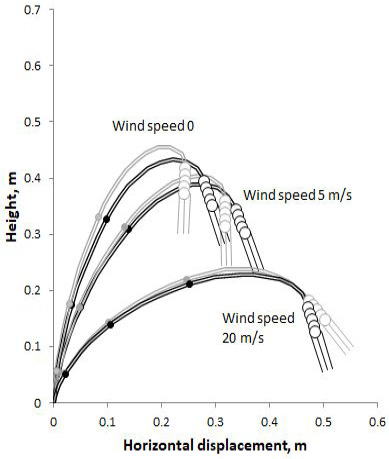

Modelled effect of straw length on lodging at 15 m s-1 wind speed. Erect plant heights (m), right to left: 0.64, 0.58, 0.52, 0.47, 0.41, 0.35.

Modelled effect of a permanent bend (set) at the top of the apical internode, at wind speeds of 0, 5 and 20 m s-1. No permanent set: grey. Permanent set: black.