Economic Viability and Profitability Analysis of Mechanical Transplanting of Rice in Rice-Wheat Cropping System of Pakistan

Research Article

Economic Viability and Profitability Analysis of Mechanical Transplanting of Rice in Rice-Wheat Cropping System of Pakistan

Muhammad Tahir Latif1*, Muzzammil Hussain1, Ayesha Latif2, Majid Hamid Bajwa1, Iftikhar Ahmad1, Ali Zohaib1, Naeem Faisal1 and Muhammad Hamza3

1Adaptive Research Farm Gujranwala, Pakistan; 2Govt. College Women University Sialkot, Pakistan; 3University of Agriculture Faisalabad, Pakistan.

Abstract | A field survey was conducted in rice-wheat cropping system of Gujranwala zone, Pakistan during Kharif season 2020 to estimate the economic viability and profitability analysis of mechanically transplanted rice (MTR) in comparison to conventional manual transplanting (CT). Convenience and snow-ball non probability sampling method was used due to less adoption rate of MTR with a sample size of 240. Among targeted MTR growers 72% had 6-row riding type mechanical transplanters (MT), 18% had 4-row walk after type MT and 10% had 8-row riding type MT. Super Basmati and PK 386 were found more adopted varieties with 47% and 38% share of rice area. An 11-13% improved yield and 16-20% more net returns estimated with MTR by acquiring required plant population in the field despite of paying 6.17% more operational cost for sowing and transplanting nursery. For service users of MT on rental basis the 292-303 values (variety wise) of marginal rate of returns (MRR%) was calculated. The project appraisal method of financial analysis illustrated the viability of MTR from the owner user or service provider’s point of view as calculated by the indicators like benefit cost ratio, net present value, internal rate of return, payback period (yr) and breakeven point (ha yr-1). Hence, the adaptation of MTR would give farmers the opportunity to increase the productivity of rice crop and their farm income by coping the issues like labor scarcity, less plant population, delay in transplanting with more aged nursery, improper fixation of nursery plants in the soil etc. The study results projected mechanically transplanting area (ha) for riding type MT as well as for walk after type MT respectively as 64.78 and 28 annually. Accordingly, there would be 36.15 (000 ha) mechanically transplanted area (5.41%) of province Punjab, Pakistan annually after completion of the Govt. prevailing project on rice.

Received | April 13, 2021; Accepted | November 04, 2021; Published | May 20, 2022

*Correspondence | Muhammad Tahir Latif, Adaptive Research Farm Gujranwala, Pakistan; Email: tahirr.uaf@gmail.com

Citation | Latif, M.T., M. Hussain, A. Latif, M.H. Bajwa, I. Ahmad, A. Zohaib, N. Faisal and M. Hamza. 2022. Economic Viability and profitability analysis of mechanical transplanting of rice in rice-wheat cropping system of Pakistan. Sarhad Journal of Agriculture, 38(2): 742-750.

DOI | https://dx.doi.org/10.17582/journal.sja/2022/38.2.743.750

Keywords | Economic, Gujranwala, Mechanical, Profitability, Rice

Copyright: 2022 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

Rice (Oryza sativa L.) is second main staple food after wheat and second major exportable crop after cotton. It contributes 3.5% of value added in agriculture sector and 0.7% in GDP of Pakistan. Rice production comprises of basmati (fine) and coarse types. During the last few years, production of coarse types is increasing (GoP, 2021). Rice-wheat is one of the significant cropping systems of Pakistan on 2.1 million ha cultivated area. The main share (57%) of the rice-wheat area is from Punjab. More than 80% of fine rice is being produced by Punjab province due to favorable climatic and soil conditions. The district Gujranwala, Sialkot, Hafizabad, Okara, Sheikhupura, Nankana, Jhang and M.B. Din are producing more than 70% of Basmati rice in Pakistan (Latif et al., 2017a).

Conventional manual transplanting (CT) has been the most widespread method of rice cultivation. The general issues with CT by hired labor are lower plant population, improper fixation of seedlings, missing plantation and irregular transplantation in paddy fields, i.e. dense and thin planted patches. Also, the rise in labour wages and labour scarcity has led a number of farmers to shift towards mechanically transplanted rice (MTR) from previous some years. The factors like required plants, proper planting depth and spacing are controlled in MTR to get optimum rice yield. Furthermore, direct seeded rice (DSR) being purely site specific sowing method has not been adapted productively due to the reasons of lower yield, additional fertilizer requirement, more weeds infestation, more pest/ disease attack, and more lodging (Latif et al., 2017a).

Mechanically transplanted rice (MTR) is the transplanting of proper aged rice seedling, that have been cultivated in seedling trays or on raised beds with polythene sheet as medium in frames, using a self-propelled mechanical transplanter (MT) (Guru et al., 2018). Generally, there are two types of rice transplanters i.e. riding type and walk-after type. Riding type is power driven and can normally transplant six lines in one pass. While walk after type is manually driven self propelled and can typically transplant four lines in one pass (Patil et al., 2016). In CT practice, for transplanting one acre there is need of 8-12 labors in a day. On the contrary, if a self-propelled MT is used, 3 labors can transplant up to 6-8 acres in a day (Rickman et al., 2015). The mean labor input in MT was 1.4 man days ha-1 while 25 man days ha-1 was in case of CT (Munnaf et al., 2014). In CT method about 250-300 man hours ha-1 (25% of total labor) is required with the issue of lower plant population (50000-60000 plants per acre) which decreases the paddy yield by 20-25% (Haider, 2019).

Saeed et al. (2020) reported about importing of Chinese rice MTs by progressive farmers for successfully adoption in Hafizabad district of Pakistan. It ensured the optimum plant population with projected 15% increased yield. Bashir et al. (2018) concluded that adopting MTR can save more than 82% of labour and increase plant population by nearly 18% compared to CT.

Shivashenkaramurthy et al. (2020) performed the 8-row selfpropelled MT and found it about 80% of labour saving with actual field capacity, field efficiency and fuel consumption values of 0.171 ha hr-1, 70.4% and 6.3 L ha-1, respectively during Kharif, 2013 in malnad regions of Uttara Kannada district of India. The higher net returns and benefit cost ratio was also recorded in MTR over CT. Sarkar et al. (2020) also estimated financial parameters of two walking type MT at Bangladesh Agricultural University, Mymensingh and at Mothbaria village of Dumuria Upazila, Khulna during 2018. The effective field capacity was found as 0.173 ha h−1-0.189 ha h−1. The NPV and IRR indicated the financial viability of rice MT entrepreneurship. The payback period and breakeven use was found as 1.51-1.60 years and 20.36-21.01 ha yr-1. Similarly, the BCR and net returns of MT was found higher than CT.

The productivity and efficiency of land and labor can be enhanced with mechanization. Presently the Govt. of Pakistan in collaboration with Govt. of the Punjab have initiated a 5-years (2019-2024) mega project with project cost of 9988.38 million Rs. under the Prime Minister’s Agriculture Emergency Programme to enhance profitability of rice farming through increasing productivity of paddy up to 10 mound acre-1 of Basmati and 20 mound acre-1 of coarse rice. Under this project 450 Riding type MT, 250 walk-after type MT, 450 nursery raising machines, 900 DSR drills, 750 Rice straw choppers, 800 water tight rotavators and 2450 knapsack sprayers are being provided to farmers on 50% cost sharing basis subsidy scheme (GoP, 2019).

The present field survey study was planned to estimate the economic viability and profitability analysis of MTR in comparison to CT in puddled soil conditions of rice-wheat cropping system. Also, perception regarding adoptability and performance of MTR was also recorded to give some policy recommendation.

Materials and Methods

Field survey was conducted for primary data collection of Kharif 2020 rice crop in agro-climatic zone of Gujranwala (rice-wheat system); due to intensive cultivation of rice as major crop in Kharif season and wheat as major crop in Rabi season. Gujranwala zone comprises of six districts namely Gujranwala, Gujrat, Hafizabad, M.B.Din, Narrowal and Sialkot (Latif et al., 2018). MTR had not been adopted on large area to found its adopters accessibly. Therefore, the sampling frame of respondent farmers was complied through the list of winners of MT and nursery raising machines on subsidy under the Govt. of Pakistan prevailing project entitled “National program for enhancing profitability through increasing productivity of Rice” and the list of owner-users, service providers, importers and service users (on hiring basis) of MT was arranged with the support of local Agricultural Extension staff.

Convenience and snow-ball non-probability sampling method was employed keeping in view the time and cost constraint to select the respondent farmers with a sample size of 240. About 120 farmers with adoption of MTR were included in sampling frame. Among those adopters 60 were owner-users and remaining 60 were service users (on hiring basis) with equal respondent farmer share (i.e. 10 owner-users and 10 service users on rental basis) out of six districts of Gujranwala division/zone. The same number of farmers with adoption of CT was interviewed from the same locality/site of MTR for comparative analysis. As the adoption rate of MTR was below 5% therefore the whole districts were included in sampling frame without the proportion and consideration of tehsils and villages of each district for ease of survey study. Pre-tested questionnaire was used for data collection.

For service users (on hiring basis) of MT the profitability analysis was carried out with the financial indicators like Net Returns (Rs ha-1), Benefit cost ratio (BCR) and marginal rate of return (MRR%). MRR% is the rate of return for a marginal increase in investment; generally, this is the marginal output resulting from a one unit increase in the use of a variable input, while other inputs remained constant. The economic viability and profitability analysis for owner-users of MT was carried out with the financial indicators like actual field capacity (ha hr-1) and fuel consumption (L ha-1) of MT, operating cost of transplanting, benefit cost ratio (BCR), net present value (NPV), internal rate of returns (IRR), Pay back period and Break-even point. The same methodology was adopted by Manjunatha et al. (2009); Munnaf et al. (2014); Latif et al. (2017a, b); Latif et al. (2018); Reddy et al. (2018) and Basir et al. (2019).

The machine performance of the MT was asked during the field survey which may be measured in terms of actual field capacity (ha hr-1) and fuel consumption (L ha-1). Actual field capacity (C) is the ratio of the total transplanted area in ha (A) to total operating time required for transplanting in hours (t). In equation form it may be as:

The operation cost of MT machine consists of fixed cost and variable cost. Fixed cost consists of depreciation, interest on invest, and housing & shelter cost. Fixed cost does not change with level of output. The straight-line method was used for calculating depreciation which is as following:

Where;

D= yearly depreciation (Rs. yr.-1), P=purchase price (Rs.), S= salvage value (Rs.) and L= machine life, assumed as 6 years because more than 75% were second handed MT.

The interest on investment is considered as an important fixed cost item as it is a direct expense item on borrowed capital. The interest on investment may be calculated by following formula:

Where;

I= interest on investment, (Rs. yr.-1) and i = rate of interest, assumed as 7% (State Bank of Pakistan, 2020). An annual charge equal to 2.5% of the purchase price was considered as the housing and shelter (Edwards, 2015).

While variable cost depends on hourly labor cost, fuel, repair and maintenance cost and the required working hours for each field operations. The fuel cost was estimated as product of fuel consumption (L hour-1) and fuel price (Rs L-1). The lubrication cost was estimated as 15% of fuel cost (Edwards, 2015).

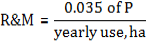

Repair and maintenance cost (R & M) was calculated by the following equation:

All the fixed cost and variable cost was converted into Rs. ha-1 and then summation was considered as operating cost (Rs. ha-1). Thus net returns (Rs ha-1) were calculated as following:

Net Returns = Gross Income – Operational Cost

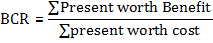

Benefit cost ratio (BCR) is the ratio of present worth benefit to present worth cost. The machinery can be said profitable if the BCR is greater than unity.

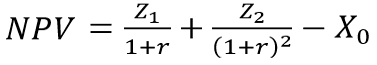

Net Present Value (NPV) is the value of all future cash flows (positive and negative) over the entire life of an investment discounted to the present. NPV analysis was used to help determine how much an investment, project, or any series of cash flows is worth.

Where;

Z1 = Cash flow in time 1, Z2 = Cash flow in time 2, r = Discount rate, X0 = Cash outflow in time 0 (i.e. the purchase price / initial investment).

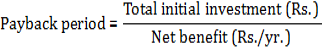

Internal Rate of Return (IRR) is the value of discount factor when the NPV is zero. The MT can be said profitable if the IRR value is greater than the bank interest rate. Payback period is the time within which the initial investment is returned as cash. The payback period may be calculated as following:

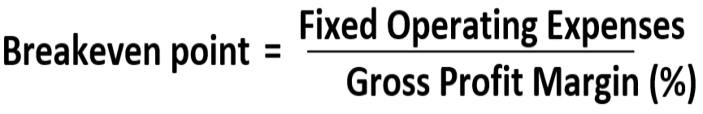

The break-even point was used to calculate the economic use of MT in terms of operated area per year as following:

As for as the basic information of rice production operations is concerned; the mean education (schooling year) were estimated at 8.24. The area under cultivation was recorded as 5.75 ha with the range of 1.62-40.49 ha. While the prevailing land rent was found as 103 thousand Rs ha-1. In studied area, the soil type was estimated as sandy (11%), clayey (52%) and loamy (37%). Among MTR adopters 72% farmers had 6-row riding type MT, 18% had 4-row walk after type MT and 10% had 8-row riding type MT. There were three types of users of MT namely, owner-users (44%), service providers (6%) and service users (50%). Usually, the farmers with large operational land size purchased MT for their own use. Kubota, Fuerda, and Yanmar machines were the most popular brands accounting for over 80% of MT machines existing in the area. Yanji, Iseki and Kukje brands were found in limited numbers. It is stated that 78% of the service provider and owner users mutually owned 1-2 MT followed by 20 percent owning 2-4 MT and 2% each owning 4-5 numbers.

The provision of transplanting services by service providers is a more recent development which started 3-4 years ago. The mean transplanting cost while on hiring basis with full package remained at 18068 Rs ha-1. However few farmers (2%) arranged rice nursery by their self and paid the cost of 11200 Rs ha-1 for only transplanting the nursery into main field. Baruah et al. (2001) found that the cost of growing mat type nursery for mechanical transplanting was about 40 percent whereas the cost for raising conventional nursery was only 25 percent of the cost of transplanting.

Except nursery sowing and transplanting cost all the other operations cost like land preparation (13659 Rs ha-1), irrigation, fertilizer, pesticides (5434 Rs ha-1) and harvesting (12906 Rs ha-1) were recorded same for CT as well as for MTR. According to survey findings 30.13 irrigations ha-1 with 2347 Rs ha-1 cost was recorded. Regarding fertilizer use per hectare; Urea (Bag), DAP (Bag) and Zinc (kg) with the values of 2.28, 1.61 and 10.13 were estimated respectively. Regarding insect and disease attack; BLB, BLS, Borrer and Leaf Roller with the mean values of 1.55%, 3.25%, 3.58% and 3.42% estimated respectively. Only 2.5% lodging was recorded from super basmati variety only. Overall, the climate remained favorable to get optimum yield during Kharif 2020 crop year. Pertaining to varietal adoption; Super Basmati was cultivated by 47%, PK 386 by 38%, PK 1121 aromatic by 10% and other varieties (including Supri, Super fine, Kissan Basmati, Chenab Basmati) by only 4% farmers. The data analysis showed non-significant differences of cost of production factors among varieties. Sheikh (2007) explained that Kallar belt is the real native soil of the Basmati rice, a source of recognition to Pakistan. The pleasant and sweet aroma Basmati rice, a specialty of Pakistani Punjab, has the quality of elongation when cooked and the fluffiness that makes it distinctive in the world.

Table 1: Salient findings related to adoption and operation of MTR.

|

Particular |

Mean |

Minimum |

Maximum |

|

Years to adopt MTR |

2.50 |

1 |

7 |

|

Area under MTR (ha) |

4.19 |

0.81 |

30 |

|

Seed rate/tray (g) |

95 |

70 |

140 |

|

Seedling age in MTR (days) |

23.71 |

20 |

35 |

|

Paddy tray cost (Rs.) |

33.25 |

14 |

64 |

|

Trays used (no. ha-1) |

237.98 |

198 |

309 |

|

Used times for trays (no.) |

4.50 |

2 |

5 |

|

Puddle soil settled time (hr) at transplanting |

33.50 |

14 |

72 |

|

Water level in puddle soil (inch) during transplanting |

1.25 |

0.75 |

2.00 |

|

Riding type MT cost (million Rs.) |

2.080 |

0.800 |

3.010 |

|

Walk after type MT cost (million Rs.) |

0.301 |

0.192 |

0.464 |

|

Actual field capacity of walk-after type MT (ha hr-1) |

0.14 |

0.10 |

0.20 |

|

Actual field capacity of riding-type MT (ha hr-1) |

0.32 |

0.30 |

0.45 |

|

Fuel consumption of walk-after type MT (L hr-1) |

2.25 |

1.75 |

2.75 |

|

Fuel consumption of riding-type MT (L hr-1) |

3.35 |

2.50 |

4.25 |

|

Transplanting cost with MT (Rs. ha-1) if rented |

18068 |

14326 |

24700 |

It was estimated that there was 2.50 years to adopt MTR with the range of 1-7 years. For seedling raising 92% farmers used mat-type nursery in which seedlings were grown on a thin layer of soil in trays and only 8% used polythene sheets. The seed rate per tray was recorded as 95 gram with per tray cost of 33 Rs. While the trays used for one hectare was estimated at 237.98. The seedling age was calculated as 23.71 days for MTR in comparison to minimum of 29 days of nursery for CT. The cost of riding type MT was estimated as 2.080 million Rs. along with actual field capacity and fuel consumption of 0.32 ha hr-1 and 3.35 L hr-1 respectively. While the cost of walk after type MT was estimated as 0.301 million Rs. along with actual field capacity and fuel consumption of 0.14 ha hr-1 and 2.25 L hr-1 respectively (Table 1).

Table 2: Cost and returns estimation for CT and MTR methods (for service users).

|

Rice variety |

CT |

MTR |

||

|

Super Basmati |

PK 386 |

Super Basmati |

PK 386 |

|

|

Yield (mound ha-1) |

97.66 |

109.54 |

108.83 |

123.65 |

|

Output price (Rs mound-1) |

1980 |

1610 |

1980 |

1610 |

|

Gross Income (Rs ha-1) |

193374 |

176367 |

215480 |

199074 |

|

Operational cost of production (Rs ha-1) |

91308 |

91308 |

96940 |

96940 |

|

Net Returns (Rs ha-1) |

102066 |

85058 |

118540 |

102134 |

|

Benefit cost ratio (BCR) |

2.12 |

1.93 |

2.22 |

2.05 |

|

Marginal rate of return (MRR %) |

292.50 |

303.19 |

||

The fuel consumption and actual field capacity were estimated respectively at 5 L ha-1 and 0.18 ha hr-1 (Murali et al., 2019), 5.25 L ha-1 and 0.12 ha hr-1 for 4-row walking type MT (Islam et al., 2016), 6.25 L ha-1 and 0.19 ha hr-1 for 8-row self-propelled type MT (Manjunatha et al., 2009) and 4.8 L ha-1 and 0.16 ha hr-1 in unpuddled soil (Basir et al., 2019) in their studies.

As per field survey results Super Basmati and PK 386 were highest in adoption; with significant difference of produce price. Therefore, for the economic viability and profitability analysis these both varieties were taken into count.

The profitability analysis for service users explained that the 11-13% improved yield difference of Super Basmati (108.83 mound ha-1) and PK 386 (123.65 mound ha-1) proved economically viable by MTR even at the operational cost difference of 5632 Rs ha-1. About 16-20% more net returns was obtained in MTR method despite of paying 6.17% more operational cost regarding sowing and transplanting nursery. Variable cost is related to the use of MT and field capacity. Similarly, higher level of BCR for Super Basmati (2.22) and PK 386 (2.05) was achieved

Table 3: Economic viability and profit analysis of rice sowing methods (for user owner).

|

Item/variety/type of MT |

Riding type MT |

Walk after type MT |

|||

|

Super Basmati |

PK386 |

Super Basmati |

PK386 |

||

|

Field capacity (ha hr-1) |

0.32 |

0.32 |

0.14 |

0.14 |

|

|

Per day efficiency @8 hrs work (ha) |

2.59 |

2.59 |

1.12 |

1.12 |

|

|

Working days in a year |

25 |

25 |

25 |

25 |

|

|

Projected area transplanted in a season (ha) |

64.78 |

64.78 |

28.00 |

28.00 |

|

|

Income (Rs) |

Increase in per ha yield (%) |

11.43 |

12.87 |

11.43 |

12.87 |

|

Total increase in production for the whole season (mound) |

722.91 |

913.36 |

312.48 |

394.80 |

|

|

Price of paddy (Rs mound-1) |

1980 |

1610 |

1980 |

1610 |

|

|

Increase in revenue due to improved yield (Rs) |

1431372 |

1470510 |

618710 |

635628 |

|

|

Fixed cost (Rs) |

Depreciation (Rs yr-1) |

263000 |

263000 |

38500 |

38500 |

|

Investment on Interest (i=7%) (Rs yr-1) |

90300 |

90300 |

12985 |

12985 |

|

|

shelter (Rs yr-1) |

52000 |

52000 |

7525 |

7525 |

|

|

Total fixed cost (Rs yr-1) |

405300 |

405300 |

59010 |

59010 |

|

|

Total fixed cost (Rs. ha -1) |

6257 |

6257 |

2108 |

2108 |

|

|

Variable cost (Rs) |

Fuel (Rs h-1) |

352 |

352 |

236 |

236 |

|

Lubricant (Rs h-1) |

53 |

53 |

35 |

35 |

|

|

Repair and Maintenance (Rs h-1) |

360 |

257 |

53 |

38 |

|

|

cost of operator (Rs h-1) |

225 |

225 |

225 |

225 |

|

|

cost of labor (Rs h-1) |

300 |

300 |

300 |

300 |

|

|

Total variable cost (Rs yr-1) |

260960 |

260960 |

169873 |

169873 |

|

|

Total variable cost(Rs. ha -1) |

4029 |

4029 |

6067 |

6067 |

|

|

Total operating cost (Rs) |

Total operating cost(Rs. ha -1) |

10285 |

10285 |

8174 |

8174 |

|

Total operating cost (Rs yr-1) |

666260 |

666260 |

228883 |

228883 |

|

|

Net cash flow (Rs yr-1) |

765111 |

804250 |

389828 |

406746 |

|

|

Benefit cost ratio (BCR) |

2.15 |

2.21 |

2.70 |

2.78 |

|

|

Net present value (NPV) Rs |

1057107 |

1217583 |

1297371 |

1366737 |

|

|

Internal rate of return (IRR) % |

24.47 |

26.93 |

127.38 |

133.17 |

|

|

Pay back period (yr) |

2.72 |

2.59 |

0.77 |

0.74 |

|

|

Break even point (ha yr-1) |

24.91 |

29.35 |

4.24 |

10.08 |

|

with MTR in comparison to lower BCR with CT method. MRR% indicated the 292.50% and 303.19% values for Super Basmati and PK 386 respectively (Table 2).

The yield of MTR and CT respectively was concluded at 54.01 q ha-1 and 53.77 q ha-1 by Manjunatha et al. (2009), 6.66 t ha-1 and 5.83 t ha-1 by Munnaf et al. (2014) and 4.71 t ha-1 and 4.50 t ha-1 by Baruah et al. (2001). Islam et al. (2016) described significantly the higher grain yield (9-14%) of MTR in comparison to CT. As for as BCR for MTR and CT is concerned it was found as 1.19 and 1.06 by Islam et al. (2016) as well as 2.24 and 1.78 by Munnaf et al. (2014).

Around 2% rice cultivated area was estimated with MTR in studied area indicating a low rate of adoption, but in increasing trend over year time. The study results projected annual transplanting area (ha) for riding type MT as well as for walk after type MT as 64.78 and 28 respectively. Accordingly, there would be 36.15 (000 ha) transplanted area (5.41%) annually with MT of province Punjab rice area after completion of the Govt. project.

The project appraisal method of financial analysis showed the acceptability of MTR from the owners or service provider’s point of view. From the analysis, at 7% discount factor (prevailing presently), BCR value of 2.15-2.21 and 2.70-2.78 was estimate for riding type and walk after type MT respectively. The BCR as higher than unity, the MT custom hire service was found to be profitable. The IRR (%) value of 24.47-26.93 and 127.38-133.17 was estimated for riding type and walk after type MT respectively. The IRR values are also higher than the bank interest rate which is the indicator of profitability. The payback period value of 2.59-2.72 year and 0.74-0.77 year was estimated for riding type and walk after type MT respectively. The payback period indicated that after this time period the owner can get back the payment for purchasing the machine (Table 3).

The IRR and payback period was calculated respectively as 55% at 10% discount rate and 1.68 years by Basir et al. (2019) while Reddy et al. (2018) estimated the payback period of Kuboto and Yanmar transplanters as 2.3 years and 2.6 years respectively without nursery raising machine.

The area covered by MTR in a day depends on many factors (such as soil type, quality of land preparation, skill of the operator and condition of the machine) making this highly variable. Estimates given by service providers vary between 2-3 acres per day under farmer field conditions at full capacity working, irrespective of the type of MT. A break-even analysis was conducted to determine the economic use of the MT in terms of projected operation area per year. The analysis illustrated that the riding type and walk after type MT if used 25-29 ha and 4-10 ha annually, it will bring profit (Table 3 and Figure 1, 2, 3 and 4).

Regarding the breakeven point of area per year, it was estimated at 28 ha with 8-row self propelled MT by Manjunatha et al. (2009), 10 ha with 6-row MT by Munnaf et al. (2014), and 19.77 ha by Basir et al. (2019). While Reddy et al. (2018) estimated 100 hours per annum breakeven usage for the 8 row Yanji rice transplanter and 550 hours per annum for Yanmar MT.

Farmers’ perception regarding adoptability of MTR

Regarding farmers’ perception about MTR adoption, 95% farmers considered MTR as solution to labor shortage and timely transplanting as it was possible to transplant the seedlings at the optimal age by saving 5-15 days than CT method. 65% perceived that with MT it was possible to get required plants population and less standing water required (1 inch) during transplanting operation which leaded to water saving. 42% viewed less transplanting shock and uniform crop stand was possible with MTR. Haider et al. (2019) highlighted the advantages of MTR over CT. Accordingly with MT seedlings were transplanted at the optimal age (20-35 days). 20-25% more yield with MT was obtained because of uniform plant spacing, less root injury during transplanting, less transplanting shock, early seedling vigor and uniform crop stand.

But in spite of having all above advantages, the demand of MT is however quite discouraging in rice tract area of the Punjab Pakistan. 60-70% farmers in the studied area thought that new MT was very expensive to afford and mat type of nursery was a laborious work. Some farmers (35%) viewed that the operators of MT were not fully skilled and trained. 90% highlighted the need to have high quality land preparation and leveling to avoid empty patches in paddy fields and also puddled soil settled time of more than 36 hr. The 25% farmers believed that there was risk of higher mortality of younger seedlings in MTR fields. Farooq et al. (2001) explained the reasons for less adoption of MTR as; laborious work of seedling preparation, poor fixing of seedlings in the soil, uprooting of seedlings by the wave action of machine movement, and 35-55% missing plantation were the most important problems identified. Chaudhary et al. (2002) explained that the adoption of MTR required significant reforms in nursery raising, irrigation management, improvement of soil organic-matter and land preparation, along with emphasis on local manufacturing of the cost effective mechanical rice transplanter.

Conclusions and Recommendations

The adoption of the riding type as well as walk after type MT by considering rice variety Super Basmati and PK 386 respectively has proved economically viable as pointed out by the indicators like the benefit cost ratio (BCR) values of 2.15-2.21 and 2.70-2.78, the internal rate of return (IRR%) values of 24.47-26.93 and 127.38-133.17, the payback period (year) values of 2.59-2.72 and 0.74-0.77, and the economic use of breakeven (ha annually) values of 25-29 and 4-10. Hence, MTR has proved to enhance the productivity of rice crop and farm income by solving the issues like labor scarcity, more wage rate, less plant population in rice field, delay in transplanting with more aged nursery, improper fixation of nursery plants in the soil etc.

Acknowledgements

The authors are thankful to Agricultural Extension and Adaptive Research wing of Agriculture Department, Govt. of Punjab for providing facilities and platform for this research study.

Novelty Statement

Required plant population at proper transplanting time with proper aged nursery is the pre-requisite for optimum yield of rice. Mechanically transplanted rice has proved economically viable option to obtain more yield and net returns by solving the issues like labor scarcity, less plant population, delay in transplanting and more wage rate.

Author’s Contribution

Muhammad Tahir Latif: Conducted the study, performed data analysis and manuscript writing.

Ayesha Latif and Muhammad Hamza: Helped in literature review.

Muzzammil Hussain and Majid Hamid Bajwa: Facilitated in conducing field survey.

Iftikhar Ahmad, Ali Zohaib and Naeem Faisal: Critically reviewed this manuscript.

All the authors read and approved the manuscript to be published.

Conflict of interest

The authors declare that they have no conflict of interest.

References

Basir, M.S., M. Ashik-E-Rabbani, S. Sarkar, and M. Alam. 2019. Techno-economic performance of mechanical transplanter for hybrid variety of rice in unpuddled soil. Progr. Agric., 30(4): 405-413. https://doi.org/10.3329/pa.v30i4.46901

Bashir, A., U. Farooq and I. Mahmood. 2018. Punjab Basmati Rice Value Chain, Pakistan Baseline Surveys: ADB TA-8578 (PAK), PARB-ADBPARC Joint Report, Social Sciences Research Institute at Faisalabad of Pakistan Agricultural Research Council, Islamabad, November 2018.

Baruah, D.C., N.G. Goswami and R. Saikia. 2001. Manual transplanting vs. mechanical transplanting of paddy: a techno-economic analysis in Assam. J. Agric. Eng., 38(3): 66-72.

Chaudhary, R.C., J.S. Nanda and D.V. Tran. 2002. Guidelines for identification of field constraints to rice production. Food Agric. Org.,

Farooq, U., A.D. Sheikh, M. Iqbal, A. Bashir and A. Zubair. 2001. Diffusion possibilities of mechanical rice transplanters. Int. J. Agric. Biol., 3(1): 17-20.

Govt. of the Punjab. 2019. National program for enhancing profitability through increasing productivity of rice (http://www.agripunjab.gov.pk/ongoingproj). Retrieved on January 02, 2021.

Govt. of Pakistan. 2021. Finance Division (https://www.finance.gov.pk/survey/chapters_21/02-Agriculture.pdf) Retrieved on October 29, 2021.

Guru, P.K., N.K. Chhuneja, A. Dixit, P. Tiwari, and A. Kumar. 2018. Mechanical transplanting of rice in India: status, technological gaps and future thrust. Oryza, 55(1): 100-106. https://doi.org/10.5958/2249-5266.2018.00012.7

Haider, Z. 2019. Pros and Cons of Mechanized Transplanting in Basmati Rice-A Case Study. J. Rice Sci., 1(1): 1-9.

Islam, A.K. M.S. Rahman, M.A. Rahman, M.T. Islam and M.I. Rahman. 2016. Techno-economic performance of 4-row self-propelled mechanical rice transplanter at farmers field in Bangladesh. Prog. Agric., 27(3): 369-382. https://doi.org/10.3329/pa.v27i3.30834

Edwards, W.M. 2011. Estimating farm machinery costs. Iowa State University, Department of Economics. (https://www.extension.iastate.edu/agdm/crops/html/a3-29.html). Retrieved on Dec 10, 2020.

Latif, M.T., S. Falak, B. Adnan, A. Muhammad, F. Naeem and H. Muzzammil. 2017a. A field survey to identify the problems in adaptability of direct seeded rice. Azarian J. Agric., 4(4):139-144.

Latif, M.T., S. Falak, A. Muhammad, H. Muzzammil and F. Naeem. 2017b. Less adaption of newly approved variety Basmati 515 among aromatic Basmati rice varieties in Kallar tract of Punjab, Pakistan. Azarian J. Agric., 4(6): 206-211.

Latif, M.T., F. Sher, M. Hussain and M. Asghar. 2018. Economics of different harvesting techniques of wheat in rice-wheat cropping pattern of Punjab, Pakistan. Azarian J. Agric., 5(3): 103-107.

Murali, M., M. Anantachar and B. Devojee. 2019. Performance evaluation of four row self propelled paddy transplanter for black cotton soil. J. Pharma. Phytochem., 8(2): 452-454. https://doi.org/10.22271/phyto.2019.v8.i2gh.19

Manjunatha, M.V., B.M. Reddy, S.D. Shashidhar and V.R. Joshi. 2009. Studies on the performance of self-propelled rice transplanter and its effect on crop yield. Karnataka J. Agric. Sci., 22(2): 385-387.

Munnaf, M.A., M.M. Hossain and F.Y. Ruma. 2014. Techno-economic performance of imported kukje self-propelled rice transplanter. J. Bangladesh Agric. Uni., 12(452-2016-35616): 161-166. https://doi.org/10.3329/jbau.v12i1.21406

Patil, D.D. and M.R. Phate. 2016. Design & development of rice planter machine. Imperial J. Interdiscip. Res., 2(8): 2454-1362.

Rickman, J.F., F. Mussgnug, C.M. Khanda, S.D. Satpathy, N. Parida, K. Singla, V. Kumar, N.C. Banik, W. Iftikar, A. Mishra and R. Malik. 2015. Operational manual for mechanical transplanting of rice. CGIAR institutions of CIMMYT, IFPRI, ILRI, IRRI and WorldFish, USA.

Reddy, P.S., P. Rajaiah, B.A. Kumar, B. Laxman and A.P. Reddy. 2018. Field Performance and Cost Economics of Popular Riding Type Mechanical Paddy Transplanters. Int. J. Curr. Microbiol. Appl. Sci., 7(10): 2867-2874. https://doi.org/10.20546/ijcmas.2018.710.334

Saeed, I., A. Mubarik, F. Umar and Y. Aqsa. 2020. Basmati rice cluster feasibility and transformation study. Cluster Development Based Agriculture Transformation Plan Vision-2025. Project, (131), pp.434.

Sarkar S, M.S. Basir, M.A. Rabbani, M.M. Hossain and M.M. Alam. 2020. Financial analysis for custom hire business of mechanical rice transplanter in Bangladesh. Fundamental Appl. Agric., 5(1): 124–132. https://doi.org/10.5455/faa.79466

Shivashenkaramurthy, M., A.D. Agasimani, S.P. Roopa, T. Praveen and G.A. Neeralagi. 2020. Mechanised paddy transplanted to combat labour scarcity in rain fed paddy cultivation in Malnad regions of Uttar Kannada district. J. Pharm. Phytochem., 9(3): .1876-1880.

Sheikh, A.D. and A. Abbas. 2007. Barriers in efficient crop management in rice-wheat cropping system of Punjab. Pak. J. Agric. Sci., 44: 341-349.

State Bank of Pakistan. 2020. Domestic Markets & Monetary Management Department. (https://www.sbp.org.pk/ecodata/sir.pdf). Retrieved on Jan 02, 2021.

To share on other social networks, click on any share button. What are these?