Furrow Bed Irrigation System: Installation and Management

Furrow Bed Irrigation System: Installation and Management

Ghani Akbar*, Muhammad Asif, Zafar Islam and Shahid Hameed

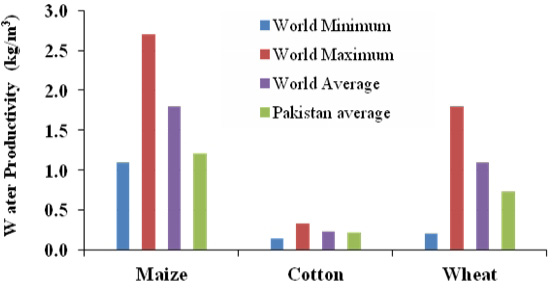

Global water productivity comparisons with Pakistan (Zwart and Bastiaanssen, 2004).

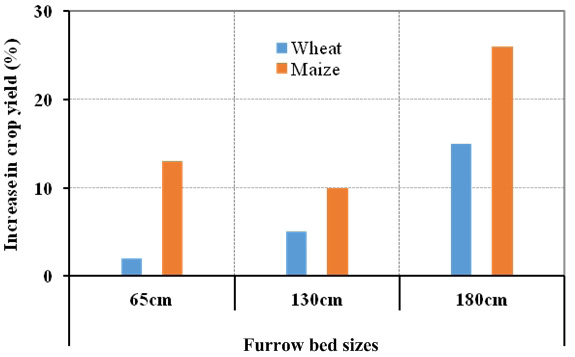

Increase in crop yield on different bed sizes relative to flat basin.

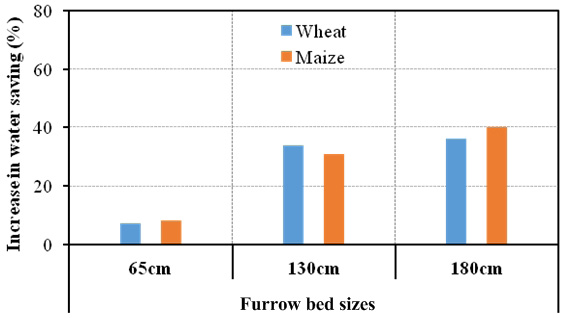

Water saving in different bed sizes relative to flat basin.

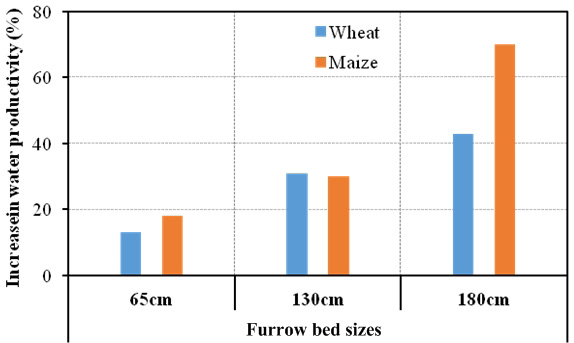

Water productivity in different bed sizes relative to flat basin.

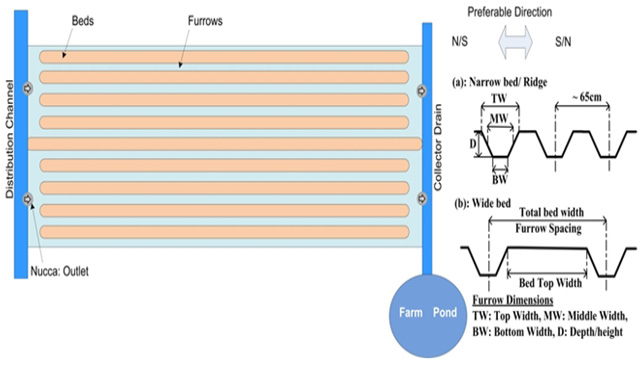

Salient features of typical furrow bed field and furrow bed configurations.

Bed former cum seeder developed by (a) CEWRI-NARC Islamabad and (b) Water Management Research center, UAF Faisalabad.

View of the bed former imported from Australia constructing narrow beds.

Seeder sowing two rows of wheat on narrow bed with row spacing of 20 cm. Insert shows diagram of the press wheel and seed placement component.

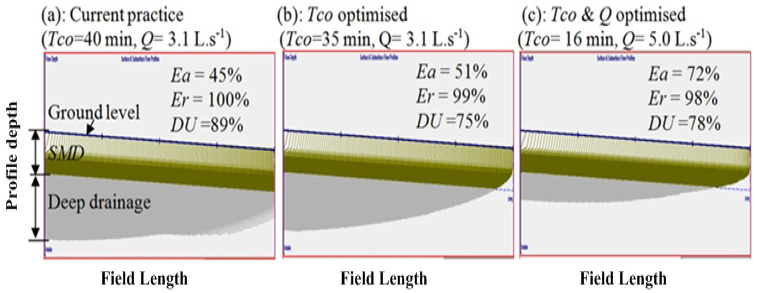

Impact of inflow rate and time to cut-off on irrigation performance under high infiltration soil.

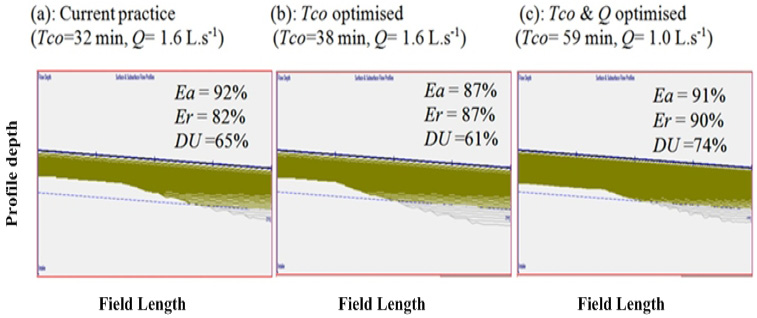

Impact of inflow rate and time to cut-off on irrigation performance under low infiltration soil.

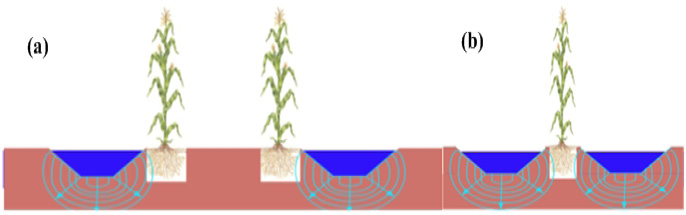

Crop rows and wetting pattern under (a) wide bed and (b) narrow bed.

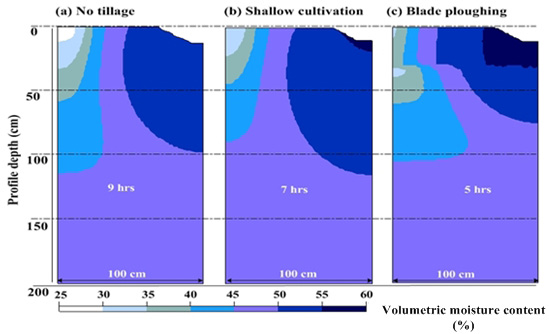

Wetting front movement across half bed width when renovated with three different tillage treatments under Vertisol soil (Akbar et al., 2015).

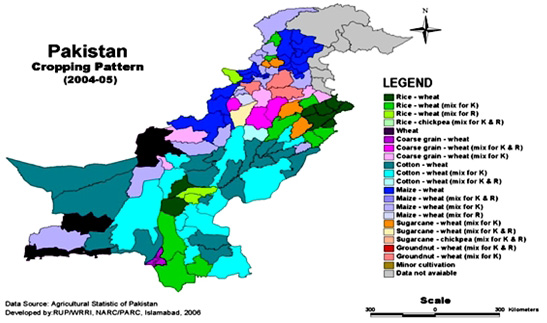

Cropping pattern on Pakistan Map during 2004-05.