Improvement of Processing Quality and Yield while Sustaining Consumer Acceptability of Cobb Broiler Meat through Zinc Biofortification

Improvement of Processing Quality and Yield while Sustaining Consumer Acceptability of Cobb Broiler Meat through Zinc Biofortification

Baila Ahmad1, Muhammad Ammar Khan1*, Zulfiqar Ahmad1,

Rana Muhammad Bilal2 and Asghar Ali Kamboh3

1Department of Food Science and Technology, Faculty of Agriculture and Environment, The Islamia University of Bahawalpur, 63100 Bahawalpur, Punjab, Pakistan

2Department of Animal Nutrition, Faculty of Veterinary and Animal Sciences, The Islamia University of Bahawalpur, 63100 Bahawalpur, Punjab, Pakistan.

3Department of Veterinary Microbiology, Faculty of Animal Husbandry and Veterinary Sciences, Sindh Agriculture University, Tandojam 70060, Sindh, Pakistan.

ABSTRACT

Inferior product developmental characteristics, high yield losses and low consumer acceptability cause hefty monitory losses to the broiler meat processing industry. This study, therefore, investigated the approach of nutritional intervention to combat these concerns. Breast meat samples were obtained from the broilers given zinc (Zn from ZnSO4) supplements (T0, T1, T2, and T3 @ 0, 10, 20 and 40 ppm, respectively of finisher diet from 21 to 42 days). Initially, the pH, expressible moisture (EM), water-holding capacity (WHC), instrumental color, drip loss (DL) and cook loss (CL) were measured. Afterward, the effect of processing (25°C, thermal treatment for 15 min, refrigeration for 3 d, and pressure treatment of 196 N for 15 min) was evaluated. The significantly (p<0.05) lowest EM, but highest (p<0.05) WHC of T3 samples depicted raw meat processing quality improvement. Moreover, dietary incorporation of 40 ppm Zn resulted in a significant (p<0.05) decline (1.88%) in DL as compared to the control that illustrated remarkable raw meat yield improvement. Similarly, the reduction (p<0.05) of CL of T3 samples increased the industrial profitability by reducing processing yield losses. Furthermore, non-significant changes (p>0.05) in ash, moisture and crude proteins indicated retention of nutritional and market value of the broiler breast. The raw meat samples were not PSE (L* was 52.43±1.6). Thermal processing increased lightness and chroma but decreased redness and hue angle. Furthermore, the 80°C treatment significantly increased product doneness and sensory scores. Finally, the correlation analysis showed that industrial, as well as consumer acceptability were influenced by dietary Zn through moderating roles of pH and WHC.

Article Information

Received 09 April 2021

Revised 17 October 2021

Accepted 03 November 2021

Available online 27 December 2021

(early access)

Published 15 July 2022

Authors’ Contribution

BA conducted the research and wrote the manuscript. MAK supervised the research and performed statistical analysis. ZA edited the manuscript. RMB co-supervised the research and reviewed the manuscript. AAK proofread the manuscript.

Key words

Meat quality, Water-holding capacity, Meat processing, Zinc supplementation, Biofortification, Consumer acceptability

DOI: https://dx.doi.org/10.17582/journal.pjz/20210409200451

* Corresponding author: ammar@iub.edu.pk

0030-9923/2022/0005-2407 $ 9.00/0

Copyright 2022 by the authors. Licensee Zoological Society of Pakistan.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

INTRODUCTION

The technological characteristics and sensory attributes are predictors of meat quality, processing behavior and consumer acceptability (Gagaoua and Picard, 2020). Particularly, the lower water-holding capacity (WHC) is a persistent economic concern that deteriorates the poultry meat quality. Moreover, it accounts for about 11% of yield losses in the poultry industry (Carvalho et al., 2018). Scientific literature shows the use of several interventions to reduce these losses, but little work has been published on the effect of nutritional supplements at the poultry farm level on processing behavior and consumer acceptability for poultry meat.

WHC depends on the structural components of muscles, particularly related to sarcoplasmic and myofibrillar proteins, which hold 3 and 50% of the myowater, respectively. The denaturation of the myofibrillar proteins reduces the WHC (Ali et al., 2015) during post-mortem glycolysis that changes muscle pH, ionic balance, and enzyme activity, which affect the oxidative stability of muscle, sarcomere length, as well as osmotic, capillary and electrostatic forces between actomyosin filaments and sarcoplasmic water (Ertbjerg and Puolanne, 2017). These changes in the structural components of muscles affect the functional attributes in terms of reductions in WHC, juiciness, and tenderness of meat, which reduce the consumer acceptability of meat (Álvarez et al., 2019).

Meats with lower WHC possess limited success in the development of premium meat products. Meat proteins need to withstand the drastic effect of processing and storage treatments, such as heating, refrigeration, pressure, etc. (Khan et al., 2014a); however, the lower WHC of meats reduces the manufacturing yields, as well as processing quality attributes, mainly due to inferior proteins functionality and behavior (Fu and Chen, 2019). These aggravated production and quality losses, hence, contribute to a remarkable reduction in profits of meat processors and consumer acceptability; hence it is utmost essential to address these issues through enhancing the WHC of muscle proteins through nutritional intervention.

The consumer acceptability of meat products is very tricky. It is strongly influenced by the sensory quality of meat products, which is primarily driven by the WHC of raw meat. Moreover, the rapid and continuously changing intrinsic nature of meat during processing and storage exerts an overriding influence on the uniformity of the final product quality. Color and tenderness are the most critical meat quality predictors that represent the textural attributes of meat products and affect the purchasing behavior of consumers (You et al., 2020). Pale, soft, and exudative (PSE) is the worst outcome of color-WHC combination (Karunanayaka et al., 2016), which is linked with the behavior of meat proteins under different processing conditions (Nair and Zhai, 2020), including myoglobin (sarcoplasmic protein, color), collagen (stromal protein, tenderness) and actin-myosin (myofibrillar proteins, WHC) (Ijaz et al., 2020). The meat products having lower customer acceptability fetch lower profits. Reliable strategies should, therefore, be developed to improve the physicochemical attributes of meat through nutritional supplements which dictate higher technological, nutritional, and sensory quality. Moreover, it is pivotal to establish the links between the physicochemical attributes of meat with consumer acceptability, particularly in the meats obtained from broilers given supplements of Zinc (Zn).

In the poultry industry, malnutrition can exacerbate serious concerns, including a weakened immune system, reduced feed consumption, retarded growth, irregular feathering, lesion formation on the skin and poor meat quality. Zn plays an integral part in the metabolism, immunity, maintenance of broiler health, and thus, affects meat quality (Hussan et al., 2021). Hence, the Zn biofortification of chicken meat will strengthen broiler immunity and metabolism, regulate enzymatic activities and pH of meat, and enhance its WHC, thereby contributing to the enhancement of technological and consumer attributes for meat processing.

Therefore, this paper aimed to improve the processing quality and yield while sustaining consumer acceptability of broiler meat through Zn biofortification in broiler chickens with ZnSO4. The main objectives of the current study were (1) to evaluate the processing quality of raw meat through the determination of EM and WHC; (2) to control yield losses assessed by DL and CL, (3) to evaluate the effect of thermal processing on product doneness and consumer acceptability, and (4) to determine the extent of interdependence and mediating roles of various interdependent variables using correlation analysis. The improved production and processing attributes will, therefore, enhance the productivity and profits of the meat processors and retailers.

MATERIALS AND METHODS

Treatments

Cobb broilers aged 21 days procured from a local farm reared in four treatment groups, three subgroups, given supplements of zinc (Zn) from ZnSO4 @ 0, 10, 20 and 40 ppm (T0, T1, T2, and T3, respectively) from d 21 to 42. Birds with uniform mean body weight (BW) were slaughtered by the Halal method as per the PS-3337:2016 regulation of Pakistan Standards and Quality Control Authority (PSQCA, 2016). The birds were bled, and portioning was done at room temperature to analyse chicken breast samples for various quality parameters. The study was conducted following the approval of the institutional bioethical committee (IBC) of the Islamia University of Bahawalpur (IUB). All the chicken breast samples were packed in sterilized polyethylene (PE) bags and stored at < 4°C until required for physicochemical analysis.

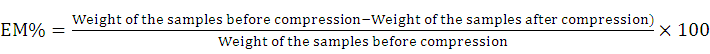

Expressible moisture

The 2 g filter paper-wrapped chicken breast samples were given pressure treatment for 15 min with 196 N force. After removal of the filter papers, the samples were reweighed, and expressible moisture (EM) was calculated using the following equation (Ali et al., 2015).

Moreover, the water-holding capacity (WHC) was determined according to the method used by Karunanayaka et al. (2016).

Proximate composition

The ash contents (AC), moisture contents (MC) and crude protein (CP) contents of the meat samples (~5 g) from each treatment were determined according to AOAC methods (AOAC, 2010).

Processing treatments

The broiler breast samples acquired from the Zn-supplemented diet were subjected to four processing treatments, i.e., room temperature treatment (25°C), thermal processing (80°C, 15 min), refrigeration treatment (4°C, 72 h), and pressure treatment (196 N, 15 min).

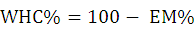

Drip loss

About 2 g PE-packed breast samples were tied and hung in a refrigeration chamber at < 4°C for 72 h, in such a way that the samples did not touch the PE bags. The drip loss (DL) percentages were calculated according to the following equation (Pingen et al., 2016).

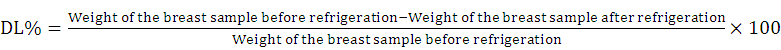

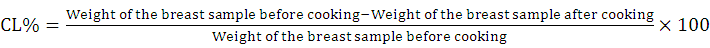

Cook loss

Approximately 2 g samples were evaluated for cook loss (CL) for each treatment following the method of Khan et al. (2014a).

Briefly, each sample was packed in two tightly sealed PE bags with removing most of the air, and subjected to 100°C in water for 15 min until the core temperature of the meat was 80°C at the end of the cooking cycle. After removing the PE bags, the samples were stayed for 2 to 3 min at room temperature, and the CL% was determined.

pH

The pH evaluation was conducted 30 to 45 min after the slaughter of the Cobb broilers using the method used by Pingen et al. (2016). The sampling was done at 2.5 cm depth under the meat surface at three different locations with a portable pH meter (InoLab, pH 7110, Germany) equipped with a probe (WTWTM, SentixTM 41, Model B161609100, Germany).

Instrumental color

The CIE lightness (L*), redness (a*) and yellowness (b*) values of the samples, along with chroma (C*) and hue angle (h°) values were evaluated according to the following equations (Khan et al., 2014b).

Moreover, the whiteness (W*) values were determined using the following equation (Won et al., 2014).

Consumer acceptability studies

The consumer acceptability studies of both the fresh and cooked samples of broiler breast meat were performed with the help of the 9-Point Hedonic Scale by the untrained panelists of the Department of Food Science and Technology, IUB, according to the method of Yang et al. (2016a).

Statistical analysis

The data were analyzed for the Analysis of Variance (ANOVA) under Factorial Design (p < 0.05) in the Statistix software (Version 8.1, USA), and written as Mean±Standard Deviation. Moreover, the differences between the significantly different mean values were determined through Least Significant Differences (LSD). The extent of interdependence and mediating roles of various interdependent variables were determined using correlation analysis.

RESULTS AND DISCUSSION

pH

The pH of raw chicken breast samples acquired from the Zn supplemented Cobb chickens ranged from 5.90 to 5.97 in this study from T0 to T3 (Fig. 1). However, there were no significant changes (p > 0.05) in the mean values under the influence of treatments. Thus, the current result was in agreement with Hussan et al. (2021), who reported no pH change of meat after nano-Zn supplementation of broiler feed.

Drastic changes in pH during rigor mortis are associated with preslaughter stress which can cause degradation of proteins and fats, thus affecting the shelf life of the meat (Davoodi and Ehsani, 2020). England et al. (2016) stated that generally, the pH of normal living animal tissues is 7.2 because glucose gets metabolized into adenosine triphosphate (ATP) during the process of respiration. The pH of the raw chicken breast samples in this study dropped after the exsanguination of the experimental broilers because the disruption of oxygen (O2) supply commenced anaerobic respiration, conversion of glucose into pyruvic, and finally, lactic acid that instigated a decline in the pH of the meat. Moreover, the inherent muscle glycogen reserves (<1%) quickly depleted that commenced the stiffening of muscles and the shrinkage of muscle fibers, commonly known as rigor mortis (Ertbjerg and Puolanne, 2017). The shrinkage of myofibrillar spaces would result in the loss of myowater, which is a major concern for industrial yield and quality.

Expressible moisture and water-holding capacity

The retention of the expressible moisture (EM) and water-holding capacity (WHC) of meat are indicators of meat quality that influence the profitability for the meat industry, consumer acceptability of meat, and suitability of raw meat for the development of premium meat products. The T3 breast meat exhibited the significantly (p<0.05) lowest EM values among all the samples (Fig. 2a), which indicated a strong positive effect of the treatment on retention of myowater during refrigerated storage. The lowest EM values indicated the lesser free water in the myofibrillar matrix but higher bound water, mainly due to the strengthening of the forces responsible for myowater retention in the myofibrillar matrix. The EM values of the current study were similar (in the range 37.63 and 35.56%) to those reported by Zakaria et al. (2017). On the contrary, T3 beast meat samples showed the significantly highest values of WHC as compared to the rest of the treatments (Fig. 2b), which depicted the improvement in the suitability of this treatment for producing premium meat products. The EM of meat gets influenced by the onset of rigor mortis, accompanied by a reduction in pH, and consequently, protein denaturation, which influences the exudation of myowater into the extracellular spaces. In this way, the EM affects the WHC of myofibrillar proteins (actin and myosin) through the dissolution or coagulation of sarcoplasmic proteins (Dai et al., 2013), disintegration of meat fibers and movement of intramyofibrillar water (Caldas-Cueva et al., 2021).

Thus, the current results suggested that the Zn treatment resulted in remarkable yield improvement of the raw chicken meat under refrigerated storage. The lower EM and higher WHC were associated with the maintenance of meat weight which was beneficial in terms of the economic value of meat. Moreover, the lowest EM and the highest WHC showed by T3 samples in this study indicated that the lower loss of myowater resulted in lower amounts of water-soluble minerals, vitamins and intracellular glycolytic enzymes (Kamruzzaman et al., 2012) that ensured higher nutrition and quality of meat, thus made it more suitable for processing as compared to the control meat samples.

Drip loss

The T0 samples of the current study revealed the highest (p<0.05) drip loss (DL) among all the treatments (Fig. 3a), which indicated weaker membrane integrity, consequently higher water and nutrient losses due to the reduced moisture-binding ability of the muscle proteins, mainly attributed to higher cellular oxidation. DL is the fundamental quality and yield determinant of the meat industry associated with the water-holding strength of the meat proteins that ultimately determine the sensory appeal and consumer acceptability of the end products (Rahbari et al., 2018). It is a serious economic concern for the meat processors as it results in as much as 10% of the production losses in the cut-up chicken. The chicken meat samples in this study exhibited reduced drip losses in a dose-dependent manner from T1 to T3. T3 exhibited the significantly (p<0.05) lowest DLs unlike the rest of the treatments, associated with the strengthening of muscle proteins to withhold myofibrillar and sarcoplasmic water. The consistent reduction of DLs from T0 to T3 in this study indicated that during the postmortem glycolysis, the shrinkage and denaturation of myofibrillar proteins in the chicken meat was influenced by the treatment level. Particularly, the enlargement of intracellular spaces within muscle fibers was higher for lower treatment levels (Álvarez et al., 2019). The lower DLs of the treated samples were associated with the higher osmotic pressure of the denatured sarcoplasmic proteins that led to a lower extracellular movement of water in treated meats from T1 to T3. The reduced DLs of the T3 samples implied higher retention of myofilbrillar and sarcoplasmic water than the rest of the treatments, hence resulted in significant improvements in the technological properties and eating quality of the meat, which are crucial for product development to generate higher monetary gains for the meat processing industry.

Cook loss

The thermal application allows the modification of raw meat for improving chewability, mastication, and digestibility. Moreover, it enhances the sensory attributes of the meat, particularly, related to taste and aroma associated with a wide range of meat products (Suleman et al., 2020). However, substantial monetary losses in weight have been associated with thermal processing, which reduces industrial profitability. The control samples of this study exhibited the significantly highest (p<0.05) cook losses (CL), followed by T1 (Fig. 3b), which occurred due to the denaturation, gelation and subsequent contraction of muscle fibers upon exposure to high temperature (Ježek et al., 2020). The heat-induced structural changes of the meat proteins in the T0 samples were instigated by the expulsion of the free water held by capillary forces from the three-dimensional protein matrix during muscle fiber shrinkage, which led to the reduction of weight and volume of the meat (Barbera, 2019). The CLs of chicken meat decreased with increasing the Zn doses. T3 demonstrated the significantly (p<0.05) lowest CLs, followed by T2, respectively, which was an indication of the enhanced cell membrane strength and integrity of muscle proteins that helped the muscle fibers to retain myowater under conditions of elevated temperature. The thermal treatment (80°C for 15 min) in this study resulted in the lateral and longitudinal shrinkage of several meat proteins, subsequently followed by the extracellular water flow (Vaskoska et al., 2020) that led to increased CLs. Moreover, heat application induced deformation and denaturation of myosin and collagen that led to increasing the edibility of the samples but lowered the myowater and product yield (Barbera, 2019). The reduction of CLs of chicken meat with higher treatment doses in the present study will be beneficial for the meat processing industry through increasing profit by saving significant yield losses during processing.

Proximate composition

The T3 samples resulted in slightly higher ash content (AC) and crude protein (CP) content than the rest of the treatments. However, the chicken breasts did not show any significant changes (p>0.05) in the CP, AC and moisture content (MC) of the meat (Table I). The nonsignificant influence of the treatments on the proximate composition of the chicken meat depicted no nutritional losses, and hence, indicated retention of the market value of the meat. The CP values of the meat samples of this experiment, which ranged from 21.18±0.66 to 22.1±0.6%. Furthermore, the AC and MC of the chicken breasts ranging from 1.47±0.25 to 1.73±0.21% and 73.43±0.95 to 74.47±1.14%, respectively, were similar to the study of Baloch et al. (2017). The unaltered proximate contents of the treated chicken samples will add to the monetary value and consumer acceptability of the meat because of saving nutritional losses.

Table I. Proximate composition of Cobb broiler meat obtained from chickens reared on Zn supplemented feed.

|

|

Ash (%) |

Moisture (%) |

Crude Protein (%) |

|

0 ppm |

1.47±0.25 |

74.43±1.05 |

21.18±0.66 |

|

10 ppm |

1.5±0.23 |

74.47±1.14 |

21.42±0.67 |

|

20 ppm |

1.6±0.18 |

73.8±0.97 |

21.86±0.35 |

|

40 ppm |

1.73±0.21 |

73.43±0.95 |

22.1±0.6 |

All values were presented as the Mean±SD. The values without English letters indicate non-significant results (p>0.05, n=3).

Pale, soft and exudative meat

Pale, soft and exudative (PSE), a key quality problem of the meat industry, accounts for about 0.1 to 10% losses in the meat industry. PSE meat possesses poor processing behavior, high spoilage rates and reduced WHC due to deteriorated muscular Ca2+ metabolism and accelerated denaturation of proteins, thus contributing to processing losses (Lan et al., 2021).

The mean L* value of the control samples used in this study was 52.93±1.4 (Fig. 4), which indicated no sign of PSE. Moreover, the treated samples were also not affected by PSE, because their L* values ranged between 51.63±2.39 and 53.07±1.54. In addition, sustained meat pH (>5.7), texture and lower drip losses during post-mortem glycolysis also corresponded to the high water-holding capacity of meat, hence, indicated a high processing quality of the meat (Álvarez et al., 2019).

Effect of refrigeration, compression and thermal processing

In this study, thermal processing showed the highest (p<0.05) values for lightness (L*) and whiteness (W*), whereas the compression treatment exhibited the highest values for redness (a*), yellowness (b*), chroma (C*), and hue angle (h°) (Fig. 4). The order of mean values was: for L* thermal > refrigeration > compression > fresh, for a* compression > fresh > refrigerated > thermal, for b* compression > refrigerated > fresh > thermal, for C* compression > refrigerated > fresh > thermal, for h° compression > fresh > refrigerated > thermal, and for W* thermal > refrigeration > fresh > compression. The changes in L* values indicated the denaturation (Ali et al., 2015) and precipitation (Yang et al., 2016b) of proteins. Molecular changes in meat proteins induced by thermal treatment aided the formation of gel-like networks that increased the edibility of thermally processed samples and improved the consumer acceptability of the processed meat. Conversion of myoglobin (red) into metmyoglobin (brown) during processing and storage influenced the a* (Khan et al., 2014a). In addition, b* of meat was influenced by the coloring compounds including carotenoids in poultry feed, stress during slaughtering and the storage environment of meat (Ali et al., 2015). Moreover, the magnitude of protein denaturation affected the color depth/ saturation index, which was shown by changes in C*. The differences in the h° values indicated its extent of discoloration, which was an indicator of the decline of quality of the fresh meat (Kim et al., 2016), but an indicator of edibility in the case of processed meat samples. The W* of meat indicated the extent of culinary doneness. Furthermore, the W* of cooked meat had a relation with time and temperature of thermal processing and was regulated by precipitation, structural alteration and molecular unfolding of meat proteins (Khan et al., 2014a). The breast samples experienced a reduction in volume, and hence alteration in protein structures under compression (Khan et al., 2019). Likewise, the pressure treatment influenced protein structures and orientation by a decrease in the volume, which affected the composition of color-related proteins. The protein denaturation under processing remarkably changed the state of meat, hence directly affected the culinary doneness, edibility, consumer acceptance, and market value of the meat samples in this study.

Consumer perception and evaluation

Consumer evaluation of meat products is central to their success in the market. In this study, an untrained panel of consumers evaluated the raw meat and processed samples using the Nine-Point Hedonic Scale. The results revealed that both the raw and processed breast samples retained their organoleptic attributes during the consumer testing against various Zn supplemental levels (Fig. 5); however, the processing conditions significantly (p<0.05) improved the organoleptic values as compared to the fresh samples. Particularly, the 80°C treatment significantly increased the hardness, visual appearance, and overall acceptability but reduced the springiness and juiciness, as opposed to the 25°C treated meat samples. Structures of meat proteins play key roles in the sensory quality of products. Drastic conformational changes in the meat proteins, including coiling, untwisting and disintegration of fibrous and globular proteins under thermal treatment led to the establishment of a three-dimensional (3D) network that increased the hardness, thus contributed to an enhancement of culinary value and edibility of cooked meat (Ali et al., 2015). Moreover, the denaturation of myoglobin, actin, and myosin improved the visual appearance of the samples. Furthermore, the precipitation of meat proteins increased gelling that decreased the springiness of 80°C treated samples (Pathare and Roskilly, 2016). In addition, the heat-induced tissue membrane disruption accelerated the extracellular moisture exchange that removed free water (Khan et al., 2019) and reduced juiciness. Despite the reduced juiciness of the thermally processed samples, the heat exchange between the muscle fibers increased the meat palatability. Moreover, thermal treatment brought about proteolytic and lipolytic changes that altered the contents of alcohol, aldehydes, ketones, esters, nitrogen- and sulfur-based compounds, hydrocarbons, etc., mainly due to lipid oxidation, vitamin degradation, and Maillard reaction, etc. which were responsible for desired taste and aroma of the processed meat samples. Hence, the overall consumer acceptability and product doneness increased due to synergistic improvements in product hardness, tenderness, visual appearance, springiness, and aroma.

Industrial and consumer acceptability analysis

Yield is the most important industrial parameter. As the supplemental Zn significantly (p<0.05) affected the WHC, DL and CL of broiler meat in this study, correlation analysis was conducted to investigate the associations and moderator roles of these variables (Table II). DL had a strong positive relationship with CL (r = 0.78); while WHC exhibited negative correlations with each of them (strong correlation for CL, r = -0.74, moderate correlation for DL, r = -0.59). These results confirmed that Zn controlled the raw and cooked yield of broiler meat by causing changes in DL and CL through moderation of WHC (Rahbari et al., 2018). The changes in hardness and springiness (r = -0.74) influence meat tenderness, and consequently consumer acceptability. The correlation of pH was positive (r = 0.63) with hardness, but negative (r = -0.83) with springiness. Although dietary Zn non-significantly influenced the pH (Fig. 1) and hardness (Fig. 5) of meat, yet the correlation analysis validated the moderator role of pH in manipulating meat hardness and springiness by Zn. Color is the foremost criterion for product acceptance. The a* of meat in this study was influenced by pH (r = -0.36), as well as by L* value (r = -0.55) that ultimately influenced meat hardness (r = -0.62). Since, redness is associated with myoglobin, hence the treatment influenced the protein structures of meat (Khan et al., 2014a). In addition, color and yield are also correlated, as in this study, b* had a moderately positive correlation (r = -0.43) with WHC. Finally, DL had a moderately positive correlation with juiciness (r = -0.46), while DL (r = -0.44) as well as CL (r = -0.52) had strong influences on consumer acceptability. These results indicated that industrial, as well as consumer acceptability were influenced by dietary Zn through moderating roles of pH and WHC.

CONCLUSION

This study aimed at reducing the problems related to meat quality traits and yield losses that reduce the profitability of the meat processing industry because of lower consumer acceptability and inferior processing

Table II. Coefficients of correlation of different physicochemical attributes of chicken meat.

|

|

pH |

DL |

CL |

WHC |

L* |

a* |

b* |

Hardness |

Springi-ness |

Juici-ness |

Color |

Aroma |

|

DL |

-0.17 |

|||||||||||

|

CL |

-0.01 |

0.78 |

||||||||||

|

WHC |

0.17 |

-0.59 |

-0.74 |

|||||||||

|

L* |

0.02 |

0.35 |

0.12 |

0.00 |

||||||||

|

a* |

-0.36 |

-0.29 |

-0.23 |

0.22 |

-0.55 |

|||||||

|

b* |

0.08 |

-0.61 |

-0.56 |

0.43 |

-0.03 |

0.18 |

||||||

|

Hardness |

0.63 |

0.09 |

-0.15 |

0.29 |

0.47 |

-0.62 |

0.25 |

|||||

|

Springiness |

-0.83 |

0.17 |

0.34 |

-0.36 |

-0.23 |

0.38 |

-0.11 |

-0.74 |

||||

|

Juiciness |

-0.26 |

0.46 |

0.32 |

-0.34 |

0.29 |

-0.34 |

-0.48 |

-0.10 |

0.24 |

|||

|

Color |

0.30 |

-0.40 |

-0.15 |

-0.05 |

0.05 |

-0.10 |

-0.06 |

-0.20 |

-0.27 |

-0.15 |

||

|

Aroma |

0.36 |

0.07 |

0.04 |

-0.06 |

0.04 |

-0.33 |

-0.22 |

0.05 |

-0.41 |

0.20 |

0.62 |

|

|

Overall acceptability |

-0.28 |

-0.44 |

-0.52 |

0.09 |

-0.02 |

-0.08 |

0.24 |

-0.06 |

0.07 |

0.08 |

0.01 |

-0.33 |

Where; DL, Drip loss; CL, Cook loss; WHC, Water-holding capacity; L*, lightness; a*, redness; b*, yellowness.

quality of meat. Nutritional intervention (Zn 0 – 40 ppm) improved the meat quality traits through the reduction of EM. Moreover, the improvement of WHC in 40 ppm fed samples indicated a higher ability of meat proteins to retain myowater for enhanced protein functionality. Consequently, the DL of the treated samples was significantly reduced, which referred to a higher raw meat yield during refrigerated storage. Similarly, the significant reduction of the CL in the 40 ppm samples indicated the yield improvement during product development. Furthermore, the treatments retained the color, proximate contents and sensory attributes of the meat similar to non-treated samples. Under thermal processing conditions, L* and W* of the product significantly increased that led to higher consumer acceptability of meat products. Finally, the correlation analysis indicated that industrial, as well as consumer acceptability were influenced by dietary Zn through moderating roles of pH and WHC. The improved technological quality and yield of the meat indicate higher profitability for the meat processing industry and quality improvement of chicken meat products. Likewise, the sustained organoleptic attributes of the chicken meat with greater quality suffice the eating quality, hence lead to higher consumer satisfaction and higher market demands. In the future, the effect of nanoparticles on meat for enhancement of safety and quality will be assessed.

Statement of conflict of interest

The authors have declared no conflict of interest.

Ali, S., Zhang, W., Rajput, N., Khan, M.A., Li, C.B. and Zhou, G.H., 2015. Effect of multiple freeze–thaw cycles on the quality of chicken breast meat. Fd. Chem., 173: 808-814. https://doi.org/10.1016/j.foodchem.2014.09.095

Álvarez, C., Morán, L., Keenan, D.F., Mullen, A.M. and Delgado-Pando, G., 2019. Mechanical and biochemical methods for rigor measurement: Relationship with eating quality. J. Fd. Qual., 2019: Article ID: 1894543. https://doi.org/10.1155/2019/1894543

AOAC, 2010. Official method of analysis. Association of Official Analytical Chemists, Washington, DC, USA.

Baloch, Z., Yasmeen, N., Pasha, T.N., Ahmad, A., Taj, M.K., Khosa, A.N., Marghazani, I.B., Bangulzai, N., Ahmad, I. and Hua, Y.S., 2017. Effect of replacing inorganic with organic trace minerals on growth performance, carcass characteristics and chemical composition of broiler thigh meat. Afr. J. agric. Res., 12: 1570-1575. https://doi.org/10.5897/AJAR2016.12104

Barbera, S., 2019. WHC trend, an up-to-date method to measure water holding capacity in meat. Meat Sci., 152: 134-140. https://doi.org/10.1016/j.meatsci.2019.02.022

Caldas-Cueva, J.P., Mauromoustakos, A. and Owens, C.M., 2021. Instrumental texture analysis of chicken patties prepared with broiler breast fillets exhibiting woody breast characteristics. Poult. Sci., 100: 1239-1247. https://doi.org/10.1016/j.psj.2020.09.093

Carvalho, L.M.D., Oliveira, M.É.D.S., Freitas, A.S., Sousa Neto, A.C., Ida, E.L., Shimokomaki, M. and Madruga, M.S., 2018. Further evidence for the existence of broiler chicken PFN (pale, firm, non-exudative) and PSE (pale, soft, exudative) meat in brazilian commercial flocks. Fd. Sci. Technol., 38: 704-710. https://doi.org/10.1590/fst.15617

Dai, Y., Miao, J., Yuan, S.Z., Liu, Y., Li, X.M. and Dai, R.T., 2013. Colour and sarcoplasmic protein evaluation of pork following water bath and ohmic cooking. Meat Sci., 93: 898-905. https://doi.org/10.1016/j.meatsci.2012.11.044

Davoodi, P. and Ehsani, A., 2020. Characteristics of carcass traits and meat quality of broiler chickens reared under conventional and free-range systems. J. World’s Poult. Res., 10: 623-630. https://doi.org/10.36380/jwpr.2020.71

England, E.M., Matarneh, S.K., Oliver, E.M., Apaoblaza, A., Scheffler, T.L., Shi, H. and Gerrard, D.E., 2016. Excess glycogen does not resolve high ultimate pH of oxidative muscle. Meat Sci., 114: 95-102. https://doi.org/10.1016/j.meatsci.2015.10.010

Ertbjerg, P. and Puolanne, E., 2017. Muscle structure, sarcomere length and influences on meat quality: A review. Meat Sci., 132: 139-152. https://doi.org/10.1016/j.meatsci.2017.04.261

Fu, X. and Chen, J., 2019. A review of hyperspectral imaging for chicken meat safety and quality evaluation: application, hardware, and software. Compr. Rev. Fd. Sci. Fd. Saf., 18: 535-547. https://doi.org/10.1111/1541-4337.12428

Gagaoua, M. and Picard, B., 2020. Current advances in meat nutritional, sensory and physical quality improvement. Foods, 9: 321-325. https://doi.org/10.3390/foods9030321

Hussan, F., Krishna, D., Preetam, V.C., Reddy, P. and Gurram, S., 2021. Dietary supplementation of nano zinc oxide on performance, carcass, serum and meat quality parameters of commercial broilers. Biol. Trace Elem. Res., 12: 1-6. https://doi.org/10.1007/s12011-021-02635-z

Ijaz, M., Li, X., Zhang, D., Hussain, Z., Ren, C., Bai, Y. and Zheng, X., 2020. Association between meat color of DFD beef and other quality attributes. Meat Sci., 161: 107954. https://doi.org/10.1016/j.meatsci.2019.107954

Ježek, F., Kameník, J., Macharáčková, B., Bogdanovičová, K. and Bednář, J., 2020. Cooking of meat: effect on texture, cooking loss and microbiological quality. A review. Acta Vet. Brno, 88: 487-496. https://doi.org/10.2754/avb201988040487

Kamruzzaman, M., Elmasry, G., Sun, D.W. and Allen, P., 2012. Prediction of some quality attributes of lamb meat using near-infrared hyperspectral imaging and multivariate analysis. Anal. Chim. Acta, 714: 57-67. https://doi.org/10.1016/j.aca.2011.11.037

Karunanayaka, D.S., Jayasena, D.D. and Jo, C., 2016. Prevalence of pale, soft, and exudative (PSE) condition in chicken meat used for commercial meat processing and its effect on roasted chicken breast. J. Anal. Sci. Technol., 58: 58-27. https://doi.org/10.1186/s40781-016-0110-8

Khan, M.A., Ali, S., Abid, M., Ahmad, H., Zhang, L., Tume, R.K. and Zhou, G., 2014a. Enhanced texture, yield and safety of a ready-to-eat salted duck meat product using a high pressure-heat process. Innov. Fd. Sci. Emerg. Technol., 21: 50-57. https://doi.org/10.1016/j.ifset.2013.10.008

Khan, M.A., Ali, S., Abid, M., Cao, J., Jabbar, S., Tume, R.K. and Zhou, G., 2014b. Improved duck meat quality by application of high pressure and heat: A study of water mobility and compartmentalization, protein denaturation and textural properties. Fd. Res. Int., 62: 926-933. https://doi.org/10.1016/j.foodres.2014.04.006

Khan, M.A., Ali, S., Yang, H., Kamboh, A.A., Ahmad, Z., Tume, R.K. and Zhou, G., 2019. Improvement of color, texture and food safety of ready-to-eat high pressure-heat treated duck breast. Fd. Chem., 277: 646-654. https://doi.org/10.1016/j.foodchem.2018.11.006

Kim, H.W., Yan, F.F., Hu, J.Y., Cheng, H.W. and Kim, Y.H.B., 2016. Effects of probiotics feeding on meat quality of chicken breast during postmortem storage. Poult. Sci., 95: 1457-1464. https://doi.org/10.3382/ps/pew055

Lan, M., Li, L., Peng, X., Chen, J., Cao, Q., He, N., Cai, J., Li, B. and Zhang, X., 2021. Effects of different lipids on the physicochemical properties and microstructure of pale, soft and exudative (PSE)-like chicken meat gel. LWT-Fd. Sci. Technol., 145: 111284. https://doi.org/10.1016/j.lwt.2021.111284

Nair, M. and Zhai, C., 2020. Application of proteomic tools in meat quality evaluation meat quality evaluation. In: Meat quality analysis: Advanced evaluation methods, techniques, and technologies (eds. A.K. Biswas and P.K. Mandal). Elsevier San Diego, CA. USA. pp. 353-368. https://doi.org/10.1016/B978-0-12-819233-7.00019-7

Pathare, P.B. and Roskilly, A.P., 2016. Quality and energy evaluation in meat cooking. Fd. Eng. Rev., 8: 435-447. https://doi.org/10.1007/s12393-016-9143-5

Pingen, S., Sudhaus, N., Becker, A., Krischek, C. and Klein, G., 2016. High pressure as an alternative processing step for ham production. Meat Sci., 118: 22-27. https://doi.org/10.1016/j.meatsci.2016.03.014

PSQCA, 2016. PS-3337:2016 (3rd ed.). Pakistan Standard and Quality Control Authority, Karachi.

Rahbari, M., Hamdami, N., Mirzaei, H., Jafari, S.M., Kashaninejad, M. and Khomeiri, M., 2018. Effects of high voltage electric field thawing on the characteristics of chicken breast protein. J. Fd. Eng., 216: 98-106. https://doi.org/10.1016/j.jfoodeng.2017.08.006

Suleman, R., Wang, Z., Aadil, R.M., Hui, T., Hopkins, D.L. and Zhang, D., 2020. Effect of cooking on the nutritive quality, sensory properties and safety of lamb meat: Current challenges and future prospects. Meat Sci., 167: 108172. https://doi.org/10.1016/j.meatsci.2020.108172

Suliman, G.M., Alowaimer, A.N., Al-Mufarrej, S.I., Hussein, E.O., Fazea, E.H., Naiel, M.A., Alhotan, R.A. and Swelum, A.A., 2021. The effects of clove seed (Syzygium aromaticum) dietary administration on carcass characteristics, meat quality, and sensory attributes of broiler chickens. Poult. Sci., 100: 100904. https://doi.org/10.1016/j.psj.2020.12.009

Tornberg, E., 2005. Effects of heat on meat proteins–Implications on structure and quality of meat products. Meat Sci., 70: 493-508. https://doi.org/10.1016/j.meatsci.2004.11.021

Vaskoska, R., Ha, M., Naqvi, Z.B., White, J.D. and Warner, R.D., 2020. Muscle, ageing and temperature influence the changes in texture, cooking loss and shrinkage of cooked beef. Foods, 9: 1289-1307. https://doi.org/10.3390/foods9091289

Won, K.B.W.R.K., Pak, M., Kang, J.E., Park, H.M., Kim, B.R. and Ahn, D.H., 2014. Effects of chicken breast meat on quality properties of Mackerel (Scomber japonicus) sausage. Korean J. Fd. Sci. Anim. Resour., 34: 122-126. https://doi.org/10.5851/kosfa.2014.34.1.122

Yang, H., Khan, M.A., Han, M., Yu, X., Bai, X., Xu, X. and Zhou, G., 2016a. Optimization of textural properties of reduced-fat and reduced-salt emulsion-type sausages treated with high pressure using a response surface methodology. Innov. Fd. Sci. Emerg. Technol., 33: 162-169. https://doi.org/10.1016/j.ifset.2015.10.007

Yang, H., Khan, M.A., Yu, X., Zheng, H., Han, M., Xu, X. and Zhou, G., 2016b. Changes in protein structures to improve the rheology and texture of reduced-fat sausages using high pressure processing. Meat Sci., 121: 79-87. https://doi.org/10.1016/j.meatsci.2016.06.004

You, Y., Her, J.Y., Shafel, T., Kang, T. and Jun, S., 2020. Supercooling preservation on quality of beef steak. J. Fd. Eng., 274: 109840. https://doi.org/10.1016/j.jfoodeng.2019.109840

Zakaria, H.A., Jalal, M., Al-Titi, H.H. and Souad, A., 2017. Effect of sources and levels of dietary zinc on the performance, carcass traits and blood parameters of broilers. Braz. J. Poult. Sci., 19: 519-526. https://doi.org/10.1590/1806-9061-2016-0415

To share on other social networks, click on any share button. What are these?